BRANNSTROM BilgMon488 User manual

BilgMon488 Instruction Manual vAD 1(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

INSTRUCTION MANUAL

BilgMon488

15 ppm Bilge Alarm

BilgMon488 Instruction Manual vAD 2(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

1TABLE OF CONTENTS

1 Table of Contents ............................................................................................................................ 2

2 Table of validity ............................................................................................................................... 4

3 Introduction..................................................................................................................................... 5

4 Construction.................................................................................................................................... 5

5 Operation ........................................................................................................................................ 5

6 Caution ............................................................................................................................................ 5

7 Specification .................................................................................................................................... 6

7.1 General.................................................................................................................................... 6

7.2 Specific 115/230 V AC model .................................................................................................. 7

7.3 Specific 24 V AC/DC model...................................................................................................... 7

8 Installation....................................................................................................................................... 8

8.1 Mechanical .............................................................................................................................. 8

8.2 Tube arrangement................................................................................................................... 9

8.2.1 Alternative 1.................................................................................................................... 9

8.2.2 Alternative 2.................................................................................................................... 9

8.3 Electrical ................................................................................................................................ 10

8.3.1 General installation ....................................................................................................... 10

8.3.2 Fresh water flushing valve installation.......................................................................... 11

8.3.3 115/230 VAC.................................................................................................................. 12

8.3.4 24V AC/DC ..................................................................................................................... 12

9 Calibration check........................................................................................................................... 13

9.1 Schedule ................................................................................................................................ 13

9.2 Calibration certificate expiry date......................................................................................... 13

9.3 Calibration check requirements ............................................................................................ 13

9.4 Sensor unit replacement ....................................................................................................... 13

10 Operating Instructions............................................................................................................... 14

10.1 Startup sequence................................................................................................................... 14

10.2 Main menu and indication LEDs............................................................................................ 14

10.2.1 Main menu .................................................................................................................... 14

10.2.2 LEDs and indications...................................................................................................... 15

10.3 Menu system......................................................................................................................... 16

10.4 Contrast adjustment.............................................................................................................. 17

10.5 Simulation.............................................................................................................................. 17

10.6 Force automatic stopping device activation ......................................................................... 19

BilgMon488 Instruction Manual vAD 3(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

10.7 Acknowledge alarm2............................................................................................................. 19

10.8 Information menu ................................................................................................................. 20

10.8.1 Master info .................................................................................................................... 20

10.8.2 Sensor info..................................................................................................................... 20

10.9 Log ......................................................................................................................................... 21

10.9.1 Log menu....................................................................................................................... 21

10.9.2 Step log.......................................................................................................................... 21

10.10 Cleaning & test .................................................................................................................. 22

10.10.1 Clean cell (zero calibration)....................................................................................... 22

10.10.2 Check 40NTU cal (calibration check)......................................................................... 22

10.10.3 Test outputs............................................................................................................... 23

10.11 Settings.............................................................................................................................. 23

10.11.1 Valve settings (automatic stopping device) .............................................................. 23

10.11.2 Alarm2 settings (bridge alarm).................................................................................. 23

10.11.3 Autoflush feature (automatic freshwater cleaning).................................................. 24

10.11.4 Set clock..................................................................................................................... 24

10.11.5 Curro mode (Current output mode).......................................................................... 25

10.11.6 Curro 20mA cal. (Calibration of current output)....................................................... 25

10.11.7 PPM display. (Select number of decimals in ppm display)........................................ 26

10.11.8 Standby display. (Select standby notification) .......................................................... 26

11 Automatic stopping device test................................................................................................. 27

11.1 While separator is active....................................................................................................... 27

11.2 While separator is not active. ............................................................................................... 27

12 Response test ............................................................................................................................ 27

12.1 Step 1..................................................................................................................................... 27

12.2 Step 2..................................................................................................................................... 27

12.3 Alternative............................................................................................................................. 27

13 Calibration check....................................................................................................................... 27

14 Log entries................................................................................................................................. 28

15 Maintenance ............................................................................................................................. 29

16 Real Time Clock (RTC)................................................................................................................ 30

16.1 Local time .............................................................................................................................. 30

16.2 Battery replacement ............................................................................................................. 30

16.3 RTC malfunction .................................................................................................................... 30

16.3.1 Set UTC time.................................................................................................................. 31

17 Log data download via USB ....................................................................................................... 32

BilgMon488 Instruction Manual vAD 4(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

17.1 Running the software............................................................................................................ 32

17.2 Installing the VCP driver ........................................................................................................ 32

17.3 Download procedure............................................................................................................. 32

18 Spare parts list........................................................................................................................... 35

19 Troubleshooting ........................................................................................................................ 37

2TABLE OF VALIDITY

The following table describes the software and hardware versions on which this document was

based.

Doc version

Master SW ver.

Master PCB ver.

Sensor SW ver.

Sensor PCB ver.

vAA, vAB

C3

Bilgbase_I.1/

Bilgbaslv_D.1/

Bilgbasco_A

Bilgemastex K.1

B5

Bilgemon J.1

vAC

C9

Bilgbase_I.1/

Bilgbaslv_D.1/

Bilgbasco_A

Bilgemastex K.1

B5

Bilgemon J.1

vAD

D1

Bilgbase_I.1/

Bilgbaslv_D.1/

Bilgbasco_A

Bilgemastex K.1

B5

Bilgemon J.1

BilgMon488 Instruction Manual vAD 5(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

3INTRODUCTION

The BilgMon488 bilge alarm has been designed specifically for use in conjunction with 15 ppm oil-

water separator units. BilgMon488 performance meets the requirements of the International

Maritime Organisation specifications for 15 ppm bilge alarms contained in resolution MEPC. 107(49).

BilgMon488 is equipped with 2 adjustable alarms that are triggered when the oil-content of the

processed sample exceeds the set limit (1 –15 ppm, works-adjusted to 15ppm). Alarm outputs

consist of relays and indicator LEDs. Additionally a 0(4) –20 mA current output signal (corresponding

to 0 –30 ppm) is available to enable remote surveillance and recording of oil contents.

