Braintree Scientific Learn & Repeat BS-900 User manual

Publication #1200-01 Revision 0 10/18/2012

Model: BS-900

Basic User Manual

Programmable Peristaltic Pump

“Learn & Repeat”™

“WHAT’S YOUR APPLICATION?”™

WARNING

NOT FOR CLINICAL

USE ON HUMANS

Braintree Scientific, Inc. www.braintreesci.com Model BS-900

Publication #1200-04: Page ii of 37 Revision 0.1 10/18/12

BS-900 Peristaltic Pump

Quick Start Instructions

Assumes that the pump was not previously

programmed with a multiple Phase Pumping

Program. Otherwise execute pump reset.

Plug in the pump. Use appropriate power

supply.

Press the power switch on the back of the pump

to turn on power.

Press any key to stop the display from blinking.

Setup Pumping Parameters

To Change Numbers:

Press the up arrow keys to increment individual

digits.

To set/clear the decimal point:

Simultaneously press the 2 up-arrow keys under

the 2 digits next to the decimal point position.

Press any non-arrow key, or wait for the display

to blink. The new value is entered and stored in

memory.

Peristaltic Tube ID (Inside Diameter):

Tubing diameter is pre-set to 3/16” ID. See full

instructions to change the default tubing

diameter.

Set the Pumping Rate:

Display the pumping rate by momentarily

pressing the ‘Rate’ key.

To change the pumping rate units:

Momentarily press the ‘Rate’ key again. The

display will show:

Press any up arrow key to select the next

available rate units while they blink.

Press any non-arrow key, or wait for the time

out to set the rate units.

Set the pumping rate. If the pumping rate is out

of range, the display will show:

Set the Volume to be Dispensed

or Continuous Pumping

Display the volume by momentarily pressing the

‘Volume’ key. ‘Dispensed’ LED should be off.

When the display shows , the pump

is set for continuous pumping. Pressing any up

arrow key will change the display to 0.

For continuous pumping: Set the volume to 0.

For a Volume to be Dispensed: Set the volume.

To change volume units, momentarily press the

‘Volume’ key again. The ‘Dispensed’ LED

should be lit. Use the up arrow keys to select the

volume units.

Set the Pumping Direction

When the ‘Withdraw’ LED is lit, the pump is set

for withdrawing. When not lit, the pump is set

for dispensing. Use the ‘ ’ key to change

the pumping direction.

Load the Peristaltic Tubing

Prepare new tube with two tie wraps 5 3/8”

apart, both knots facing the same direction.

Remove pump head by turning cassette

counterclockwise, Remove rotor.

Add grease to pump shaft and tubing.

Insert rotor onto Shaft, Placing tube between

Cassette and rotor. Tie Wrap knots facing

Cassette.

Install pump head to base by first, lining up rotor

and driving axle, and second applying forward

pressure and rotating cassette clockwise until it

enters its groove. Continue turning until it stops.

Prime/Purge: Press and hold the

‘Start/Stop’ key for one second. Release to

stop.

Start the Pump: Momentarily press

the ‘Start/Stop’ key to start or stop the

pump.

While Pumping

The pumping rate can be changed.

With continuous pumping, the pumping direction

can be changed.

PUMP RESET:

Press and hold the right-most up arrow key while

turning on power to the pump.

Publication #1200-04 revision V0.1 10/18/12

Selecting Dispense Programs

Multiple dispense settings can be stored and selected as needed. The last selected dispensing program will

be the default dispense program when the pump is powered on. Up to 40 dispense programs can be

stored.

To view or select the current dispense program number or to select a different program, press and hold

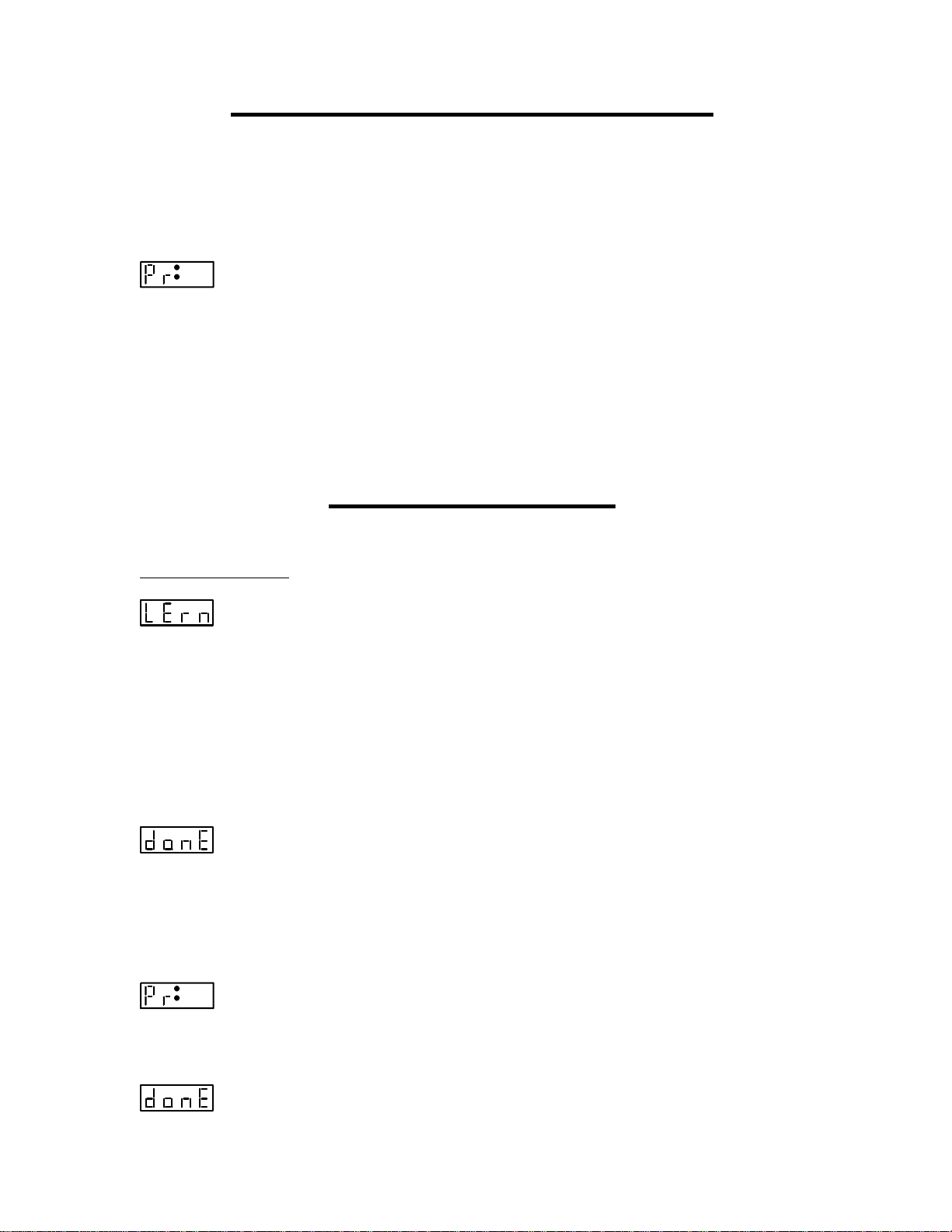

either the ‘Rate’ or ‘Volume’ key. The display will show:

nn

Where ‘nn’ indicates the currently selected dispense program. Use the arrow keys to change the dispense

program number. Press ‘LEARN’ to select, or wait for the 5 second time out. The display will blink

when selected.

Press the ‘Start’ key to immediately start the selected dispense.

Press the ‘Rate’ or ‘Volume’ keys to display the settings for the selected dispense. Any changes made to

the pumping rate or dispense volume will be stored in the selected dispense program.

