BRADEN BG4A Manual

B R A D E N

BG4A & BG4B

HYDRAULIC HOIST

INSTALLATION, MAINTENANCE AND

SERVICE MANUAL

PACR WINCH DIVISION

P . O. BOX 547 BROKEN ARROW, OK U . S.A. 74013

PHONE (918) 251-8511 FAX (918) 259-1575

www.paccarwinch.com

LIT2193 R4

3/2008

Printed in U.S.A.

TABLE OF CONTENTS

FOREWORD…...………………………………………....…........................……….…....…1

PARTSANDSERVICE…………………………………...….............................……...…...2

GENERAL SAFETY RECOMMENDATIONS…………..…...........................…….....…..3

THEORYOF OPERATION………………………………...…..........................………..….4

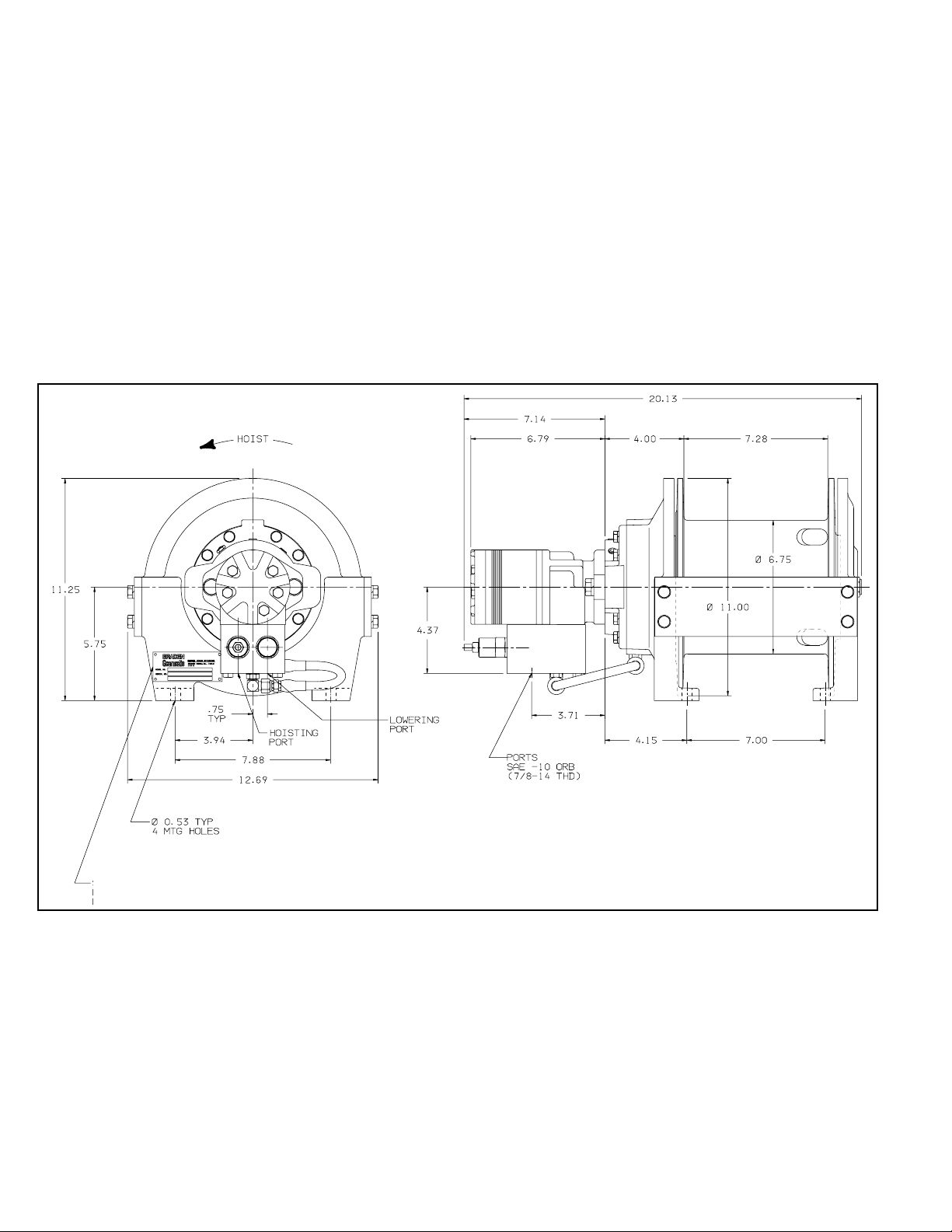

DIMENSIONAL DATA………………………………………...........................…………....6

HOIST AND WIRE ROPE INSTALLATION………...………..........................………...…7

PREVENTATIVEMAINTENANCE……………..……………...........................………..…8

RECOMMENDED GEAR OIL………………….……………........................…………...10

HOIST EXPLODED VIEW DRAWING…......................................................................11

PARTS KEY.................................................................................................................11

TROUBLESHOOTING……………………………………..……...........................……...13

HOISTSERVICE……………………………………………...…........................…....……16

HOIST DISASSEMBLY………………………………….…..…............................…..16

DRUM ASSEMBLY SERVICE………………………….…..……….......................…17

PLANET GEAR SERVICE………………………...........................……...................17

BRAKE CYLINDER ENDPLATE SERVICE………….............................…….…….18

HOIST ASSEMBLY………………………………….................................……....….19

REVERSING DRUM HOIST ROTATION.……………...................................….…….….8

FASTENER TORQUE CHART....................................................................................22

METRIC CONVERSION TABLE………………………..................................................24

1

FOREWORD

Read and understand this entire publication BEFORE operating or servicing your BRADEN hoist. Retain this manual for

future reference.

The minimum service intervals specied are for operating hours of the prime mover.

The following service instructions have been prepared to provide assembly, disassembly and maintenance information

for the Model BG4 series hoist. It is suggested that before doing any work on these units, all assembly and disassembly

instructions should be read and understood.

Some illustrations in this manual may show details or attachments which may be different from your hoist. Also, some

components may be removed for illustrative purposes.

Continuing product improvement may cause changes in your hoist which may not be included in this manual. When a ques-

tion arises regarding your hoist or this manual, contact your nearest BRADEN dealer or the factory Service Department.

Provide the complete hoist model number and serial number when making inquiries. The model and serial numbers are

stamped into the data plate attached to the tie plate as shown below.

Braden Technical Support Department

Phone: (918) 251-8511

08:00 to 16:30 CST

Monday thru Friday

Fax: (918) 259-1575

Internet: hoist.service@paccar.com

PARTS AND SERVICE

BRADEN provides parts and service through a network of

authorized dealers. Parts and service are not available di-

rectly from the factory. For the name of your nearest dealer,

consult your local phone directory or call us at the phone

number shown above.