Downloading the operating log of BilgMon488 can be done through a USB-interface. This requires

driver software and cables that can be supplied on demand.

4CONSTRUCTION

BilgMon488 consists of two main parts, the MASTER unit (housing with LCD, buttons and LEDs) and

the SENSOR unit (housing with pipe fittings).

The MASTER unit contains all the electronics used for control and data storage of the bilge alarm.

Mounted in the lid of the MASTER housing is the main memory containing the bilgealarm log.

The SENSOR unit contains electronics for measuring the sample stream. The SENSOR unit also holds

the measurement calibration data. Communication with the MASTER unit is done wireless hence the

SENSOR unit is hermetically sealed and shall not be opened.

5OPERATION

Optical sensors monitors the amount of light scattered and absorbed by the oil droplets in the

sample stream. Sensor signals are processed by a microprocessor to produce a corresponding oil

content (ppm) output. The output is communicated to the MASTER unit where it is processed. The

MASTER unit takes action, such as alarm activation, logging etc., depending on the oil content and

the separator signal.

Settings that affect the behaviour of the bilge alarm are described in detail in section 10 Operating

Instructions.

Zero point calibration can be re-adjusted on site whereas full sensor calibration according to IMO-

requirements is performed by manufacturer.

6CAUTION

Do NOT remove the internal battery for more than a couple of hours (see 16.2 Battery replacement)

Do NOT open the SENSOR unit as this will invalidate the calibration.

Do NOT open the MASTER unit when it is energized. Hazardous voltages are present inside.

BilgMon488 Instruction Manual vAD 6(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

7SPECIFICATION

7.1 GENERAL

Measurement:

Oil range:

0 –30 ppm

Resolution:

0.1 ppm

Accuracy:

According to IMO MEPC.107(49)

Response time:

< 5 sec

Alarms:

Alarm 1 (automatic stopping device) delay:

0-10 sec user adjustable

Alarm 2 (annunciation) delay:

0-60 sec user adjustable1

Alarm points 1 and 2:

1-15 ppm user adjustable

Alarm hysteresis:

0.5 ppm (below alarm point)

Data storage and retrieval:

Calibration storage:

Stored in sensor housing.

IMO required data:

Stored in BilgMon488 main housing (sensor

housing may be replaced with data remaining on

board).

Data retrieval via display.

Optional data retrieval:

Via USB port.

User interface:

LCD display:

2x16 alphanumeric display

Control:

4 button keypad

Environment:

Ambient temperature range:

According to IMO MEPC.107(49), (0-55°C)

Enclosure ingress protection rating:

IP65

Installation:

Sample line inlet operating range:

Recommended: 1-2 bar (200 –300 l/h)

Maximum: 3 bar

Sample temperature:

Maximum: 50 °C

1

0-600 sec on master unit software versions before C9, shown on certificate and in “Info” menu.

BilgMon488 Instruction Manual vAD 7(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

7.2 SPECIFIC 115/230 VAC MODEL

Input/Output:

Current output:

0 –20 mA or 4 –20 mA for 0 –30 ppm

Communications:

USB serial communication (separate cable and

software)

Alarm outputs:

2 x relays (0.25A)

Clean water solenoid valve output:

1 x relay (0.5A, supply voltage)

Switch input:

1 x switch input for separator status

System and supply:

Supply:

1 A, 115 or 230 V AC, 50 –60 Hz

Power consumption electronics:

10 VA

Power consumption solenoid:

18 VA

7.3 SPECIFIC 24 VAC/DC MODEL

Input/Output:

Current output:

0 –20 mA or 4 –20 mA for 0 –30 ppm

Communications:

USB serial communication (separate cable and

software)

Alarm outputs:

2 x relays (1A)

Clean water solenoid valve output:

1 x relay (1A, supply voltage)

Switch input:

1 x switch input for separator status

System and supply:

Supply:

1.5 A, 24 V AC (50 –60 Hz) or 24 V DC

Power consumption electronics:

10 VA

Power consumption solenoid:

18 VA

BilgMon488 Instruction Manual vAD 8(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

8INSTALLATION

NOTE: If drain valve is fitted. It should always be closed while separator is running.

8.1 MECHANICAL

Illustration 1: Mechanical installation

BilgMon488 Instruction Manual vAD 9(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