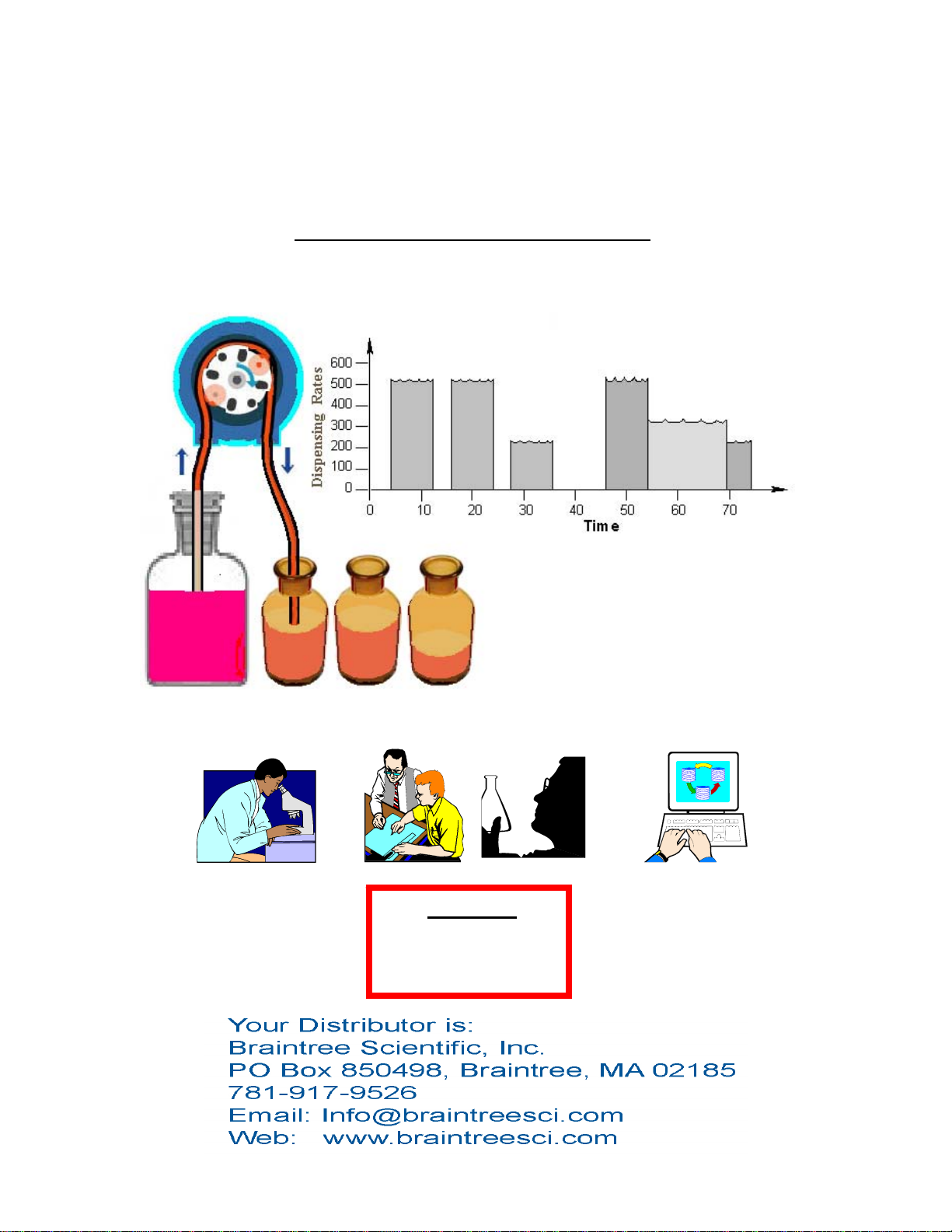

Learn and Repeat

Learn and repeat easily teaches the pump a dispense volume. Then you can immediately repeat this

dispense.

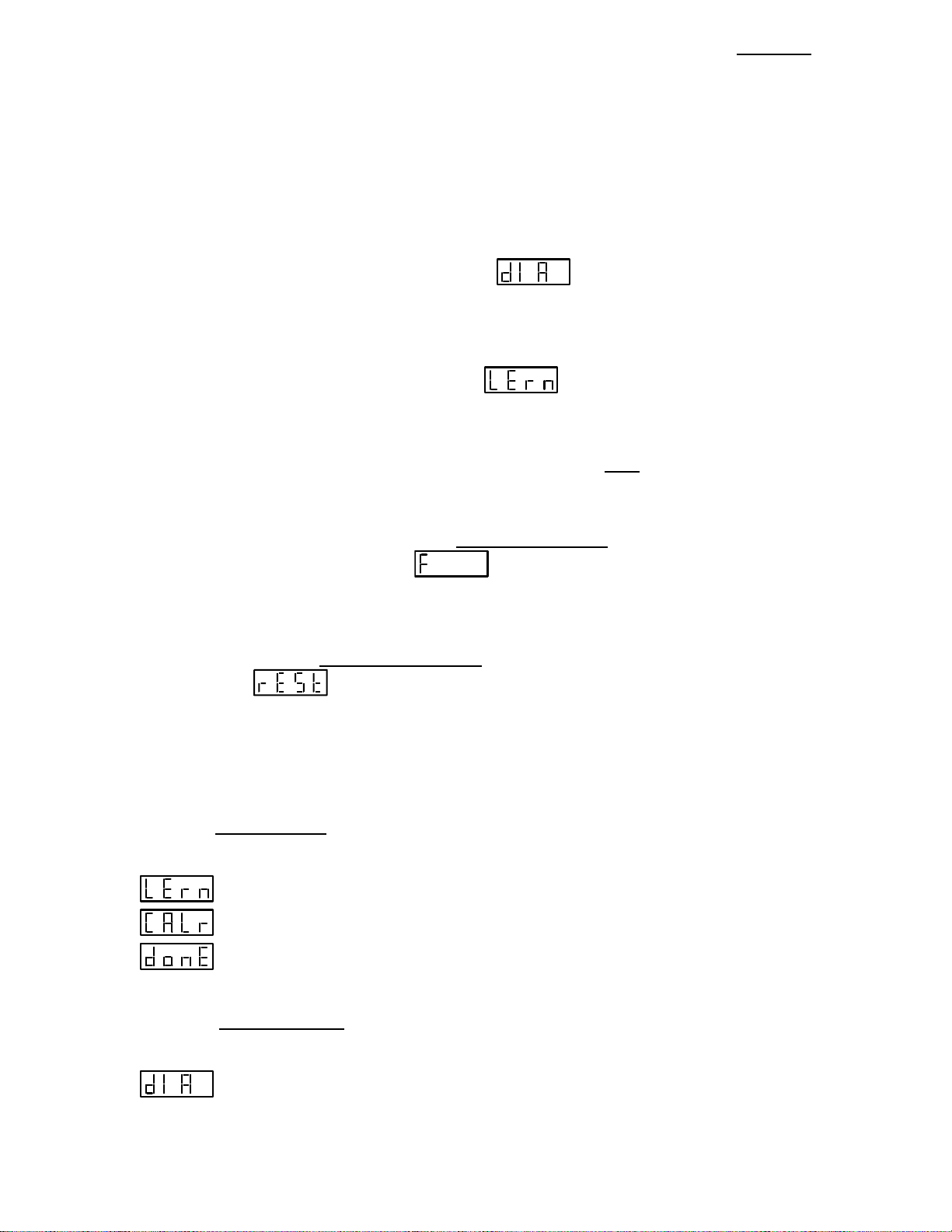

While turning on power, press and hold the ‘LEARN’ key. The display will show:

Press and hold the ‘Start’ key to begin dispensing. As the desired volume is approached, you can release

the key to stop the pump, then periodically press the ‘Start’ key to slowly and accurately approach your

dispense volume.

While pumping, the volume dispensed will be displayed. When the ‘Start’ key is released, the display will

alternate between displaying the volume dispensed and the currently selected dispense setting number.

Press the ‘LEARN’ key, or wait for the time out, to immediately store the dispensed volume in the

currently selected dispense setting. A double beep will sound and the display will show:

Press any key to return to the currently selected dispense program display.

Press ‘Start’ to immediately begin the newly learned dispensed.

The learned dispense can be stored in a different dispense setting number. After the required dispense

volume is reached, press any of the up arrow keys. The display will show:

nn

Where ‘nn’ is the crrently selected dispense setting number. Use the up arrow keys to select a different

location to store the dispense. Press the ‘LEARN’ button or wait for the time out. A double beep will

sound and the display will show:

Press the ‘Start’ button to immediate begin dispensing the learned dispense.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 iv 10/18/12

Tubing Calibration

Calibration mode fine tunes the dispense accuracy. Continued use of tubing will cause it to stretch and

deform which creates dispensing errors. Also, differing viscosities and/or pumping speeds can also affect

pumping accuracy.

Calibration uses the currently selected dispense program. Also, you will need a calibrated measuring cup

to verify the actual dispense volume.

