2

INSTALLATION __________________________________________________________

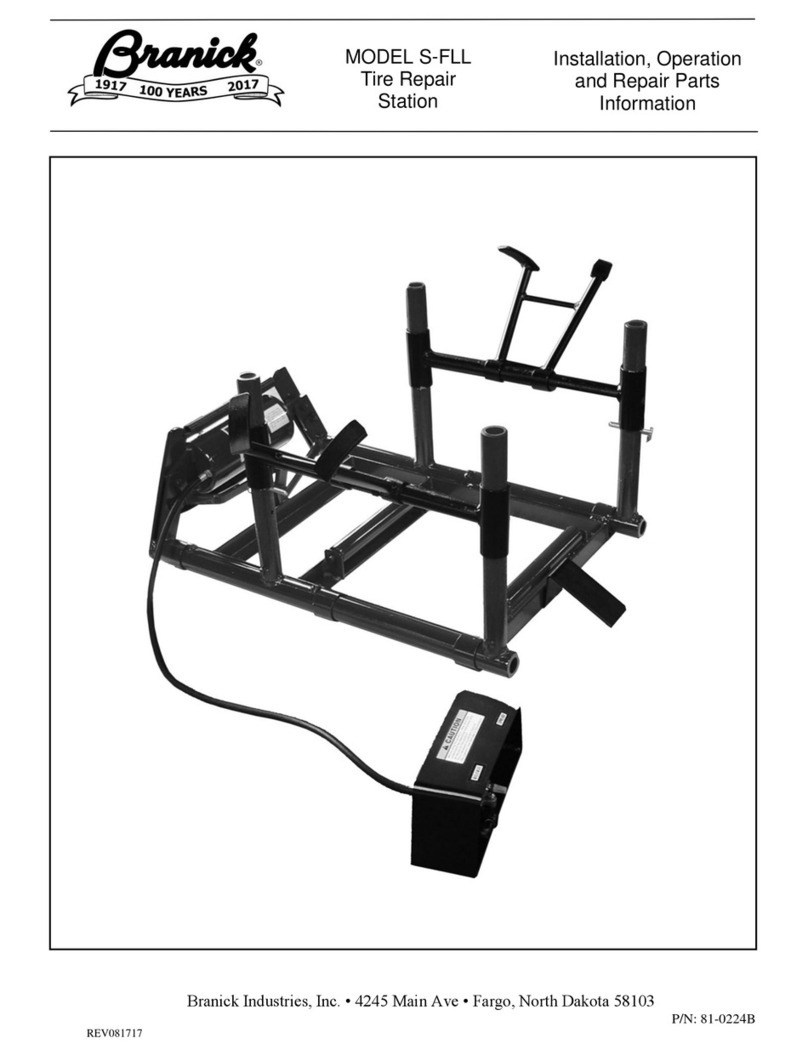

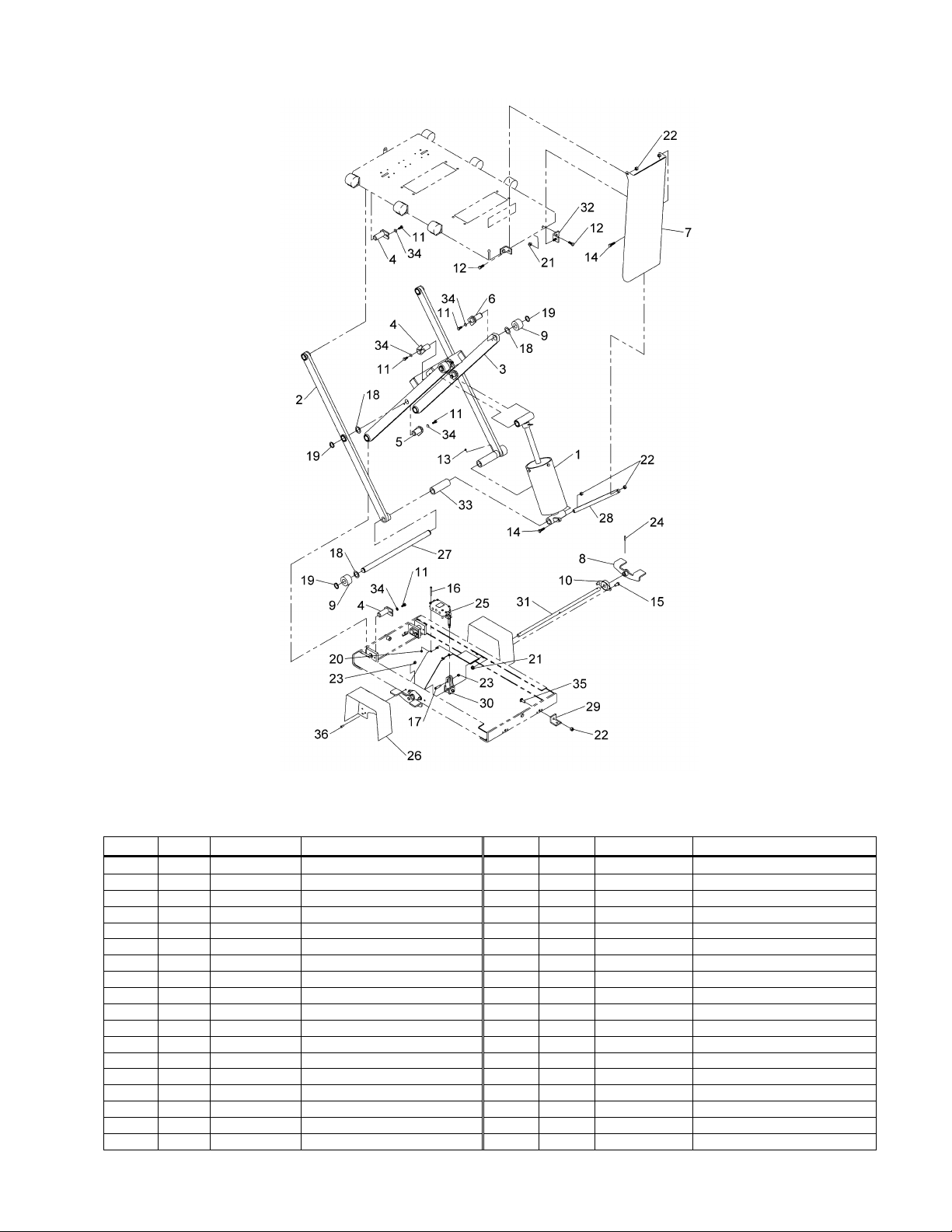

1) Attach the tire ramp (item 15) and retractor bar (item 45) to the Model 5500 with hardware provided.

Tighten nylon lock nuts enough to allow free rotation at pivot points (see page 3).

2) Position the Model 5500 on a solid level floor leaving a minimum of 36 inches of clearance on operation

sides and 24 inches of clearance on tool tray side.

3) Attach a 1/4 NPT quick coupler nipple (not provided) into the fitting located on lower frame on tool tray side

of machine. Use 1/4 inch air hose with 100 p.s.i. minimum.

OPERATION _____________________________________________________________

1) Make sure the spreader platform is in the lowest position.

2) Pull the spread hook arms out into the upright position.

3) Roll the tire up the ramp and onto the spreader platform rollers. Steady tire with hand and insert spread

hooks between tire beads.

4) Raise the spreader platform to comfortable working height using the platform lift foot valve.

5) Adjust spread hooks to proper height for the tire size being repaired. The spread hook arms are held in

position with a hitch pin. To adjust the spread hook arms, pull the hitch pin and move spread hook arm up

or down to one of the four adjustment holes. Most larger truck tires will use the uppermost adjustment

holes. Both spread hook arms must be adjusted to the same height.

6) Spread tire to desired width using the hand operated valve attached to tool tray. If tire is lifted off tire

rollers when it is spread, the spread hook arms are positioned too high and should be lowered.

7) After tire repairs are complete, lower the spreader platform to lowest position.

8) Release spread hook arm pressure and remove spread hook arms from the tire bead.

9) Standing at the end of the ramp, pull the tire down the ramp using both hands.