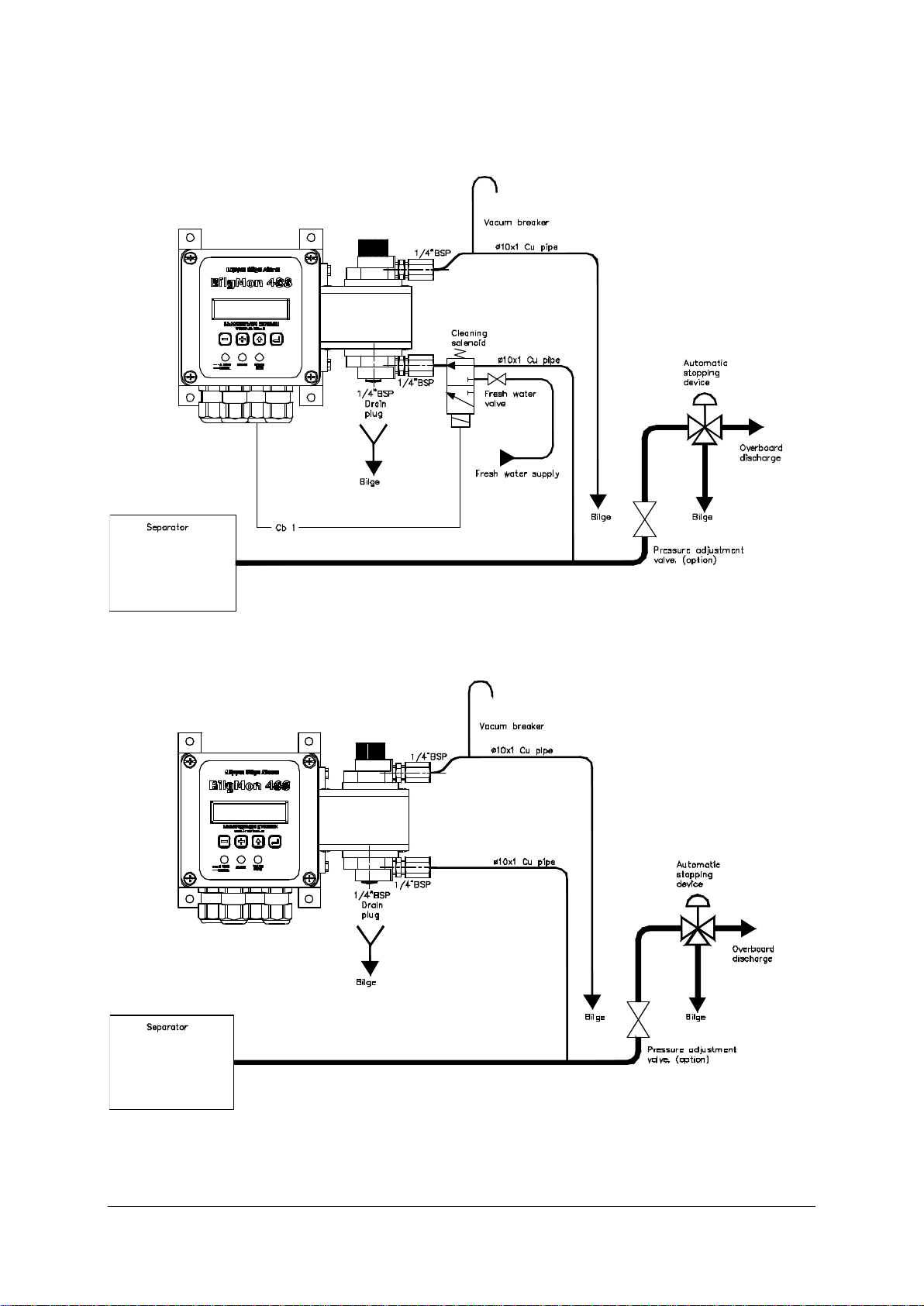

8.2 TUBE ARRANGEMENT

8.2.1 Alternative 1

Illustration 2: Tube arrangement alt. 1

8.2.2 Alternative 2

Illustration 3: Tube arrangement alt. 2.

BilgMon488 Instruction Manual vAD 10(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

8.3 ELECTRICAL

8.3.1 General installation

Bilgmon488 is manufactured in two base models, 115/230 VAC and 24 V AC/DC. The main difference

between these two models is the base PCB of the MASTER unit.

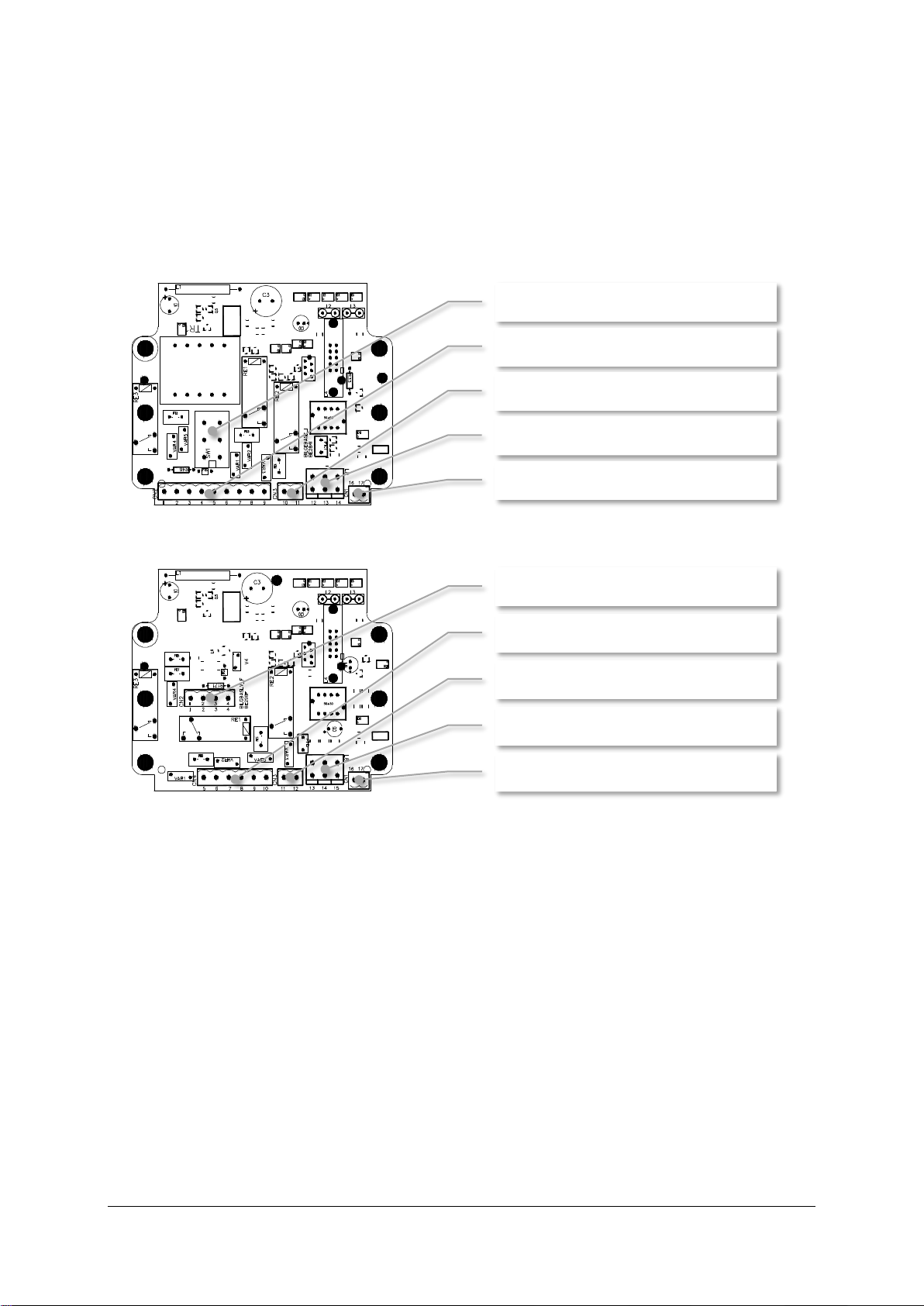

Illustration 4: Base PCB of 115/230 VAC MASTER unit.