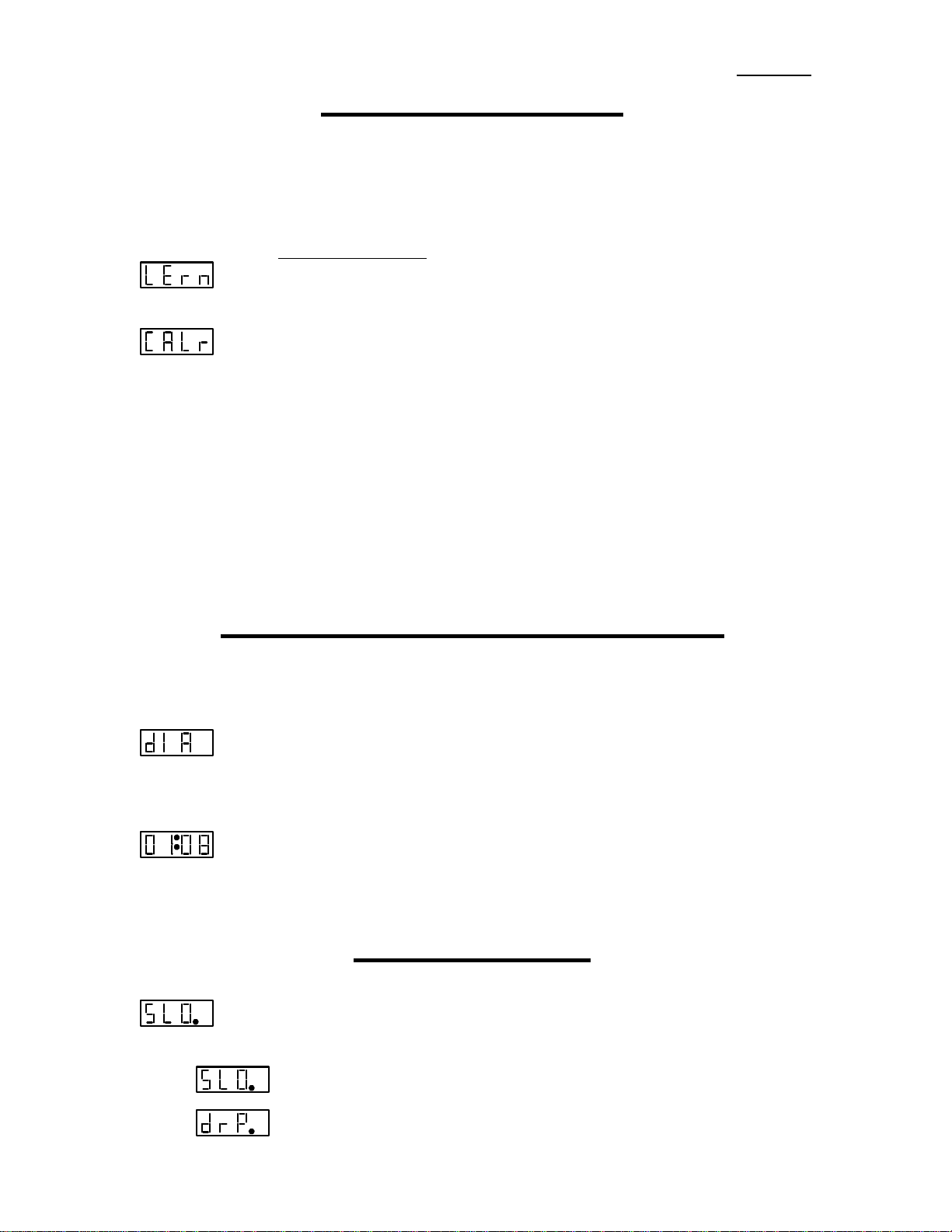

To begin calibration: While turning on power, press and hold the ‘LEARN’ key until the display shows:

Press any up arrow key for the next Learn selection: Calibration:

Press the ‘Start’ key to begin the dispense.

When the dispense is complete, the pump will stop, and the dispensed volume will be displayed with the

volume units LED blinking.

Press the ‘LEARN’ key to accept this volume, or use the up arrow keys to enter a measured dispense

volume.

Press ‘LEARN’ after the measured dispense volume has been entered.

The pump uses the entered volume to recalibrate the dispense volumes. Dispense volumes will be

adjusted according to the measured volume entered.

Tubing Inside Diameter Setting

For most applications, the default tubing inside diameter does not need to be changed since the pumping

head is optimized for 3/16” inside diameter (ID) tubing.

If needed, to change the tubing diameter setting, enter Diameter Setting mode:

While turning on power, press and hold the ‘Diameter’ key until the display shows:

Press the ‘DIAMETER’ key again to select. The display will show the current diameter and the ‘mm’

units LED will blink. While the units LED is blinking, use the up arrow keys to enter the new diameter.

For example, to enter 1/8” id tubing, use the up arrow keys to change the display to:

Press the ‘LEARN’ key, or wait for the time out to enter the new setting. The tubing diameter will now

be set to the new setting. The new diameter will be used as the current calibration setting.

Special Modes

Press and hold the ‘Diameter’/’Setup’ key to access the Special Modes setup menu The first mode,

“Slow-Down” will be displayed:

n

Press the’LEARN’ key to move to the next mode, or wait for the time out. The following is the sequence

of diplays:

n Slow Down mode, where ‘n’ is the current setting.

n Anti-Drip mode, where ‘n’ is the current setting.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 v10/18/12

n Dispense and pause mode, where ‘n’ is the current setting.

nn When pasue mode is enabled, displays the pause setting.

Display secondary setup menu: Press any up arrow key to select.

Slow Down Mode

n Setting: ‘0’ = Disabled, ‘1’ = Enabled.

Slow-Down mode prevents over dispensing when pumping a large volume at a high speed. When

enabled, the pumping speed will ramp down as the volume dispensed approaches the target dispense

volume.

Anti-Drip Mode

n Setting: ‘0’ = Disabled, ‘1’ = Enabled.

When enabled, Anti-Drip mode will withdraw a small volume after the completion of a dispense to

prevent dripping or oozing when the pump stops. The volume withdrawn is added to the next dispense.

Dispense, Pause, Repeat Mode

n Setting: ‘0’ = Disabled, ‘1’ = Enabled.

When enabled, will create a more automated dispensing system, whereby the pump will continuously

repeat the current dispense after a fixed time delay. The time delay will be displayed next:

nn

Where ‘nn’ is the pause time in seconds. Use the arrow keys to change the dispense time.

Advanced Settings Menu

The “Other” menu selection provides access to the additonal settings menu.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 110/18/12

Table of Contents

1. GENERAL INFORMATION...........................................................................................3

1.1. SAFETY............................................................................................................................3

1.2. DISCLAIMER....................................................................................................................4

1.3. WARRANTY .....................................................................................................................4

1.4. PACKING LIST.................................................................................................................5

2. OVERVIEW ......................................................................................................................5

2.1. GLOSSARY OF TERMINOLOGY AND CONCEPTS............................................................4

3. SETUP................................................................................................................................5

4. LOADING PERISTALTIC TUBING.............................................................................6

4.1 REMOVE TUBING FROM PUMP............................................................................................6

4.2. INSTALL NEW TUBING........................................................................................................7

5. PERISTALTIC TUBING.................................................................................................8

6. USER INTERFACE..........................................................................................................8

6.1. ENTERING VALUES.........................................................................................................8

6.2. LCD DISPLAY .................................................................................................................9

6.3. LEDS...............................................................................................................................9

6.4. ARROW AND DECIMAL POINT KEYS .............................................................................9

6.4.1. DECIMAL POINT KEY..............................................................................................10

6.5. ‘DIAMETER’AND ‘SETUP’KEY....................................................................................10

6.6. ‘RATE’AND ‘LEARN /PROGRAM PHASE #’ KEY........................................................10

6.6.1. PUMPING RATE UNITS ............................................................................................10

6.6.2. PROGRAM ENTRY MODE OR DISPENSE SELECTION................................................11

6.7. ‘VOLUME’AND ‘PROGRAM FUNCTION’KEY .............................................................11

6.7.1. DISABLING “VOLUME TO BE DISPENSED”..............................................................11

6.7.2. CLEARING “VOLUME DISPENSED” .........................................................................11

6.7.3. VOLUME UNITS.......................................................................................................11

6.7.4. PROGRAM ENTRY MODE ........................................................................................11

6.8. PUMPING DIRECTION KEY...........................................................................................12

6.9. ‘START’/’STOP’KEY ....................................................................................................12

6.10. DISPENSE SELECTION...............................................................................................12

6.11. ‘SETUP’KEY..............................................................................................................12

6.12. SPECIAL SETUP KEY.................................................................................................13

6.13. LEARN KEY ...............................................................................................................13

6.14. SPECIAL POWER-UP FUNCTIONS.............................................................................13

6.14.1. FIRMWARE VERSION DISPLAY............................................................................13

6.14.2. RESET THE PUMP.................................................................................................13

6.14.3. LEARN AND CALIBRATE SELECTION...................................................................13

6.14.4. SPECIAL SETUP....................................................................................................13

6.15. ERROR AND ALARM MESSAGES...............................................................................14

6.16. STATUS MESSAGES ...................................................................................................14

7. OPERATION...................................................................................................................15

