BRAHMA EUROFLAT Series User manual

EUROFLAT SERIES

TYPES MT11 MT31

AUTOMATIC GAS BURNER CONTROL

SYSTEMS FOR GAS BURNERS AND GAS

BURNING APPLIANCES WITH OR

WITHOUT FAN MONOELECTRODE WITH

EXTERNAL IGNITION DEVICE.

Application

This range of electronic gas burner control systems has

been designed specifically for atmospheric and fan assisted

burners for intermittent operation (systems for non-

permanent operation).

These types of automatic burner control units differ from the

standard model essentially in the operating cycle and in the

features of the ignition-detection device. Due to the design

and the technical-structural characteristics, the controls of

this series can be used in general in gas firing installations

with atmospheric burner.

Features

Table 1 shows the main features of this series. Other

important features are:

− in accordance with EN298 (European standard for

automatic gas burner control systems);

− flame monitoring by the rectification property of the

flame: ionization;

− electrical service life at max. loading >250.000

operations;

− two independent safety contacts in series on the gas

valve output;

− electronic ignition device (transformer TC1 – TD1

series).

TABLE1 BURNER

single flame

atmospheric without fan

atmospheric with fan

classification code according to

EN298

MT11 * * AMCLXN

MT31 * * FMCLXN

3999_r01

1/4

TECHNICAL DATA

Supply Voltage: 230V∼50-60Hz

Operating temperature range: -20°C +60°C

Ambient humidity: 95% max at 40°C

Protection degree: IP 00

Times:

- Waiting or pre- purge time (TW):

1,5/3/5/10/20/30/40 s

- Safety time (TS): 3/5/8/10/20/50/60 s

- Ignition time (TSP): (40% di TS) s

- Drop out time on running flame failure: < 1 s

The times given on the burner control label correspond to

the values guaranteed. The actual values differ slightly from

the values given, warm time is in fact longer and safety time

shorter than their nominal values.

Power consumption, at starting up:

atmospheric burner 13 VA

atmospheric fan-assisted burner 15 VA

Contact rating: I max

-Thermostat: 4A cos ϕ≥0.4

-VG1: 0.5 A cos ϕ≥0.4

-Fan: 1A cos ϕ≥0.4

-Alarm: 0,5 A cos ϕ= 1

Max. length of the cables of

external components: 1 m

Fuse rating internal: 4A T

Fuse rating external: 3,15 A F

Flame control:

The ionization flame detector device makes use of the

rectification property of the flame.

The ionization flame detector device is not a safe to touch

output (no provision with protective impedances).

-Minimum ionization current: 0.5µA

1.2µA

-Recommended ionization current:

3 ÷ 5 times the minimum ionization current

-Max length of the cable: 1 m

-Minimum insulation resistance of cable and flame

detector device to earth: ≥50MΩ

-Max. parasitic capacitance of

detection probe: ≤1nF

-Max. short circuit current: < 200µA AC

Weight: 200 g

CONSTRUCTION

The enclosure made of plastic material protects the control

from mechanical damage, dust and dirt from the conditions

of installation.

The printed circuit board dimensions have been reduced by

means of a module with surface mounted components.

A varistor protects the control from voltage transients on the

mains supply. An internal fuse protects the relays of the

control in case of short circuits on the outputs (valve, fan,

lock-out signal and ignition / detection device). This is not an

accessible fuse and the control must be protected with a

fuse of the fast blow type suitable to the load connected and

never exceeding 3,15A.

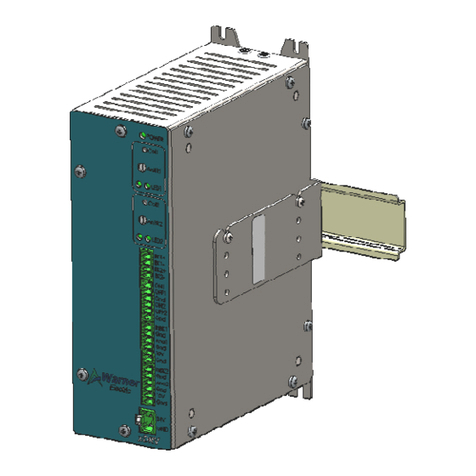

Overall Dimensions

The following figure Fig. 1 shows the overall dimensions of

the controls.