Illustration 5: Base PCB of 24 V AC/DC MASTER unit.

When installing the 115/230 VAC model be sure to put the voltage selection switch (SW1, Illustration

4) in the correct position (marked 115 resp. 230).

Terminals 12-14 (L8, Illustration 4) resp. 13-15 (L8, Illustration 5) are coupled and can be used for

routing of external protective earth connections.

See sections 8.3.3 and 8.3.4 for detailed information of electrical connections.

SW1: Voltage selection switch (115/230)

CN2: Terminals 1 –9

CN3: Terminals 10 - 11

L8: Terminals 12 - 13

CN1: Terminals 16 - 17

CN2: Terminals 1 - 4

CN4: Terminals 5 –10

CN3: Terminals 11 - 12

L8: Terminals 13 - 15

CN1: Terminals 16 - 17

BilgMon488 Instruction Manual vAD 11(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

8.3.2 Fresh water flushing valve installation

This section is valid for systems using a cleaning solenoid according to Illustration 2: Tube

arrangement alt. 1 or similar installation.

115/230 VAC model: There are two coils delivered with the BilgMon

488, one to be used with 115 VAC (marked 96 V) and one to be used

with 230 VAC (marked 205 V). Be sure to install the proper one for

the chosen voltage.

24 V AC/DC model: Only one coil delivered with this model (marked

24 V).

NOTE: Both models are equipped with a cable and rectifier (in

connection plug for solenoid). The rectifier is necessary for all AC installations.

BilgMon488 Instruction Manual vAD 12(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

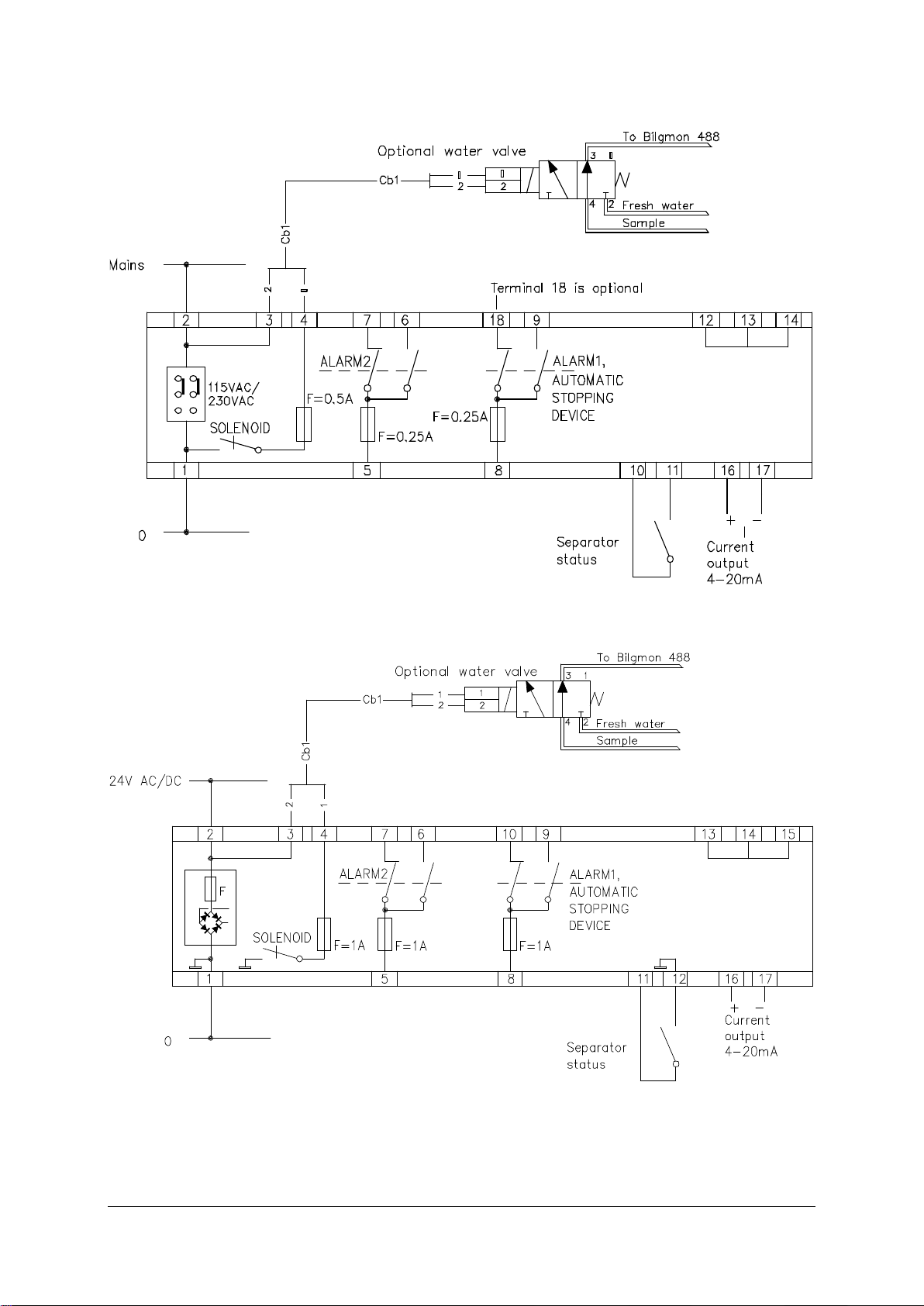

8.3.3 115/230 VAC

Illustration 6: 115/230 VAC electrical connections

8.3.4 24V AC/DC

Illustration 7: 24V AC/DC electrical connections

BilgMon488 Instruction Manual vAD 13(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

9CALIBRATION CHECK

9.1 SCHEDULE

Two items needs to be addressed when setting up the maintenance schedule for the BilgMon488:

Expiry date of the factory issued calibration certificate.

