1. GENERAL INFORMATION

Attention: All users must read these operating

instructions carefully prior to the initial operation. These

instructions are intended to acquaint the user with the

hoist controller and enable him/her to use it to the full

extent of its intended capabilities.

The operating instructions contain important information

on how to handle the hoist controller in a safe, correct and

economic way. Acting in accordance with these

instructions helps to avoid dangers, reduce repair costs

and downtime and to increase the reliability and lifetime of

the hoist controller.

Anyone involved in doing any of the following work with

the hoist controller must read the operating instructions

and act accordingly:

•Operation, including preparation, trouble shooting and

cleaning

•Maintenance, inspection, repair

•Transport

Apart from the operating instructions and the accident

prevention act valid for the respective country and area

where the hoist controller is used, also the commonly

accepted regulations for safe and professional work must

be adhered to.

The user is responsible for the proper and professional

instruction of the operating personnel.

Suitable for entertainment use

The PROLYFT AETOS hoist controllers are specially

designed for use in the Entertainment industry. They must

only control electric chain hoists that are suitable for use

in the Entertainment industry.

Combining the hoist controller with different type of

electric chain hoists might lead to unwanted, unexpected

or dangerous situations.

The PROLYFT AETOS hoist controllers are not designed

to control hoists suspending or lifting loads above people.

Read the manual of the electric chain hoists before

starting to operate them with the hoist controller.

Regulations

The accident prevention act and/or safety regulations of

the respective country for using manual and electric chain

hoists must be strictly adhered:

•Europe:

•Machine Directive 2006/42/EG

•Safety of Machinery NEN 12100:2010

•Germany: BGV D6, BGV D8

Additional regulations are in effect for lifting or suspending

loads over people.

Germany: SQ P2

The Netherlands: NPR8020-10

United Kingdom: BS7950-1

Maintenance/Repair

In order to ensure correct operation, not only the

operating instructions, but also the conditions for

inspection and maintenance must be complied with. If

defects are found or abnormal noise is to be heard stop

using the hoist controller immediately.

Attention: Before starting to work on electrical

components the power-supply is to be cut off.

2. INCORRECT OPERATION

•Do not exceed the rated power capacity per controlled

channel.

•Do not lift stuck or jammed loads.

•Do not shortly and frequently actuate the up/down

switch.

•Do not control hoists if the movement of the load is not

visible from the operating position.

•Do not control hoists if you are skilled for lifting loads

•Do not use cables with damaged strain reliefs and/or

isolation.

•Do not use any input- or output cables that are not

suitable for the supplied voltage and / or current.

•Do not use the Thuja data connection (link in, link out)

with other network devices unless these devices are

specified to be suitable for use in the Thuja data

network.

•Do not connect the controller to a mains connection that

is not properly fused.

•Do not use the controller without proper grounding.

•Do not connect more then one hoist on a single

channel.

3. ELECTRIC CONNECTIONS

All electric connections must be used with respect for the

specified voltages and maximum power consumption.

Power input:

The power input connector is a 5pin CEEform connector

suitable for 3 phase 32Amp / 400Volt. 3 Phases, neutral

and ground.

Depending on the type of controller it can be plugged in to

either a 3 phase 400V or a 3 phase 230V mains

connections.

Make sure the mains connection is fused at maximum

32Amps per phase. It is advised to use circuit breakers

with a C or D characteristic.

Make sure the mains connection is properly grounded.

Improper grousing might lead to dangerous with the risk

of electric shock.

Maximum power consumption per hoist.

Each hoist channel is capable of switching an electric

chain hoist with maximum power consumption of 1,5kW.

Power output to the hoists

For each 4 hoist channels there is a Harting 16 output

connector.

Make sure the cables (and each individual wire of the

cable) connected to the output connector are suitable for

minimum 10Amps at 400V per wire.

To avoid voltage drops longer cables should have bigger

wire diameters.

AETOS Range

11

Inspection of chain end stop

The chain end stop must be connected to the dead (idle) end of the chain

strand.

Inspection of chain reeving

All units with two or more chain strands should be inspected prior to initial

operation for twisted or kinked chains. The chains of 2-strand hoists may be

twisted if the hook block was rolled over (Fig. 13).

