– 10 –

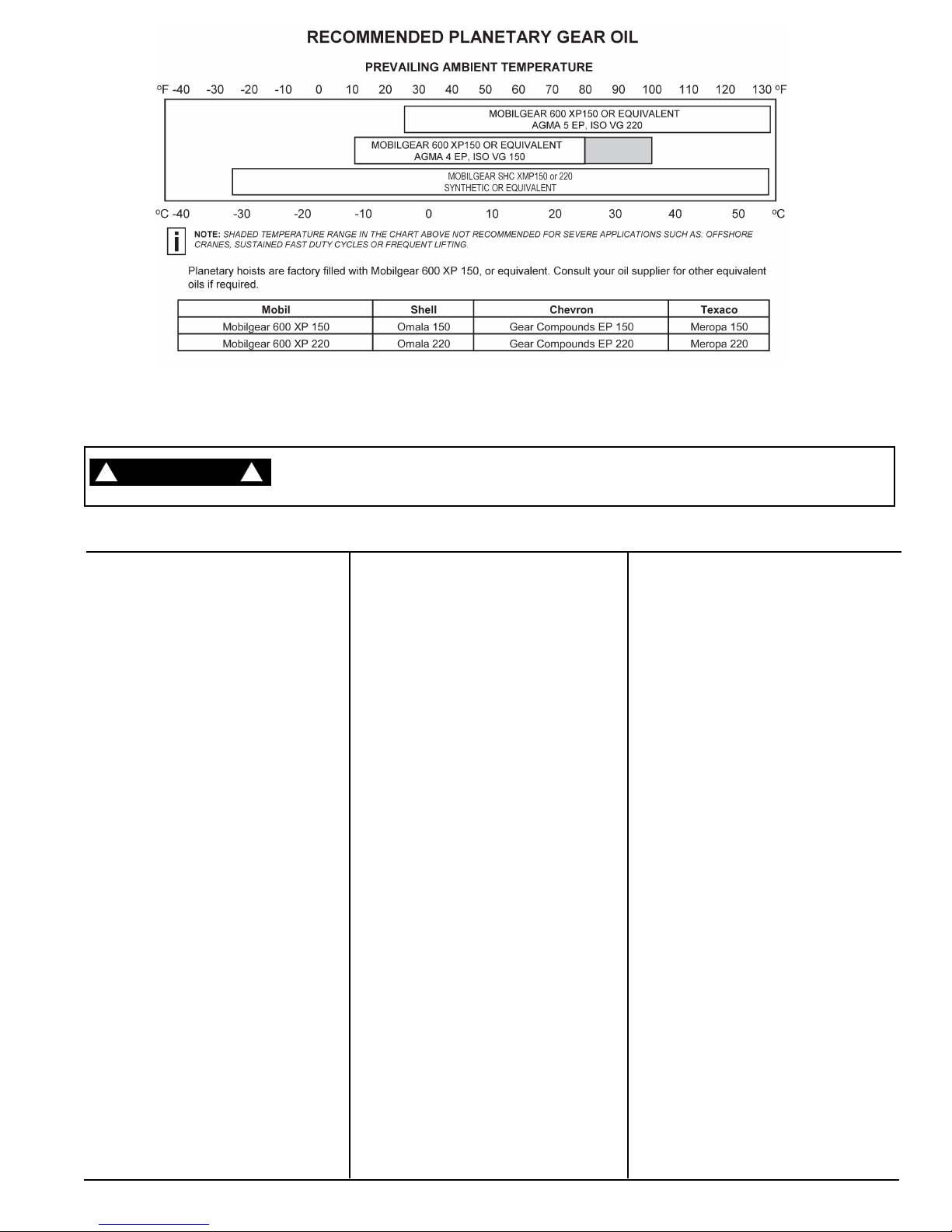

clutch operation. Our tests indicate that

excessively heavy or thick gear oil may contribute

to intermittent brake clutch slippage. Make certain

that the gear oil viscosity used in your winch is

correct for your prevailing ambient temperature.

Failure to use the proper type and viscosity of

planetary gear oil may contribute to brake clutch

slippage which could result in property damage,

severe personal injury or death. Refer to

“Recommended Planetary Gear Oil” for additional

information.