Occasionally a calibration check is required within the validity period of the factory issued

calibration certificate.

The following two subchapters explain how to resolve these two items.

9.2 CALIBRATION CERTIFICATE EXPIRY DATE

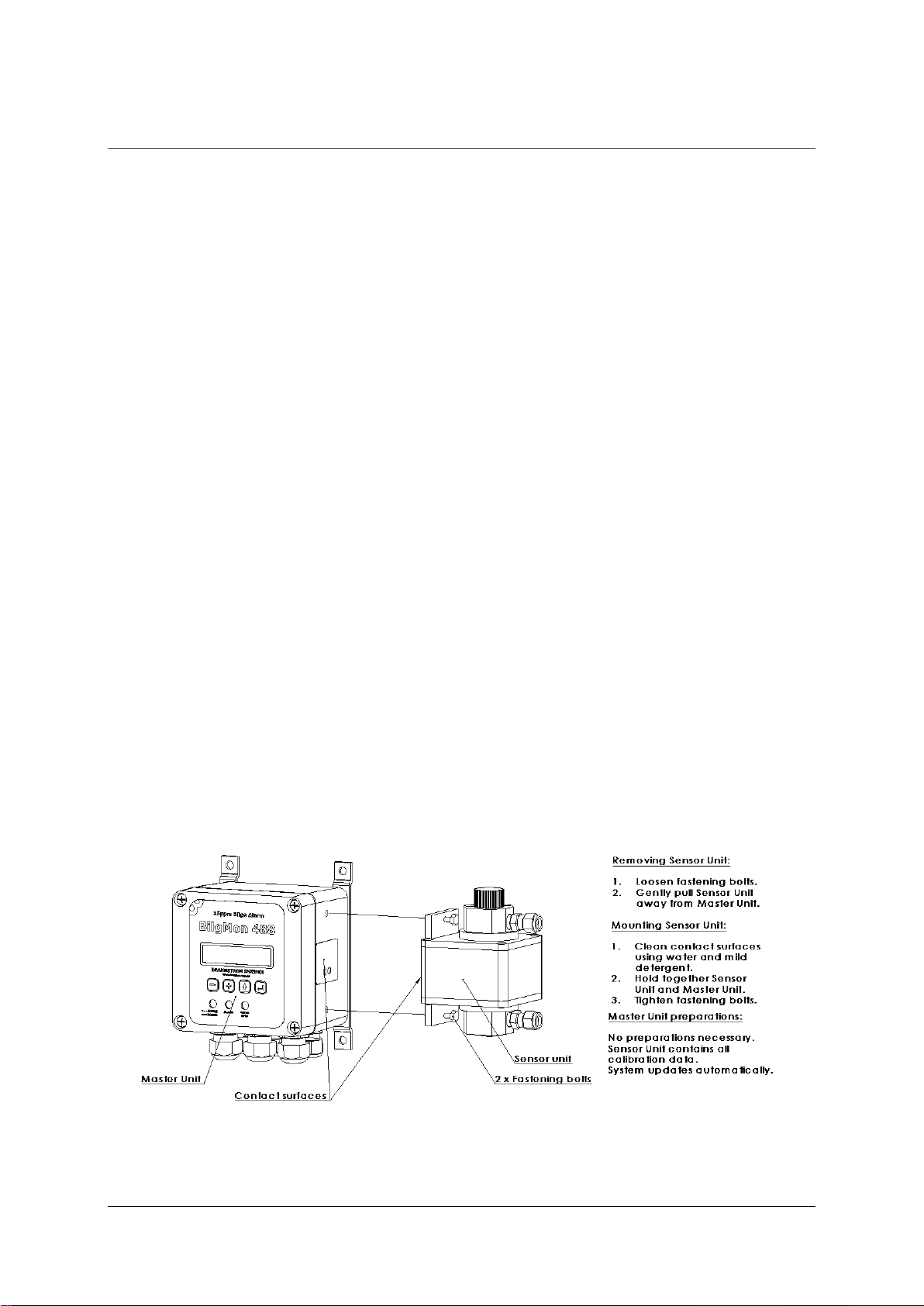

If the factory issued calibration certificate expires, the SENSOR unit must be replaced.

The SENSOR of BilgMon488 is designed to be easily replaced by the crew, see 9.4 Sensor unit

replacement. Replacement does not require any adjustments of the MASTER unit setup.

Each new SENSOR is accompanied with a new factory issued calibration certificate.

9.3 CALIBRATION CHECK REQUIREMENTS

On occasion ships may be required to perform a “calibration check” on their units. This might be

required to take place at shorter intervals than the validity period of the factory issued calibration

certificate.

Calibration check can be achieved in the following ways:

Checking calibration with a “Calibration Check Kit”.

(Requires ordering a kit or consult a service agent)

If the calibration check fails (calibration values are not within limits), a new SENSOR must be

installed.

9.4 SENSOR UNIT REPLACEMENT

Illustration 8: Sensor unit replacement procedure.

BilgMon488 Instruction Manual vAD 14(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

10 OPERATING INSTRUCTIONS

10.1 STARTUP SEQUENCE

When BilgMon488 is powered up the LCD display will show an initialization sequence.

Sequence:

1. Internal time reference (Real Time Clock, RTC) is

checked.

2. Information about unit setup is shown.

Explanation of example shown in 2.:

BilgMon 488 - Product name.

00A9 - Software version of master unit.

1dec - PPM value display precision.

CO - Current Output facility enabled.

15max - Maximum PPM level for alarm2 and automatic

stopping device settings.

1.

2.