Serial Number and Model Number are stamped into the data

plate located on left lower corner the motor support when

viewing hoist from motor end. Always refer to the Serial

Number and Model Number when requesting information or

service parts.

EXPLANATION OF MODEL NUMBER

BG 4 B 05 119 01 H

BRADEN

GEARMATIC

MAX

RATING

DESIGN

MODEL

GEAR

RATIO

MOTOR

SIZE

DRUM

SIZE

OPTIONAL

HIGH LINE

PULL

BG DESIGNATES BRADEN GEARMATIC

4 DESIGNATES 4,000 lb (1,810 kg) FIRST LAYER LINE PULL

B DESIGNATES THE MODEL SERIES RELATING TO DESIGN CHANGES

05 DESIGNATES TOTAL GEAR REDUCTION

119 DESIGNATES HYDRAULIC MOTOR DISPLACEMENT IN cu in./rev

DECIMAL POINT ELIMINATED (119 = 11.9 cu in./rev [195 cu cm])

01 DESIGNATES THE DRUM

H DESIGNATES 5,000 lb. (2,270 kg) FIRST LAYER LINE PULL OPTION

2

CAUTION

WARNING

! !

GENERAL SAFETY

RECOMMENDATIONS

Safety for operators and ground personnel is of prime con-

cern. Always take the necessary precautions to ensure

safety to others as well as yourself. To ensure safety, the

prime mover and hoist must be operated with care and

concern by the operator for the equipment, and a thorough

knowledge of the machine’s performance capabilities.

The following recommendations are offered as a general

safety guide. Local rules and regulations will also apply.

Safety informational callout’s used in this manual

include:

1. Read all warning tag information and become familiar with

all controls BEFORE operating hoist.

2. NEVER attempt to clean, oil or perform any maintenance

on a machine with the engine running, unless instructed to

do so in the service manual.

3. NEVER operate hoist controls unless you are properly

seated at the operators station on the prime mover and

you are sure personnel are clear of the work area.

4. Assure that personnel who are responsible for hand sig-

nals are clearly visible and that the signals to be used are

thoroughly understood by everyone.

5. Ground personnel should stay in view of the prime mover

operator and clear of hoist drum. DO NOT allow ground

personnel near hoist line under tension. A safe distance of

at least 1½ times the length of the cable should be main-

tained. NEVER allow anyone to stand beneath a suspend-

ed load

6. On machines having hydraulically, mechanically and/or

cable controlled equipment, be certain the equipment is

either lowered to the ground or blocked securely before

servicing, adjusting and/or repairing the hoist. Always ap-

ply the prime mover parking brakes and lower equipment

before dismounting the prime mover.

7. Inspect rigging, hoist and hydraulic hoses at the beginning

of each work shift. Defects should be corrected immedi-

ately.

8. Keep equipment in good operating condition. Perform

scheduled servicing and adjustments listed in the “Pre-

ventive Maintenance” section of this manual.

9. An equipment warm-up procedure is recommended for all

start-ups and is essential at ambient temperatures below

+40ºF (14°C.) Refer to “Warm-up Procedure” listed in the

“Preventive Maintenance” section of this manual.

10. Be sure of equipment stability before operating hoist.

11. The hoists described herein are neither designed nor

intended for use or application to equipment used in the

lifting or moving of persons.

12. DO NOT exceed the maximum pressure (PSI) or ow

(GPM) stated in the hoist specications.

13. Operate hoist line speeds to match job conditions.

14. Leather gloves should be used when handling hoist

cable.

15. NEVER attempt to handle hoist cable when the hook

end is not free.

16. When winding hoist cable on the hoist drum, NEVER

attempt to maintain tension by allowing hoist cable to slip

through hands. Always use “hand-over-hand” technique.

17. NEVER use hoist cable with broken strands. Replace

hoist cable.

18. DO NOT weld on any part of the hoist.

19. DO NOT use knots to secure or attach hoist cable.

20. Use recommended hydraulic oil and gear lubricant.

21. Keep hydraulic system clean and free from contamina-

tion at all times.

22. Use correct size cable anchor for cable and pocket in

cable drum.

23. The BRADEN wire rope anchors are capable of sup-

porting the rated load only when installed properly. For

additional safety, ALWAYS maintain a minimum of ve (5)

wraps of wire rope on the drum.

This emblem is used to warn against potential or unsafe

practices which COULD result in personal injury or product

or property damage if proper procedures are not followed.

CAUTION

This emblem is used to warn against hazards and unsafe

practices which COULD result in severe personal injury or

death if proper procedures are not followed.

FAILURE TO OBEY SAFETY RECOMMENDATIONS

MAY RESULT IN PROPERTY DAMAGE, PERSONAL IN-

JURY OR DEATH.

3

CAUTION

WARNING

! !

THEORY OF OPERATION

DESCRIPTION OF HOIST

The hoist has three basic assemblies:

1. Hydraulic motor, brake valve block and counter-

balance cartridges.

2. Static brake assembly.

3. Cable drum assembly.

The hydraulic motor is bolted to the motor adapter which

in turn is bolted to the brake cylinder end plate of the hoist.

The cable drum assembly is supported on the motor end by

a bronze bushing and on the support end by a roller bear-

ing. The ring gear for the single planetary reduction set is

machined into the inside of the cable drum. The cable drum

features two anchor pockets for winding cable on the drum

in either direction.

PLANETARY GEAR TRAIN

The hydraulic motor shaft is directly splined to the brake

coupling which is connected to the sun gear of the planetary

reduction set. The planet carrier is splined to the bearing

support end plate and cannot rotate. The hydraulic motor

rotates the brake coupling and sun gear, driving the planet

gears which in turn drive the ring gear/cable drum.

DUAL BRAKE SYSTEM

DYNAMIC BRAKE

The dynamic brake consists of two basic components:

1. Brake Valve block and cartridges;

2. Hydraulic motor.

The brake valve contains a counterbalance cartridge valve,

pilot-operated check valve and a shuttle valve. The check

valve opens at approximately 30 PSI (207 kPa) to allow the

hoist to rotate in the raising direction. During lowering, oil is

sent to the counterbalance cartridge which blocks the ow

of oil out of the motor until the valve cracks opens at ap-

proximately 750 PSI (5,170 kPa) with no load. After the

valve cracks open, the pilot pressure becomes ow depen-

dent modulating the cartridge valve to control the lowering

speed. The shuttle valve directs oil to the internal brake from

both directions, releasing the brake during both raising and

lowering operations.

Note: Early BG4A hoists included (2) counterbalance car-

tridges in the valve block. When servicing, one cartridge

may be replaced with the check valve cartridge currently

in use.