The load chain has to be installed according to illustration (Fig. 15). Hereby the

welds on the standing links must face away from the load sheave.

Inspecting the hooks

Check the load hook and the suspension hook for deformations, cracks,

damages, abrasion and signs of corrosion.

Attaching the load

Attach the load to the hoist using only approved and certified slings or lashing

devices. Never use the load chain as sling chain. The load must always be

seated in the saddle of the hook (Fig. 14). Never attach the load to the tip of

the hook. Two parts of a bridles of slings or steels must not exceed an angle of

45 degrees. Use a shackle to attach the bridle. Do not remove the safety latch

from the load hook. Always check the attachment of the load after the load has

“landed”.

Lifting/lowering the load

• Never lift a load without direct visual contact with the load.

• The load is lifted by depressing the UP-button, it is lowered by

depressing the DOWN-button.

• For hoists with two speeds: The first stage of button depression

activates the slow speed, further depression activates the faster speed. In

order to raise the load, always use the lowest available lifting speed. The

chain must be loaded at this speed and should not lie slack on the floor.

The slow speed should only be used for short distances.

• The chain end stop may not be used as operational limit switch.

• Always follow the instructions in the manual of the operating/control

device.

Emergency stop

All movement can be immediately halted by depressing the red, mushroom

shaped button on the pendant control.

Attention: Operating the red emergency button does NOT ALWAYS

automatically disconnect the mains supply to the hoist. To release the

emergency stop, rotate the button in a clockwise direction.

End limit switch

This hoist is provided with an end limit switch for the lowest and highest hook

position as standard. This limit switch is a safety device and may not be used

as operational limiting device.

7.OPERATION / USE

Operator skills

Operators delegated to install, service or independently operate the hoist must

have had suitable training and be competent.

Operators are to be specifically nominated by the company and must be

familiar with all relevant safety regulations of the country of use.

Visual inspection before starting work

Before starting work inspect the hoist, chains and all load bearing components

every time for visual defects. Furthermore test the brake and make sure that

the load and hoist are correctly attached by carrying out a short work cycle of

lifting and lowering. Selection and calculation of the proper suspension point

and beam construction are the responsibility of the operating company.

Inspection of load chain

Inspect the chain for sufficient lubrication and visually check for external

defects, deformations, superficial cracks, wear or signs of corrosion.

5. FUNCTIONAL CHECK BEFORE EVERY INSTALL

Prior to initial operation of the hoist lubricate the load

chain when it is not under load (see chapter 8.6).

Before the hoist is put into regular service, the following

additional inspections must be made:

• Are all screwed connections on the hoist tight and are

all locking devices in place and secure?

• Is the chain drive correctly reeved?

• Is the chain bag bracket fitted correctly. It should be able

to swivel?

• The chain end stop must be correctly fitted to the loose

end of the load chain.

• The dead-end of the chain must be correctly fitted to the

dead-end of chain connection on the chain bag bracket.

• Has the chain bag the right capacity?

• Is the chain bag fitted correctly to the chain bag bracket

• All units equipped with two or more chain strands

should be inspected before initial operation for twisted

or kinked chains. The chains of 2-strand/double reeved

hoists may e.g. be twisted if the hook block is rolled

over.

• Check the function of the limit switches by running the

buffers of the chain end stop resp. hook block against

the limit switch under neath the housing. The lifting

resp. lowering operation must be stopped immediately.

• Check the brake function when lifting and lowering.

6. COMMISSIONING

Inspection before each initial operation

Each hoist must be inspected prior to EACH initial

operation by a competent person and any failures be

removed. The inspection is visual and functional. These

inspections have to assure that the hoist is safe and has

not been damaged by incorrect transport or storage.

Inspections should be made by suitably trained

personnel. Inspections are instigated by the user or

operating company.

**In the Entertainment industry hoists are often moved

from one position or venue , transported and installed at

another position or venue. After every “re-installation of a

hoist it MUST be inspected as with an initial installation as

described above. Inspections are always instigated by

the user or operating company.

Inspection by an expert

If the hoist is used with an unguided load with a capacity

of at least 1000 kg, or when multiple hoists are lifting a single

object the lifting installation has to be inspected and

approved by an expert before initial operation. This

inspection has to be registered in the inspection

logbook. The inspection by the expert has to be

instigated by the operating company.

