Skope OD260 User manual

OD260

Service Manual

MAN800056 Rev. 1.1 April 2020

SKOPE Open Deck Chiller

OD260

SKOPE Open Deck Chiller

Service Manual

MAN80056

Rev. 1.1 April 2020

© 2017 SKOPE Industries Limited. All rights reserved.

SKOPE Industries Limited reserve the right to alter specifications without notice.

is a registered trademark of SKOPE Industries Limited.

SKOPE INDUSTRIES LIMITED

Head Office

PO Box 1091, Christchurch

New Zealand

Freephone: 0800 947 5673

Fax: (03) 983 3896

E-mail: [email protected]

Website: www.skope.com

Trademark Infringement

The SKOPE trademark on this product is infringed if the owner, for the time being, does

any of the following:

• Applies the trade mark to the product after their state, condition, get-up or packaging

has been altered in any manner

• Alters, removes (including part removal) or obliterates (including part obliteration) the

trade mark on the product

• Applies any other trade mark to the product

• Adds to the product any written material that is likely to damage the reputation of the

trade mark

Notice of the above contractual obligations passes to:

• Successors or assignees of the buyer

• Future owners of the product

SKOPE OD260

Service Manual iii

CONTENTS

1Specifications

Models. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

OD260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2Electronic Controller

Electronic Controller Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Faceplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Running the Chiller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Compressor and Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Temperature Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Defrost Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Messages and Alarms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Controller Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Cold Climate Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Hardware Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Hardware Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Temperature Probe Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Wiring Termination . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Programming the Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . 12

Temperature Setpoint . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Parameter History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

3Wiring

Model: OD260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

4Spare Parts

Cabinet Assembly - OD260 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Electrics Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Unit Electrics Box Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Refrigeration Unit Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5Installation

Climate Class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chiller Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Air Movement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Stabiliser Feet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Installing the Shelves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6Replacement Procedures

SKOPE OD260

Service Manual

iv

Isolating Electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Interior Lights . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

LED Driver Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Cabinet Electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Electrics Plate Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Sweat Wire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Front Upstand . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Vertical Bumpers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Wheels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Honeycomb Air Grille . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removing the Refrigeration Unit . . . . . . . . . . . . . . . . . . . . . . . . . 33

Unit Junction Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Condenser Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Evaporator Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Compressor Electrics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Electronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Temperature Probes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Condenser Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Evaporator Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Service Probe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Cabinet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Condenser Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

7Troubleshooting

5

SKOPE OD260

Specifications

Service Manual

1Specifications

Models

This service manual is applicable to the SKOPE chillers detailed below. The

type is used to distinguish between different models throughout this manual.

OD260 Cabinet

Refrigeration Unit

Model Description Type

OD260 2 × interior lights O26CY

Description Open Deck Chiller

Type O26CY

Construction

Insulation 40mm thick, polyurethane foam. Cyclo-iso Pentane

blowing agent: C5H10/C5H12

Doors n.a.

Dimensions External Internal

Height 1400mm 850-910mm

Width 650mm 565mm

Depth 735mm (includes rear

spacer) 495-595mm

Floor area 0.48m2(includes rear spacer)

Internal volume 230 litres

Shelves

2 × flat or angled (8°), adjustable height shelves, and 1 ×

fixed, angled bottom shelf.

Top shelf: 545mm wide ×

296mm deep. Middle shelf: 545mm wide × 371mm deep.

Bottom shelf: 545mm wide × 442mm deep.

Operating conditions

Climate class: 3. Tested at 25°C

Product temp. range 1°C to 5°C (2°C to 4°C product mass average)

Electrical 220-240 Volts a.c. 50 Hz, single phase supply

Tot al run A m p s 3.2 Amps (includes unit 3.0 Amps)

Sign lighting n.a.

Internal lighting 2 × 9 Watt LED strip side lights (18 Watts total)

Description Electronically controlled, bottom mounted SKOPE

refrigeration unit

Unit model UB89ABF-107IE

Compressor Embraco NEK6210Z

Controller Carel S4 Evo

Nominal capacity 815 Watts

Refrigerant R134a / 420 gms

6Electronic Controller

Service Manual

SKOPE OD260

2Electronic Controller

Electronic Controller Operations

Introduction The chiller is fitted with a Carel S4 Evo electronic controller which is visible

through a cutout in the cabinet front panel, and is housed inside the

electronic controller box assembly at the front of the refrigeration unit.

The electronic controller controls and displays the chiller temperature, and

signals temperature alarms.

To ensure efficient operation, the electronic controller automatically forces a

defrost cycle when required.

The electronic controller is pre-programmed. SKOPE does not recommend

that settings be changed unless it is absolutely necessary.

7

SKOPE OD260

Electronic Controller

Service Manual

Faceplate Because the electronic controller plays such an important role, it’s helpful to

know the parts of the faceplate you may use.

ES

12

3

4

5

68

7

No. Item Description

1

Digital display of cabinet temperature or messages.

The temperature is what the sensor inside the chiller detects,

and not necessarily the product temperature. However, they

may be very close depending on how the controller is set to

sense temperature.

2Up: Button. Used for programming.

3Set (mute): Button. Press to mute the alarm. Press and hold

to access parameters. Also used for programming.

4Light (down): Button. Press to switch the cabinet light on

and off. Also used for programming.

5

Defrost: Indicator. ON when the defrost is activated. Flashes

when the activation of the defrost is temporarily delayed due

to procedures in progress.

6

Compressor: Indicator. ON when the compressor and

condenser fan starts. Flashes when activation of the

compressor is temporarily delayed.

7

Fan: Indicator. ON when the internal cabinet fans are

activated. Flashes when activation of the fans is temporarily

delayed.

8Alarm: Indicator. ON when alarm is signalled.

ES

8Electronic Controller

Service Manual

SKOPE OD260

Running the Chiller

Operating

Modes The electronic controller runs the chiller in constant ‘Normal’ mode. The

OD260 does not use an energy saving/night mode (or similar).

Note: Normal mode is suitable for perishable product (all shelves maintain

temperature below 5°C).

During some conditions or refrigeration system alarms, the electronic

controller may run the chiller in cold climate protection mode, or may shut

down the lights and/or refrigeration system. Refer to “Cold Climate

Protection” on page 10, or “Messages and Alarms” on page 9 for more

information.

Compressor

and Fans The compressor and condenser fan will start just after the chiller is turned

on. The compressor and condenser fan will stop when the control probe

temperature reading reaches 2.0°C (parameter St), and on again when it

reaches 4°C (parameter St + rd).

The evaporator fan starts approximately 3 seconds (parameter F0) after the

compressor and condenser fan. To verify, check that the FAN light is lit on

the electronic controller faceplate.

Temperature

Probes Three temperature probes feed data to the electronic controller: the control

probe, the evaporator probe, and the condenser probe.

