BRAHMA MICROFLAT Series User manual

3997_r02 1/13

MICROFLAT SERIES

TYPES C...F S...F

M...F T...F

AUTOMATIC CONTROL SYSTEMS FOR

GAS BURNERS AND GAS BURNING

APPLIANCES WITH OR WITHOUT FAN

AND WITH BUILT-IN ANTI-EMISSIONS

FILTER

APPLICATION

This range of electronic gas burner control systems has

been specifically designed for atmospheric burners for

intermittent operation (systems for non-permanent

operation), with or without fan in the combustion circuit.

These controls are provided with both non-volatile lockout

and volatile lockout: in the first case restart from the safety

shutdown condition can only be accomplished by a manual

reset of the system; in the second case restart from the

safety shutdown condition can only be accomplished by an

interruption of the main power and its subsequent

restoration.

The automatic burner control units of this series are

suitable for:

-combi boilers;

-heating boilers;

-warm air generators;

-radiant heaters;

-water heaters.

Thanks to their design and variety of models, they can also

be used for the automation of ovens, cookers and in gas

firing installations with atmospheric burner in general.

FEATURES

Table 1 shows the main features of this series. Other

important features are:

− EC certification (CE Reg. N°0694BP0669) in

accordance with Gas Appliance Directives 90/396 and

93/68;

− in accordance with EN 298 (European standard for

automatic gas burner control systems and flame

detectors);

− completely solid and high efficient inbuilt ignition device

with built-in E.M. filter;

− possibility of mounting a resistor (0 ÷220 ohm) in series

to the valve output, in case the valves operate with

direct current obtained through the rectification of the

supply alternate current by means of one or more

diodes.

This resistor allows to reduce electromagnetic

disturbances generated by diodes switching;

− possibility of mounting a resistor (0 ÷470 Kohm) in

series to the lockout signal output, to avoid possible

damages to the control in case the connections of the

reset button and the connections of the lockout signal

are inverted;

− two independent safety contacts in series on the gas

valve output (only for non-volatile lockout types);

− auxiliary contact for low power ignition or main gas

valve control for intermittent pilot systems; this contact

is not isolated from the main supply voltage by

reinforced isolation, therefore the relay contact is not

suitable to supply SELV circuits - Safety Extra Low

Voltage, e.g.24V;

− flame monitoring by the rectification property of the

flame (ionization).

2/13 3997_r02

Table 1

Burner Features

Non-volatile lockout

Volatile lockout

Single flame

Dual flame

Atmospheric without fan

Atmospheric with fan

Monoelectrode

Auxiliary contact

Safety thermostat provision

Connector type molex

According to EN 298 :1993

According to EN 298 :2003

Classification code according to EN 298

CM11F

* * * * * * AMCLXN

CM12F

* * * * * * ATCLXN

CM31F

* * * * * * FMCLXN

CM32F

* * * * * * FTCLXN

SM11F

* * * * * * * ATCLXN

SM31F

* * * * * * * FTCLXN

MM11F

* * * * * * * AMCLXN

MM12F

* * * * * * * ATCLXN

MM51F

* * * * * * * * ATCLXN

MM31F

* * * * * * * FMCLXN

MM32F

* * * * * * * FTCLXN

TM11F

* * * * * * AMCLXN

TM12F

* * * * * * * ATCLXN

TM31F

* * * * * * FMCLXN

TM32F

* * * * * * * FTCLXN

CE11F

* * * * * AMCVXN

CE12F

* * * * * ATCVXN

CE31F

* * * * * FMCVXN

CE32F

* * * * * FTCVXN

SE11F * * * * * * ATCVXN

SE31F * * * * * * FTCVXN

ME11F

* * * * * * AMCVXN

ME12F

* * * * * * ATCVXN

ME51F

* * * * * * * ATCVXN

ME31F

* * * * * * FMCVXN

ME32F

* * * * * * FTCVXN

TE11F * * * * * AMCVXN

TE12F * * * * * * ATCVXN

NOTE

TECHNICAL DATA

Supply voltage: 220/240V @ 50/60Hz

On request:

