3

Table of Contents

1Safety advice...............................................................................................................................................5

1.1 Regulations..................................................................................................................................................5

1.2 Proper use of electric chain hoists...............................................................................................................6

1.3 Application conditions..................................................................................................................................6

1.4 Prohibitions for use......................................................................................................................................7

1.5 Operating instructions..................................................................................................................................7

1.6Spare parts..................................................................................................................................................7

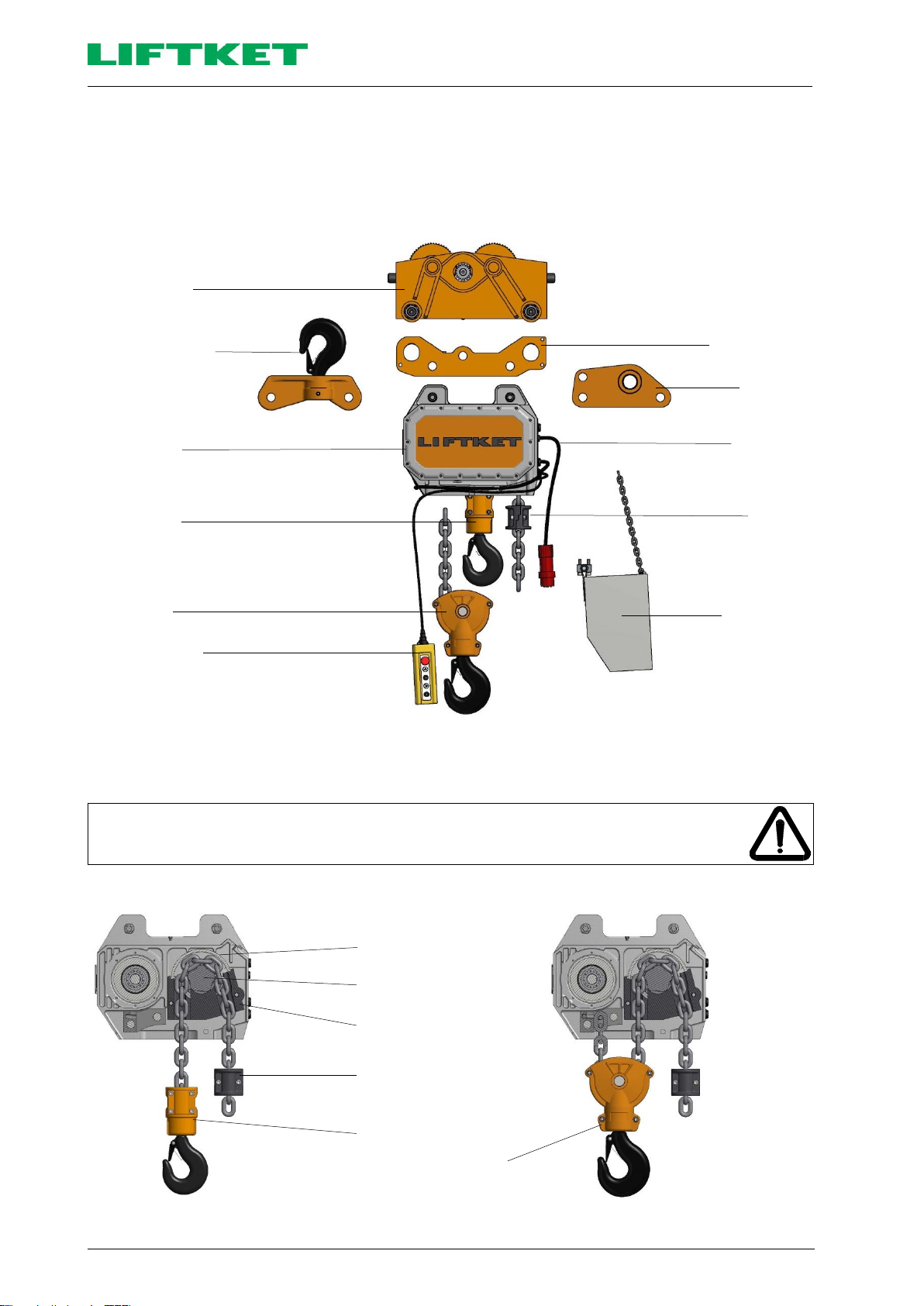

2Technical overview......................................................................................................................................8

2.1 Assembly possibilities..................................................................................................................................8

2.2 Fitting the load chain....................................................................................................................................8

2.3Sectional view..............................................................................................................................................9

2.4 Explanation of type designation...................................................................................................................9

3Transportation and storage........................................................................................................................10

3.1 Transportation ...........................................................................................................................................10

3.2 Storage......................................................................................................................................................10

4Assembly...................................................................................................................................................11

4.1 Mechanical assembly ................................................................................................................................11

4.1.1 Hook tackle................................................................................................................................................11

4.1.2 Hook block.................................................................................................................................................11

4.1.3 Stationary suspension ...............................................................................................................................12

4.1.3.1 Suspension with suspension eye...............................................................................................................12

4.1.3.2 Suspension with single hole suspension eye.............................................................................................13

4.1.3.3 Suspension with suspension hook.............................................................................................................15

4.1.4 Hoisting gear with electric trolley ...............................................................................................................17

4.1.4.1 Mechanical assembly ................................................................................................................................17

4.1.4.2 Electric connection of trolleys ....................................................................................................................18

4.1.4.3 Electric control of the brake.......................................................................................................................18

4.1.5 Chain box ..................................................................................................................................................19

4.1.5.1 Mounting the chain box..............................................................................................................................19

4.1.5.2 Oversize chain box....................................................................................................................................20

4.1.6 Lift limiter...................................................................................................................................................21

4.1.7 Gear ventilation..........................................................................................................................................21

4.1.8 Schematic sketch of the load chain configuration - single fall version .......................................................22

4.1.9 Schematic sketch of the load chain configuration - double fall version......................................................23

4.1.10 Replacing the load chain, the chain guide and the chain hold-down.........................................................24

4.1.10.1 Single fall operation...................................................................................................................................24

4.1.10.2 Double fall operation..................................................................................................................................25

4.2 Electric connections...................................................................................................................................26

4.2.1 Mains connection.......................................................................................................................................26

4.2.2 Low voltage control....................................................................................................................................27

4.2.3 Electric control of the hoist brake...............................................................................................................27

4.2.4 Electric limit switch.....................................................................................................................................27

4.2.4.1 Location of electric limit switches...............................................................................................................27

4.2.4.2 Disassembling and assembling the limit switch shaft ................................................................................28

5Operation...................................................................................................................................................29

5.1 Control pendant.........................................................................................................................................29

5.2 Radio remote control .................................................................................................................................30

5.3 Load slinging .............................................................................................................................................30

6First use.....................................................................................................................................................31

6.1 General conditions and prerequisites ........................................................................................................31

6.2 Inspection before first use..........................................................................................................................31

6.3 Inspection at first use.................................................................................................................................31

6.3.1 Inspection contents....................................................................................................................................31

6.3.2 Conducting the investigation......................................................................................................................32