The control probe monitors and controls the chiller temperature, provides

the chiller temperature for the electronic controller to display, and notifies the

electronic controller of any erratic or abnormal temperatures that could

identify an issue within the refrigeration system.

The evaporator probe controls the refrigeration system defrost initiation and

termination.

The condenser probe monitors the refrigeration system condenser

temperature and notifies the electronic controller of any abnormally high

temperatures that could identify an issue within the refrigeration system.

Refer to page 37 for service information.

Defrost Cycle The defrost cycle will begin after 2 hours (parameter dl) of compressor run

time. During the defrost cycle the compressor stops and the evaporator fan

runs continuously. The defrost cycle will terminate when the evaporator

probe reaches 4°C (parameter dt), or after the defrost cycle has been

running for 30 minutes (parameter dP).

Lighting Press the Light button on the electronic controller faceplate to manually

switch the lights on and off.

9

SKOPE OD260

Electronic Controller

Service Manual

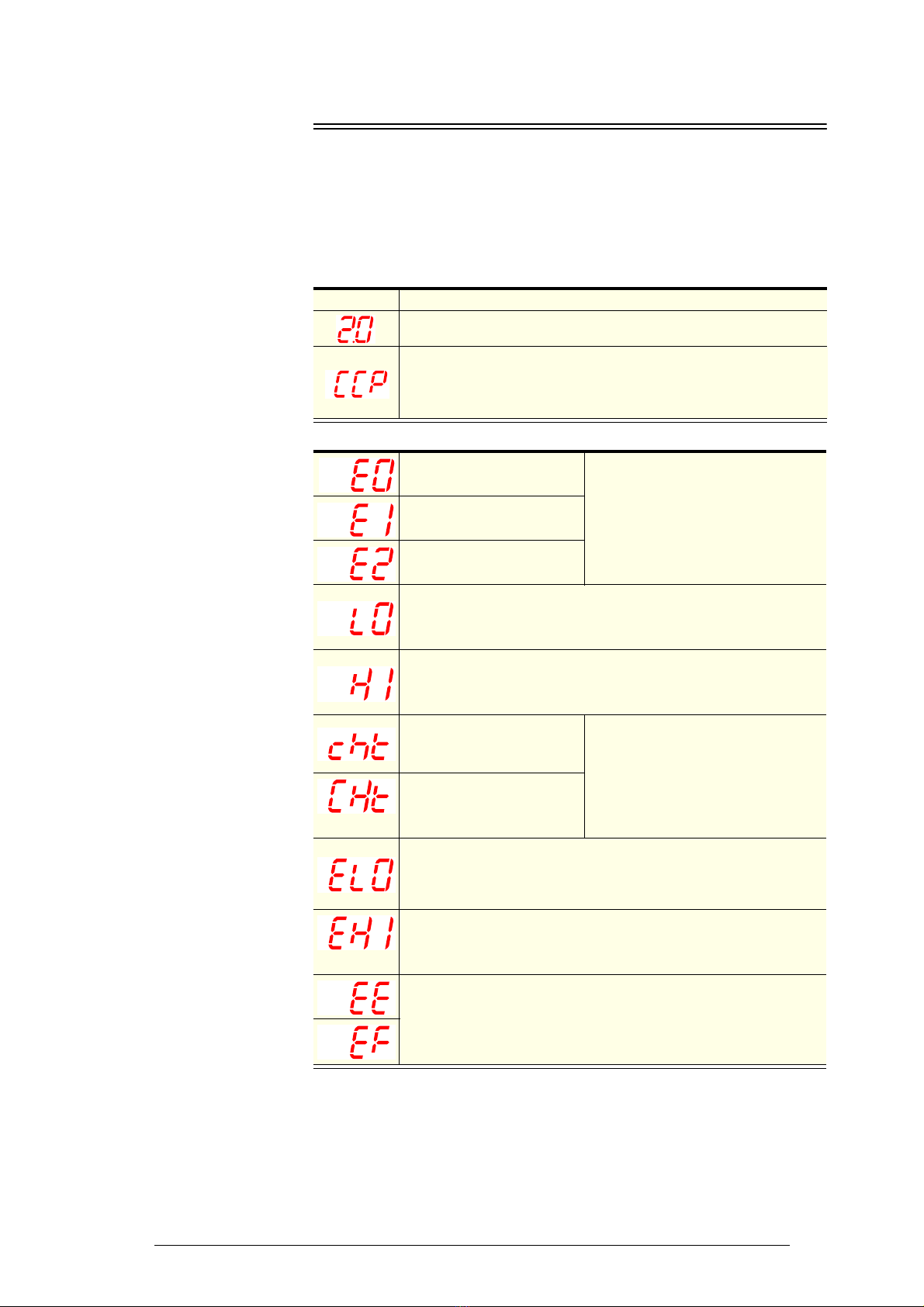

Messages and Alarms

Controller

Display The following table explains messages and alarms that the electronic

controller displays.

Alarms signal unexpected operational changes in the chiller and can be

muted by pressing the set (mute) button on the electronic controller

faceplate (see page 7).

Messages

Alarms

Display Description

The chiller is in Normal mode and the electronic controller displays the

chiller temperature.

The chiller is in Cold Climate Protection mode. The chiller enters Cold

Climate Protection mode if the control probe detects the interior

temperature below -0.3°C (parameter St - CCt) for more than 30 minutes

(parameter CCd). The lights remain on and cannot be switched off (see

over page for more information).

Probe 1 error.

See parameters (page 12) for probe

function.

Probe 2 error.

Probe 3 error.

Low temperature alarm. An alarm sounds. The temperature inside

the chiller is too cold and an alarm sounds. The controller will

automatically reset the alarm once the temperature inside the chiller

raises.

High temperature alarm. An alarm sounds. The temperature inside

the chiller is too warm and an alarm sounds. The controller will

automatically reset the alarm once the temperature inside the chiller

drops.

Refrigeration system high

temperature

Pre-warning (auto reset)

1. Check refrigeration ventilation and

ensure the cabinet is installed in a

suitable location (see page 24).

2. To reset the ‘CHt’ alarm - unplug

the cabinet from the power supply

for 1 minute, then reconnect to

power supply.

Refrigeration system high

temperature

Shutdown (manual reset)

Low voltage alarm. An alarm sounds. The mains voltage is low. An

alarm sounds and the controller switches off the compressor. The

controller will automatically reset the alarm once the mains voltage

raises.

High voltage alarm. An alarm sounds. The mains voltage is high. An

alarm sounds and the controller switches off the compressor. The

controller will automatically reset the alarm once the mains voltage

drops.

Electronic controller fault.

10 Electronic Controller

Service Manual

SKOPE OD260

Cold Climate

Protection The chiller will enter cold climate protection (CCP) mode if the ambient

temperature becomes too cold. This happens if the control probe (at the

evaporator air out) detects the interior temperature below -0.3°C (parameter

St - CCt) for more than 30 minutes (parameter CCd). The lights will stay on

and cannot be switched off while the chiller is in CCP mode. The chiller will

return to Normal operation mode once the control probe reading raises to

2°C (parameter St).