AB

WINCH

BRAKE

BR

2 COUNTERBALANCE CARTRIDGES

(Early BG4A Hoists)

BOTH CIRCUITS ARE WITH A SINGLE SPEED MOTOR,

BRAKE EFFECTIVE BOTH DIRECTIONS

HYDRAULIC CIRCUITS

Winch Brake

Pump

Control

Valve

Winch Assembly

W/Brake Valve

& Static Brake

Hoist

Lower

Pilot

Operated

Check

Valve

Winch Motor

Counterbalance Cartridge

1 COUNTERBALANCE CARTRIDGE

1 PILOT OPER. CHECK VALVE

4

STATIC BRAKE

The static brake consists of three basic components.

1. Spring applied, multiple friction disk brake pack.

2. Solid brake coupling.

3. Hydraulic brake cylinder and spring plate.

The brake pack consists of alternatively stacked friction

and steel brake disks. The steel brake disks are externally

splined to the motor adapter and cannot rotate. The friction

disks are internally splined to the brake coupling. When

the hoist is not being operated, spring force compresses

the brake pack and locks the brake coupling to the motor

adapter, preventing the gear train or cable drum from ro-

tating in either direction. The solid brake coupling makes

the static brake “effective both directions”. This means the

static brake must be released before the hoist can operate

in either the raise or lower direction.

The static brake is released by pilot pressure applied to the

brake cylinder. It releases at a pressure lower than that re-

quired to open the pilot operated counterbalance cartridge,

typically approx. 600 PSI (4,140 Kpa.) This sequence as-

sures that dynamic braking is done by the counterbalance

cartridge and that little, if any, heat is absorbed by the fric-

tion brake.

The static or friction brake is primarily a load holding brake

and will provide dynamic braking only during extremely slow

operation when there is insufcient ow and pressure to

open the counterbalance cartridge.

OPERATION

Since the static brake on this hoist is “effective both direc-

tions”, the brake must be hydraulically released to operate

the hoist in either the hoist or lower direction.

When the hoist is powered in either direction, the motor can-

not rotate until sufcient pilot pressure is present to open the

counterbalance cartridge or check valve. The friction brake

will completely release at a pressure lower than required to

open the counterbalance cartridge during lowering. The ex-

tent to which the cartridge opens will determine the amount

of oil that can ow through it and the speed at which the

cable drum will turn. Increasing the ow of oil to the hoist

motor will cause the pressure to rise and the opening in the

cartridge to enlarge, speeding up the cable drum. Decreas-

ing the ow causes the pressure to drop and the opening in

the cartridge to decrease, slowing down the cable drum.

During raising operations, the check valve recieves a pilot

signal from the motor inlet port opening the check valve to

allow free ow of oil through the motor. When the control

valve is returned to the neutral or center position, pressure

will rapidly drop and the counterbalance cartridge will close,

stopping the load. The friction brake will engage and hold

the load after the cartridge is closed.

HOIST AND WIRE ROPE

INSTALLATION

1. The hoist should be mounted with the centerline of the

cable drum in a horizontal position. The mounting plane of

the hoist may be rotated in any position around this cen-

terline providing the vent in the motor adapter is above the

centerline of the cable drum. The vent should be as close to

top dead center as possible.

2. When mounting the hoist, use all four (4) mounting holes

and Grade 8 bolts and nuts. Evenly tighten the nuts to the

torque in the “Recommended Torque” chart. Refer to “Di-

mensional Drawing” for bolt hole size and pattern.

It is important that the hoist is mounted on a sur face that

will not ex when the hoist is in use, and cause binding of

the gear train. Binding in the gear train will result in accel-

erated wear and heat. Also, the mounting surface should

be at with ± 0.020 inches. If necessary, install shims

under the hoist mounting pads to achieve even mounting.

3. The hydraulic lines and components that operate the hoist

should be of sufcient size to assure minimum back pres-

sure at the hoist. The back pressure at the motor must not

exceed 100 psi (690 kPa) to maintain full brake system de-

sign factor and optimum motor seal life.

The hoist directional control valve must be a three position

four way valve with a motor spool such that when the valve

is in the center position both work ports are open to tank

(open center, open port.)

4. High quality hydraulic oil is essential for satisfactory per-

formance and long hydraulic system component life. Oil hav-

ing 150 to 330 SUS viscosity at 100°F (38°C) and viscosity

index of 100 or greater will give good results under normal

temperature conditions. The use of an oil having a high

viscosity index will minimize cold start trouble and reduce

the length of warm-up periods. A high viscosity index will

minimize changes in viscosity with corresponding changes

in temperature.

Maximum cold weather start-up viscosity should not exceed

5,000 SUS with a pour point at least 20°F (11°C) lower than

the minimum ambient temperature.

Under continuous operating conditions the temperature of

the oil at any point in the system must not exceed 180ºF

(82°C). 120-140°F (49-60°C) is generally considered opti-

mum.

In general terms:

For continuous operation at ambient temperatures between

50 and 110°F (10-43°C) use ISO VG 46 – 68 (SAE20); for

continuous operation between 10 and 90°F (-12 and 32°C)

use ISO VG 32 (SAE10W); for applications colder than 10°F

(-12°C), contact the BRADEN Product Support Department.

The use of multi-viscosity oils is generally not recommend-

5

ed.

5. The hydraulic oil lter should have a 10 micron nominal

rating and be full ow type.

6. The vent plug in the motor adapter must be located as

close to top dead center as possible. If the hoist is mounted

on a pivoting surface, the vent plug must remain above the

centerline of the cable drum to prevent gear oil leakage.

7. Refer to “Dimensional Drawing” for relationship between

drum rotation and which port is pressurized.

Dimensions shown in inches

6

Stamp Name Tag as Follows:

Line 1. Model Number

Line 2. Hoist Serial Number

Figure 1 Figure 2

Drive down from

this side

Correct Installations

Wedge and wire rope fully seated in pocket

Incorrect Installations

Wedge pulled too

far through anchor

pocket

Wedge not fully

seated

-Wire Rope not tight against wedge

-Wedge may be too large

-”Dead” end of wire rope and/or wedge

may interfere with proper spooling

-Wedge may be too small

THE CABLE ANCHORS ALONE ON HOISTS ARE NOT

INTENDED TO HOLD RATED LOADS.

Hoist loads applied directly to the wire rope anchor may cause

the wire rope to pull free and result in the sudden loss of load

control and cause property damage, personal injury or death. A

minimum of 5 wraps of wire rope must be left on the drum barrel

to achieve rated load.