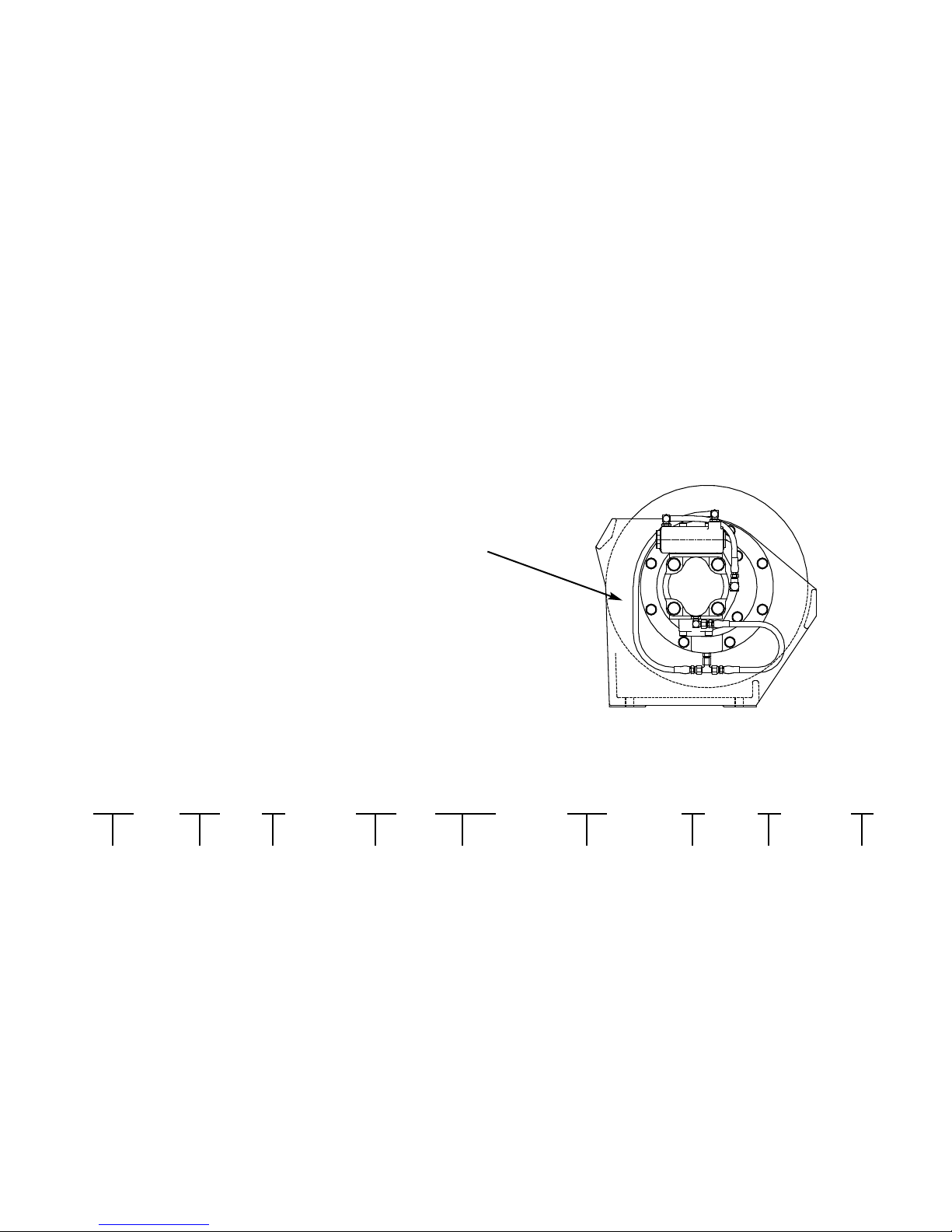

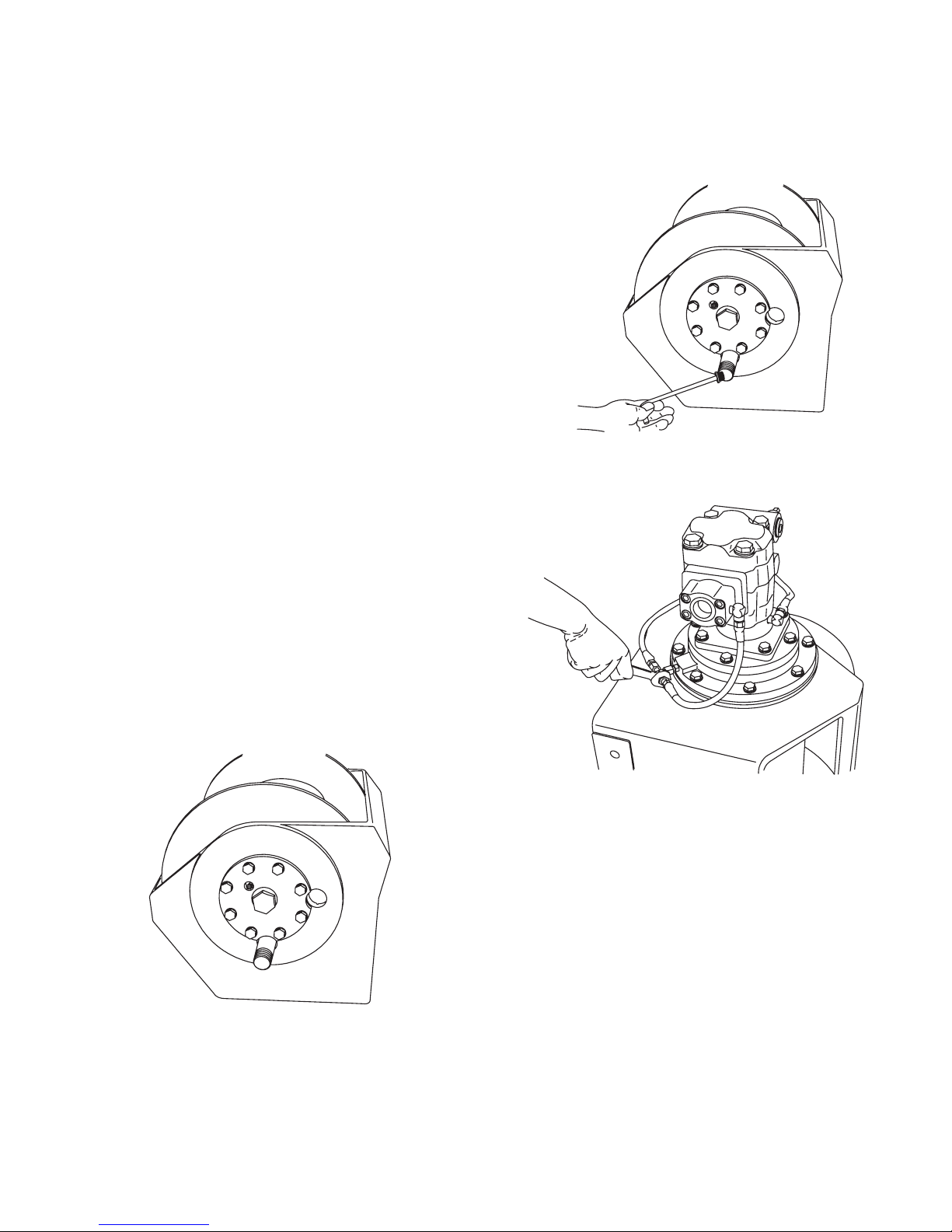

3. Vent Plug

The vent plug is located in the drum support as

shown. It is very important to keep this vent clean

and unobstructed. Whenever gear oil is changed,

remove vent plug, clean in solvent and reinstall.

Do not paint over the vent or replace with a solid

plug.