11

SKOPE OD260

Electronic Controller

Service Manual

Hardware Setup

Hardware

Inputs The controller has three hardware inputs as detailed in the table below. All

use pin 9 as common.

Electronic controller hardware inputs

Temperature

Settings Standard temperature settings are set-up for perishable product. All product

temperatures are continuously below 5°C. The temperature can be altered

by changing the set point (parameter St).

Temperature

Probe

Readings

Control probe

If parameter /4 is set to 1, the control probe temperature reading is displayed

on the controller faceplate during normal operation. If parameter /4 is not set

to 1, it can be changed to 1 to view the control probe temperature reading.

Condenser probe

To view the condenser probe temperature reading, press the ES (up) and

Set (mute) buttons simultaneously. The temperature reading will display on

the controller faceplate.

Evaporator probe

To view the evaporator probe temperature reading, enter the parameter

menu and navigate to parameter d/2 to display the evaporator probe

reading.

Wiring

Termination Refer to the diagram below for controller termination details.

Pins (on rear of

controller)

Hardware description

9-8 Control probe

9-10 Condenser probe

9-11 Evaporator probe

Condenser Probe (10)

Evaporator probe (11)

Common (9)

Control probe (8)

Supply (6, 7)

Compressor (4, 5)

Lights (1)

12 Electronic Controller

Service Manual

SKOPE OD260

Programming the Electronic Controller

The electronic controller parameter configuration program is set by SKOPE

at the factory. A label on the controller box indicates the parameter

configuration program number (e.g. the OD260 uses program 107).

The electronic controller parameters can be modified using the keypad.

Frequent parameters can be accessed and changed without entering a

password (e.g. temperature setpoint). Locked parameters are protected by

a password to prevent accidental or unauthorised modifications.

Temperature

Setpoint

The chiller temperature setpoint is factory set at 2°C for storage of

perishable products (all shelves maintain temperatures below 5°C). The

cabinet setpoint can be adjusted between 0°C and 4°C if required (see over

page).

SKOPE do not recommend that the setpoint be changed unless it is

absolutely necessary, and then only by small increments at a time.

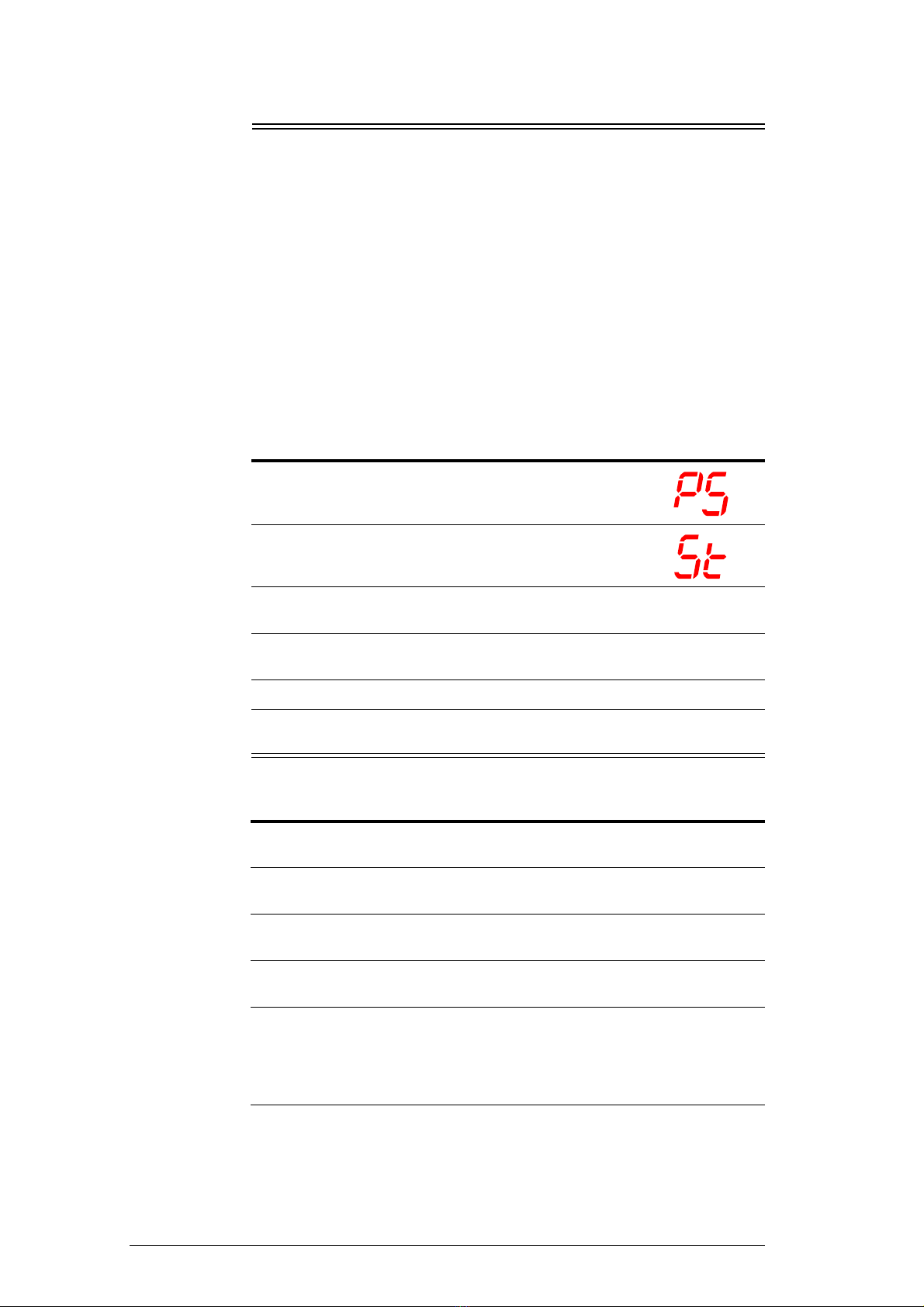

To view and adjust the temperature setpoint

Parameters Follow the steps below to access the locked parameters.

To access the locked parameters

1. Press and hold the Set (mute) button for 3 seconds

until PS is shown on the display, indicating entry into

the controller settings menu.

2. Press the up or down button to scroll the menu until St

is shown on the display.

3. Press the Set (mute) button. The current setpoint value is shown on the

display.

4. Press the up or down button to increase or decease the setpoint value to the

required temperature.

5. Press the Set (mute) button to temporarily save the setpoint value.

6. Press and hold the Set (mute) button for 3 seconds to permanently save the

setpoint value and exit the controller settings menu.

1. Press and hold the Set (mute) button for 3 seconds until the display shows

‘PS’.