The wedge and anchor pocket must be clean and dry. The

end of the wire rope being anchored to the drum must be clean

and dry and not frayed. Anything on the end of the wire rope

to keep it from fraying (i.e. tape or wire) must not be in contact

with the wedge when the installation is complete. Consult the

wire rope manufacturer on the proper treatment of the dead

end of the wire rope. Some rope manufacturers recommend

when using rotation resistant wire rope, that the rope end be

seized, welded or brazed before inserting the wire rope into the

wedge socket to prevent core slippage or loss of rope lay.

WIRE ROPE INSTALLATION

(ONE PIECE CABLE WEDGE)

Take the free end of the wire rope and insert it through the

small opening on the cable drum. Loop the wire rope and

push the free end about 3/4 of the way back through the

pocket. Install the wedge as shown in gure 1, then pull

the slack out of the wire rope. The “dead” end of the rope

needs to extend slightly beyond the end of the wedge as

shown in gure 2.

Using a hammer and brass drift, drive the wedge as deep

into the pocket as possible to ensure it is fully seated and

no further movement is detected. Applying a load on the

wire rope will also help seat the wedge in the pocket.

Check to ensure the wedge does not protrude from either

end of the pocket, causing it to interfere with proper spool-

ing of wire rope onto the drum (see gures 3 & 4).

If there is interference or the wedge does not seat rmly,

contact the BRADEN Product Support Department at

1-918-251-8511 to determine the proper wedge size.

It is important that the wire rope have the proper tensioning

when it is installed on the drum. When the wire rope is rst

installed, you should operate the hoist, with light to moder-

ate loads, with reeving that let’s you place these loads on

the block and the drum with all the rope off the drum except

for the last ve wraps.

7

CAUTION

WARNING

! !

1. Remove and reverse the positions of the counterbalance

and check valve cartridges in the brake valve block. For

standard rotation, the counterbalance cartridge is installed

in the left hand (LH) port when looking at the motor end of

the hoist. For opposite, or reversed, rotation, the counterbal-

ance cartridge must be installed in the right hand (RH) port.

NOTE: On early units with dual counterbalance cartridges,

skip this step.

2. Remove and reverse the positions of the hydraulic motor

lines connected to the brake valve. The line for powering the

motor in the hoisting direction must be installed in the port

that is in-line with the counterbalance cartridge.

reverse rotation

Check Valve

Counterbalance Cartridge

Hoisting Port

Lowering Port

standard rotation

Check Valve

Counterbalance Cartridge Lowering Port

Hoisting Port

REVERSING DIRECTION OF DRUM

ROTATION

For standard rotation when hoisting, the cable drum rotates

counter clock-wise (CCW) when viewed from the motor

end.

In order to reverse the direction of rotation of the cable drum,

two changes must be made on the motor end of the hoist.

PREVENTIVE MAINTENANCE

A regular program of preventive maintenance for your plan-

etary hoist is strongly recommended to minimize the need

for emergency servicing and to promote safe and reliable

hoist operation.

The user of BRADEN hoist products is responsible for hoist

inspection, testing, operator training and maintenance noted

below with the frequency dependent on the hoist duty cycle

and the thoroughness of the preventive maintenance pro-

gram. Field experience, supported by engineering testing,

indicates the three (3) service procedures listed below are

the MOST critical to safe, reliable hoist operation and MUST

be observed.

• Regular Gear Oil Changes – every 1000 hours, or six (6)

months.

• Use of Proper Gear Oil – recommended type and viscos-

ity for prevailing ambient temperatures.

•Periodic Disassembly and Inspection of All Wear Com-

ponents – for recommendations, refer to Bulletin PB-308.

Crane inspection records, as well as records of hoist preven-

tive maintenance, repairs and modications, must be avail-

able for a minimum of ve (5) years. These records should

include, but not be limited to, hoist model and serial number,

name and employer of repair technician, date of work and

description of work performed.

1. Oil Level

The gear oil level should be checked every 500 operating

hours, three (3) months, or whenever an oil leak is detect-

ed; whichever occurs rst. To check the oil level, remove

the large plug located in the center of the bearing support

endplate. The oil should be level with the bottom of this

opening. If additional oil is needed, refer to “Recommended

Planetary Gear Oil” for correct oil type.

Hoist gear oil capacity is approx. 2 pints (1 liter.)

2. Oil Change

The gear oil should be changed after the rst 100 operat-

ing hours or three (3) months, whichever occurs rst. The

gear oil should then be changed once every 1,000 operating

hours or every six (6) months, whichever occurs rst. The

gear oil must be changed to remove wear particles that im-

pede the reliable and safe operation of the brake clutch and

erode bearings, gears and seals.

Failure to change gear oil at these suggested minimum in-

tervals may contribute to intermittent brake slippage which

could result in property damage, severe personal injury or

death.

CAUTION

WARNING

! !

8

6. Mounting Bolts

Tighten all hoist base mounting bolts to recommended

torque after the rst 100 hours of operation, then every 1000

operating hours or six (6) months, whichever occurs rst.

7. Warm-up Procedure

A warm-up procedure is recommended at each start-up and

is essential at ambient temperatures below +40°F (4°C).

The prime mover should be run at its lowest recommended

RPM with the hydraulic hoist control valve in neutral allow-

ing sufcient time to warm up the system. The hoist should

then be operated at low speeds, forward and reverse, sev-

eral times to prime all lines with warm hydraulic oil, and to

circulate gear lubricant through the planetary gear sets.

8. Recommended Planetary Gear Oil

Field experience, supported by extensive engineering tests,

indicates the use of the proper planetary gear oil is essential

to reliable and safe operation of the brake and obtaining long

gear train life.

For simplicity, we have listed one (1) readily available prod-

uct in each temperature range which has been tested and

found to meet our specications. This is not to say that other

lubricant brands would not perform equally as well.

If the specied lubricant brands are not available in your

area, make certain your lubricant vendor supplies you with

oil that is equivalent to those products listed.

Failure to use the proper type and viscosity of planetary

gear oil may contribute to intermittent brake slippage which

could result in property damage, severe personal injury or

death. Some gear lubricants contain large amounts of EP

(extreme pressure) and anti-friction additives which may

contribute to brake slippage and damage to brake friction

discs or seals. Oil viscosity with regard to ambient tem-

peratures is also critical to reliable brake operation. Our

tests indicate that excessively heavy or thick gear oil may

contribute to intermittent brake slippage. Make certain that

the gear oil viscosity used in your hoist is correct for your

prevailing ambient temperature.

CAUTION

WARNING

! !

The gear oil should also be changed whenever the ambient

temperature changes signicantly and an oil from a different

temperature range would be more appropriate. Oil viscos-

ity with regard to ambient temperature is critical to reliable

brake operation. Make certain that the gear oil viscosity

used in your hoist is correct for your prevailing ambient tem-

perature. Failure to use the proper type and viscosity of

planetary gear oil may contribute to brake slippage which

could result in property damage, severe personal injury or

death. Refer to “Recommended Planetary Gear Oil” for ad-

ditional information.