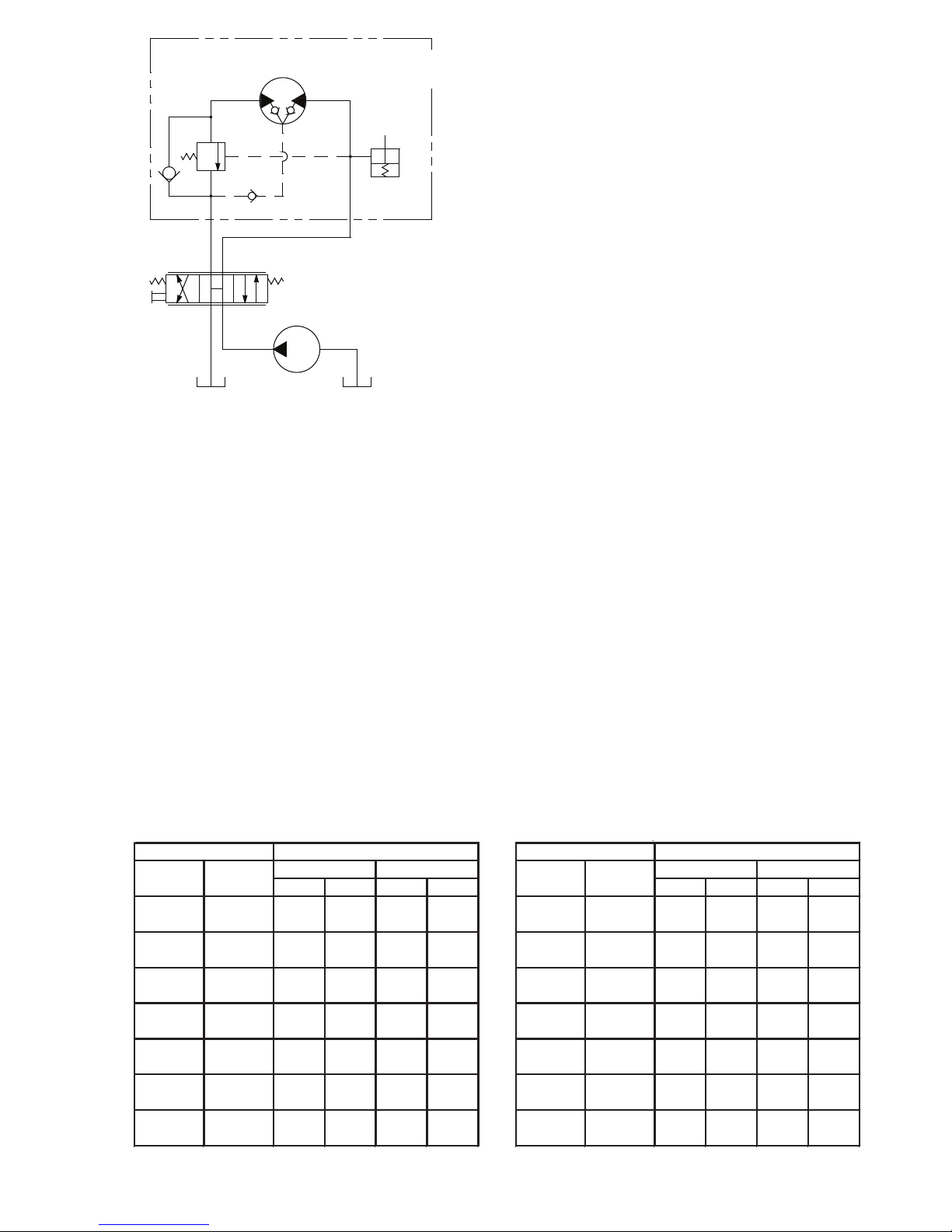

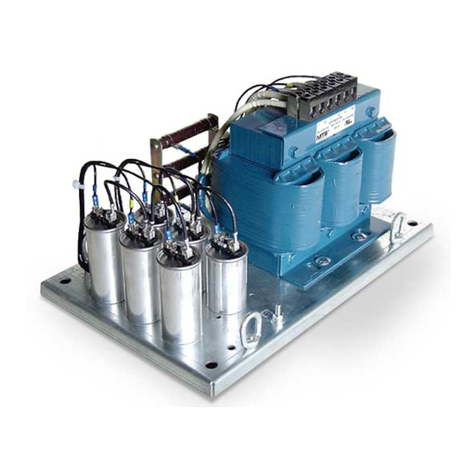

4. Hydraulic System

The original filter element should be replaced after

the first fifty (50) hours of operation, then every 500

operating hours or three (3) months, or in

accordance with the equipment manufacturer’s

recommendations.