2. Press the Set (mute) button to access the password parameter, ‘0’ is

displayed.

3. Use the ES (up) and Light (down) buttons to display the password ‘22’

(default password).

4. Press the Set (mute) button to confirm the password. The display shows

‘PS’.

5. Use the ES (up) and Light (down) buttons to scroll the parameter codes and

locate the required parameter.

Parameter categories can be identified by the initial symbol or letter of the

code, and the icon displayed on the electronic controller faceplate:

Continued over page

13

SKOPE OD260

Electronic Controller

Service Manual

Parameter

History To see if the parameters have changed from the factory settings, check the

H5 parameter. If it is a positive value the parameters are still at factory

settings. If H5 is a negative value, the parameters have been changed and

are not at factory settings.

6. Press the Set (mute) button to display the value associated with the

parameter code.

7. Use the ES (up) and Light (down) buttons to increase or decrease the value

of the parameter.

8. Press the Set (mute) button to temporarily save the new value. The display

shows the parameter code.

IMPORTANT

If no buttons are pressed for 60 seconds or the power is

disconnected before the temporarily saved values are

permanently saved, the temporarily saved values will be

cancelled and the previous setting will be restored.

9. If necessary, repeat steps 5 - 7 to change other parameters as required.

10. Press and hold the Set (mute) button for 3 seconds to permanently save the

parameters and exit the parameter menu.