7. OPERATION / USE

Operator skills

Operators delegated to install, service or independently

operate the hoist must have had suitable training and be

competent.

Operators are to be specifically nominated by the

company and must be familiar with all relevant safety

regulations of the country of use.

Visual inspection before starting work

Before starting work inspect the hoist, chains and all load

bearing components every time for visual defects.

Furthermore test the brake and make sure that the load

and hoist are correctly attached by carrying out a short

work cycle of lifting and lowering. Selection and

calculation of the proper suspension point and beam

construction are the responsibility of the operating

company.

Inspection of load chain

Inspect the chain for sufficient lubrication and visually

check for external defects, deformations, superficial

cracks, wear or signs of corrosion.

Inspection of chain end stop

The chain end stop must be connected to the dead

(idle) end of the chain strand.

Inspection of chain reeving

All units with two or more chain strands should be

inspected prior to initial operation for twisted or kinked

chains. The chains of 2-strand hoists may be twisted if the

hook block was rolled over (Fig. 13).

The load chain has to be installed according to

illustration (Fig. 15). Hereby the welds on the standing

links must face away from the load sheave.

Inspecting the hooks

Check the load hook and the suspension hook for

deformations, cracks, damages, abrasion and signs of

corrosion.

Attaching the load

Attach the load to the hoist using only approved and

certified slings or lashing devices. Never use the load

chain as sling chain. The load must always be seated in

the saddle of the hook (Fig 14). Never attach the load to

the tip of the hook. Two parts of a bridles of slings or

steels must not exceed an angle of 45 degrees. Use a

shackle to attach the bridle. Do not remove the safety

latch from the load hook. Always check the attachment of

the load after the load has “landed”.

WWW.PROLYTE.COM

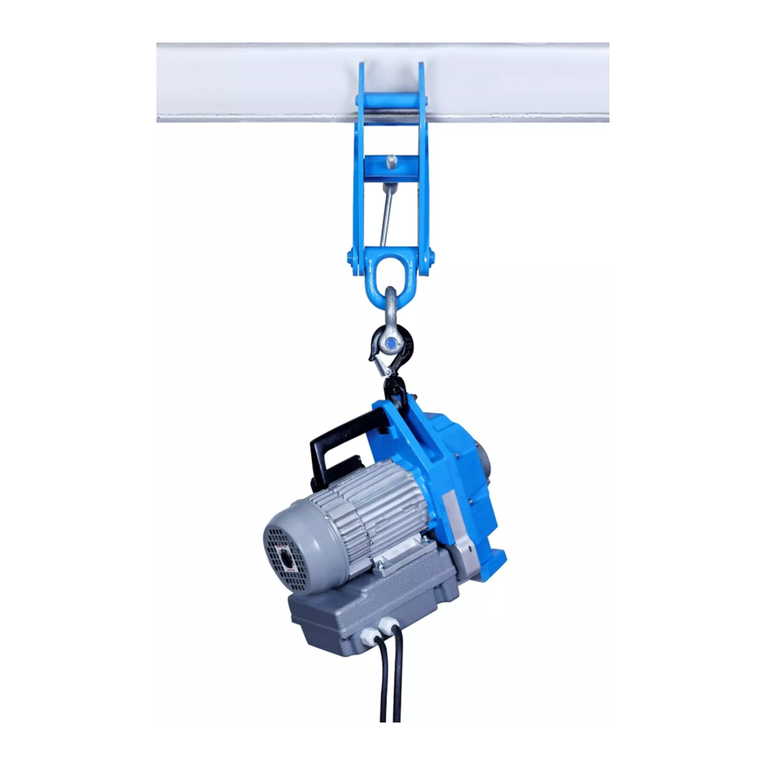

INTRODUCING THE PROLYFT AETOS RANGE

When Simplicity in Motion is the ultimate goal, there’s always a next level to

meet. ProLyft invites you to take that level further with a product range that is fit

to meet the future

Get Ready for the Next Level

ProLyft AETOS is the brand new ProLyft hoist range. The AETOS range is fully

equipped to meet future demands in lifting equipment and offers clever features

and carefully engineered product attributes. The AETOS range comprises of a

standard 500kg and 1000kg hoist and will be expanded in the near future.

