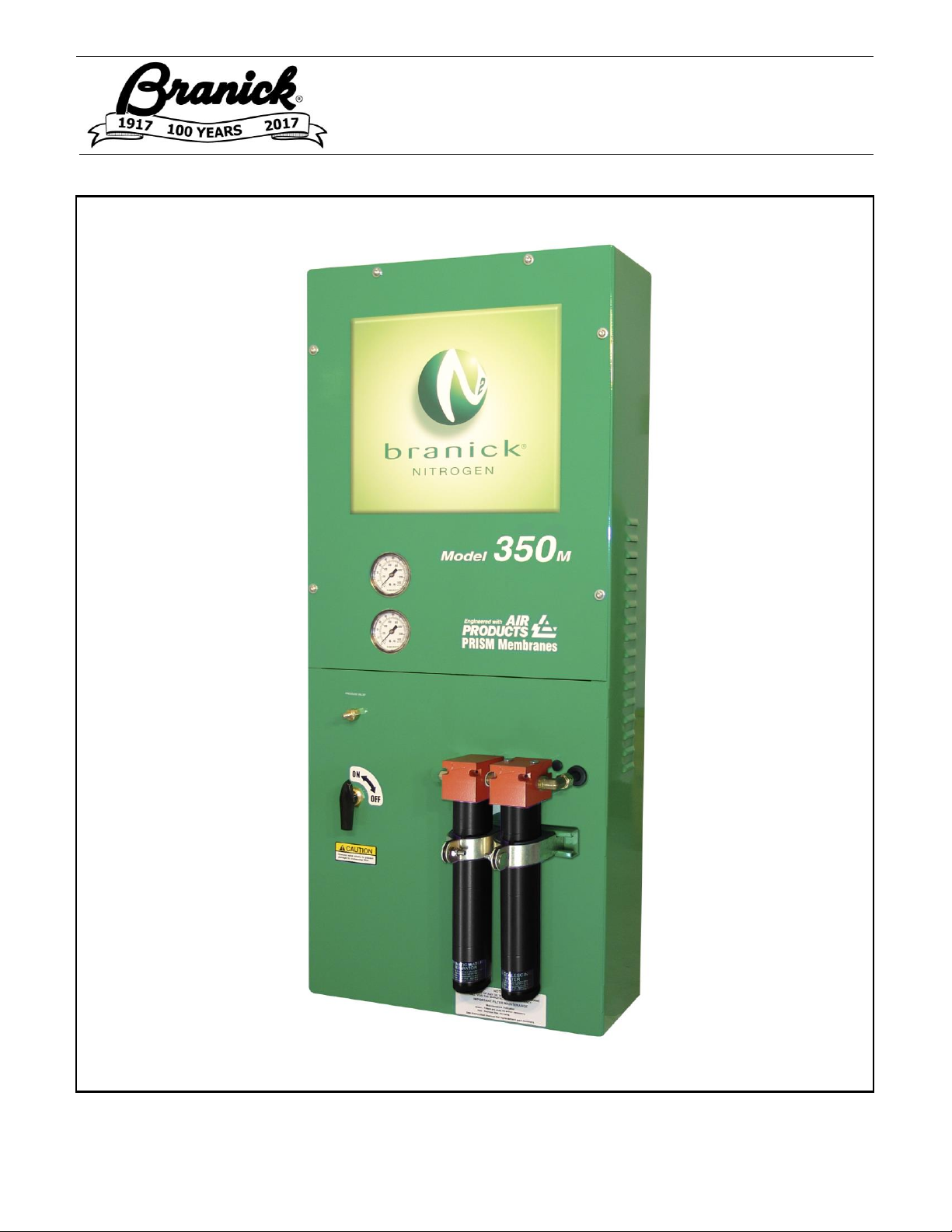

Branick Industries, Inc.

Nitrogen Products

COMMERCIAL WARRANTY

(Non-Transferrable)

This product is warranted by BRANICK INDUSTRIES, INC. to the original user-owner against defective

materials or workmanship. During the warranty period, if Branick determines the product or components

to be defective, it will be repaired or replaced (at Branick’s option).