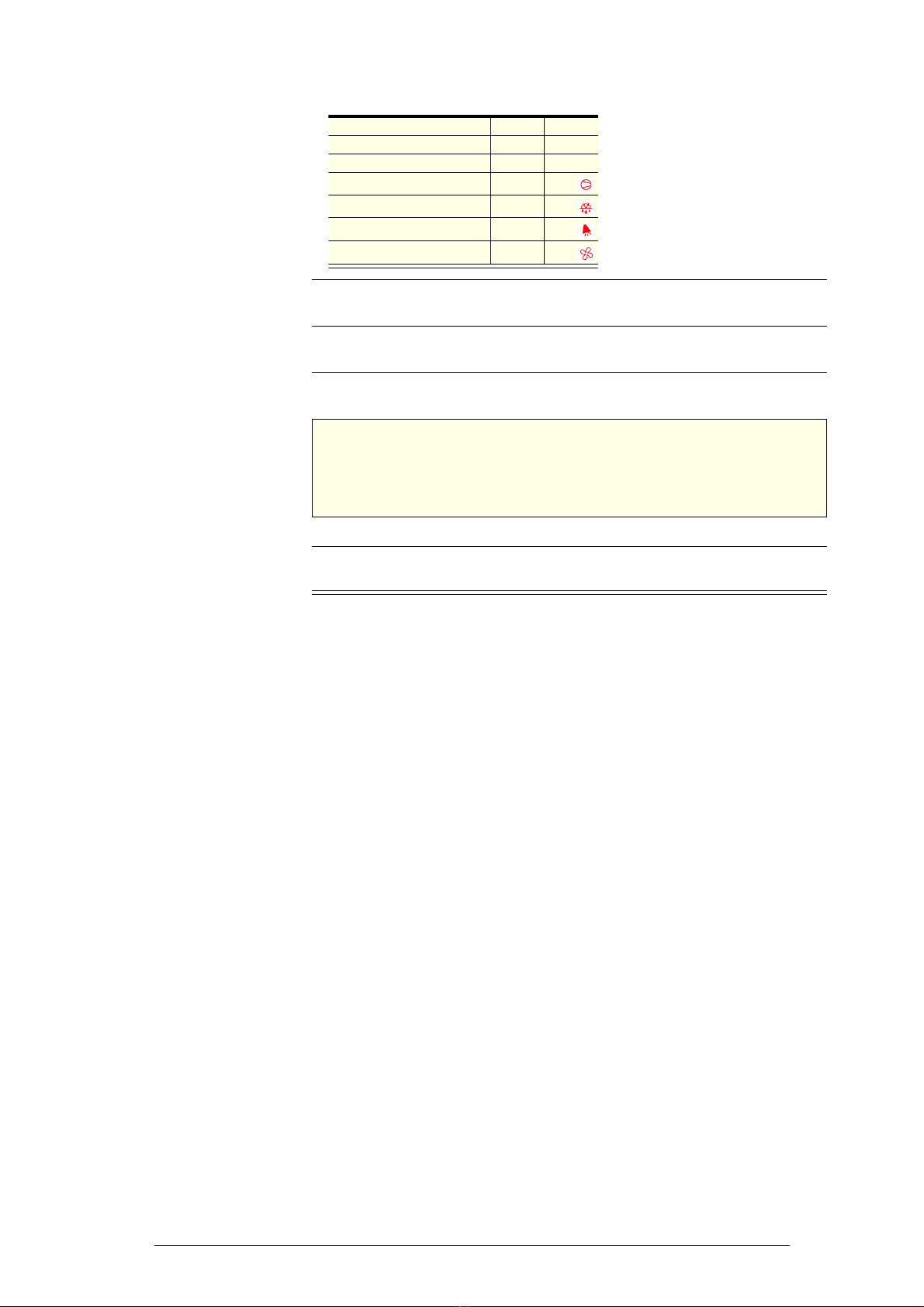

Category Initial Icon

Probe parameters / -

Control parameters r -

Compressor parameters c

Defrost parameters d

Alarm parameters A

Fan parameters F

14 Electronic Controller

Service Manual

SKOPE OD260

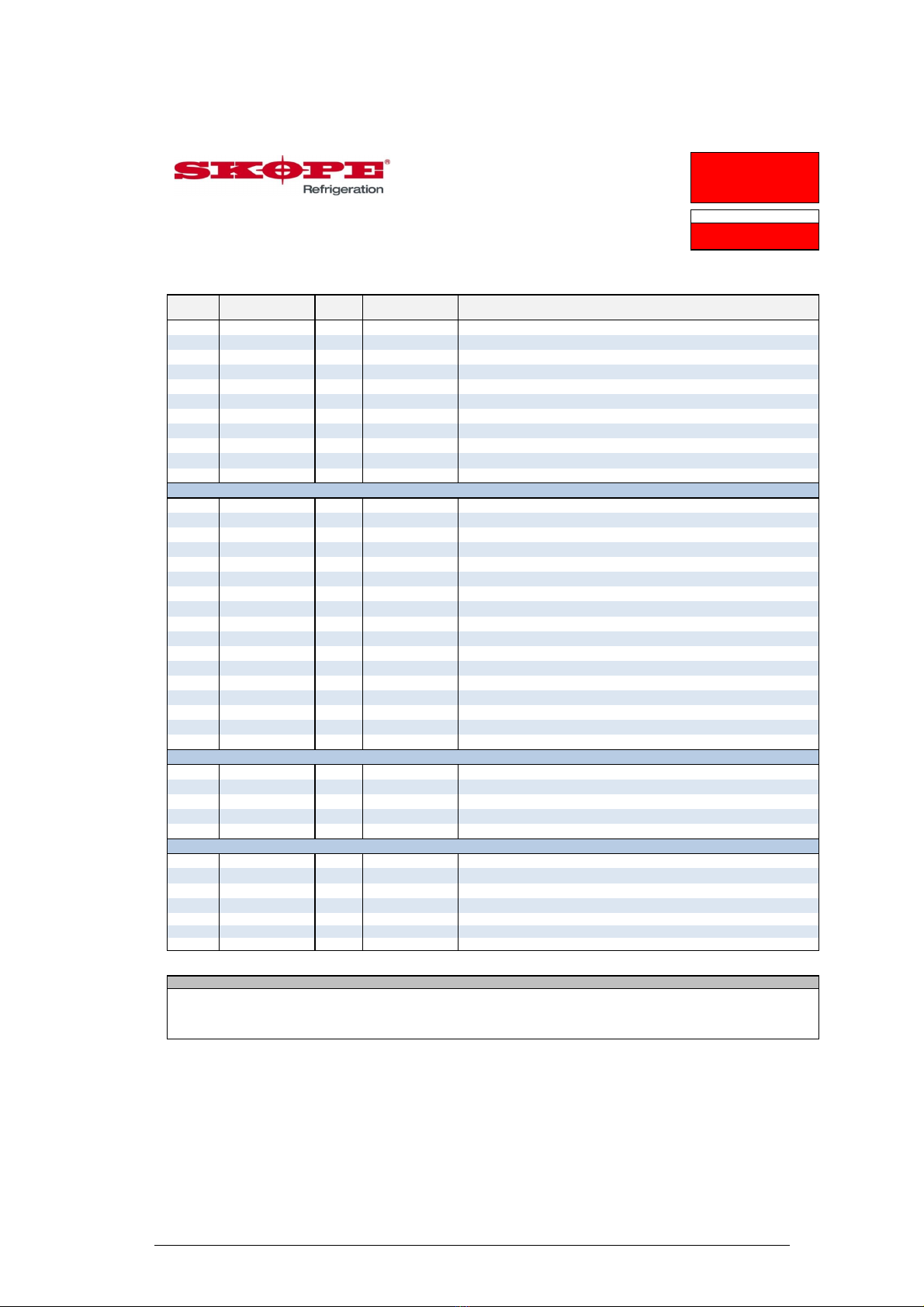

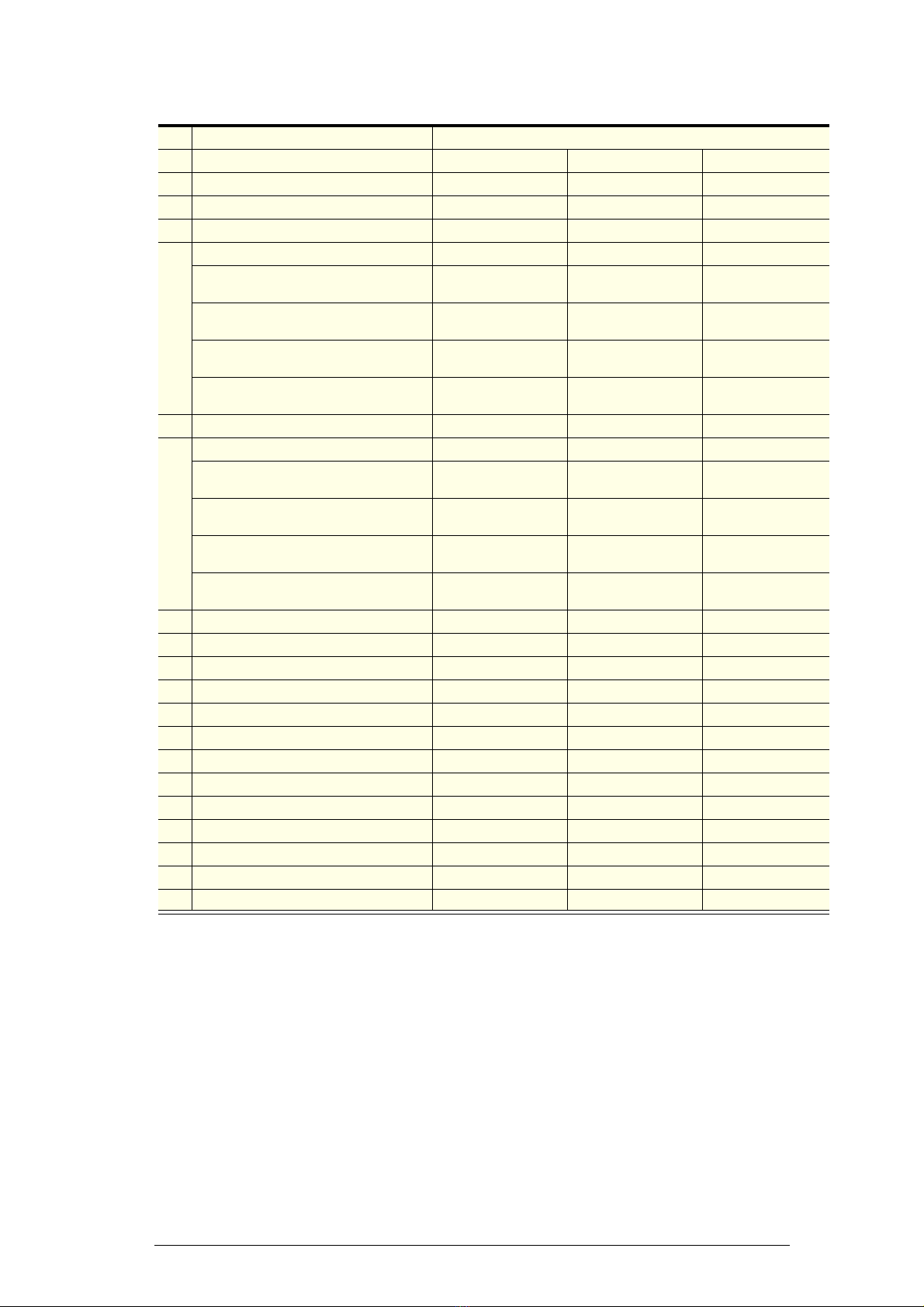

Parameter list - Program 107 - OD260 (page 1 of 2)

Revision: 1.1

Application

OD260

Controller Type

SKOPE S4 EVO

Controller Model & Revision

PZSKC0H002K (Rev 1.414)

SKOPE Part Number

ELZ11478-107

Setting Unit

SET0 Min Max

Probe Parameters

PS 22 F0200

Password (Read Only)

/2 15 C115

Measurement stability (Applies to all probes)

/4 1 C15

Select probe displayed

/5 0 C01

Select °C/°F ( 0=°C ; 1=°F )