7.1. PERISTALTIC TUBE INSIDE DIAMETER .......................................................................15

7.1.1. CHANGING VOLUME UNITS....................................................................................15

7.2. STORED DISPENSE SELECTIONS ..................................................................................15

7.3. START/STOP TRIGGERS................................................................................................15

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 210/18/12

7.4. OPERATING THE PUMP.................................................................................................16

7.5. PRIME AND PURGING....................................................................................................16

7.6. CHANGING THE PUMPING RATE AND DIRECTION WHILE PUMPING........................16

7.7. VOLUME DISPENSED.....................................................................................................16

7.8. RESUMING WHEN PAUSED...........................................................................................17

8. LEARN AND REPEAT ..................................................................................................17

9. CALIBRATION ..............................................................................................................18

10. SETUP CONFIGURATION ..........................................................................................18

10.1. SLOW DOWN MODE..................................................................................................19

10.2. ANTI-DRIP MODE......................................................................................................19

10.3. DISPENSE,PAUSE,REPEAT MODE ...........................................................................20

10.4. ADVANCED SETTINGS MENU....................................................................................20

10.5. POWER FAILURE MODE ...........................................................................................20

10.6. AUDIBLE ALARM ENABLE........................................................................................20

10.7. TTL I/O OPERATIONAL TRIGGER CONFIGURATION .............................................20

10.8. TTL I/O DIRECTIONAL CONTROL INPUT CONFIGURATION..................................21

10.9. PUMP MOTOR OPERATING TTL OUTPUT CONFIGURATION .................................21

10.10. KEYPAD LOCKOUT ...................................................................................................21

10.11. KEYPAD BEEP ENABLE.............................................................................................22

10.12. RS-232 PUMP NETWORK CONFIGURATION ............................................................22

10.13. SET TUBING INSIDE DIAMETER SETTING................................................................22

10.14. SET DISPENSE MODE ................................................................................................23

10.15. SET PROGRAM MODE LOCKOUT .............................................................................23

10.16. EXIT SPECIAL SETUP MENU ......................................................................................23

11. PUMPING PROGRAM..................................................................................................23

12. RS-232 COMMUNICATIONS.......................................................................................23

13. LOGIC INTERFACE: TTL INPUT AND OUTPUT .................................................23

13.1. TTL I/O OPERATIONAL CONTROLS........................................................................25

13.2. TTL I/O CONTROL FROM THE PUMPING PROGRAM..............................................26

13.3. TTL I/O CONTROL FROM RS-232 ...........................................................................26

14. APPENDIX ......................................................................................................................26

14.1. RS-232 COMMAND SUMMARY .................................................................................26

14.2. RS-232 PUMP NETWORK CONNECTOR WIRING.....................................................27

14.3. ACCESSORIES ............................................................................................................28

14.3.1. ANA-BOX..........................................................................................................28

14.3.2. RS-232 NETWORK CABLES.................................................................................28

14.3.3. AUTOMATION CABLE:DUAL PUMPS CONTROL CABLE.....................................28

14.3.4. VALVE CONTROLLER..........................................................................................28

14.3.5. FOOT SWITCH......................................................................................................28

14.3.6. LOCKOUT DISABLE KEY .....................................................................................28

14.3.7. FIRMWARE UPGRADE..........................................................................................29

14.4. TROUBLESHOOTING AND MAINTENANCE ...............................................................29

14.5. SPECIFICATIONS........................................................................................................29

14.5.1. MECHANICAL &ELECTRICAL.............................................................................29

14.5.2. OPERATIONAL .....................................................................................................29

14.6. CUSTOM APPLICATIONS...........................................................................................30

14.7. TUBE CHEMICAL CHARACTERISTICS......................................................................30

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 310/18/12

1. General Information

Thank you for purchasing the BS-900 Programmable Peristaltic Pump. With the BS-900 peristaltic pump

you will be able to perform simple fluid dispensing or implement a complex automated dispensing system.

Please familiarize yourself with the BS-900’s operation by reading this user's manual. For future

reference, record the serial number, located on the rear of the pump, and the date of purchase.

Serial Number ____________________, Date of Purchase ___________________________,

This Operating Manual, and the BS-900’s hardware, electronics and firmware are copyrighted.

Copyright 1999-2010, all rights reserved.

1.1. Safety

In the interests of safety, this pump and the tubing selected should only be installed and used by

competent, suitably trained personnel after they have read and understood this manual, and considered any

hazards involved.

Markings & Symbols

The following are the meanings of the markings and symbols used in these Safety Precautions.

!

Warning This symbol indicates information that, if ignored or applied incorrectly, creates

the possibility of death or serious personal injury. i.e. fire, explosion.

!

Caution This symbol indicates information that, if ignored or applied incorrectly,

possibility of minor or moderate personal injury or property damage.

!

Warning

Read the user’s manual

This product is designed for liquid only.

User is responsible to determine the suitability of the pump to its desired function.

Verify that tubing is appropriate for liquid being pumped.

Disconnect power from the pump when replacing tubing or connecting or disconnecting cables.

Never leave any dangerous liquid inside of tubing when replacing tubing and disposing pump. Remaining

liquid may cause serious injury.

Never use in atmosphere with flammable gas.

Never use in any location where there is a possibility of high humidity, high temperature, or extreme dust.

Use only with the supplied power supply connected to a power source as specified on the power supply

label.

Never use a voltage that is different from voltage specified in this manual. Unless Authorized by NEW

ERA PUMP SYSTEMS INC.

Do not operate with any foreign matter (water, dirt, metal or other materials) inside the Pump-head.

Do not push objects of any kind into the chassis openings, except for appropriate cables and connectors.

Never try to take the unit apart or modify it except as described in this manual or authorized by NEW

ERA PUMP SYSTEMS INC.. No user serviceable parts inside.

Do not immerse the pump in liquid. If spilling occurs unplug pump immediately.

Install on a stable surface.

The pump can automatically start when the Pumping Program is operating or when attached to an

external control device.

Prevent liquids from entering openings in the rear of the pump.

If the pump becomes damaged, do not use unless certified safe by a qualified technician. Damage

includes, but is not excluded to, frayed cords and deterioration in performance.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 410/18/12

!

Caution

Do not transport and store this product where the temperature and the humidity are high or fluctuate

greatly, or the product is subjected to direct sunlight.

Remove tubing from pump when not in use. Tubing will become deformed changing dispensed volume

per rotation.

Tubing wall may become permanently damaged if the roller compresses the same part of the tubing for

a long time.

During installation and use, be careful not to cut yourself on the edge of the Pump parts.

Tubing life depends upon chemical and operating environment.

Tubing Chemical compatibility list mentioned is only a guide. The user is responsible to determine the

tubing compatibility to the chemical to be used.

Keep delivery and suction lines as short as possible, use a minimum number of bends.

Pump operates best at medium speeds. At very slow speeds pump will get hot. At high speeds pump

and tubing life will decrease, pump will lose force/ pressure and may stall.

Run at slow speed and use larger diameter tubing when pumping viscous liquid.

User is responsible to determine the maximum speed the pump can operate.

Discharge static from control cables before connecting by touching the cable to ground.

Before touching the pump, discharge static by touching ground.

1.2. Disclaimer

NEW ERA PUMP SYSTEMS INC. makes no representations or warranties, expressed, statutory or

implied, regarding the fitness or merchantability of this product for any particular purpose. Further, NEW

ERA PUMP SYSTEMS INC. is not liable for any damages, including but not limited to, lost profits, lost

savings, or other incidental or consequential damages arising from ownership or use of this product, or for

any delay in the performance of its obligations under the warranty due to causes beyond its control. NEW

ERA PUMP SYSTEMS INC. reserves the right to make any improvements or modifications to the

product described in this manual at any time, without notice.

Design and specifications are subject to change without notice.

The information contained in this document is believed to be correct but NEW ERA PUMP SYSTEMS

INC. accepts no liability for any errors it contains, and reserves the right to modify this document without

notice.

NEW ERA PUMP SYSTEMS INC. products are not designed, intended, or authorized for use in

applications or as system components intended to support or sustain human life, as a clinical medical

device for humans, or for any application in which the failure of the product could create a situation where

personal injury or death may occur.

All brand and product names used in this manual are the trademarks of their respective owners.

1.3. Warranty

NEW ERA PUMP SYSTEMS INC. warranties this product and accessories for a period of two year, parts

and labor, from the date of purchase. The repaired unit will be covered for the period of the remainder of

the original warranty or 90 days, whichever is greater.

The Peristaltic Pump Head Assembly and peristaltic tubing are considered replaceable items and are not

covered under overall product warranty.

A return authorization number must be obtained from NEW ERA PUMP SYSTEMS INC. before

returning a unit for repair. Warranty covered repairs will not be performed without a return authorization

number. At the option of NEW ERA PUMP SYSTEMS INC., a defective unit will be either repaired or

replaced.