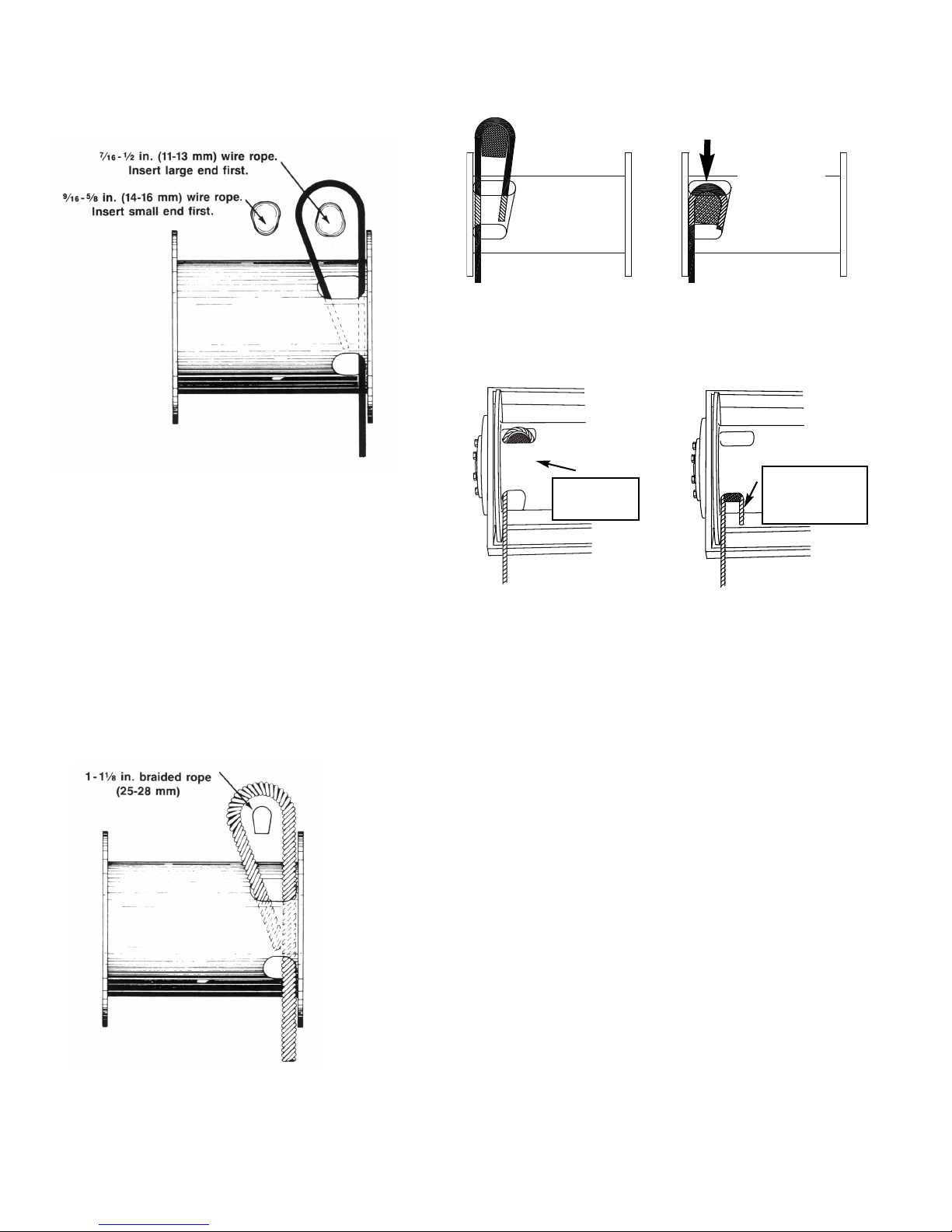

5. Wire Rope

Inspect entire length of wire rope according to wire

rope manufacturers recommendations.