10.2 MAIN MENU AND INDICATION LEDS

10.2.1 Main menu

After the initialization sequence is done the unit is ready for operation and the main menu will be

shown:

The main menu shows date and time followed by PPM

measurement and fresh water flushing valve selection.

Date and time is set at factory to UTC time (Coordinated Universal Time) and is displayed on the

format:

YYMMDD hh:mm:ss (YY –year, MM –month, DD –day, hh –hour, mm –minutes, ss –seconds)

PPM measurement shows the latest measurement of oil content in parts per million as reported by

the sensor unit.

Fresh water flushing valve selection shows the current selection (control output) to the optional fresh

water flushing valve:

SPL –sample from separator selected

WTR –fresh water flushing input selected

If the internal clock battery backup voltage is too low the

display will display a warning (see right) every 2 seconds.

See 30 Real Time Clock (RTC) for further information.

BilgMon 488 00A9

1dec CO 15max

RTC check:

In progress!

140612 09:10:48

PPM=12.3 SPL

WARNNG:

Change battery!

BilgMon488 Instruction Manual vAD 15(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

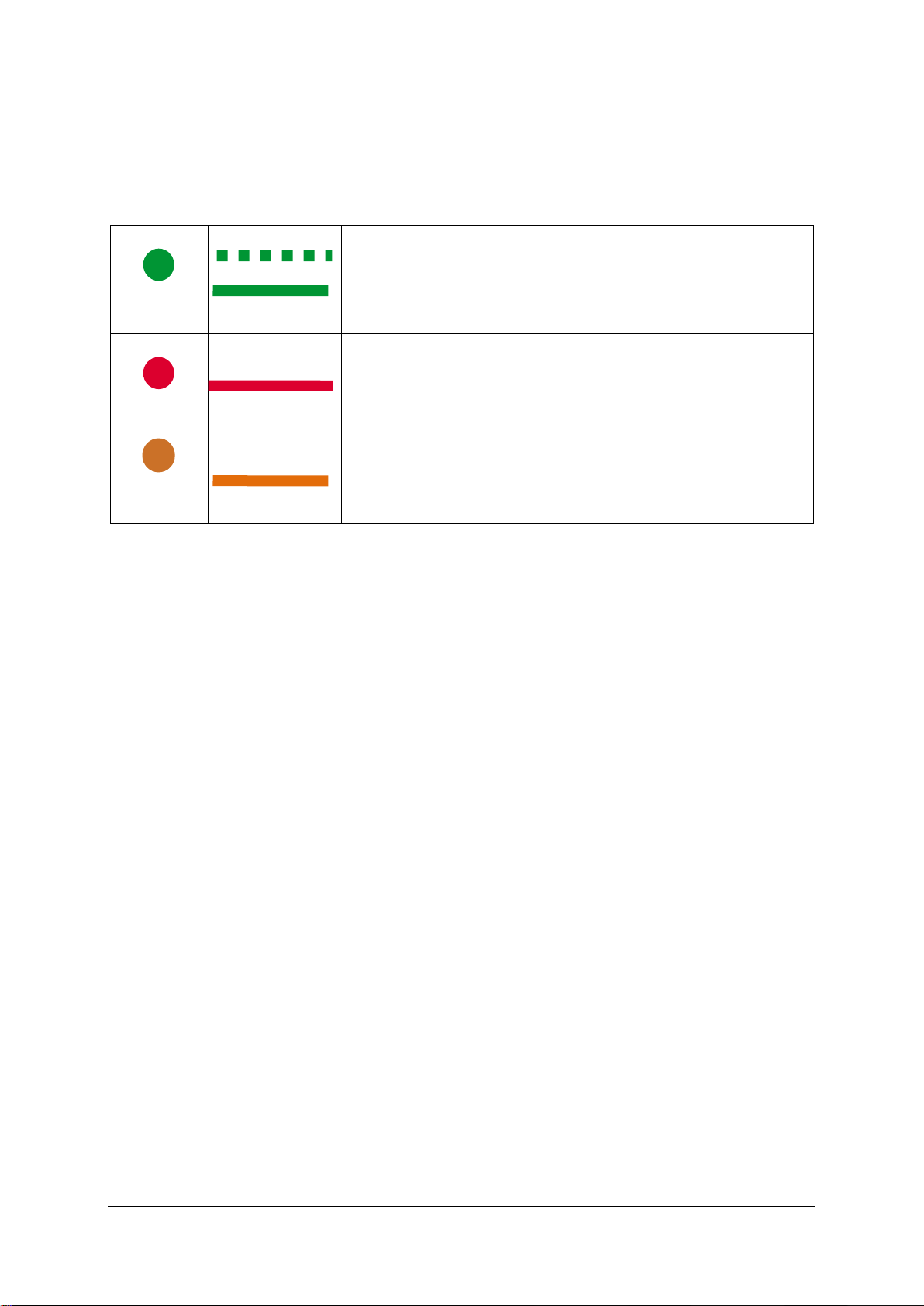

10.2.2 LEDs and indications

The LED lamps on the front panel indicate the status of the equipment. The straight/dashed lines

indicate if the lamps are lit continuously/flashing.

The LED lamps on the front panel indicate the status of the equipment. The straight/dashed lines

indicate if the lamps are lit continuously/flashing.

(green)

ACTIVE

POWER

Bilgmon488 is in ACTIVE mode (separator is running).

BilgMon488 is in POWER mode (menu subsystem is active).

(red)

ALARM

(no signal)

No alarm2 present.

Alarm2.

(yellow)

VALVE

OPEN

(no signal)

Automatic stopping device activated (back to bilge tank).

Automatic stopping device NOT activated (overboard valve open).