This warranty does not cover damage by any cause including, but not limited to, any malfunction, defect

or failure caused by or resulting from unauthorized service or parts, improper maintenance, operation

contrary to furnished instructions, shipping or transit accidents, modifications or repair by the user, harsh

environments, misuse, neglect, abuse, accident, incorrect line voltage, fire, flood, other natural disasters,

or normal wear and tear. Changes or modifications not approved by NEW ERA PUMP SYSTEMS INC.

could void the warranty.

The foregoing is in lieu of all other expressed warranties and NEW ERA PUMP SYSTEMS INC. does not

assume or authorize any party to assume for it any other obligation or liability.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 510/18/12

1.4. Packing List

Included with the BS-900 Programmable Peristaltic Pump are the following items:

One of the following external unregulated power supply adapters:

Input: One of: 120V AC 60 Hz, 220V AC 50 Hz, 240V AC 50 HZ,

or other custom specified power supply

Output: 24V DC @ 1A

4 feet of Norprene A-60-G®tubing.

4 tie wraps (2 assembled).

0.5oz sample of Super-Lube®.

This Operating Manual

2. Overview

The BS-900 is a general purpose single peristaltic pump capable of dispensing and withdrawal. It is

controlled from a microcontroller based system which drives a step motor, allowing a wide range of

pumping rates configured to the inside diameter of the peristaltic tube.

Features:

Dispense and withdrawal pumping

Pumping rates from 0.041 ml/min to 904.4

ml/min with a 3/16 ID tubing. Depending

on tube characteristics.

Dispense and withdrawal volumes

separately accumulated.

Programmable dispense volumes.

Non-volatile memory of all operating

parameters and Pumping Program.

Programmable Phases allowing complex

pumping applications and interaction with

external devices.

RS-232 bi-directional control.

Built-in pump network driver. Pump

network supports up to 100 pumps and

other devices.

Two modes of RS-232 control, Basic and

Safe. Safe mode provides communication

error detection, loss of communication

detection, and automatic transmitting of

alarm conditions.

TTL I/O with software filtered control

inputs to eliminate glitches and ringing on

the control inputs.

Configurable TTL operational trigger.

Power Failure Mode: Restarts the Pumping

Program after a power interruption.

Audible Alarm.

Many more features!

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 4

2.1. Glossary of Terminology and Concepts

When a device has as many features as the BS-900, understanding its operation could be a daunting task at

first. By understanding the key concepts and terminology used in this manual, the operation of the BS-

900 will become quite intuitive. Every effort has been made to design the BS-900 with a consistent and

intuitive user interface.

To facilitate and enhance your understanding of the BS-900’s operation, please take the time to familiarize

yourself with the basic concepts below:

Fig 1. Pump Head Assembly

Terminology

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 5

Momentar

y

Press: A quick press, less then 1 second, then release of a key on the keypad.

Dis

p

la

y

Blink: A momentary blanking of the LCD display. This indicates that the new data

entered by the user is valid and has taken affect.

Pum

p

in

g

Pro

g

ram

Operating: When the pump is started with the ‘Start’/’Stop’ key, or any other source, the

pump begins performing the operations in the Pumping Program until the

Pumping Program either stops automatically or the pumped is stopped when

the ‘Start/Stop’ key is pressed, or from any other source. While performing

the operations defined in the Pumping Program, the Pumping Program is

referred to as operating.

While Operating, the motor can be pumping or stopped, according to the

Pumping Program.

Pum

p

in

g

Pro

g

ram

Stopped:

The motor is stopped and the pump is not operating the Pumping Program.

Pum

p

in

g

Pro

g

ram

Paused:

The Pumping Program has been stopped, but can be resumed at the point

where it was stopped.

Pum

p

in

g

Pro

g

ram

Resumed: Continuing a Pumping Program that was Paused before the completion of the

Pumping Program. The Pumping Program continues at the point where the

Pumping Program was stopped.

Executed: The pump has performed a single operational Phase as defined in the

Pumping Program.

Start Tri

gg

er: The Pumping Program may be started, or stopped, from multiple sources.

These are the keypad’s ‘Start’/’Stop’ key, the TTL I/O ‘Operational Trigger’

input, or from a command received through the RS-232 connection.

3. Setup

Place the pump on a stable surface.

Plug the round connector end of the supplied power supply adapter into the power plug located on the

lower right of the pump's rear. See section 13, Logic Interface: TTL Input and Output, for a diagram

of the rear of the pump. Plug the other end of the power supply adapter into an appropriate electrical

outlet. The pump will be powered when the bottom of the power switch, located on the upper right of

the rear of the pump, labeled ‘1’, is pressed. The red indicator on the switch is visible when the

power switch is in the ‘on’ position. After power is applied to the pump, the pump’s display will

flash.

Next the Pumping Program can be entered. Before the Pumping Program can be operated, the pump

needs the measurement of the peristaltic tube inside diameter. The peristaltic tube inside diameter can

be entered using the keypad. Refer to ‘Diameter’ and ‘Setup’ Key.

Finally, the peristaltic tube can be loaded and the pump started.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 6

4. Loading Peristaltic Tubing

!

Remove tubing from pump when not in use. Tubing will become

deformed changing dispensed volume.

4.1 Remove Tubing from Pump

4.1.1. Remove liquid from tubing.

1) Turn on power to the Pump.

2) Press and hold Start/Stop and purge out fluid in Tubing.

3) Remove tubing from liquid.

4) Turn off power to the pump.

!

Warning: Liquid will siphon through tubing when it is removed from pump.

!

Warning: Dangerous Liquid in the tubing may cause injury.

4.1.2. Uninstall Cassette

Turn Cassette counterclockwise until it stops. Then pull it out.

4.1.3. Remove Tubing

1. Remove one side of peristaltic tubing from Cassette.

2. Pull out Tubing. Hold rotor from falling.

3. Remove the other side of tube from Cassette.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 7

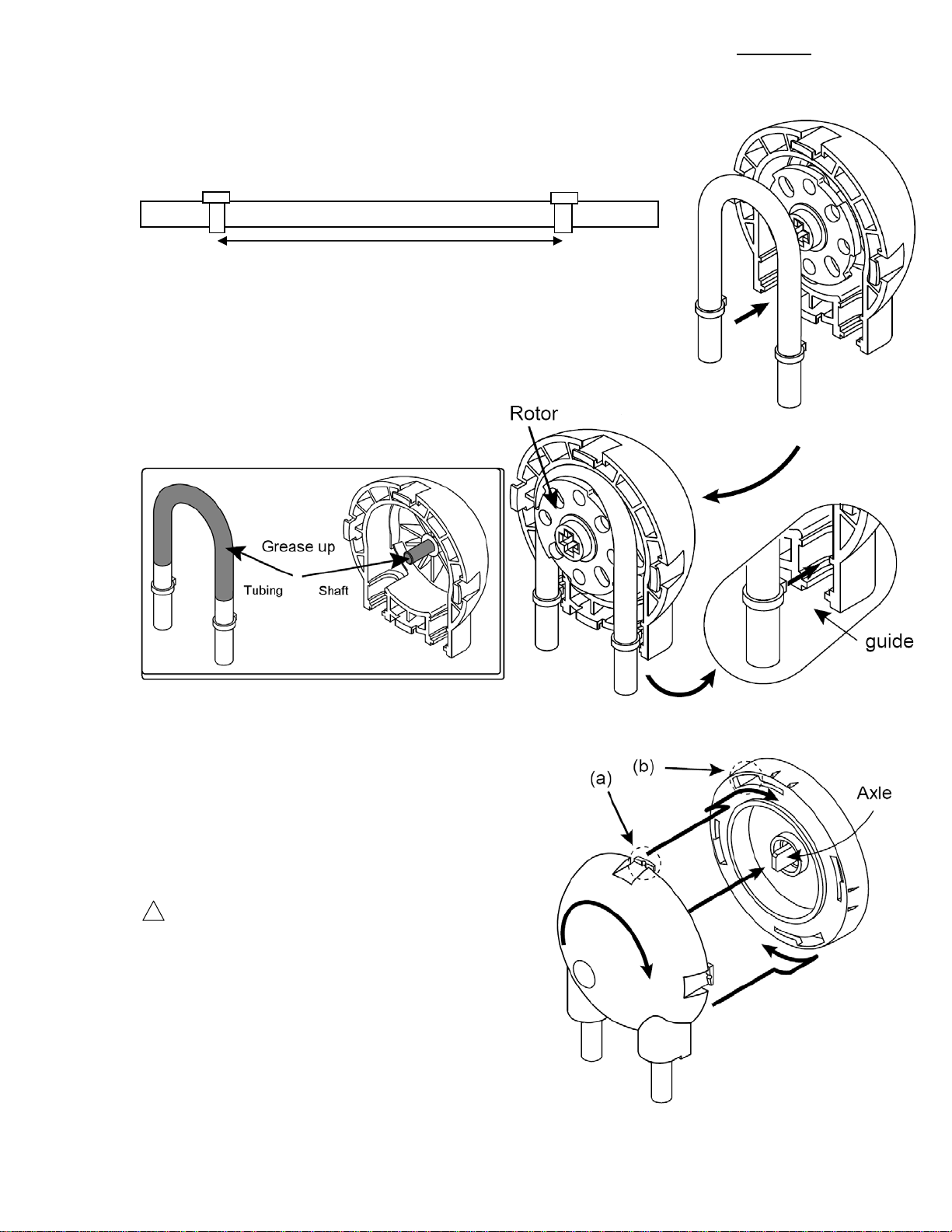

4.2. Install New Tubing

4.2.1. Prepare New Tubing

1) Wrap 2 tie wraps 5 3/8” apart (136 millimeters apart) on the new Tubing.