The Unique ProLyft Program

ProLyft sustains a unique service programme on its complete hoist range,

developed to offer maximum service and support for all hoist owners.

This program encompasses:

• Installed network of trained and certified Service Points

• Lifetime warranty

• Individual identification - easy web-enabled track and trace functions

• ProLyft Service database – automatic reminders for re-certification

• Test certificates worldwide available for owners of every hoist

Standard Features of the AETOS Range:

• Available in a 500kg and a 1000kg hoist body

• Fixed speed of 4m/min

• Red CEE form plug 16Amp 4pin and cable with strain relief

for power connection

• Yellow CEE form plug 16Amp 4pin and cable with strain relief

for low voltage control (optional)

• Equipped with limit switches on all hoists

• End limit switches are activated by chain stop for 100% repeatable accuracy

and easy of use

• External limit switches can be used for hoists used above a grid or false ceiling

• Multiple voltage motor

• Chain bags for 30mtr up to 80mtr available

• 5-pocket load wheel

• Zinc-plated load chain

• 100% sealed aluminium transmission house without oil plugs

• Standard swivel hook on hoist body and hoist chain

• IP 55 protection

Easily Adaptable:

• Covers 180 degree rotatable for motor-up use

• Easy mounting of optional second brake

• Brake shaft and electronics prepared for second brake

• Output shaft prepared for rotary limit switch or encoder connection

• All hoists can be double reeved

• Swivelling chain bag bracket for motor-down and motor-up use

• Multiple voltage motor

AETOS Range

Lifting/lowering the load

• Never lift a load without direct visual contact with the

load.

• The load is lifted by depressing the UP-button, it is

lowered by depressing the DOWN-button.

• For hoists with two speeds: The first stage of button

depression activates the slow speed, further

depression activates the faster speed. In order to raise

the load, always use the lowest available lifting speed.

The chain must be loaded at this speed and may not

lie slack on the floor. The slow speed may only be used

for short distances.

• The chain end stop may not be used as operational

limit switch.

•Always follow the instructions in the manual of the operating

/control device.

Emergency stop

All movement can be immediately halted by depressing

the red, mush room shaped button on the pendant

control.

Attention: Operating the red emergency button does

NOT ALWAYS automatically disconnect the mains supply

to the hoist. To release the emergency stop, rotate the

button in a clockwise direction.

End limit switch

This hoist is provided with an end limit switch for the

lowest and highest hook position as standard. This limit

switch is a safety device and may not be used as

operational limiting device.

8. SERVICE

8.1. GENERAL

• Service and inspections may only be carried out by a

competent person.

• The inspection must determine that all safety devices

are present and fully operational and covers the

condition of the hoist, lifting gear, accessories and

supporting constructions.

• The service intervals and inspections noted are for

normal working conditions. Adverse working conditions,

e.g. heat, high humidity, or chemical environments, and

regular transportation can dictate shorter periods.

• The PROLYFT chainhoist AETOS series conform to

FEM group 1Am in accordance with FEM 9.511. This

results in a theoretical service lifetime of 800 operating

hours under full load.

• This is equivalent to minimum 10 years under normal

operating conditions. After this period the hoist requires

a general overhaul. Further information is contained in

BGV D6 resp. FEM 9.755.

• Attention: Maintenance work requires subsequent

function testing with nominal load.

8.2. PROLYFT SERVICE PROGRAM / LIFETIME

WARRANTY

Initial Certificate

• All PROLYFT hoist are provided with a test certificate,

describing the hoist and showing the results of the load

test. The graph of the load test shows a minimum lifting

capacity of 125% of the nominal load.

• All PROLYFT hoist are equipped with a RFID tag with a

unique number. The number of the tag refers to the

record of the hoist and the result of the load test in the

PROLYFT ServiceBase.

Registration

• After purchasing the hoist go to the website

“service.prolyft.com” to register your hoist.

• After registering your hoist you will have access to all

recorded information, certificates, history and load tests

connected to your hoist.

• By registering your hoist you get access to the Lifetime

Warranty program.

Yearly inspection and re-certification

• Every owner of registered hoists will receive an

automatic reminder for the yearly inspection and re-

certification of the hoist.