BilgMon488 Instruction Manual vAD 16(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

10.3 MENU SYSTEM

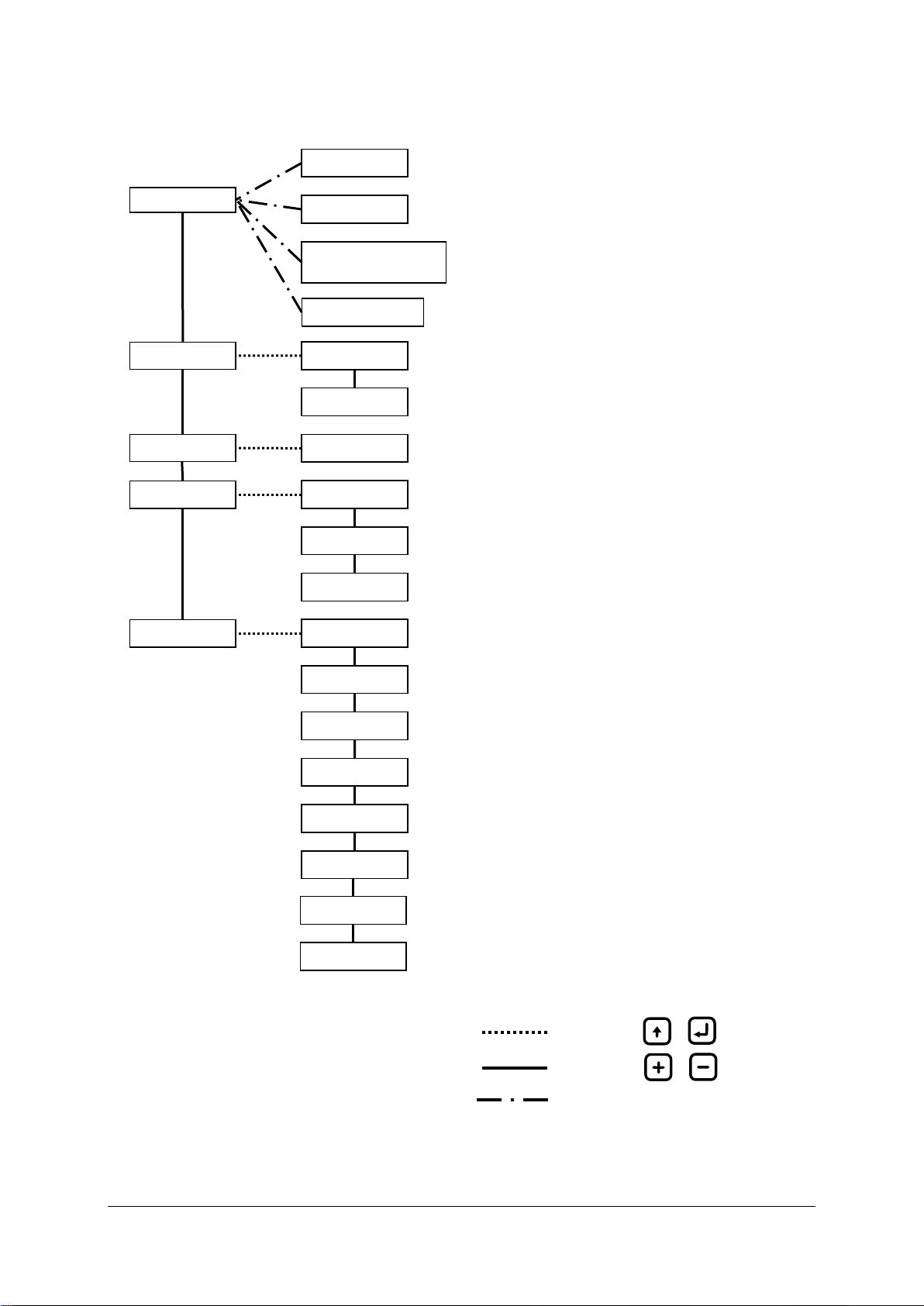

Illustration 9: Menu layout

Main

Info

Navigation using or

Navigation using or

Contrast

Simulation

Force automatic stopping

device activation

1) Transition only possible when BilgMon488 is in POWER mode (see 10.2).

Master info

Sensor info

Log

Step log

Cleaning & test

Clean cell

Check 40NTU cal

Test outputs

Settings

Valve

Alarm

Autoflush

Clock

Curro mode

Curro 20mA cal.

1)

1)

Adjust LCD contrast.

See 10.4 Contrast adjustment

Simulate PPM measurement and separator status.

See 10.5 Simulation

Temporarily activate automatic stopping device.

See 10.6 Force automatic stopping device activation

Show information about MASTER unit.

See 10.8.1 Master info

Show information about SENSOR unit.

See 10.8.2 Sensor info

Step, search and download the log.

See 10.9 Log

Zero calibration of SENSOR unit.

See 10.10.1 Clean cell (zero calibration)

Calibration check of SENSOR unit.

See 10.10.2 Check 40NTU cal (calibration check)

Relays and input test menu.

See 10.10.3 Test outputs

Set PPM limit and delay of automatic stopping device.

See 10.11.1 Valve settings (automatic stopping device)

Set PPM limit and delay of alarm2.

See 10.11.2 Alarm2 settings (bridge alarm)

Set interval and duration of fresh water autoflush feature.

See 10.11.3 Autoflush feature (automatic freshwater cleaning)

Adjust displayed time and date.

See 10.11.4 Set clock

Select current output logic.

See 10.11.5 Curro mode (Current output mode)

Calibrate 20mA output.

See 10.11.6 Curro 20mA cal. (Calibration of current output)

Navigation, see 10.4 - 10.7

Acknowledge alarm

Acknowledge alarm2.

See 10.7 Acknowledge alarm2

PPM display

Standby display

Select displayed number of decimals in PPM value.

See 10.11.7 PPM display. (Select number of decimals in ppm

display)

Show PPM or STANDBY at inactivity in POWER mode.