110/120V @ 50/60Hz

Operatine temperature range: -20°C ÷+60°C

Ambient humidity: 95% MAX @ 40°C

Protection degree: IP 00

Times:

- prepurge or waiting time (TW):

1.5 … 40 s

- safety time (TS):

3 ... 120 s

- response time on running flame failure (TR):

<1 s

The times given on the burner control label correspond to the

values guaranteed. The actual values slightly differ from the values

given, pre-purge and waiting time is in fact longer and safety time

shorter than their nominal values.

Power consumption, at starting up:

types without burner 10VA

types with burner 12VA

Power consumption, running:

types without burner 7VA

types with burner 9VA

Contact rating:

- Thermostat: 4A cosϕ≥0.4

- VG1: 0.5A cosϕ≥0.4

- VG2: 0.5A cosϕ≥0.4

- Fan motor: 1A cosϕ≥0.4

- Lock-out signalling: 1A cosϕ= 1

- Auxiliary contact: 0.5A cosϕ≥0.4

Max. length of the cables of external components:

1 m

Internal fuse rating: 4A fast

External fuse rating: 3.15A fast

Flame control:

The ionization flame detection device makes use of the

rectification property of the flame.

The ionization flame detector device is not a safe to touch

output (no provision with protective impedances).

- Minimum ionization current: 0.5µA

on request:

1.2µA / 2.5µA

- Max ionization current @ 230V: 8.5µA DC

- Recommended ionization current: 3÷5 times the

minimum value

- Max. length of the cable: 1 m

- Minimum insulation resistance of the

cable and the flame

detector device to earth:

≥50 MΩ

- Max. parasitic capacitance of the

detection probe: ≤1 nF

- Max. short circuit current: <200µA AC

This contact is not isolated from the main supply voltage by

reinforced isolation, therefore the relay contact is not suitable to

supply SELV circuits – Safety Extra Low Voltage.

Safety thermostat opening causes cycle repetition and

volatile/non-volatile lockout.

Standard connectors are Stelvio-Stocko models, as shown in

Fig.2.

.

Flame failure durino TS causes spark restoration.

Device is compliant only if the note “EN 298:2003 compliant”

and the option “#” are report on the label.

3997_r02 3/13

Ignitor:

- Peak ignition voltage: 15KV con carico di

30pF

on request:

12/18 KV

- Peak current: 800 mA

- Spark repetition rate: 25 Hz

on request:

1 ... 8/10/12/16 Hz

- Max. length of the cable: 2 m

- Spark gap recommended: 2-4 mm

- Consumption: 2.5 VA

- Spark energy: 20 mJ

Weight: 170 g

CONSTRUCTION

The enclosure made of plastic material and the varnishing

of the circuit board protect the control from mechanical

damages, dust and dirt from the conditions of installation.

Through the use of a board assembled with surface

mounted components and of a new patented circuit

generating the ignition spark which limits the EM to a

minimum, it has been possible to reduce the printed circuit

board dimensions and to realize even the most complex

executions with extremely compact dimensions.

A varistor protects the control from voltage transient on the

main supply, caused for example by discharges such as

thunderbolds. An internal fuse protects the relays of the

control box in case of short circuits on the outputs (valves,

fan and lockout signal). In any case the control must be

protected with a fast blow external fuse suitable to the load

connected and never exceeding 3.15 A.

OVERALL DIMENSIONS

The control units of the MICROFLAT series can be

supplied in different executions but with the same

enclosure. The following figure (Fig. 1) shows the overall

dimensions of the controls.