Tie wrap knots facing the same direction

4.2.2. Install New Tubing

2) Remove Rotor

3) Add grease to the Cassette shaft and the surface of New Tubing.

( See gray area below )

4) Return Rotor to shaft of Cassette.

5) With both knots of the tubing facing the

Cassette install one knot into the guide.

6) Pull out the Rotor a little bit and place

Tubing between the Cassette and the Roller.

7) Install the other knot into the guide.

4.2.3. Install Cassette to Base

1) Rotate Rotor so that it fits into axle.

2) Attach Cassette onto Base of Pump by

placing (a) into (b).

3) Turn Cassette clockwise until it stops.

Verify that each indent of the Cassette is

matched perfectly with each marking on

the Base of Pump.

4) Prime Pump before Starting Dispense

Cycle.

!

Warning

Be careful not to be cut or injured

by the edge of the Pump parts.

5 3/8”

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 8

5. Peristaltic Tubing

Refer to last section of this Manual for tubing recommendations.

If you intend to use a long extension of tubing it is recommended that you (move the segment)

change the segment that is used in the pump regularly.

Be aware that the tubing will wear out because of friction. The rotating mechanism will also

wear out because of friction. Always lubricate rollers, shaft and tubing.

Note: The following flow rates and volumes are adjusted accordingly when the pump is

calibrated.

Tube Size Approximate Volume Dispensed Flow Rate (mL/min)

ID X OD [in] Per 1 revolution Maximum Minimum

3/16 X 5/16 2.434 mL (0.0822 US fl.oz) 904.4 0.041

1/8 X 1/4 1.211 mL (0.0379 US fl.oz) 416.6 0.019

3/32 X 7/32 0.642 mL (0.0217 US fl.oz) 238.4 0.011

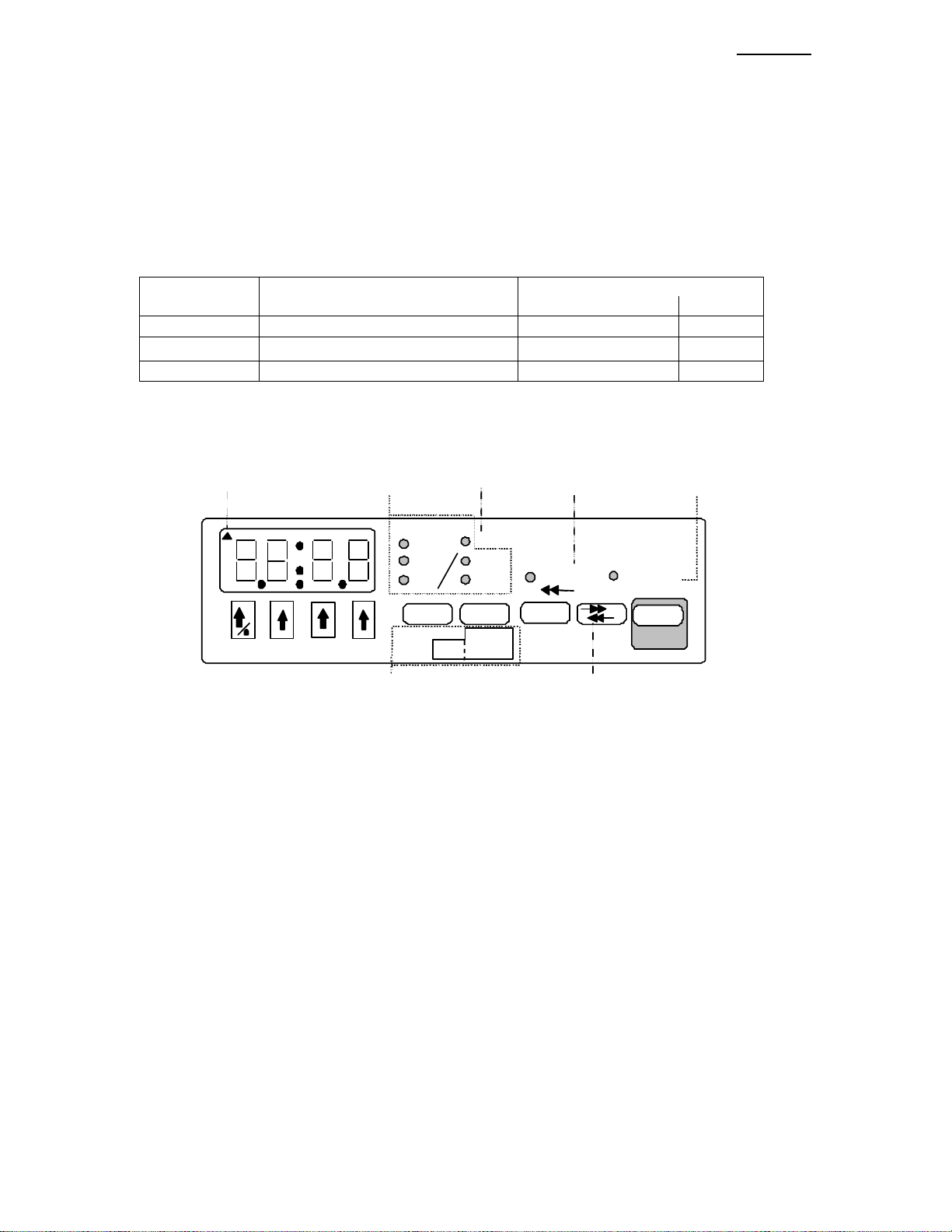

6. User Interface

Tubing ID

Inches Dispensed

mL Withdraw

min

Sec Pumping

Rate Volume Diameter Start

Program

Ph as e #

Program

Function Setup

Oz

RS-232

Indicator Units

Indicators Pumping Direction

Indicator

Volume Dispensed

Indicator

Stop

Motor

Operating

Program Entry Functions Pumping Direction Key

:

Learn

Figure 1: Front Panel

6.1. Entering Values

When applicable, values can be changed by either displaying the current value, then using the arrow keys,

or from a computer connected to the pump. The new value will be stored in the pump’s non-volatile

memory, meaning that the new value will not be lost the next time that power is applied to the pump. The

only exception is when the pumping rate is changed from an attached computer while the Pumping

Program is operating. In this case the new pumping rate will not be stored in non-volatile memory.

A displayed value can be changed by pressing the arrow keys below each digit. If the value to be changed

is not currently displayed, when applicable, press the key associated with the required value. The display

will show the setting’s current value and its units, if any.

While the current value is being changed, the units LEDs associated with the value, if any, will blink.

Except where noted, the new value is stored, and/or the selected operation takes affect, when either

If the new value is valid and different from the original value, the display will blink, indicating that the

new value was stored. Otherwise, if the value was invalid, an error message will be displayed. Pressing

any key clears the error message and restores the original value.

In general, if a parameter has 2 values, ‘off’ and ‘on’, they are represented by the numbers ‘0’ and ‘1’,

respectfully.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 9

6.2. LCD Display

The display consists of a 4 digit reflective LCD (Liquid Crystal Diode) display. This is the general

purpose user display device for displaying numerical data, functions and parameters. The colon (:) is used

for displaying time or for separating function abbreviations from their parameter values. In the upper left

corner is a triangle that indicates valid reception of RS-232 remote communications.