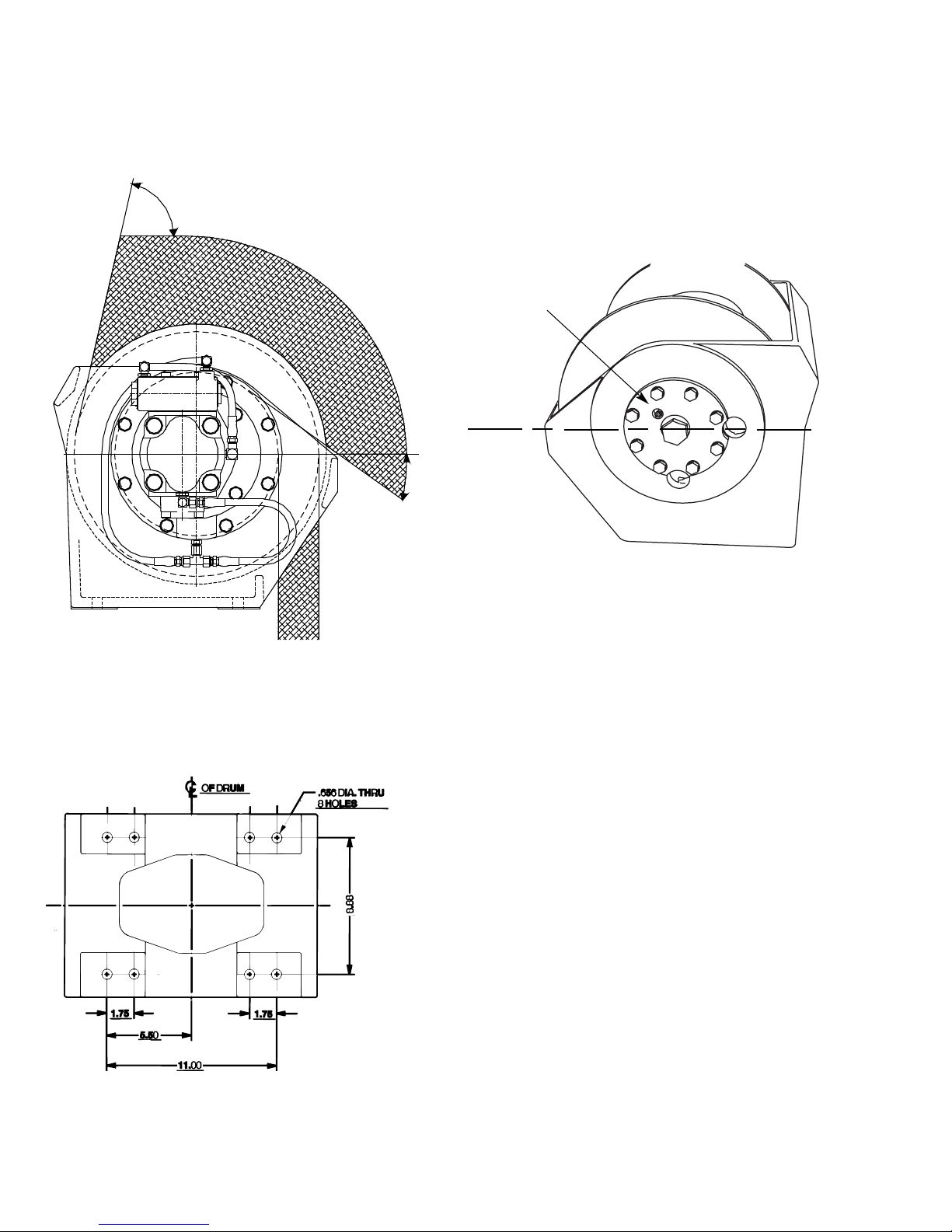

6. Mounting Bolts

Tighten all winch base mounting bolts to

recommended torque after the first one hundred

(100) hours of operation, then every 1000 operating

hours or six (6) months, whichever occurs first.

7. Warm-up Procedures

Awarm-up procedure is recommended at each

start-up and is essential at ambient temperatures

below +40°F (4°C).

The prime mover should be run at its lowest

recommended RPM with the hydraulic winch

control valve in neutral allowing sufficient time to

warm up the system. The winch should then be

operated at low speeds, forward and reverse,

several times to prime all lines with warm hydraulic

oil, and to circulate gear lubricant through the

planetary gear sets.

8. Recommended Planetary Gear Oil

Field experience, supported by extensive

engineering tests, indicates the use of the proper

planetary gear oil is essential to reliable and safe

operation of the brake clutch and obtaining long

gear train life.

For simplicity, BRADEN has listed one (1) readily

available product in each temperature range which

has been tested and found to meet our

specifications. This is not to say that other lubricant

brands would not perform equally as well.

If the following lubricant brands are not available in

your area, make certain your lubricant vendor

supplies you with oil that is equivalent to those

products listed below.

BRADEN planetary winches are factory filled with

Texaco Meropa 150 or equivalent AGMA No. 4EP

gear oil.