3. Vent Plug

The vent plug is located in the motor adapter. It is very im-

portant to keep this vent clean and unobstructed. Whenever

gear oil is changed remove the vent plug, clean in solvent

and reinstall.

Do not paint over the vent or replace with a solid plug.

4. Hydraulic System

The original lter element should be replaced after the rst

fty (50) hours of operation, then every 500 operating hours

or three (3) months, or in accordance with the equipment

manufacturer’s recommendations.

5. Wire Rope

Inspect entire length of wire rope according to wire rope

manufacturer’s recommendations.

CAUTION

WARNING

! !

Failure to properly warm up the hoist, particularly under

low ambient temperature conditions, may result in tempo-

rary brake slippage due to high back pressures attempting

to release the brake, which could result in property dam-

age, severe personal injury or death

Oil Change

To change the gear oil, the hoist must be removed from the

platform. Remove the wire rope from the cable drum to aid

handling the hoist during oil changes. Stand the hoist on a

stable surface with the motor end up. Remove the motor

and brake valve assembly, brake release line and brake cou-

pling. Turn the hoist over and drain the oil through the brake

opening.

Stand the hoist with the motor end up and rell through the

brake opening with two (2) pints (.95 L) of the recommended

gear oil. Reinstall the brake coupling, hydraulic motor and

brake valve and brake release line as dened in the “Hoist

Assembly” section of this manual.

Position the hoist on its mounting feet and let stand for a

short time. Check the oil level as dened in “Oil Change”

(above).

9

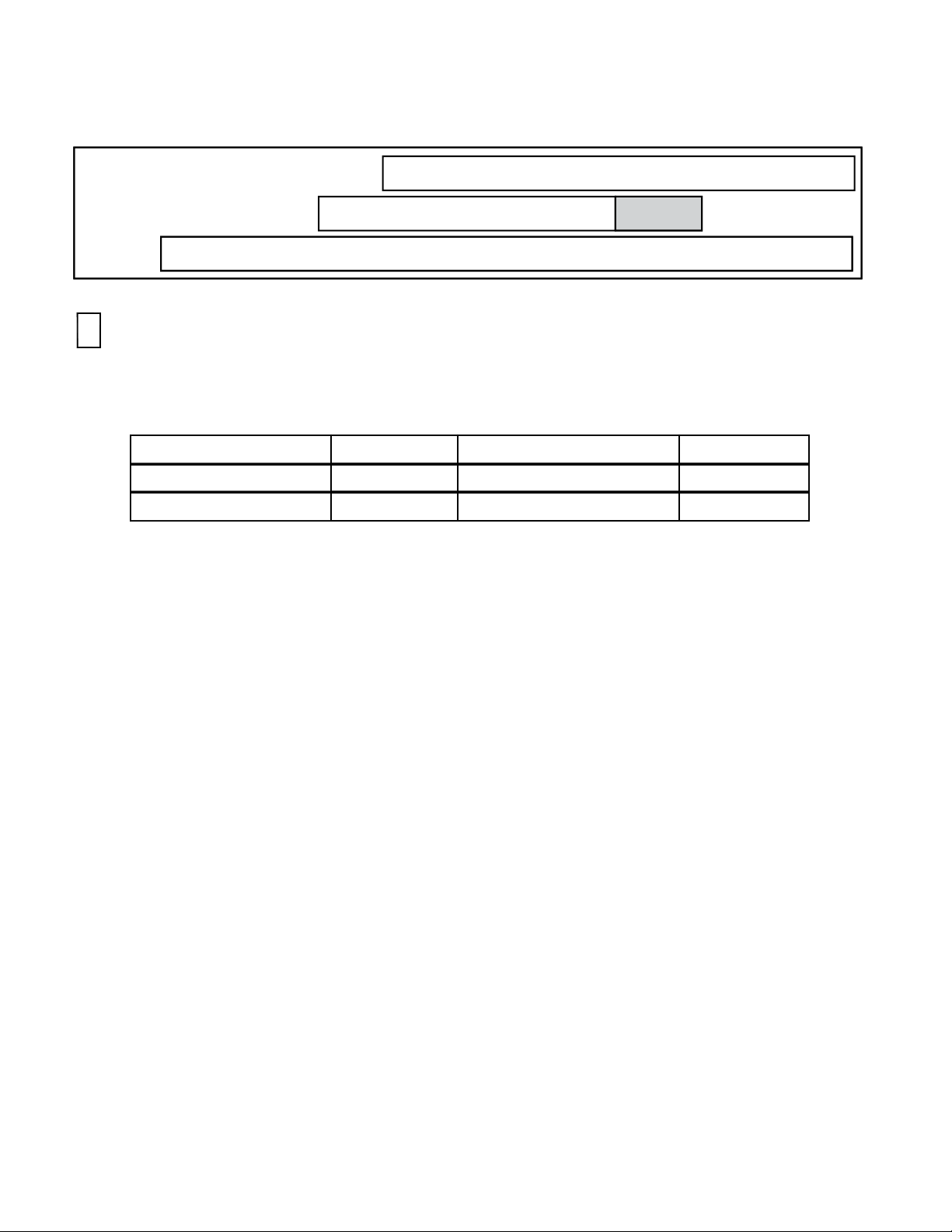

RECOMMENDED PLANETARY GEAR OIL

PREVAILING AMBIENT TEMPERATURE

oF-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 oF

AGMA 5 EP, ISO VG 220

AGMA 4 EP, ISO VG 150

MOBILGEAR SHC 150

SYNTHETIC OR EQUIVALENT

oC-40 -30 -20 -10 0 10 20 30 40 50 oC

NOTE: SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

i

TexacoShell

Meropa 150

Meropa 220

Omala150

Omala220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

RECOMMENDED PLANETARY GEAR OIL

PREVAILING AMBIENT TEMPERATURE

oF-40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130 oF

AGMA 5 EP, ISO VG 220

AGMA 4 EP, ISO VG 150

SYNTHETIC OR EQUIVALENT

oC-40 -30 -20 -10 0 10 20 30 40 50 oC

NOTE: SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

i

TexacoShell

Meropa 150

Meropa 220

Omala150

Omala220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

TexacoMobil Shell

Meropa 150

Meropa 220

Omala150

Omala220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

MOBILGEAR 600 XP 220 OR EQUIVALENT

MOBILGEAR 600 XP 150 OR EQUIVALENT

Mobilgear 600 XP 150

Mobilgear 600 XP 220

Planetary hoists are factory filled with Mobilgear 600 XP 150, or equivalent. Consult your oil supplier for other equivalent

oils if required.