• The yearly inspection and re-certification can be done at

any PROLYFT Service Point as you can find on the back

of this manual or on the website “service.prolyft.com”

• The yearly inspection and re-certification of the hoist

guarantees a full visual check of the hoist and the chain,

a brake test, and a load test.

• After passing the inspection a new certificate proving the

quality of the hoist, including a graph of the load test will

be handed over.

• A yearly certified hoist will keep Lifetime Warranty

8.3. DAILY CHECKS

• Visually check the pendant control switch and cable for

damage.

• Function test of brake.

• Function test of end limit switch.

• Function test of lifting / lowering.

WWW.PROLYTE.COM

INTRODUCING THE PROLYFT AETOS RANGE

When Simplicity in Motion is the ultimate goal, there’s always a next level to

meet. ProLyft invites you to take that level further with a product range that is fit

to meet the future

Get Ready for the Next Level

ProLyft AETOS is the brand new ProLyft hoist range. The AETOS range is fully

equipped to meet future demands in lifting equipment and offers clever features

and carefully engineered product attributes. The AETOS range comprises of a

standard 500kg and 1000kg hoist and will be expanded in the near future.

The Unique ProLyft Program

ProLyft sustains a unique service programme on its complete hoist range,

developed to offer maximum service and support for all hoist owners.

This program encompasses:

• Installed network of trained and certified Service Points

• Lifetime warranty

• Individual identification - easy web-enabled track and trace functions

• ProLyft Service database – automatic reminders for re-certification

• Test certificates worldwide available for owners of every hoist

Standard Features of the AETOS Range:

• Available in a 500kg and a 1000kg hoist body

• Fixed speed of 4m/min

• Red CEE form plug 16Amp 4pin and cable with strain relief

for power connection

• Yellow CEE form plug 16Amp 4pin and cable with strain relief

for low voltage control (optional)

• Equipped with limit switches on all hoists

• End limit switches are activated by chain stop for 100% repeatable accuracy

and easy of use

• External limit switches can be used for hoists used above a grid or false ceiling

• Multiple voltage motor

• Chain bags for 30mtr up to 80mtr available

• 5-pocket load wheel

• Zinc-plated load chain

• 100% sealed aluminium transmission house without oil plugs

• Standard swivel hook on hoist body and hoist chain

• IP 55 protection

Easily Adaptable:

• Covers 180 degree rotatable for motor-up use

• Easy mounting of optional second brake

• Brake shaft and electronics prepared for second brake

• Output shaft prepared for rotary limit switch or encoder connection

• All hoists can be double reeved

• Swivelling chain bag bracket for motor-down and motor-up use

• Multiple voltage motor

AETOS Range

1

1

2

2

3

3

4

4

5

5

6

6

A A

B B

C C

D D

Fixing screws

Chain anchor

Anchor bolt

Fig. 15

5. FUNCTIONAL CHECK BEFORE EVERY INSTALL

Prior to initial operation of the hoist lubricate the load

chain when it is not under load (see chapter 8.6).

Before the hoist is put into regular service, the following

additional inspections must be made:

• Are all screwed connections on the hoist tight and are

all locking devices in place and secure?

• Is the chain drive correctly reeved?

• Is the chain bag bracket fitted correctly. It should be able

to swivel?

• The chain end stop must be correctly fitted to the loose

end of the load chain.

• The dead-end of the chain must be correctly fitted to the

dead-end of chain connection on the chain bag bracket.

• Has the chain bag the right capacity?

• Is the chain bag fitted correctly to the chain bag bracket

• All units equipped with two or more chain strands

should be inspected before initial operation for twisted

or kinked chains. The chains of 2-strand/double reeved

hoists may e.g. be twisted if the hook block is rolled

over.

• Check the function of the limit switches by running the

buffers of the chain end stop resp. hook block against

the limit switch under neath the housing. The lifting

resp. lowering operation must be stopped immediately.

• Check the brake function when lifting and lowering.

6. COMMISSIONING

Inspection before each initial operation

Each hoist must be inspected prior to EACH initial

operation by a competent person and any failures be

removed. The inspection is visual and functional. These

inspections have to assure that the hoist is safe and has

not been damaged by incorrect transport or storage.

Inspections should be made by suitably trained

personnel. Inspections are instigated by the user or

operating company.