/6 0 C01

Disable decimal point

/8 0.0 °C C -99.00 99.0 Display Offset (Only if /E > 0)

/9 0.0 °C C -40.0 /A Minimum Display value (Only if /E > 0)

/A 199 °C C /9 /b Maximum Display Value (Only if /E > 0)

/b 199 °C C /A 199 Visualization Error Threshold (Only if /E > 0)

/E 1 C050

Display Dampening Coefficient

/C1 1.5 °C C -50.0 50.0 Probe 1 Calibration Offset

/C2 0.0 °C C -50.0 50.0 Probe 2 Calibration Offset

/C3 0.0 °C C -50.0 50.0 Probe 3 Calibration Offset

Regulation Parameters

St 2.0 °C F r1 r2 Set point

rd 2.0 °C C 0.0 19.0 DAY differential

r1 0.0 °C C -50.0 r2 Minimum set point value

r2 4.0 °C C r1 150 Maximum set point value

r3 0 C01

Enable Auto Day/Night Mode Switching

r4 0.0 °C C -50.0 50.0 Night Mode set point delta (added to St)

r5 2.0 °C C 0.0 19.0 Night differential

r6 0 hrs C 0 90 Night Mode Start Delay (time period with no door openings)

r7 90 hrs C 1 90 Night Mode Timeout (time period in night mode)

r10 0 hrs C 0 24 Light Delay On Time after entering DAY mode

Cold Climate Protection Parameters

CCt 2.0 °C C 0.1 20.0 Cold Climate Protection Temperature Delta

CCd 30 mins C 0 199 Cold Climate Protection Delay

Pull Down Mode Parameters

Pt 127 °C C 0 127 Pull-down Mode - Activation Temperature

Pd 250 hrs C 0 250 Pull-down Mode - Maximum Duration

Compressor Parameters

c0 1 mins C 0 200 Comp. and Fan start delay at power-up.

c1 0 mins C 0 100 Minimum time between consecutive compressor starts

c2 3 mins C 0 100 Minimum compressor off time

c3 3 mins C 0 100 Minimum compressor on time

c4 10 mins C 0 100 Compressor on time with duty setting

c5 1 C01

Enable mains voltage protection (0 = disabled, 1 = enabled)

Defrost Parameters

d0 0 C01

Type of defrost ( 0 = Electric, 1 = Hot Gas)

dI 2 hrs C 0 199 Defrost interval time (Time between defrosts)

d2 1 C01

Run defrost interval timer only when compressor running

dt 4 °C C -50.0 127 Defrost Termination temperature

dP 30 mins C 1 199 Maximum defrost duration

d4 0 C01

Defrost request at power-on: (0 = no, 1 = yes)

d5 0 mins C 0 199 Defrost delay on power-up (when d4=1)

d6 1 C01

Display during defrost (0 = "dEF", 1 = Temperature at start of defrost)

dd 0 mins C 0 15 Dripping time (compressor and fans stopped after defrost)

d8 0 mins C 0 199 Bypass high temperature alarm after defrost or door opening

Parameter

107

CPS1017-107-SET0

Last revised on

12-Feb-2018

Full List

SET0

Access

Level

Range

Description

Electronic Controller Parameter Sheet

Page 1 of 2

15

SKOPE OD260

Electronic Controller

Service Manual

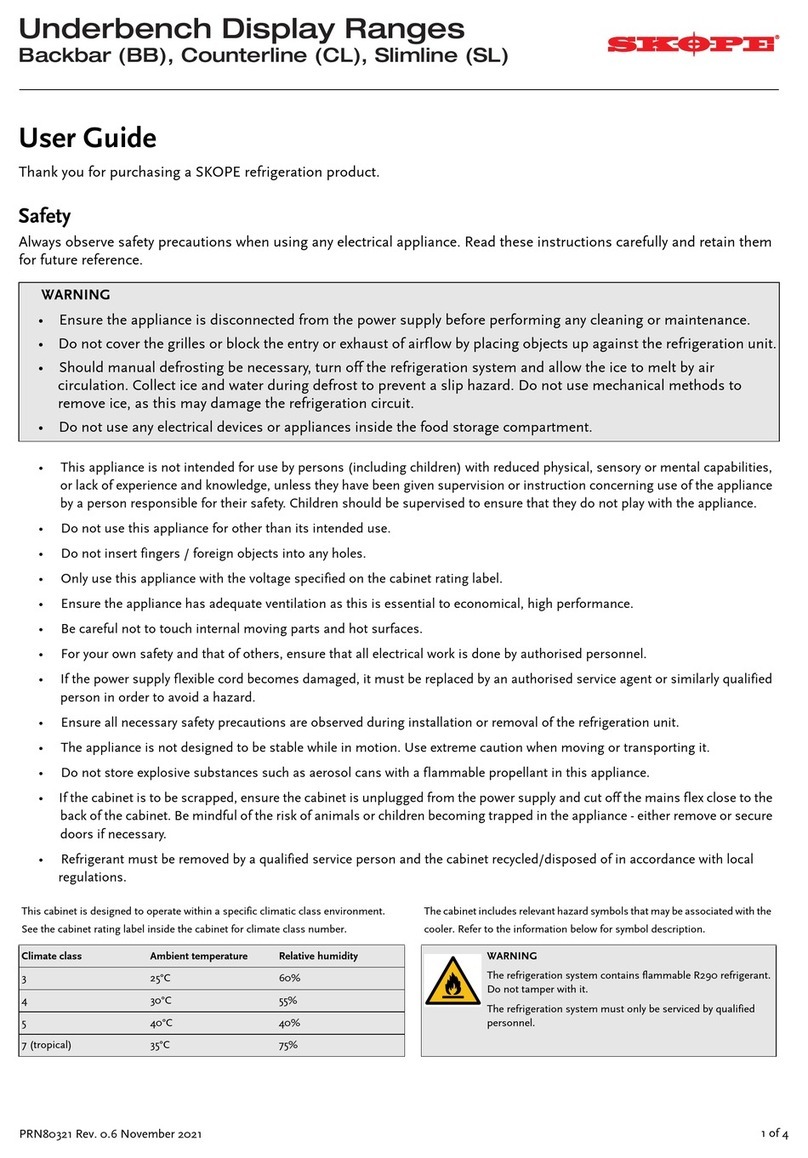

Parameter list - Program 107 - OD260 (page 2 of 2)

Revision: 1.1

Application

OD260

Controller Type

SKOPE S4 EVO

Controller Model & Revision

PZSKC0H002K (Rev 1.414)