10

BG4 Components

NOTE: BG4 version “A” features splined brake discs, pictured left. The

“B” version features lobed discs as shown in explosion above. Addition-

ally spring count and brake disc count (items 27, 34, & 36) may vary from

depiction above; consult the appropriate Material List for your particualr

hoist model for accurate brake spring and brake disc quantities.

ITEM # DESCRIPTION QTY

1 Bearing Support Endplate 1

2 Brake Cylinder Endplate 1

3 Cable Drum 1

4 Tie Plate 2

5 Capscrew (3/8-16 x 1 GD8) 8

6 Lockwasher (3/8) 8

7 Sight Gauge 1

8 Oil Seal 1

9 Ball Bearing 1

10 Oil Seal 1

11 Ball Bearing 1

12 Output Planet Carrier 1

13 Ouptut Planet Gear 3

14 Output Planet Carrier Shaft 3

15 Roller Bearing 3

16 Thrust Race 6

17 Rollpin 3

27 Spring 8

28 Spring Locator 1

29 Brake Coupling 1

30 Retaining Ring 1

31 Spring Plate 1

32 Brake Piston Seal 1

ITEM # DESCRIPTION QTY

33 Brake Plate Spacer 1

34 Friction Disc 8

35 Steel Disc 9

36 O-Ring 1

37 Gasket 1

38 Motor Adaptor 1

39 Brake Valve Block 1

40 Counterbalance Cartridge 1

40A Check Valve Cartridge 1

41 Sun Gear 1

42 Vent Plug 1

43 Tube Assembly 1

44 Capscrew (5/16-18 x 3 GD8) 4

45 Elbow Fitting 2

46 O-Ring 2

47 Capscrew (5/16-18 x 1 GD8) 8

48 Lockwasher (5/16) 8

49 Hydraulic Motor 1

50 Capscrew (1/2-13 x 1 1/4) 2

51 Lockwasher (1/2) 2

52 Retaining Ring 1

53 Plug, Brake Cylinder Endplate 1

88 Allen Head Plug Brake Cylinder 2

11

TROUBLESHOOTING

The following troubleshooting section is provided as a general guide. You may also need to contact the Original Equipment

Manufacturer (OEM) for additional information.

If a hoist exhibits any sign of:

- Erratic operation such as poor load control, load creeping down or chattering.

- Unusual noise.

- Gear oil leaks

- A sudden rise in wear particles from oil analysis

The hoist MUST be removed from service until the problem has been corrected. If a hoist has been subjected to a sudden

heavy load (shock-load) or overload, the hoist must be removed from service, disassembled and all internal components

thoroughly inspected for damage. Continued operation with a defect may result in loss of load control, property damage,

injury or death.

A

The hoist will not lower the load or not

lower the load smoothly.

Remove the counterbalance cartridge

from the valve block and inspect. Clean

and reseal as required. Cartridges are

supplied pre-set to the pressure re-

quired for proper hoist operation. Fur-

ther adjustment should not be required

Check brake cylinder seal as follows:

A. Disconnect the brake release tube

from the brake release port. Connect

a hand pump with accurate 0-2000 psi

(13,800 kPa) gauge and shut-off valve

to the tting in the brake release port.

B. Apply 1000 psi (6,900 kPa) to the

brake. Close shut-off valve and let stand

for ve (5) minutes.

C. If there is any loss of pressure in ve

(5) minutes, the brake cylinder should

be disassembled for inspection of the

sealing surfaces and replacement of the

seals. Refer to “Brake Cylinder Service”

section of this manual.

Disassemble brake to inspect brake

discs. Refer to “Brake Cylinder Service”

section of this manual.

1. The counterbalance valve cartridge

may be plugged, damaged, or out of

adjustment

2. The friction brake may not be releas-

ing as a result of a defective brake cyl-

inder seal.

NOTE: If the brake cylinder seal is de-

fective you will usually nd oil leaking

from the hoist vent plug.

3. Friction brake will not release as a

result of damaged brake discs.

TROUBLE PROBABLE CAUSE REMEDY

12

B

Oil leaks from vent plug

Same as A2.

Hydraulic System back pressure must

not exceed 100 psi (690 kPa.) Inspect

hydraulic system for a restriction in the

return line to the reservoir.

Oil analysis may indicate contamination

has worn motor shaft and seal. Thor-

oughly ush entire hydraulic system

and install new lters and oil. Install new

motor seal.

1. Same as A2.

2. Motor seal may be defective as a

result of high back pressure in the mo-

tor case drain circuit or contaminated

oil. Contamination will usually cause

the seal to wear a groove in the motor

shaft.

TROUBLE PROBABLE CAUSE REMEDY

C

The brake will not hold a load with the

control lever in neutral

The pressure at the motor lowering port

is also transmitted to the brake release

pilot circuit. Inspect hydraulic circuit for

restrictions, plugged lters or control

valves not centering.

Same as Remedy of Trouble A3.

1. Excessive system back pressure

acting on the brake release port.

2. Friction brake will not hold due to

worn or damaged brake discs.

D

The hoist will not hoist the rated load

Reinforce mounting surface.

If necessary, use shim stock to level

hoist. Refer to “Hoist Installation”.

First loosen, then evenly retighten all

hoist mounting bolts to recommended

torque.

Check relief pressure as follows:

A. Install an accurate 0-5000 psi

(34,500 kPa) gauge into the inlet port of

the brake valve.

B. Apply a stall pull load on the hoist

while monitoring pressure.

C. Compare gauge reading to hoist

specications. Adjust relief valve as re-

quired.

NOTE: If pressure does not increase

in proportion to adjustment, relief valve

may be contaminated or worn out. In ei-

ther case, the relief valve may require

disassembly or replacement.

1. The hoist may be mounted on an un-

even or exible surface which causes

distortion of the hoist base and binding

of the gear train. Binding in the gear

train will absorb horsepower needed to

hoist the rated load and cause heat.

2. System relief valve may be set too

low. Relief valve needs adjustment or

repair.

13

Trouble “D” Continued From

Previous Page

Remove the counterbalance or check

valve cartridge and clean for inspection.

Reseal or replace as required.

Same as remedies for Trouble D1 &

D2.

Same as remedies for Trouble E2.

Refer to hoist performance charts for

additional information.

Perform rigging service as recommend-

ed by crane manufacturer.

3. Check valve or counterbalance valve

may be clogged or stuck. BG4 hoists

use a check valve which requires the

brake to be released while hoisting or

pulling wire rope.

4. Be certain hydraulic system tem-

perature is not more than 180°F (82°C).

Excessive hydraulic oil temperatures

increase motor internal leakage and re-

duces motor performance.