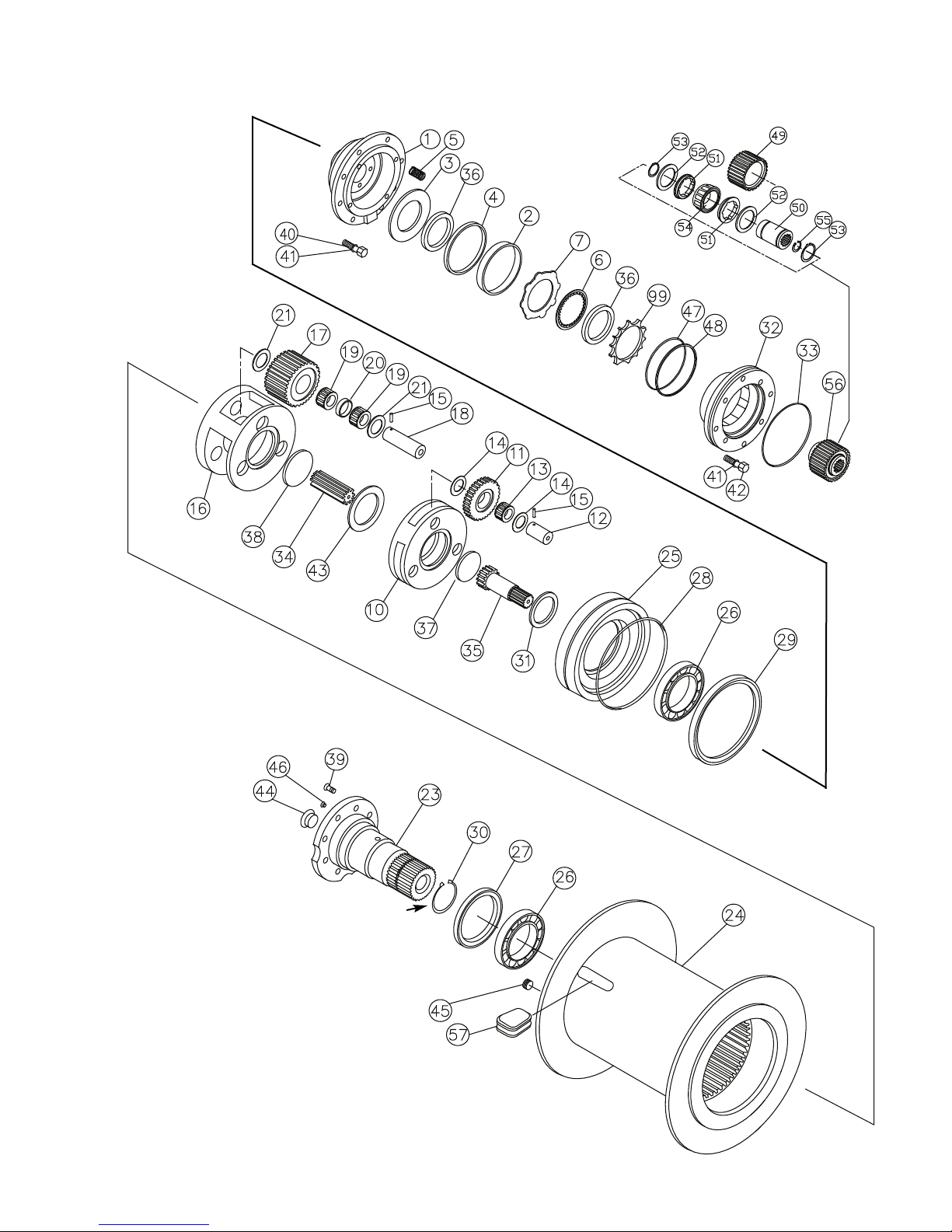

9. Inspection

In compliance with ANSI specification number

B30.5c1987 and API Recommended Practice RP

2D section 3, we recommend that the winch be

disassembled for a thorough inspection of all wear

items every 2,000 hours of operation or twelve (12)

months, whichever occurs first.

A. Bearings and Gears – Refer to

DISASSEMBLYOF WINCH, page 15; and

PLANET CARRIER SERVICE, page 20.

B. Brake Cylinder – Refer to MOTOR

SUPPORT– BRAKE CYLINDER SERVICE,

pages 22 and 23.

C. Brake Clutch – Refer to BRAKE CLUTCH

SERVICE, page 26.

Failure to properly warm up the winch, particularly

under low ambient temperature conditions, may

result in temporary brake slippage due to high back

pressures attempting to release the brake, which

could result in property damage, severe personal

injury or death.

Failure to use the proper type and viscosity of

planetary gear oil may contribute to intermittent brake

clutch slippage which could result in property

damage, severe personal injury or death. Some gear

lubricants contain large amounts of EP (extreme

pressure) and anti-friction additives which may

contribute to brake clutch slippage and damage to

brake friction discs or seals. Oil viscosity with regard

to ambient temperature is also critical to reliable

brake clutch operation. Our tests indicate that

excessively heavy or thick gear oil may contribute to

intermittent brake clutch slippage. Make certain that

the gear oil viscosity used in your winch is correct for

your prevailing ambient temperature.