SKOPE Part Number

ELZ11478-107

Setting Unit

SET0 Min Max

Parameter

107

CPS1017-107-SET0

Last revised on

12-Feb-2018

Full List

SET0

Access

Level

Range

Description

Electronic Controller Parameter Sheet

d9 0 C01

Defrost priority over compressor protectors

d/1 - °C F - - Probe reading on 2nd Input (read only)

d/2 - °C F - - Probe reading on 3rd Input (read only)

d10 -9.0 °C C -50.0 127 On demand defrost Start Temperature

d11 10 mins C 0 60 On demand defrost: start delay

d12 127 °C C -50.0 127 Enabling defrost condition: Control probe threshold

d13 1 C01

Evaporator Fans During Defrost (0 = Off 1 = ON)

d19 15 mins C 0 200 No Downward Tendency Defrost - Start Delay (0 = function disabled)

d20 15 mins C 1 < d19 No Downward Tendency Evaluation (Sample Time)

d21 0 C05

Number of NDT defrosts before R.S.F. "Err" alarm (0 = function disabled)

d22 0.1 °C C 0.0 5.0 No Downward Tendency Evaluation (Temperature Delta)

Alarm & Input Configuration Parameters

A0 -2.0 °C C -20.0 20.0 Temperature Alarm Differential

AL 0.0 °C C -50.0 150 Low temperature alarm setpoint. (Relative if A0>0, Absolute (A0≤0)

AH 10.0 °C C -50.0 150 High temperature alarm setpoint. (Relative if A0>0, Absolute (A0≤0)

Ad 120 mins C 0 199 Temperature alarm delay ( 0 = AL and AH alarms disabled)

A10 0 mins C 0 10 Door Open Alarm delay (0 = door open alarm disabled)

A11 2 C05

2nd Input Configuration

A12 3 C016

Number of cA alarm events to trigger manual reset 'CA' alarm

A13 24 hrs C 0 240 cA alarm counter reset delay

A14 60 mins C 0 240 cA alarm reset delay

A15 1 C01

Lights switched OFF when CHt, cA or CA alarm occurs

A18 1 C01

Allow power cycle to reset CA alarm

A20 15 mins C A10 60 Faulty door/curtain switch E2 alarm delay

Ac 60.0 °C C -50.0 250 High condenser temperature alarm set point

AE 10.0 °C C 0.1 20.0 High condenser temperature alarm differential

Acd 0 mins C 0 250 High condenser temperature alarm delay

Acr 1 C02

High condenser temperature alarm reset method

A21 1 C05

3rd Input Configuration

Evaporator Fan Parameters

F0 3 secs C 1 100 Loads Activation Delay

Fd0 20 mins C 1 100 Fan DAY Duty Cycle : ON time

FdF 0 mins C 0 100 Fan DAY Duty Cycle : OFF time

Fn0 25 mins C 1 100 Fan NIGHT Duty Cycle : ON time

FnF 0 mins C 0 100 Fan NIGHT Duty Cycle : OFF time

Other Parameters

H0 1 C 0 207 Supervisor Serial address

H01 1 C01

Baud Rate (0 = 9600, 1 = 19200)

H02 2 C02

Stop Bits

H03 0 C02

Parity ( 0 = None, 1 = Odd, 2 = Even)

H2 2 C03

Enable Keypad

H4 0 C01

Disable buzzer (0 = Buzzer Enabled, 1 = Buzzer Disabled)

H5 107 F 0 199 ID code (read-only)

Warning

1. Only make program modifications with reference to relevant Operating Manual.

2. This programming sheet is exclusively for SKOPE refrigeration systems with its dedicated Carel controller.

3. Any alteration from this program may adversely affect the SKOPE Refrigeration System operation.

4. Specification may change without notice. Please check with SKOPE Customer Service for latest revision.

Page 2 of 2

16 Wiring

Service Manual

SKOPE OD260

3Wiring

Model: OD260

WIRE COLOURS

BK Black

BN Brown

RD Red

OG Orange

GN Green

BU Blue

GY Grey

WH White

GNYE Green-Yellow

Based upon IEC 757 Standard

LEGEND

T1 Unit terminal S3 & P3 Compressor socket and plug (blue 4-way)

T2 Evaporator fan junction box terminal S4 & P4 Condenser fan socket and plug (red 4-way)

T3 Cabinet terminal S5 & P5 Evaporator fan socket and plug (white 4-way)

T4 Cabinet light and terminal S6 & P6 LED power supply output socket and plug (white 4-way)

T5 Heater wire terminal S7 & P7 Control probe socket and plug (blue 2-way)

S1 & P1 IEC mains isolation socket and plug S8 & P8 Condenser probe socket and plug (red 2-way)

S2 & P2 Unit to cabinet socket and plug S9 & P9

Evaporator probe socket and plug (black 2-way)

LED Ballast

N

L

+

-

T

1-1 & 2

S2-2 P2-2

S2-4 P2-4

EMC Filter

M

M

T1-3 &

4

BU

BN

Evaporator

Fan

Condenser

Fan

T5-2

BU

RD

BK

BU

P2-1 S2-1

BN BN

BN

M

Evaporator

Fan

T2-2

T2-1

BUBN

BN

GNYE

BU

GNYE

T3-2

RD RD

BK

BK

T4-1

T4-2

Cabinet Heater Wire

BU

T3-1

WH

Left

Cabinet Light

BN BU

S1-L P1-L P1-N S1-N

BN BU

BU

BU

BN

BN

BU

BN

Fuse

3A

LNE

BU

BU

T5-1T3-3

BN

BN

BN

Right

Cabinet Light

BN BU

P5-1 S5-1

S3-2 P3-2

S4-2 P4-2 S4-1 P4-1

S3-1 P3-1

S5-2 P5-2

S6-4 P6-4

S6-3 P6-3

RD

S6-2 P6-2

RD

BK

S6-1 P6-1

BK

BU

6 7

4 5

2

Fan

3

1

Lights

8

9

10

11

S4 EVO

Comp.