5. Hoist line pull rating is based on 1st

layer of wire rope.

6. Rigging and sheaves not operating

efciently.

TROUBLE PROBABLE CAUSE REMEDY

E

The hoist runs hot

Same as remedies for Trouble D1.

Thoroughly clean exterior and ush in-

terior.

Fill/drain to proper level.

Same as remedies for Trouble D2.

Engine low on horsepower or R.P.M.

Tune/adjust engine.

Check suction line for damage.

Pump worn. Replace pump.

Use correct hydraulic oil.

Disassemble hoist to inspect/ replace

worn parts.

1. Same as D1.

2. Be certain that the hydraulic system

temperature is not more than 180°F

(82°C). Excessive hydraulic oil temper-

atures may be caused by:

A. Plugged heat exchanger.

B. Too low or too high oil level in hy-

draulic reservoir.

C. Same as D2

D. Hydraulic pump not operating ef-

ciently.

E. Hydraulic oil is wrong viscosity for

operating conditions.

3. Excessively worn or damaged inter-

nal hoist parts.

14

G

The wire rope does not spool smoothly

on the drum.

Check mounting distance and eet

angle. Reposition hoist as required to

achieve ½ to 1½ degree eet angle.

Refer to “Hoist Installation”.

Consult wire rope manufacturer for

recommendation of wire rope that best

suits your application.

Replace wire rope and conduct opera-

tor/rigger training as required.

1. The hoist may be mounted too close

to the main sheave, causing the eet

angle to be more than 1½ degrees.

2. The hoist may not be mounted per-

pendicular to an imaginary line between

the center of the cable drum and the

rst sheave.

3. Could possibly be using the wrong

lay rope. There is a distinct advantage

in applying rope of the proper direction

of lay. When the load is slacked off,

the several wraps on the drum will stay

closer together and maintain an even

layer. If rope of improper lay is used,

the coils will spread apart each time the

load is removed. Then, when hoisting

is resumed, the rope has a tendency

to criss-cross and overlap on the drum.

The result is likely to be a attened and

crushed rope.

4. The hoist may have been overload-

ed, causing permanent set in the wire

rope.

F

Hoist “chatters” or surges while raising

rated load.

TROUBLE PROBABLE CAUSE REMEDY

Same as remedies for Trouble D2.

Same as remedies for Trouble D3

Same as remedies for Trouble E2.

Conduct operator training as required.

1. Same as D2.

2. Same as D3

3. Hydraulic oil ow to motor may be too

low.

4. Controls being operated too quickly.

15

DO NOT clean brake friction disks in solvent. Solvent may

cause damage to friction material which may result in brake

failure and loss of load control.

CAUTION

WARNING

! !

HOIST SERVICE

FOREWORD TO HOIST SERVICE

Before any part is removed from the hoist, all service instruc-

tions should be read and understood.

Work in a clean, dust free area as cleanliness is of utmost

importance when servicing hydraulic equipment.

Remove wire rope prior to removing hoist from crane.

Inspect all replacement parts, prior to installation, to detect

any damage which might have occurred in shipment.

Use only genuine BRADEN replacement parts for optimum

results. Never reuse expendable parts such as oil seals and

O-rings.

Inspect all machined surfaces for excessive wear or dam-

age…before reassembly operations are begun.

Lubricate all O-rings and oil seals with gear oil prior to instal-

lation.

Use a sealing compound on the outside surface of oil seals

and a light coat of thread sealing compound on pipe threads.

Avoid getting thread compound inside parts or passages

which conduct oil.

Thoroughly clean all parts in a good grade of non-ammable

safety solvent. Wear protective clothing as required.

Refer to exploded view drawing for item numbers used in

service procedures.

• Perform all applicable trouble shooting operations BE-

FORE disassembling hoist. To identify specic parts by part

number, refer to BG4 material list.

HOIST DISASSEMBLY

1. Disconnect all hoses and ttings from the motor.

2. Stand the hoist on the bearing support plate. Remove the

brake release tube assembly (42) between the brake valve

block and the brake cylinder end plate. Remove the cap-

screws (47) and lockwashers (48) which secure the motor

(49) to the motor adapter (38), and lift the motor out of the

motor adapter. Remove and discard the gasket installed on

the pilot of the motor.

3. Remove the brake coupling (29) and sun gear (41) from

the hoist.

4. Remove the four capscrews (5) and lockwashers (6) hold-

ing the tieplates (4) to the brake cylinder endplate. The drum

is supported on the endplate by a large bushing. Carefully

separate the endplate assembly from the drum. The end-

plate assembly includes the static brake cylinder. Remove

the brake cylinder endplate from the drum.

5. Remove the other four capscrews and lockwashers hold-

ing the tieplates to the bearing support endplate. Remove

the planet assembly from the drum and separate the drum

from the bearing support endplate.