MAINTENANCE __________________________________________________________

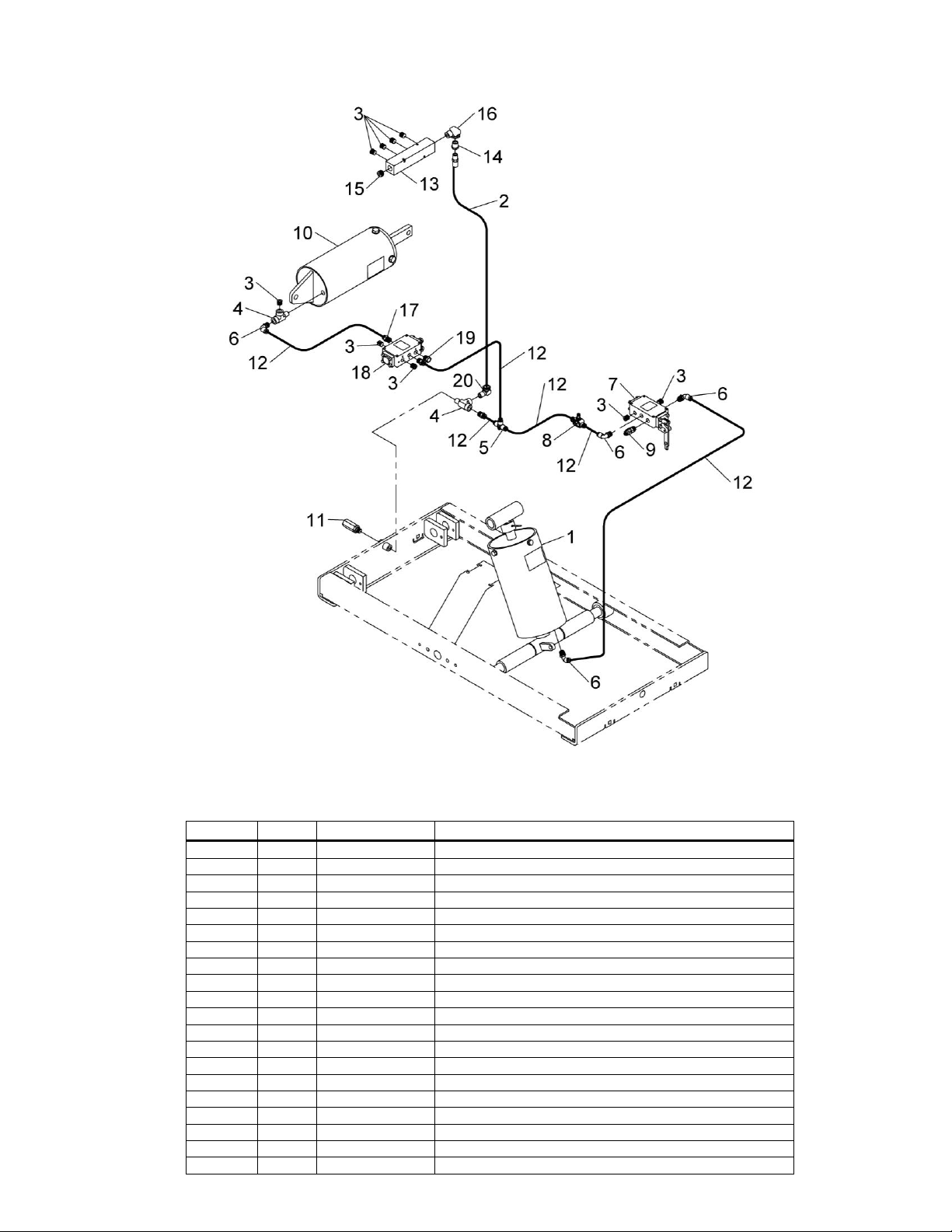

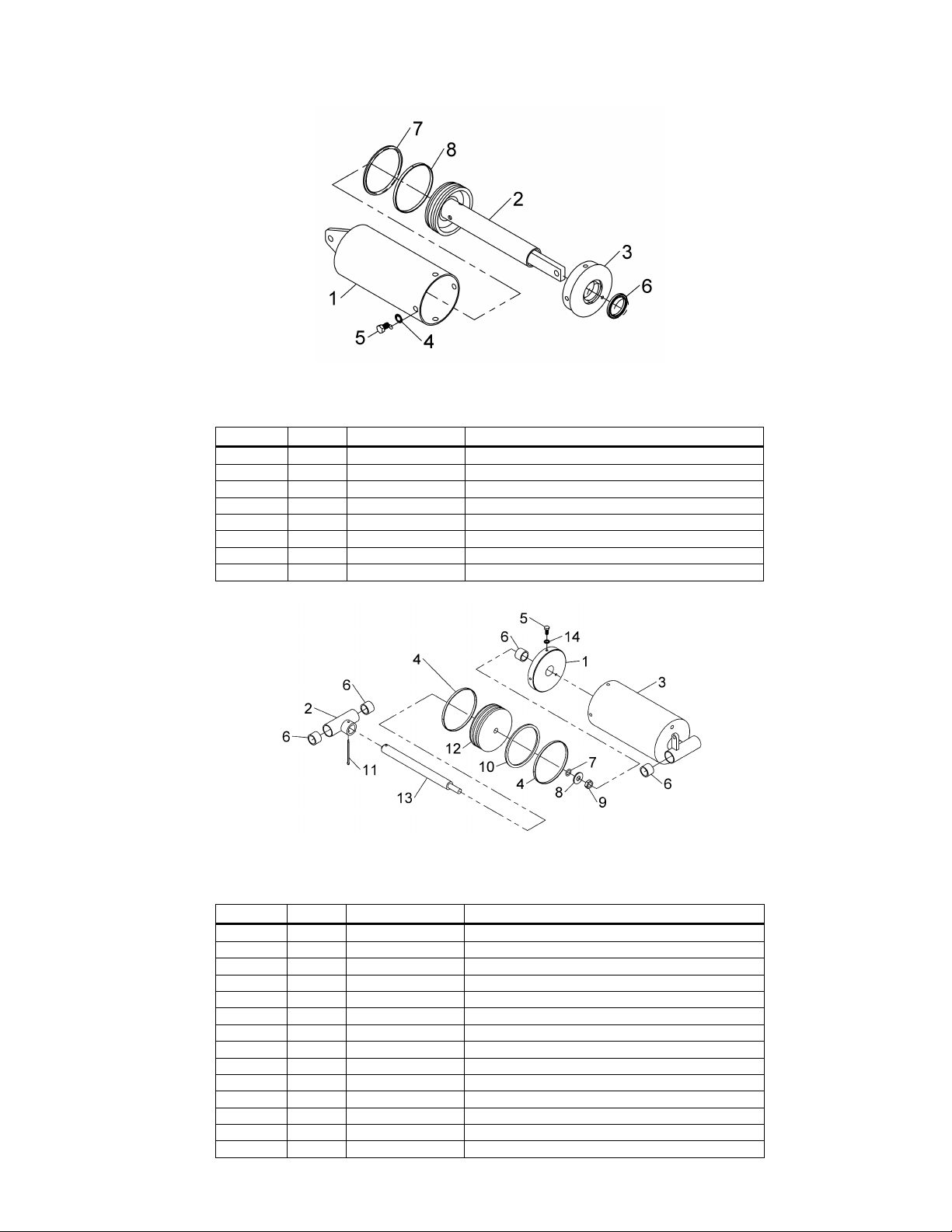

Monthly: On the spread cylinder, remove the slotted plug from the tee fitting at the end of the cylinder

and put in a few ounces of 10 or 20 weight oil. On the lift cylinder, put a few ounces of oil in the

¼ inch hole in top cover plate.

CAUTION

Before using this product, read and fully understand the operating

instructions and all decals on the product. This is necessary to prevent

injury to the operator and damage to the product.

Use this product only for lifting, spreading and repairing tire casings. Do

not use this product for any other purpose.

Keep fingers and hands clear of spread hooks during tire spread.

Do not use this product if it is visibly worn, distorted or damaged.

Always wear appropriate eye protection.