WARNING:

USING DEFECTIVE WIRE ROPE CAN CAUSE EQUIPMENT DAMAGE, SERIOUS

PERSONAL INJURY, OR DEATH.

5.)Alwaysusesafetyfootwear,safetyglasses,and

6.)Wearheavyleathergloveswhenhandlingwire

4.)AllpersonnelshallbeprotectedbyOSHA

compliantfallprotectionwhereapplicable.

headprotectiondevices.

ofmovingparts.

hoistisbeingoperated.Keepallbodypartsclear

preventunathorizeduse.Neverassumeyouwill

findthehoistinthesameconditioninwhichyou

20.)Donotattempttomakeadjustmentswhilethe

21.)Atendofoperation,thehoistshouldbesecuredto

leftit.

22.)Donotweldorotherwisemodifythehoist.Such

23.)Onlytrainedpersonnelareauthorizedtomake

alterationsmayweakenthestructuralintegrityof

repairs.

thehoist.

62156789901

Donotclimbthetrack;usealadder.

hasstoppedcompletely.

16.)Keepoutfromunderaraisedload.Neverhoist

19.)Nopersonshallbeallowedtorideonthehoist.

17.)Neverstandin-linewiththeraisingorloweringof

theplatformateitherthetoporthebottomofthe

18.)Donotremovematerialfromtheplatformuntilit

10.)Donotoperatehoistwhenundertheinfluenceof

11.)Donotoperatehoistifbrakeropeiswet.

13.)NeverexceedtheRatedLoadCapacityof200lbs.

forPL-250hoist,or400poundsforthePL-400

14.)Iftheengineormotorfailsduringoperation,

releasecontrolleverstopreventloadfromfalling.

15.)Controlloadatalltimes.Avoidsuddenstops

hoist.TheRatedLoadCapacityisthemaximum

loadthatmusteverbeappliedtothehoist.

7.)Hoistingareaistobekeptclearofunathorized

personnelatalltimes.Placebarricadesorsecure

theareainsuchmannerthatiftherewerean

8.)Hoistingareaistobeclearofpowerlines.Consult

PowerCompanybeforeyouworknearpower

equipmentfailure,nopersonnelwouldbeinjured.

9.)FollowthePre-HoistingChecklistbeforeoperating.

overanopendoorway.

hoisttrack.

drugs,alcohol,ormedication.

12.)Secureloadbeforelifting.

andshockloads.

lines.

rope.

individualresponsibilities,personalprotective

PL-250/400HOISTSAFETYRULES:

operatingthishoist.Atrainedpersonisonewho

1.)Operatorsmustbethoroughlytrainedbefore

hasreadandthoroughlyunderstandsthe

instructionmanualandrelatedequipment

manualsand,throughtrainingandexperience,

hasshownknowledgeregardingsafeoperating

2.)Priortosettingupthehoisttheremustbeaplanof

actionoutliningtheworktobeaccomplished,

3.)Agoodlineofcommunicationmustbemaintained

betweenthehoistoperatorandroofcrew.

equipment,andmethodofcommunication.

procedures.

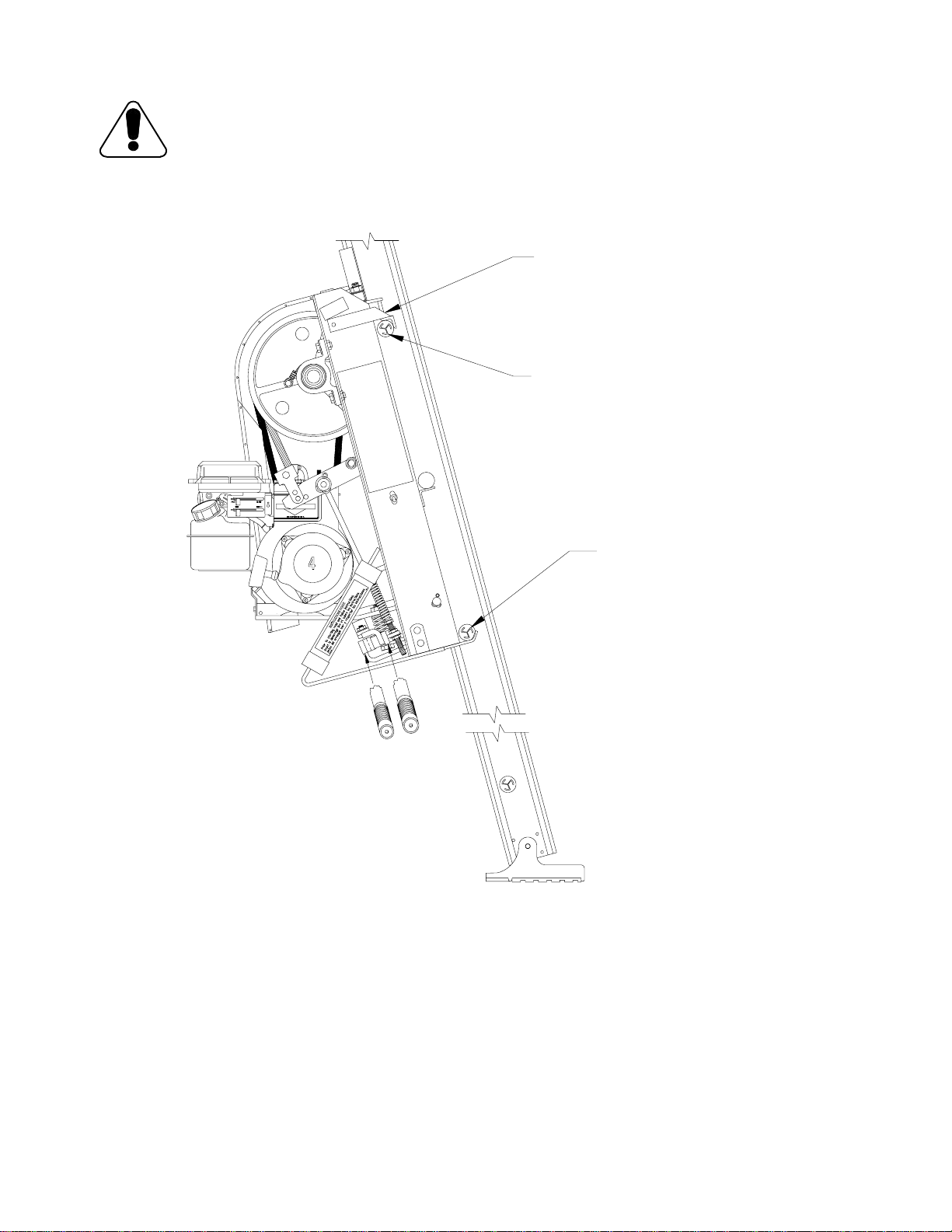

3RD CROSSTIE

CROSS TIE CLAMP

5TH CROSSTIE

Figure 3-1.

Classic Power Drive 250HG Installation on Pro track

5