BN

OG

BK

Embraco Compressor

C

S

St ar t C apac it o r

Relay

Ove rlo ad Compressor

L

N21

R

BU

BU

BN

WH

S7-1 P7-1

BK

BK

OG

BK

RD

BK

BK

BK

BK

S7-2 P-2

S8-1 P8-1

S8-2 P8-2

S9-1 P9-1

S9-2 P9-2

Cabinet

Probe

Evaporator

Probe

Condenser

Probe

BK

BK

T6-1

BK

BN

BK

P4-4

17

SKOPE OD260

Wiring

Service Manual

Notes

18 Spare Parts

Service Manual

SKOPE OD260

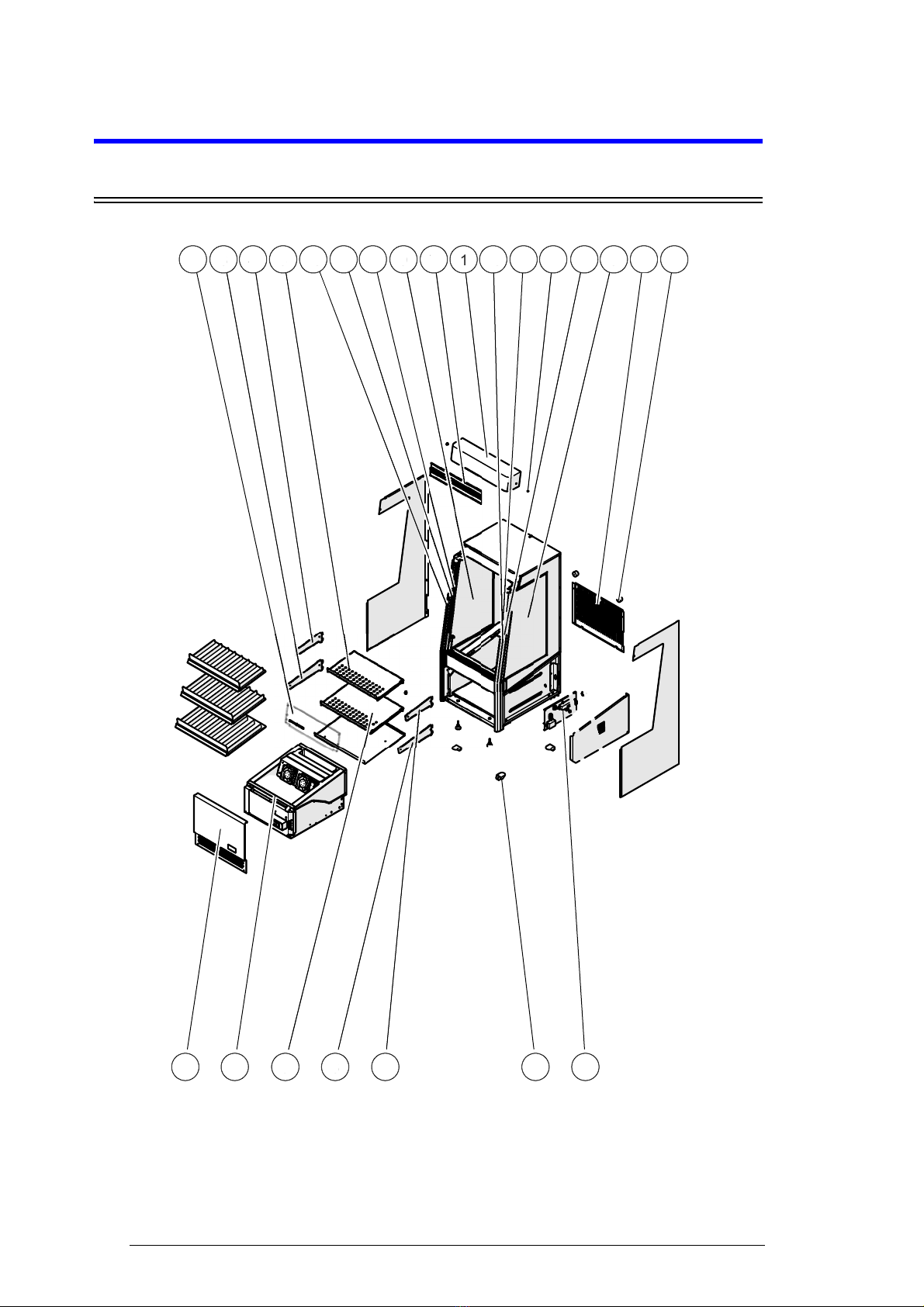

4Spare Parts

Cabinet Assembly ‐OD260

15 14

17

91110

18

12 81110 126 4 3

5

113

6

2

19

7

416

1

10

10

11

11

2

3

4

4

5

6

6

7

8

9

19

SKOPE OD260

Spare Parts

Service Manual

Parts — Cabinet OD260

*See page 27 for information on shelf bracket variations

Item Description SKOPE Part No.

Standard White Black

1Plastic lid -PLM1662A-WH PLM1662A-BK

2Plastic lid screw -PLM10437WH PLM10437BK

3Top shelf -O260/591C-32 O260/591C-49

4

Top shelf bracket - one part version* -STY11671-32 STY11671-49

Top shelf bracket LH - two part

version* -STY10956L-32 STY10956L-49

Top shelf bracket RH - two part

version* -STY10956R-32 STY10956R-49

Top shelf height adjustment piece LH

- two part version* -O230C/598CL-32 O230C/598CL-49

Top shelf height adjustment piece RH

- two part version* -O230C/598CR-32 O230C/598CR-49

5Middle shelf* -O260/591B-32 O260/591B-49

6

Middle shelf bracket* -STY11670-32 STY11670-49

Middle shelf bracket LH - two part

version* -STY10955L-32 STY10955L-49

Middle shelf bracket RH - two part

version* -STY10955R-32 STY10955R-49

Middle shelf height adjustment piece

LH - two part version* -O230C/598BL-32 O230C/598BL-49

Middle shelf height adjustment piece

RH - two part version* -O230C/598BR-32 O230C/598BR-49

7Point of sale header --PLE11610-0550

8Side window RH GLA11663R - -

9Side window LH GLA11663L - -

10 Vertical bumper strip --PLE4077BK-260L

11 Light module ELL11123 - -

12 Light cover O260/E71 - -

13 Acrylic upstand PLY11672 - -

14 Rear spacer RUM4105 - -

15 Rear panel -O260/N86-32 O260/N86-49

16 Front panel -O260/131-32 O260/131-49

17 Castor SXX10289 - -

18 Electrics plate assembly O260/G29 - -

19 Refrigeration unit assembly UB89ABF-107IE - -

20 Spare Parts

Service Manual

SKOPE OD260

Electrics Plate Assembly

Parts — Electrics Plate Assembly

Item Description SKOPE Part No.

0Electrics plate assembly O260/G29

1EMI filter ELZ10136

2Light power supply O260/K08

33A fuse ELZ9654

Fuse holder ELZ9655

132

1

2

3

Table of contents

Other Skope Chiller manuals

Skope

Skope ActiveCore TME-N Series User manual

Skope

Skope TME1000 User manual

Skope

Skope BME1200-AC User manual

Skope

Skope SERENE SC112G User manual

Skope

Skope TME ActiveCore Series User manual

Skope

Skope BB Series User manual

Skope

Skope OD400-2 User manual

Skope

Skope TME Series User manual

Skope

Skope TME1000 User manual

Skope

Skope B600G-2 User manual

Skope

Skope ActiveCore BME-N Series User manual

Skope

Skope Pegasus PG100HC-2 User manual

Skope

Skope SC112N-AC User manual

Skope

Skope B1200-2 User manual

Skope

Skope SK650-2 Service manual

Skope

Skope TME-N ActiveCore User manual

Skope

Skope BB Series User manual

Skope

Skope TME650N-3C User manual

Skope

Skope SC112N-AC User manual

Skope

Skope OD460 User manual