___________________________________________________________________________________________

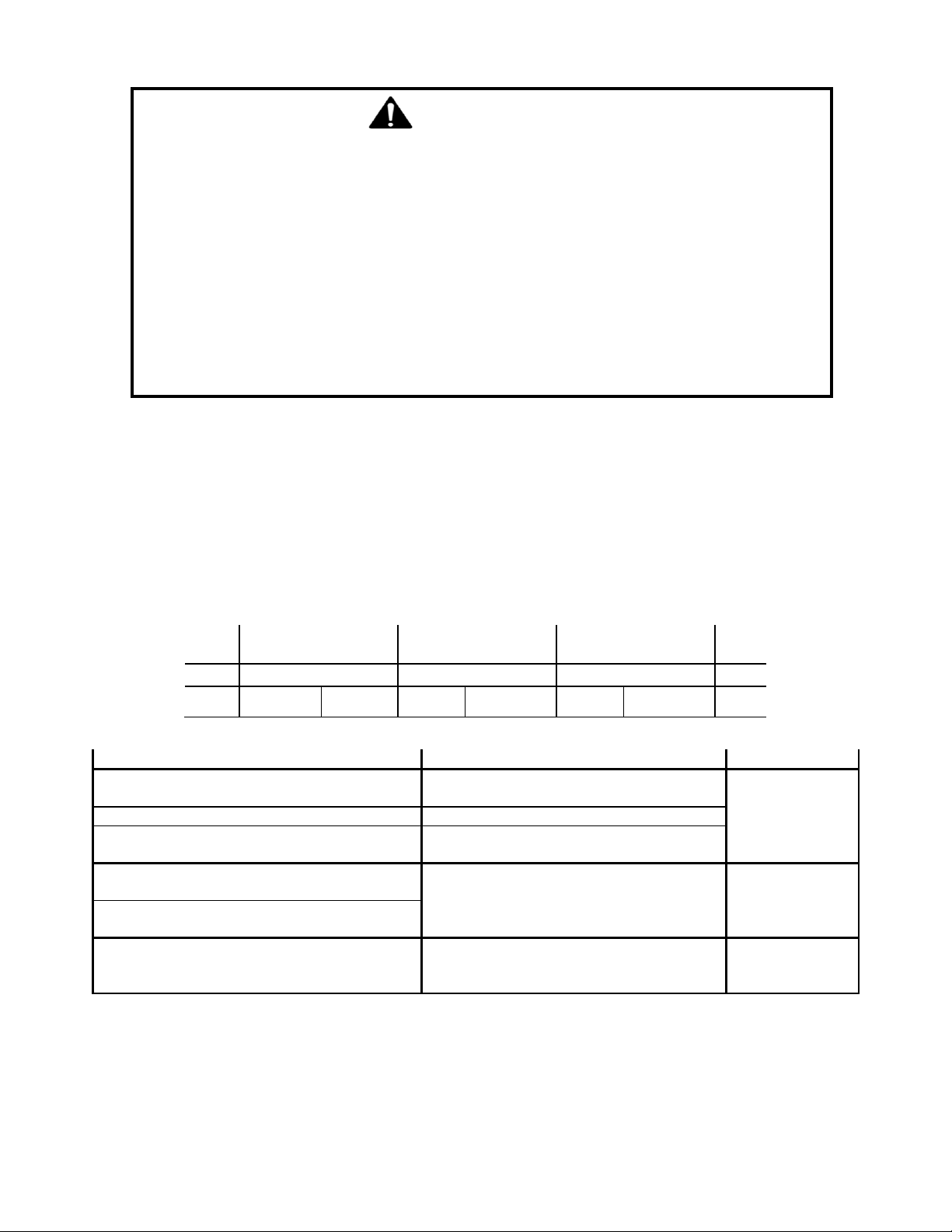

Warranty Period

Labor: 12 months from the date of delivery.

Parts: 12 months from the date of delivery.

Nitrogen Membranes: 60 month warranty from the date of delivery. Proper pre-filter maintenance must

be followed as stated in this manual including changing filters every six (6)

months, and using ONLY filters purchased through Branick. Not doing so will void

the five year warranty. Contamination in the membrane including water, oil,

solvents, particles, and other contaminants will void the warranty. Connecting to

an airline with an oiler, or an unmaintained compressor will void the five

year warranty. In order for a membrane to be considered for warranty

replacement, it must be returned for inspection.

Service or Repair: Warranty service or repairs must be performed by a Branick designated service

company. Membranes replaced under warranty will remain under warranty for

the remaining portion of the original warranty period.

This warranty does not cover damage to the product caused by abuse, misuse, overloading, accident (including

shipping damage), improper maintenance, alteration, or any other cause not the result of defective materials or

workmanship.

Replacement is the exclusive remedy for defective product under this warranty. This warranty is expressly in lieu

of all other warranties, including any implied warranty of merchantability or any implied warranty of fitness for a

particular purpose of this product. Branick industries, inc. Shall not be liable for any consequential or incidental

damages.

BRANICK INDUSTRIES, INC. reserves the right to make changes in the design or construction of our products

without obligation to incorporate such changes in products already sold and without notice.

Service parts, warranty, and regular repair service for Nitrogen products are available Monday through Friday,

7:30am to 4:30pm CST.

BRANICK INDUSTRIES, INC.

4245 Main Ave.

Fargo, North Dakota 58103

1-877-N2-HOTLINE

© Copyright 2018 by Branick Industries, Inc. Printed in U.S.A.