CLIP TO

EXTRACT

THE INTERNAL

FUSE

Fig. 1

POSSIBLE FIXING

top: self-tapping screw UNI 6951AB 2,9x22

M3x22 screw UNI6107

bottom:

Screwplast self-

forming screw

ISO0003 F

3.5x13

Screwplast self-

forming screw

ISO0003 F

3.9x13

ACCESSORI

The control units are usually supplied with a kit of female

connectors and/or a reset button (see Fig.2 and Fig.3).

Do not fit terminals and female connectors of different

types.

RESET BUTTON

DRILLING PLAN

FEMALE CONNECTOR

TERMINALS

RESET

LOCK-OUT SIG.

NEUTRAL

Fig. 2

FEMALE CONNECTOR

TERMINALS

Fig. 3

CONNECTION

The use of non-reversible connectors with a different

number of poles makes the connection easy and reliable.

One-way fast-on connectors of different sizes for ignition

and detection electrodes permit their easy installation and

replacement.

The dual output ignition device allows spark generation on

one point (3a), two points (3b) or between two electrodes

isolated from the metal frame of the burner (3c), see Fig.4.

The configuration (3c) assures a limited EM emission.

Fig. 4

Provisions such as strain relieves, sufficient earth terminals

and neutral terminals should be present in the appliance or

in external connection boxes. With all types it is possible to

execute the connection with a J3 connector as shown in

Fig.5.

Types TM..F are prearranged for the connection of a safety

thermostat ST which stops the supply to the gas valve VG1

and causes a safety shutdown after a delay which is the

sum of waiting (pre-purge) and safety times.

4/13 3997_r02

(4a) W ith saf ty th rmostat (4b) Without saf ty th rmostat

Fig. 5

DIRECTIONS FOR USE

− For technical and safety reasons a regulation shutdown

must occur every 24 hours (systems for non-permanent

operation);

− automatic controls are safety devices and must not be

opened. The manufacturer’s responsibility and

guarantee are invalidated if the control is opened;

− the control must be connected and disconnected only

after switching off the main power;

− the control can be mounted in any position;

− avoid exposing the control unit to dripping water;

− ventilation and the lowest temperature ensures the

longest life of the control;

− make sure that the type (code and times) you are using

is correct before installing or replacing the control;

− the gas appliance on which the control is installed must

provide adequate protection against the risk of electrical

shock (at least IP20).

ELECTRICAL INSTALLATION

− The applicable national regulation and the European

standards (e.g. EN 60335-1/prEN 50165) regarding

electrical safety must be respected;

− live and neutral should be connected correctly, a

mistake could cause a dangerous situation, i.e. the

valves would still be live with the thermostats and limits

switched off. If live-neutral polarity is not respected the

control performs a non-volatile lockout at the end of the

safety time at starting up;

− before starting the system check the cables carefully.

Wrong connections can damage the control and

compromise the safety;

− the earth terminal of the control, the metal frame of the

burner and the earth on the main supply must be well

connected;

− avoid putting the detection cable close to power or

ignition cables;

− use a heat resistant cable for the detection probe, well

insulated to the ground and protected from possible

moisture (or water in general);

− use an ignition cable as short and straight as possible

and keep it far from other conductors to reduce the

emission of interference (max.length <2m and

insulation voltage >25KV).

In case of live-neutral network with unearthed neutral or

live-live network (with centre of the star not earthed) the

control can operate correctly by means of a built-in resistor.

In case of "partial" short circuits or bad insulation between

live and earth the voltage on the ionization probe can be

reduced until it causes the lockout of the control, because

of the impossibility of detecting the flame signal.

In the presence of this kind of network it is advisable to use

our step-up transformer type AR1.

CHECKING AT START

Always check the control before the first start and also after

any substitutions or a long period of non-operation of the

system. Before any ignition attempt make sure that the

combustion chamber is free from gas.