Fig. 1

Accessories

The control units are usually supplied with a kit of female

connectors and/or reset button. Do no fit terminals and

female connectors of different types.

These accessories can be supplied upon request (see

Fig.2).

RESET BUTTON DRILLING PLAN

COD.: 81020980 Reset 1

Lock-out s. 2

3 Neutral

FEMALE CONNECTORS TERMINALS

STOCKO: MKF 2800 STOCKO: RFB 7851

STELVIO:BS95/... STELVIO: CT84

Fig.2

Connection

Using non reversible connectors with different number of

poles makes the connection easy and reliable.

One–way fast–on connectors of different sizes permit their

easy installation and replacement.

Regarding the connection of the control units, provisions

such as strain reliefs, sufficient earth terminals and neutral

terminals should be present in the appliance or in external

connection boxes.

M4 SCREW

SLOT

2/4 3999_r01

The controls are prearranged to operate with only one

electrode for ignition and flame detection (the ignition

electrode also makes the flame detection function by means

of wire connection between pin 16 of J4 and fast-on J5 as

shown in figure 4a); they can also correctly operate with

separate ignition electrode and detection electrode (as

shown in figure 4b).

DIRECTIONS FOR THE USE

− For technical-safety reasons a regulation shutdown must

occur every 24 hours (systems for non-permanent

operation).

− Automatic controls are safety devices and shall not be

opened. Responsibility and guarantee of the

manufacturer is invalidated if the control is opened.

− The control must be connected and disconnected only

without the main power.

− The control can be mounted in any position.

− Avoid exposure of the control unit to dripping water.

− Ventilation and the lowest temperature ensures the

longest life of the control.

− Make sure that the type (code and times) you are using

is correct before installing or replacing the control.

− The gas appliance in which the control is installed must

provide adequate protection against the risk of electrical

shock (at least IP20).

Electrical installation

− The applicable national regulation and European

standards (e.g. EN60335-1/EN50165) regarding

electrical safety must be respected.

− Live and neutral should be connected correctly, a

mistake could cause a dangerous situation, i.e. the

valve would still be live with the thermostats and limits

switched off. Besides, if live-neutral polarity is not

respected the control performs a non-volatile at the end

of the safety time at starting up.

− Before starting check the cables carefully. Wrong

connections can damage the control and compromise

the safety.

− Take great care while connecting the lock-out signal and

reset button: an inversion in the connection can damage

the control.

− The earth terminal of the control, the metal frame of the

burner and the earth on the mains supply must be well

connected.

− Use an ignition cable as short and straight as possible

and keep it far from other conductors.

− Using the control with separate detection electrode, a

heat resistant cable and detection probe must be used,

well insulated to the ground and protected from possible

woisture (or water in general).

IMPORTANT: in the event of "partial" short circuits or

bad insulation between phase(s) and earth the voltage

on the ionization device can be reduced until it causes

the lock-out of the control.

Checking at start

Always check the control before the first start and also after

substitutions or a long period of non operation of the

system. Before any ignition attempt make sure that the

combustion chamber is free from gas.

Then make sure that:

− if the attempt to start occurs without the gas supply the

control performs a non-volatile or volatile lock-out after

TS;

− when stopping the gas flow (while the control is in

running state) supply to the gas valve is interrupted

within 1 second and after a recycling, the control

proceeds to a non-volatile lock-out;

− operating times and sequence are suitable;

− the level of the flame signal is sufficient, see Fig.4 for the

measuring test;

− the intervention of limiters or safety devices causes a

safety shut-down according to the application.

Fig.3

Operation

At every start the control unit proceeds to a self-checking of

its own components.