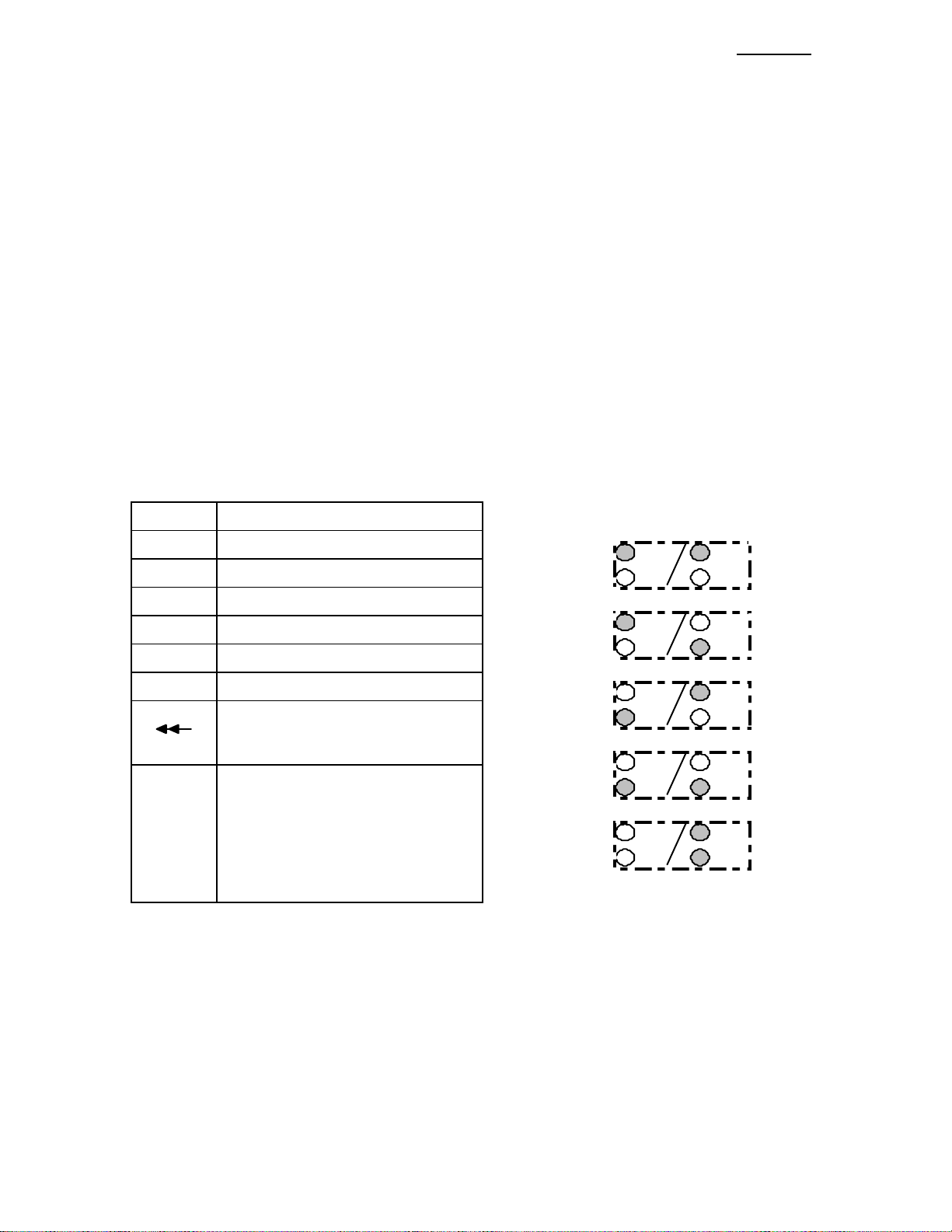

6.3. LEDs

To the right of the LCD are 8 red, round, LED (Light Emitting Diode) indicators. The first 2 columns

display the units of the displayed values. Units are expressed using 1 or 2 LEDs. For instance, ‘ml / Sec’

is expressed by lighting the ‘ml’ and the ‘Sec’ LEDs.

‘Dispensed’ indicates that the displayed volume is the total ‘Volume Dispensed’ or pumped.

When ‘Pumping’ is lit (not blinking), the motor is operating, either dispensing or withdrawing. If

blinking, the motor is not operating, and the Pumping Program is paused. When the pump is restarted, the

Pumping Program will resume at the point where the Pumping Program was interrupted. When not lit

(not blinking) the pump is stopped, but the Pumping Program may be operating a pause Phase. Starting

the pump, when the Pumping Program is stopped, will start the Pumping Program from the beginning

(Phase 1).

‘Withdraw’ indicates that the pumping direction is set for withdrawing. If not lit, then the pumping

direction is set for dispensing. Also, the ‘Withdraw’ LED indicates that the “Volume Dispensed” refers to

the volume withdrawn. If not lit, the “Volume Dispensed” refers to the volume dispensed.

LED Description

Inches Tubing inside diameter in inches

mL Milliliters

min Minutes

Oz Ounces

sec Seconds

Dispensed Volume dispensed displayed

Withdraw Pumping Direction:

Lit: Withdraw

Not lit: Dispense

Pumping Lit: Motor is operating

Blinking: The Pumping Program is

paused

Not lit: The Pumping Program is

stopped or executing a pause

Phase

6.4. Arrow and Decimal Point Keys

Each of the four digits in the display is associated with the up arrow key directly below it. When

applicable, the arrow key is used to increment the value of that digit, or advance to the next selection in a

list of functions or settings.

Each press of an up arrow key will increase the digit by 1, up to 9, and then back to 0. The arrow keys

may also be held down for continuous incrementing of numbers. Some parameters, such as the RS-232

baud rate, scroll through a selection of values when the arrow keys are pressed. Other parameters have a

fixed range of values, such as some setup parameters that are either turned on or off. In these cases, the

arrow key will only scroll up to the maximum value for that parameter, then back to the minimum value.

P

umping rate units are expressed using 2 LEDs:

‘ml/min’ =

mL min

Sec

Oz :

‘ml/sec’ =

mL min

Sec

Oz :

‘Oz/min’ =

mL min

Sec

Oz :

‘Oz/Sec’ =

mL min

Sec

Oz :

‘min:sec’ =

mL min

Sec

Oz :

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 10

When changing the pumping rate units, each press of any arrow key will change the units LEDs to the

next units selection.

When the display blinks, the new value is stored and takes affect. This will occur when a non-arrow key

is pressed or after a 2 second delay since the last key press.

6.4.1. Decimal Point Key

There are 4 decimal point positions on the LCD display. Each decimal point position is to the right of a

digit in the display. The last decimal point position, to the right of the right-most digit is not displayed,

indicating whole numbers with no decimal point.

To move the decimal point, simultaneously press the 2 up arrow keys under the 2 digits next to the

decimal point position. Press the same 2 up arrow keys to clear the decimal point, to display a whole

number.

Alternatively, to move the decimal point position, use the left-most arrow key / decimal point key (/).

Press and hold this key for at least 1 second and wait until the left-most digit scrolls past ‘9’ to ‘0’. While

continuing to hold this key, the decimal point will shift 1 position to the right. After the right-most

decimal point position, the decimal point will shift to the first decimal point position. Release the key

when the decimal point is in the required position.

6.5. ‘Diameter’ and ‘Setup’ Key

The ‘Diameter’ key allows the peristaltic tube inside diameter to be viewed and set. While being

displayed, the ‘Tubing ID Inches’ LED is lit. The diameter can be changed by holding the ‘Diameter’ key

while turning on power, then selecting ‘DIA’.

If the ‘Diameter’ key is pressed and held, ‘Setup’ mode will be entered. (see sec. 6.11, ‘Setup’ ).

When the Pumping Program is operating, pressing this key will display the current peristaltic tube

diameter for review. When the key is released, the display returns to its previous display.

The diameter is displayed as a fraction: 03:16 indicates 3/16” ID tubing.

6.6. ‘Rate’ and ‘Learn / Program Phase #’ Key

When the Pumping Program is stopped, except in “Program Entry Mode”, the ‘Rate’ key allows the

pumping rate to be viewed or changed. If the currently selected function allows selection of rate units,

momentarily pressing this key will switch between the ‘Rate’ display and the select rate units mode.

To change the pumping rate displayed, use the arrow keys.

While the Pumping Program is operating, pressing this key will display the current pumping rate, if

applicable. After the key is released, the pumping rate will continue to be displayed for 2 seconds. While

displayed, the current pumping rate can be changed by pressing the arrow keys. The rate units will blink

while the rate is being changed. The new pumping rate takes effect when the display blinks after a 2

second delay or when a non-arrow key is pressed. The new pumping rate is stored in the current Program

Phase.

A pumping rate of 0.0 will stop the pump. When the pumping rate is changed, if it is out of range of the

pumping rate limits, the display will show nn , where ‘nn’ indicates the currently selected Phase

Number. Pressing any key clears the message and returns to the previous pumping rate. See section 14.7,

“Tube Chemical Characteristics”, for a list of minimum and maximum pumping rates.