Then make sure that:

− if the starting attempt occurs without gas supply the

control performs a non-volatile lockout after TS;

− when stopping the gas flow while the control is in

running state the supply to the gas valve is interrupted

within 1 second, and after a recycling the control

proceeds to a non-volatile lockout;

− operating times and sequence are suitable;

− the level of the flame signal is sufficient, see Fig.6 for

the measuring test;

− the ignition probe(s) is (are) adjusted in the most

stable way for a spark gap between 2-4 mm;

− the intervention of limiters or safety devices causes a

safety shutdown according to the application.

Fig. 6

OPERATION

At every start the control unit proceeds to a self-checking of

its own components. During the waiting or prepurge time

(TW) the operation of the flame signal amplifier is checked:

the internal circuit makes a test of the flame signal amplifier

circuit. A parasitic flame signal or a fault in the amplifier

prevent the control from starting.

In the types with fan control, before the elapsing of the

prepurge time, the air pressure switch contacts are

checked to prove their "no air flow" state.

Only if the test is positive the fan is started and with the air

pressure switch in "air flow" state the prepurge time begins.

At the end of the waiting or prepurge time the VG1 gas

valve is energized and the ignition device is operated. In

this way the safety time (TS) begins. If the presence of

flame is detected during the safety time the ignition device

is inhibited and, in the suitable models, the main valve

(VG2) is supplied or the independent auxiliary contact will

switch from off to flame detected position.

On the contrary, if the control detect no presence of flame

by the end of TS, it proceeds to non-volatile lockout, the

VG1 gas valve and the ignition device are switched off

while the lockout signal output is supplied.

Flame failure during the safety time causes the ignition

device to be activated within one second.

The attached diagrams are useful to understand how each

control operates.

NON-VOLATILE LOCKOUT - RESET OF THE CONTROL

When a control has gone to non-volatile lockout, a ten-

second delay should be allowed before attempting to reset

the control unit; if this time is not observed the control may

not reset correctly.

VOLATILE LOCKOUT – RESET OF THE CONTROL

The restart from the safety shut-down condition can only be

accomplished by an interruption of the main power and it

subsequent restoration.

This types of burner control units do not contain an

independent manual reset function. The application of

these types of controls is therefore restricted to only those

appliances where resetting by switching off the heat

demand is allowed by European standards.

3997_r02 5/13

In general, resetting of the appliance must occur in sight

and in the near vicinity of the appliance. Resetting must

also occur by means of a conscious manual action and not

by means of automatic device like thermostats or timers.

Please note that it is allowed to combine the reset button

together with the main switch on the appliance. In this case

the alarm light will have to be installed too.

CONTROLS DENOMINATION

Type Options

(1) (2) (3) (4) F (5) (6) (7) (8) (9) (10)

(11)

(12)

(13)

Types description

(1) Installations

C

Wall boilers

S

General uses

M

Monoelectrode

T

With safety thermostat

(2) Reset

M

Manual

E

Electrical

(3) Type of burner

1 Without fan

3 With fan

5 Special types

(4) Gas valves

1 Single flame

2 Dual flame

Options description

(5) Compliance

According to EN 298:1993

# According to EN 298:2003

(6) Kind of connectors

Stocco-Stelvio connectors

X

Molex connectors

(7) Internal fuse

Not-accessible internal fuse

F Accessible internal fuse

(8) Resistor in series with VG2

Not present

W

Present

(9) Resistor in series with VG1

Not present

V

Present

(10) Protection against the inversion of the connections of the lockout signal and the connections of the reset button

Not present

R

Present

(11) Protection against air pressure switch reversal connection

Not present

P

Present

(12) Ignition coltage

15 Kv (standard)

H

18 kV

L 12 kV

(13) Spark repetition rate

25 Hz (standard)

nn Number represents the discharge frequency

6/13 3997_r02

CONNECTION DIAGRAM

TYPES WITH MANUAL RESET WITHOUT FAN

THERMOSTAT FUSE BURNER LOCK

-OUT FIRST GAS SECOND GAS SAFETY RESET MAIN

SIGNAL VALVE VALVE THERMOSTAT SWITCH

TYPE CM11F

TYPE SM11F

TYPE MM11F

TYPE TM11F

TYPE MM51F

TYPE CM12F

TYPE TM12F

TYPE MM12F

NOTA: the limit thermostat has to be wired in series to the live.