In the type with control of the fan, before the elapsing of pre-

purge time (TW), the air pressure switch contacts are

checked to prove their "no air flow" state.

Only if the test is positive the fan is started and with the air

pressure switch in "air flow" state, pre-purge time begins.

At the end of wanting or pre-purge time the gas valve is

supplied and the ignition device, so that safety time TS and

ignition time TSP begin.

The ignition device is kept in operation for 40% of the safety

time TS under all operating condition (time TSP ending). If

during remaining time TS, the control unit will keep the gas

valve supplied until a flame failure occurs (followed by a

recycling) or the regulation ring opens. On the contrary, if

the control doesn't detect a flame by the end of TS, it

proceeds to non-volatile (or volatile) lock-out, the gas valve

is switched off while the lock-out signal output is supplied.

The attached diagrams are useful to understand how each

control operates.

Reset of the control

When a control has gone to non-volatile or volatile lock-out,

an interval of 10 seconds should be allowed before

attempting to reset the control unit; if this time is not

observed then the control may not reset correctly.

In general, resetting of the appliance must occur in sight and

in the near vicinity of the appliance. Resetting must also

occur by means of a conscious manual action and not by

means of automatic device like thermostats or timers.

Please note that it is allowed to combine the reset button

together with the main switch on the appliance. In this case

the alarm light will have to be installed too.

IGNIT. / DETEC.

ELECTRODE

J4 J5 J6

A

-+

I ion

BROWN

BLUE

G/V

3999_r01

3/4

BRAHMA S.p.A.

Via del Pontiere, 31

37045 Legnago (VR) – ITALY

Tel. +39 0442 635211 – Fax +39 0442 25683

2011/06/07 subject to amendments without notice

http://www.brahma.it

CONNECTION DIAGRAMS

F 3.15A

L N

SB

RESET

N

1 2 3 4 5 6 7

J1

N

VG1

13 14 15

J3

TYPE MT11 TYPE MT31

PA V

J2

N

8 9 10 11 12

F 3.15A

L N

SB

RESET

N

1 2 3 4 5 6 7

J1

N

VG1

13 14 15

J3

IGNIT. / DETEC.

ELECTRODE

BROWN

BLUE

G/V

1619 18 17

J4 J5 J6

F 3.15A

L N

SB

RESET

N

1 2 3 4 5 6 7

J1

N

VG1

13 14 15

J3

TYPE MT11 TYPE MT31

PA V

J2

N

8 9 10 11 12

F 3.15A

L N

SB

RESET

N

1 2 3 4 5 6 7

J1

N

VG1

13 14 15

J3

Fig. 4a CONNECTION DIAGRAMS WITH SINGLE IGNITION / DETECTION ELECTRODE

Fig. 4b CONNECTION DIAGRAMS WITH SEPARATE DETECTION ELECTRODE

IGNITION

ELECTRODE

BROWN

BLU

G/V

1619 18 17

J4 J5 J6

DETECTION

ELECTRODE

IGNIT. / DETEC.

LECTRODE

BROWN

BLUE

G/V

1619 18 17

J4 J5 J6

IGNITION

ELECTRODE

BROWN

BLUE

G/V

1619 18 17

J4 J5 J6

DETECTION

ELECTRODE

T

ION

Tw Tsp

Ts Ts

Tw Tsp

TYPE MT11

Ts

TYPE MT31

Tw Tsp Tw

Ts

Tsp

SB

VG1

SB

ION

VG1

T

PA

V

TR

TR

PA ION SB

TR

VG1

V

T

THERMOSTAT FAN AIR PRESSURE

SWITCH FIRST GAS

VALVE EXTERNAL IGNITION

DEVICE FLAME

SIGNAL

LOCK - OUT

SIGNAL

OPERATING CYCLES

4/4 3999_r01

NOTE: the limit thermostat has to be wired in series to the live

ATTENTION

-

> Company Brahma S.p.A. takes no responsibility for any damage resulting from Customer's tamp

ering with the device.

This manual suits for next models

2

Other BRAHMA Control System manuals