6.6.1. Pumping Rate Units

The pumping rate units can only be changed when the Pumping Program is not operating. If the currently

selected function allows selection of rate units (‘RATE’ function), a momentary press of the ‘Rate’ key

will enter Rate Units Change mode. The 2 LEDs representing the units will blink and the display will

show: .

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 11

Each press of any arrow key selects the next rate units, as indicated by the blinking units LEDs. When the

required rate units are blinking, press any non-arrow key or wait 2 seconds. The display will blink,

indicating the rate units are stored. The rate units are stored in the currently selected Program Phase. The

rate units can be independently set for each Phase with a ‘RATE’ function.

6.6.2. Program Entry Mode or Dispense Selection

While the Pumping Program is stopped, pressing and holding the ‘Rate’ key will enter “Program Entry

Mode” or “Dispense Selection Mode”.

If Dispense mode is enabled, the display will show the currently select dispense: nn

Otherwise, the current Program Phase number is displayed: nn

‘nn’ indicates the currently selected dispense or Program Phase.

A momentary press of the Rate or Volume key will exit return to the rate or volume display.

6.7. ‘Volume’ and ‘Program Function’ Key

When the Pumping Program is stopped, except in “Program Entry Mode”, momentary presses of this key

will switch the display between the “Volume to be Dispensed” and the “Volume Dispensed” displays, as

indicted by the ‘Dispensed’ LED.

While display “Volume to be Dispensed”, use the up arrow keys to enter a new value. Enter 0.0 to disable

the “Volume to be Dispensed” for continuous pumping. The new value is stored in the current Program

Phase or selected dispense.

If the “Volume to be Dispensed” is disabled, pressing any arrow key will change the display to 0.0. The

“Volume to be Dispensed” can now be set using the arrow keys.

While pumping, pressing and holding this key will display the current “Volume to be Dispensed”.

6.7.1. Disabling “Volume to be Dispensed”

To disable the “Volume to be Dispensed”, i.e. continuous pumping, set the “Volume to be Dispensed” to

0.0. After being stored, the display will show , indicating the “Volume to be Dispensed” is

off. In this mode, the pump will not stop at a set volume and will pump continuously until the pump is

stopped, or an “event trigger”, programmed into the Pumping Program, occurs.

6.7.2. Clearing “Volume Dispensed”

While displaying the “Volume Dispensed”, pressing and holding any up arrow key for one second will

reset the dispense and withdrawal dispensed volumes to 0.

Pressing any arrow key while displaying the “Volume Dispensed” will enter the “Set Volume Units”

mode.

6.7.3. Volume Units

With the Pumping Program stopped, and the “Volume Dispensed” displayed, as indicated by the

Dispensed LED, the volume units can be changed. Momentarily press any up arrow key. The display will

show and the volume units will blink.

Press any up arrow key to change the volume units. Wait for the time out or press any non-arrow key to

enter the setting.

NOTE: Changing the volume units changes the units for all dispenses and Program Phases.

6.7.4. Program Entry Mode

While the Pumping Program is stopped, pressing and holding the ‘Volume’ key will enter “Program Entry

Mode” or “Dispense Selection Mode”.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 12

If Dispense mode is enabled, the display will show the currently select dispense: nn , where ‘nn’

indicates the currently selected dispense.

Otherwise, the current Program Phase function is displayed: nn

“Program Entry Mode” can be entered by pressing and holding the ‘Rate’ key. Release the key when the

display shows the current Program Phase number:, where ‘nn’ indicates the current Program Phase

number.

A momentary press of the Rate or Volume key will exit return to the rate or volume display.

6.8. Pumping Direction Key

The pumping direction key, ‘ ’, changes the direction of pumping. Pressing this key switches the

pumping direction between ‘dispense’ and ‘withdraw’, as indicated by the ‘Withdraw’ LED. When the

LED is lit, the pumping direction is ‘withdraw’, otherwise the pumping direction is ‘dispense’. The new

pumping direction is stored in the current Program Phase.

The “Volume Dispensed” is accumulated separately for dispense and withdrawal. When the pumping

direction is changed, the current “Volume Dispensed” is also changed accordingly between the dispense

and withdrawal “Volume Dispensed“ accumulations.

When the Pumping Program is operating and the “Volume to be Dispensed” is non-zero, the pumping

direction cannot be changed. Otherwise, when pumping continuously (“Volume to be Dispensed”

disabled), the pumping direction can be changed.

6.9. ‘Start’/’Stop’ Key

The ‘Start/Stop’ key starts or stops the Pumping Program’s operation. Pressing this key switches between

the Pumping Program operating and the Pumping Program paused. When the ‘Start/Stop’ key is pressed

before the completion of a Program, the motor is stopped and the Pumping Program will be paused. The

‘Pumping’ LED will then blink, indicating that the Pumping Program is paused.

Pressing this key again will resume the Program at the point it was paused. If any other key is pressed

while the Pumping Program is paused, the Pumping Program will be stopped and reset. Pressing the

‘Start/Stop’ key will then start the Pumping Program from the beginning (Phase 1).

Pressing and holding this key while starting the Pumping Program will start the prime/purge mode. Purge

will begin after the key is held for one second, and continue until the key is released. The pump will stop

after the key is released.

6.10. Dispense Selection

When in Dispense Mode, pressing and holding either the Rate or Volume keys will enter “Dispense

Selection Mode”. The display will show: nn , where ‘nn’ is the current dispense selection.

To change the current Dispense Selection, press the up arrow keys below the Dispense Selection’s digits.

The maximum Dispense number is 40. To reset to Dispense number 1, press and hold either the Rate or

Volume keys until Dispense number is 1.

Momentarily press the Rate or Volume keys to exit Dispense Selection Mode.

6.11. ‘Setup’ Key

The secondary function of the ‘Diameter’ key is ‘Setup’. While the Pumping Program is not operating,

press and hold the ‘Diameter’ key until the first setup configuration parameter, “Slow Down Mode”, is

displayed:.

n

The display will consecutively display, for about 2 seconds, each Setup Configuration parameter and its

current setting. Pressing any non-arrow key will immediately advance to the next Setup Configuration

parameter.

www.braintreesci.com Braintree Scientific, Inc. Model BS-900

Publication #1200-04 13

To change a Setup Configuration parameter, press an arrow key under the parameter’s value. To store the

new value, press any non-arrow key or wait 2 seconds. If the parameter value differs from its previous

value, the display will blink. The new parameter value will be stored and the next parameter will be

displayed.

After the last configuration parameter is displayed, the display reverts back to displaying the peristaltic

tube diameter. Any new parameter value will take affect immediately upon being stored.

6.12. Special Setup Key

While turning on power to the pump, press and hold the ‘Setup’ key to access the special setup menu. The

first menu entry “Set Tube Diameter” will be displayed:

6.13. Learn Key

While turning on power to the pump, press and hold the ‘Learn’ key to access the Learn mode menu. The

first menu entry “Learn and Repeat” will be displayed

6.14. Special Power-Up Functions

The following special functions are accessed by pressing the relevant key, while turning on power to the

pump.

6.14.1. Firmware Version Display

To display the pump’s firmware version, press the left-most up arrow key (/) while turning on

power to the pump. The display will show:

n.nn , where ‘n.nn’ is the firmware version number.

Pressing any key will clear the display.

6.14.2. Reset the Pump

To reset the pump, press the right-most up arrow key () while turning on power to the pump. The

display will show . Pressing any key will clear the display.

With a pump having as many complex features as the BS-900, it is easy for a novice user experimenting

with the pump's setup to get the pump into a 'weird' state. Performing this reset function will bring the

pump out of a 'weird' state. A default pumping rate and tubing diameter will be set.

6.14.3. Learn and Calibrate Selection

Pressing the 'Rate'/'LEARN' key while turning on power to the pump will display the Learn selection

menu. Use the up arrow keys () to scroll through the selections. Press a non-arrow key or wait for the

time out to select.

Learn and Repeat Dispense

Tubing calibration

Exit without making any selection.

6.14.4. Special Setup

Pressing the ‘Diameter’/’Setup’ key while turning on power to the pump will enter the Special Setup

selection menu. Use the up arrow keys () to scroll through the selections. Press a non-arrow key or

wait for the time out to select.

Set Tubing Inside Diameter

Table of contents

Popular Water Pump manuals by other brands

Grundfos

Grundfos DPK Service instructions

HEISSNER

HEISSNER HFP5000-00 Instructions for use

Berkeley

Berkeley 6S Series owner's manual

Pentax

Pentax DP 40 Installation and operation manual

Wilo

Wilo Wilo-Drain TS Installation and operating instructions

VERDER

VERDER JEC PUMPS JRZS Series Operation and maintenance manual