3997_r02 7/13

TYPES WITH MANUAL RESET AND FAN

THERMOSTAT FAN AIR PRESSURE FUSE BURNER LOCK

-OUT FIRST GAS SECOND GAS SAFETY RESET MAIN

SIGNAL VALVE VALVE THERMOSTAT SWITCH

TYPE CM31F

TYPE SM31F

TYPE MM31F

TYPE TM31F

TYPE CM32F

TYPE MM32F

TYPE TM32F

NOTA: the limit thermostat has to be wired in series to the live.

8/13 3997_r02

TYPES WITH ELECTRICAL RESET WITHOUT FAN

TYPE CE11F

TYPE SE11F

TYPE ME11F

TYPE TE11F

TYPE CE12F

TYPE ME51F

TYPE ME12F

TYPE TE12F

THERMOSTAT FUSE BURNE

R LOCK-OUT FIRST GAS SECOND GAS SAFETY MAIN

SIGNAL VALVE VALVE THERMOSTAT SWITCH

NOTA: the limit thermostat has to be wired in series to the live.

3997_r02 9/13

TYPES WITH ELECTRICAL RESET AND FAN

TYPE CE31F

TYPE SE31F

TYPE ME31F

TYPE TE31F

TYPE CE32F

TYPE ME32F

TYPE TE32F

THERMOS

TAT FAN AIR PRESSURE FUSE BURNER LOCK

-

OUT FIRST GAS SECOND GAS SAFETY MAIN

SIGNAL VALVE VALVE THERMOSTAT SWITCH

NOTA: the limit thermostat has to be wired in series to the live.

10/13 3997_r02

OPERATING CYCLES

TYPES WITH MANUAL RESET WITHOUT FAN

3997_r02 11/13

TYPES WITH MANUAL RESET AND FAN

12/13 3997_r02

TYPES WITH ELECTRICAL RESET WITHOUT FAN

3997_r02 13/13

TYPES WITH ELECTRICAL RESET AND FAN

THERMOSTAT FAN AIR PRESSURE

SWITCH IGNITION FLAME

SIGNAL LOCK-OUT

SIGNAL FIST GAS

VALVE SECOND GAS

VALVE AUXILIARY

CONTACT SAFETY

THERMOSTAT

TYPE CE31F - ME31F TYPE TE31F

TYPE CE32F - ME32F TYPE TE32F

TYPE SE31F

BRAHMA S.p.A.

Via del Pontiere, 31

37045 Legnago (VR)

Tel. +39 0442 635211 - Telefax +39 0442 25683 07/04/04 Subject to amendments without notice

http://www.brahma.it

E

-

ATTE

N

TION

-

>

Company

Brahma S.p.A.

d

e

c

l

i

n

e

s

a

n

y

respons

i

bilit

y

f

o

r

a

n

y

d

a

m

a

g

e

r

e

s

u

l

t

i

n

g

f

r

o

m

t

h

e

C

u

s

t

o

m

e

r

’

s

i

n

t

e

r

f

e

r

i

n

g

w

i

t

h

th

e

de

vic

e

.