16

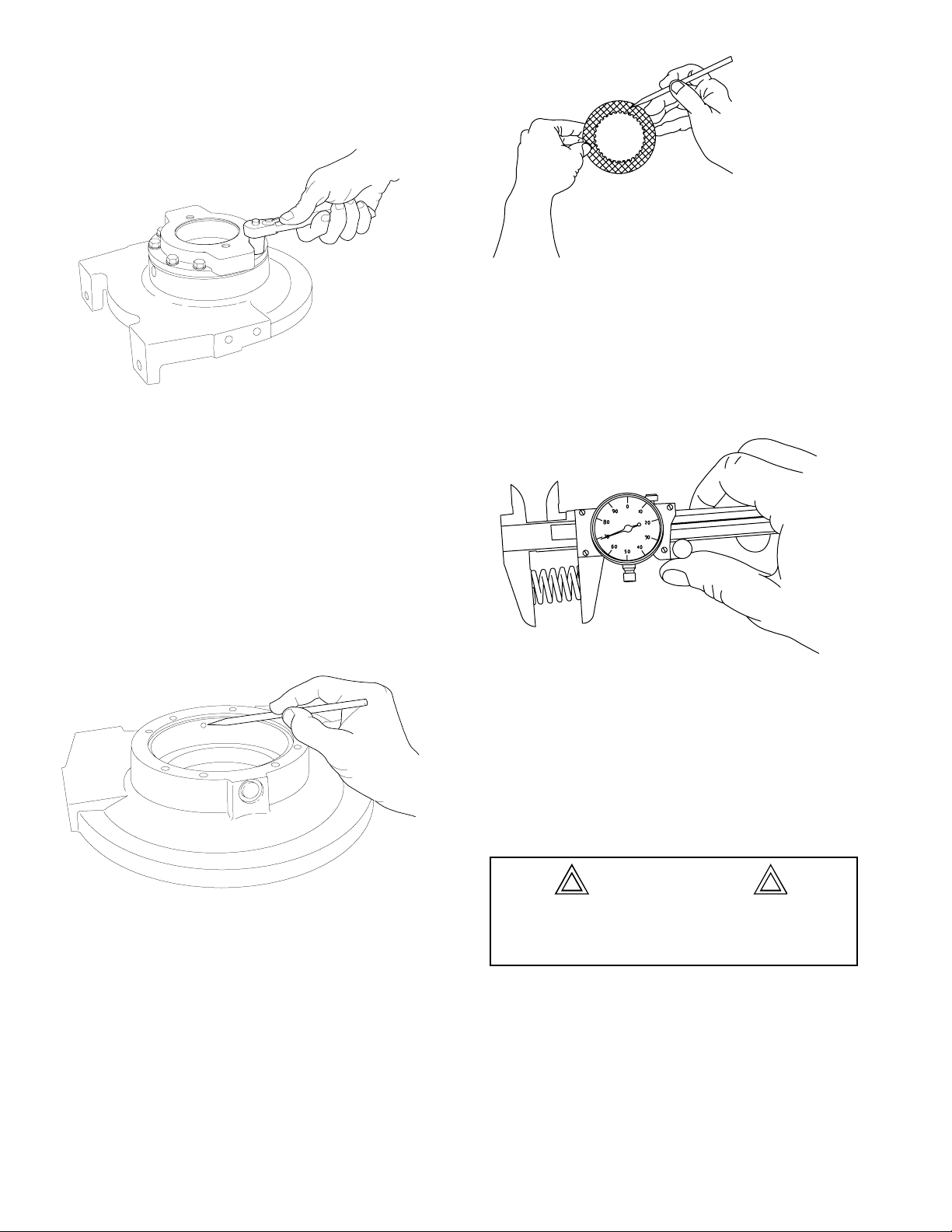

DRUM ASSEMBLY SERVICE

1. Remove the bearing and seal from each end of the drum.

Check the ring gear teeth (machined into the inside surface

of the drum) for nicks, spalling or excessive wear. Replace

the drum if wear is greater than 0.015 in. (0.4 mm) when

compared to unworn area of teeth.

2. Install new bearings in the drum if replacement is neces-

sary. Apply a non-hardening sealant on the outside diameter

of each new seal and press the seals into the drum, using a

at plate to avoid distortion.

PLANET CARRIER SERVICE

1. First drive the rollpins (17) into the center of the planet

shafts (14). Now you can remove the planet shaft (14), two

thrust races (16), planet gear (13) and roller bearing (15).

Repeat this procedure for the other two planet gears. Thor-

oughly clean all parts and inspect for damage and wear. The

bearing rollers should not exhibit any irregularities. If the

rollers show any sign of spalling, corrosion, discoloration,

material displacement or abnormal wear, the bearing should

be replaced.

Likewise, the cage should be inspected for unusual wear or

deformation, particularly the cage bars. If there is any dam-

age that will impair the cage’s ability to separate, retain and

guide the rollers properly, the bearing should be replaced.

The thrust washer contact areas should be free from any

surface irregularities that may cause abrasions or friction.

The gears and shafts should be inspected for abnormal wear

or pitting. Replace if necessary.

2. Insert a bearing into a planet gear and place a thrust race

on each side of the gear. Position this assembly in the plan-

et carrier and slide the planet gear shaft through the carrier.

Align the pin hole in the shaft with the hole in the carrier and

drive a NEW rollpin into place. ALWAYS USE NEW ROLL-

PINS. When properly positioned, the rollpin will be slightly

below the surface of the carrier.

3. With a center punch, stake the carrier next to the pin hole

as shown. This will distort the hole so the pin will not back

out when in service. Repeat these steps for each of the

three planet gears.

17

3. Place each friction disc on a at surface and check for

distortion with a straight edge. Friction material should ap-

pear even across entire surface with groove pattern visible.

Replace friction disc if splines are worn to a point, disc is dis-

torted, friction material is worn unevenly or groove pattern is

worn away. Place each steel disc on a at surface and check

for distortion with a straight edge. Check surface for signs

of material transfer or heat. Replace steel disc if splines are

worn to a point, disc is distorted or heat discolored.

4. Check free length of each brake spring. Minimum free

length is 15/16 inch (23.8 mm). Check springs for any signs

of cracking or failure. If a brake spring must be replaced for

any reason, then ALL brake springs must be replaced.

BRAKE CYLINDER ENDPLATE

SERVICE

DISASSEMBLY AND INSPECTION.

1. NOTE: The capscrews in the motor adapter should be

evenly removed in 1 or 2 turn increments since the motor

adapter is under spring tension. Remove the capscrews

(47) and lockwashers (48) holding the motor adapter (38)

to the endplate (2). Install 2 capscrews and a short piece of

chain or two 1/2-13 eyebolts into the motor mounting holes.

Using the chain as a handle, lift the motor adapter out of

the endplate. Remove and discard the O-ring (36) from the

motor adapter. Remove and discard the brake piston seal

(32). Remove brake plate spacers (33), steel discs (35),

friction discs (34), spring plate (31), springs (27) and spring

spacer (28).

2. Thoroughly clean and inspect all parts at this time. Check

brake piston sealing surfaces on motor adapter and brake

cylinder endplate. The sealing surfaces must be smooth.

Light scoring from contaminants in the gear oil may be

smoothed with an extra-ne abrasive cloth. Be sure the

brake release port in the endplate (shown above) is free of

contamination. Remove the vent plug (42) from the motor

adapter, clean in solvent and reinstall. DO NOT paint over

the vent or replace it with a solid plug.

Failure to replace brake springs as a set may result

in uneven brake application pressure and repeated

brake spring failure.

CAUTION

18

This manual suits for next models

1

Table of contents

Popular Chain Hoist manuals by other brands

CMCO

CMCO TIGRIP TAG Translated Operating Instructions

Columbus McKinnon

Columbus McKinnon CM LODESTAR A-H Operating, Maintenance & Parts Manual

little mule

little mule FEL Series Operating, Maintenance & Parts Manual

Paccar Winch

Paccar Winch Gearmatic GH30B Service and maintenance manual

Raider

Raider RD-EH01 user manual

SVERO

SVERO 20123A manual

RGC

RGC Classic Power Drive 250HG instructions

Tractel

Tractel supertirfor TU16A Operating and maintenance instruction

MW TOOLS

MW TOOLS SH125-R manual

Prolyte

Prolyte PRO LYFT AETOS PAE-250DC Series Operating and maintenance manual

Jet

Jet JWS Series Operating instructions and parts manual

Tractel

Tractel tralift 19709 Operation, maintenance and parts manual