**In the Entertainment industry hoists are often moved

from one position or venue , transported and installed at

another position or venue. After every “re-installation of a

hoist it MUST be inspected as with an initial installation as

described above. Inspections are always instigated by

the user or operating company.

Inspection by an expert

If the hoist is used with an unguided load with a capacity

of at least 1000 kg, or when multiple hoists are lifting a single

object the lifting installation has to be inspected and

approved by an expert before initial operation. This

inspection has to be registered in the inspection

logbook. The inspection by the expert has to be

instigated by the operating company.

7. OPERATION / USE

Operator skills

Operators delegated to install, service or independently

operate the hoist must have had suitable training and be

competent.

Operators are to be specifically nominated by the

company and must be familiar with all relevant safety

regulations of the country of use.

Visual inspection before starting work

Before starting work inspect the hoist, chains and all load

bearing components every time for visual defects.

Furthermore test the brake and make sure that the load

and hoist are correctly attached by carrying out a short

work cycle of lifting and lowering. Selection and

calculation of the proper suspension point and beam

construction are the responsibility of the operating

company.

Inspection of load chain

Inspect the chain for sufficient lubrication and visually

check for external defects, deformations, superficial

cracks, wear or signs of corrosion.

Inspection of chain end stop

The chain end stop must be connected to the dead

(idle) end of the chain strand.

Inspection of chain reeving

All units with two or more chain strands should be

inspected prior to initial operation for twisted or kinked

chains. The chains of 2-strand hoists may be twisted if the

hook block was rolled over (Fig. 13).

The load chain has to be installed according to

illustration (Fig. 15). Hereby the welds on the standing

links must face away from the load sheave.

Inspecting the hooks

Check the load hook and the suspension hook for

deformations, cracks, damages, abrasion and signs of

corrosion.

Attaching the load

Attach the load to the hoist using only approved and

certified slings or lashing devices. Never use the load

chain as sling chain. The load must always be seated in

the saddle of the hook (Fig 14). Never attach the load to

the tip of the hook. Two parts of a bridles of slings or

steels must not exceed an angle of 45 degrees. Use a

shackle to attach the bridle. Do not remove the safety

latch from the load hook. Always check the attachment of

the load after the load has “landed”.

WWW.PROLYTE.COM

INTRODUCING THE PROLYFT AETOS RANGE

When Simplicity in Motion is the ultimate goal, there’s always a next level to

meet. ProLyft invites you to take that level further with a product range that is fit

to meet the future

Get Ready for the Next Level

ProLyft AETOS is the brand new ProLyft hoist range. The AETOS range is fully

equipped to meet future demands in lifting equipment and offers clever features

and carefully engineered product attributes. The AETOS range comprises of a

standard 500kg and 1000kg hoist and will be expanded in the near future.

The Unique ProLyft Program

ProLyft sustains a unique service programme on its complete hoist range,

developed to offer maximum service and support for all hoist owners.

This program encompasses:

• Installed network of trained and certified Service Points

• Lifetime warranty

• Individual identification - easy web-enabled track and trace functions

• ProLyft Service database – automatic reminders for re-certification

• Test certificates worldwide available for owners of every hoist

Standard Features of the AETOS Range:

• Available in a 500kg and a 1000kg hoist body

• Fixed speed of 4m/min

• Red CEE form plug 16Amp 4pin and cable with strain relief

for power connection

• Yellow CEE form plug 16Amp 4pin and cable with strain relief

for low voltage control (optional)

• Equipped with limit switches on all hoists

• End limit switches are activated by chain stop for 100% repeatable accuracy

and easy of use

• External limit switches can be used for hoists used above a grid or false ceiling

• Multiple voltage motor

• Chain bags for 30mtr up to 80mtr available

• 5-pocket load wheel

• Zinc-plated load chain

• 100% sealed aluminium transmission house without oil plugs

• Standard swivel hook on hoist body and hoist chain

• IP 55 protection

Easily Adaptable:

• Covers 180 degree rotatable for motor-up use

• Easy mounting of optional second brake

• Brake shaft and electronics prepared for second brake

• Output shaft prepared for rotary limit switch or encoder connection

• All hoists can be double reeved

• Swivelling chain bag bracket for motor-down and motor-up use

• Multiple voltage motor

AETOS Range

Fig. 14

Fig. 15

Fig. 13