This manual suits for next models

32

Table of contents

Other BRAHMA Control System manuals

Popular Control System manuals by other brands

Ariston

Ariston Chafforeaux elco 3319130 Assembly and operation instructions

Norac

Norac UC5 Topcon X30 installation manual

Lifebreath

Lifebreath max series Homeowner's guide

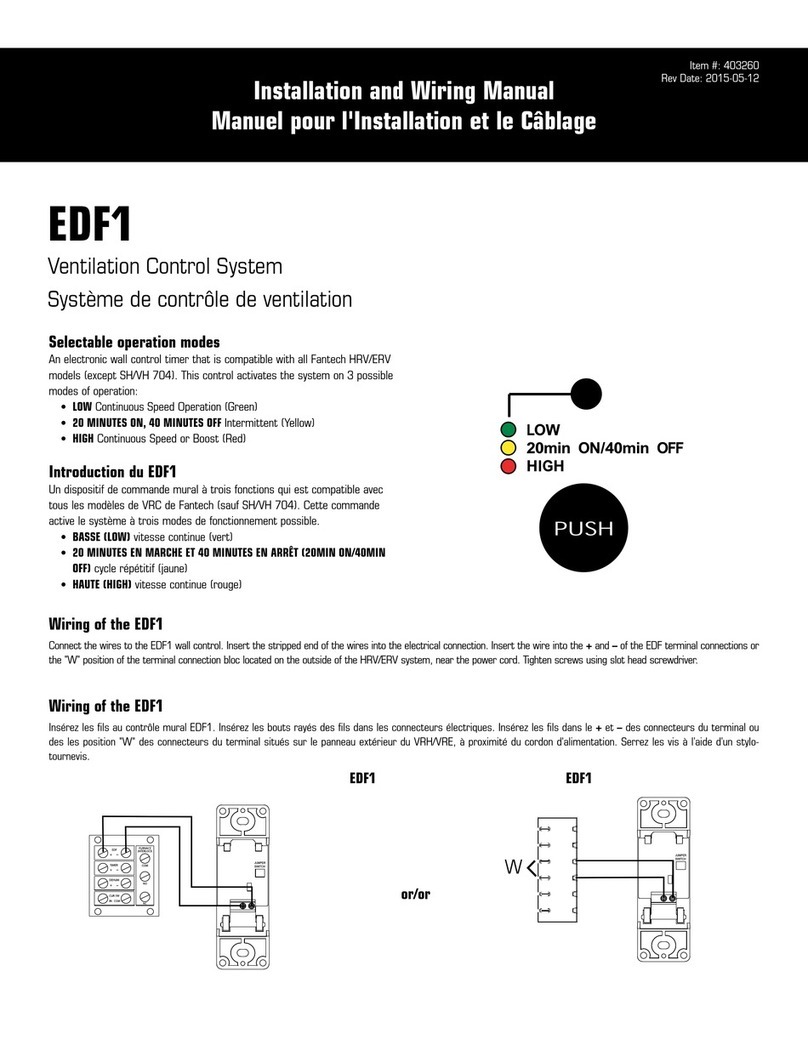

Fantech

Fantech EDF1 Installation and wiring manual

Redmond

Redmond SkyCenter RSC-12S-A user manual

Elstat

Elstat ems75vr Installation and user guide

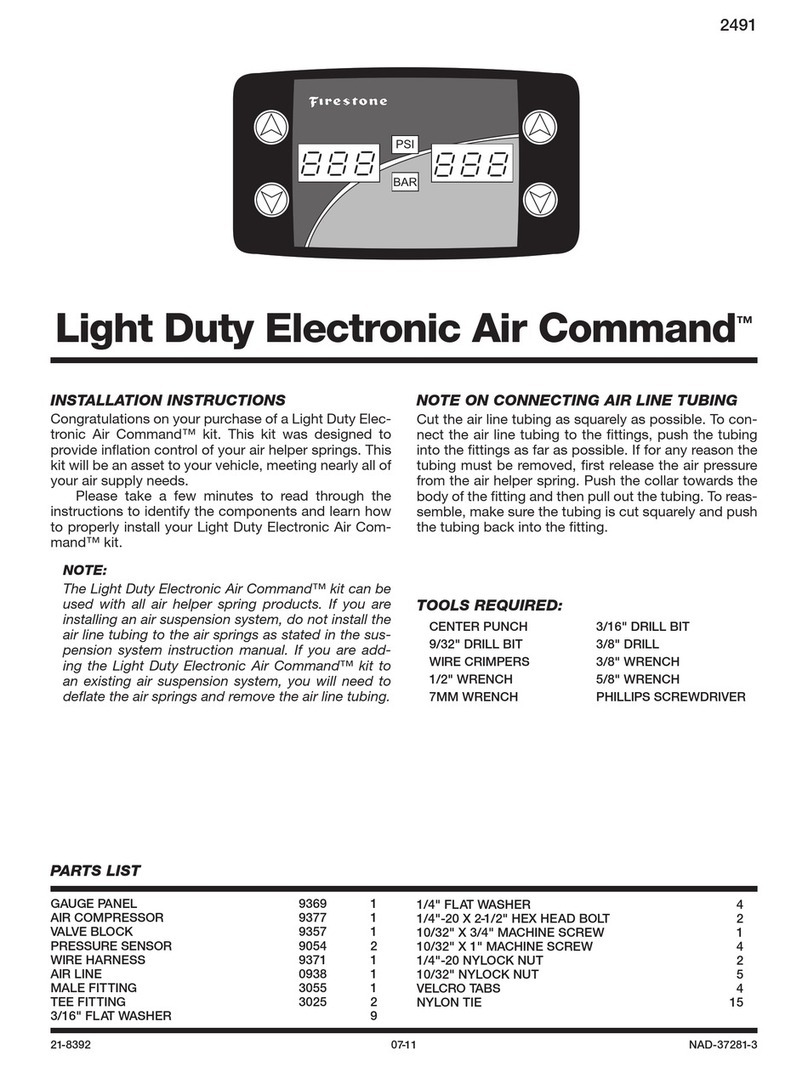

Firestone

Firestone 2491 installation instructions

Toshiba

Toshiba TOSDIC-CIE DS Function manual

Aiphone

Aiphone AC Series Quick start programming guide

Lutron Electronics

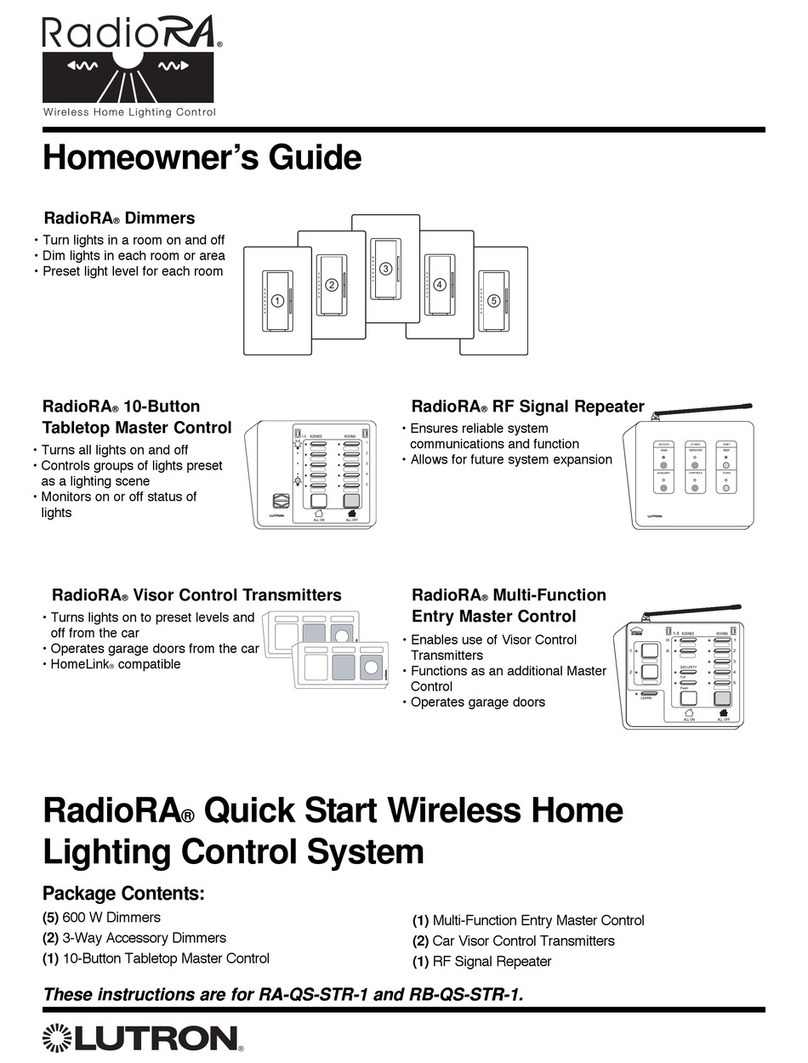

Lutron Electronics RadioRA Homeowner's guide

Lutron Electronics

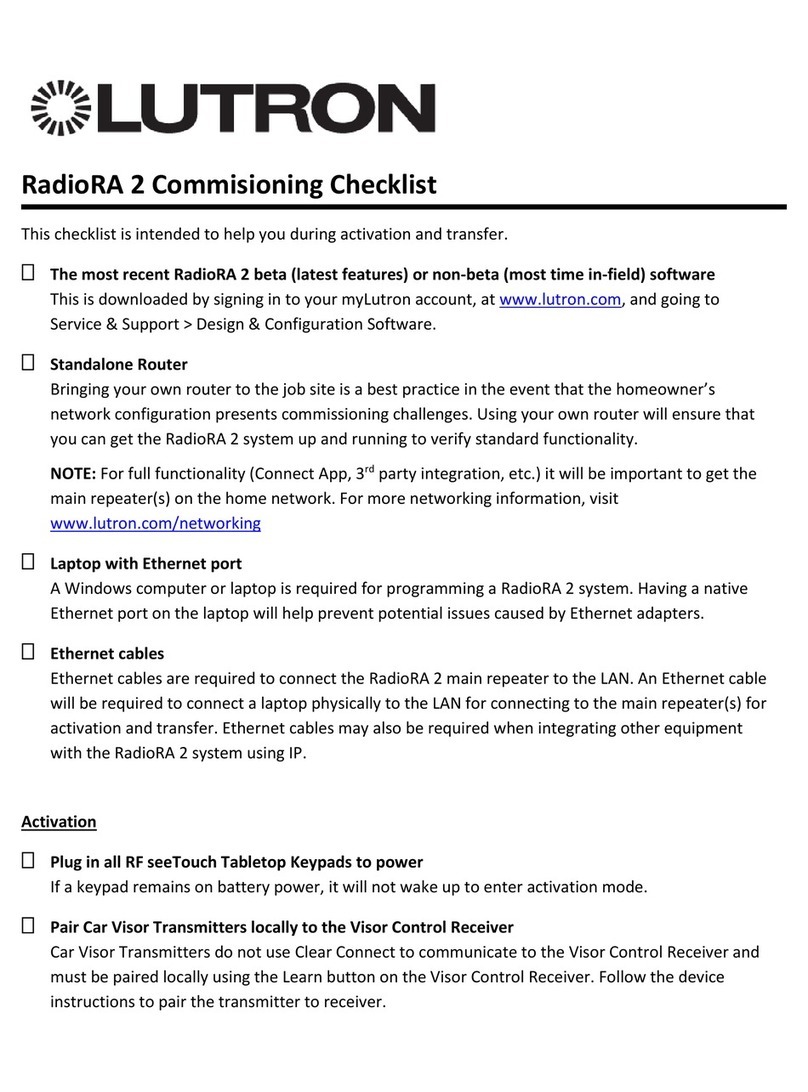

Lutron Electronics RadioRA 2 Commisioning Checklist

Schaudt

Schaudt Electroblock EBL 271 instruction manual