See 10.11.8 Standby display. (Select standby notification)

BilgMon488 Instruction Manual vAD 17(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

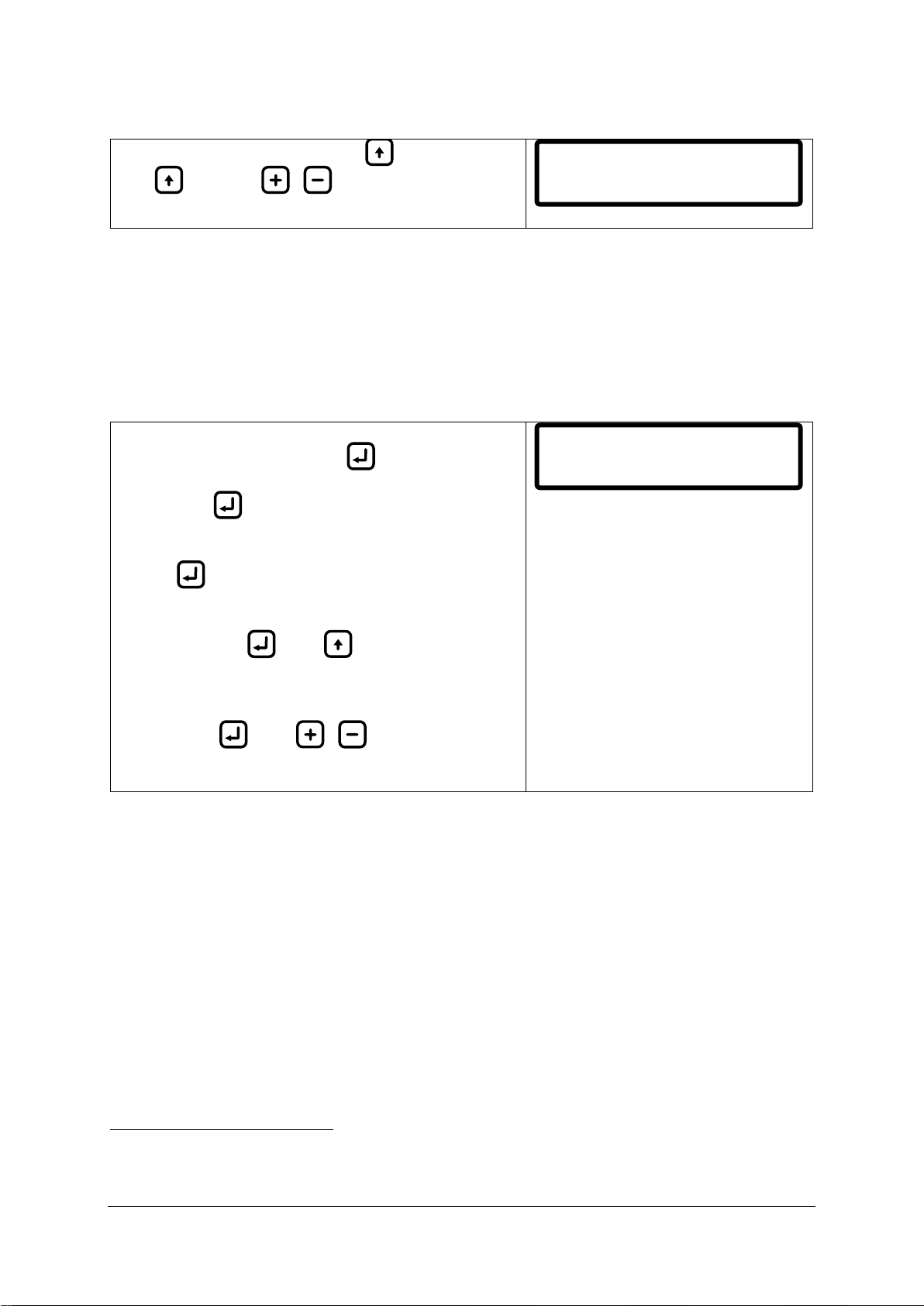

10.4 CONTRAST ADJUSTMENT

While in main menu press and hold .

With held press / to increment/decrement

contrast setting by 10%.

10.5 SIMULATION

The simulation menu lets user simulate the PPM input from the sensor unit as well as the separator

status input state to verify that the installation of the unit is correct and that it responds as expected

to different oil content measurements.

Simulated events will be stored in the log starting with a SIM_ON event and ended with a SIM_OFF

event.

Enter simulation menu2:

From main menu press and hold . The LCD will now

show something similar to the picture on the right.

Keep holding to stay in the simulation menu.

Leave simulation menu:

Release .

Toggle the simulated separator status input:

While still holding , press to toggle between

separator on/off (SEP_ON/SEP_OFF shown in LCD).

Increment/decrement simulated PPM value:

While holding , press / to

increment/decrement the simulated PPM value in steps

of 1.0.

2

To enter the simulation menu the BilgMon488 needs to be in POWER mode. POWER mode is when

the unit is powered but separator is not running (separator status input is open, see 8.3 Electrical).

Contrast: 010%

Simulation SPL

PPM>30.0 SEP_OFF

BilgMon488 Instruction Manual vAD 18(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

Example of simulation with explanations:

1) Start in main menu with separator off (separator

status input open).

ALARM LED –OFF

VALVE LED –OFF (no discharge)

2) Hold (do not release until step #7 in this

example).

Automatic stopping device (ASD) is now active3

and the alarm2 is not active since the separator is

not running.

ALARM LED –OFF

VALVE LED –OFF (no discharge)

3) Press to simulate that the separator starts

running (toggle to SEP_ON).

ASD and alarm2 is now active since the PPM

value is above 15 PPM and the separator is

running.

ALARM LED –ON

VALVE LED –OFF (no discharge)

4) Press repeatedly until PPM value is below

15.0 ppm (14.0 or lower value shown).

ASD and alarm2 is now NOT active since the PPM

value is below 15.0 ppm and the separator is

running.

ALARM LED –OFF

VALVE LED –ON (discharge)

5) Press repeatedly until PPM value is above

15.0 PPM (16.0 or higher value shown).

ASD and alarm2 is now active since the separator

is running and the PPM value is above 15.0 ppm.

ALARM LED –ON

VALVE LED –OFF (no discharge)

6) Press to simulate that the separator stops

running (toggle to SEP_OFF).

ASD is now active and the alarm2 is not active

since the separator is not running.

ALARM LED –ON

VALVE LED –OFF (no discharge)

7) Release to return to main menu and end

simulation.

ALARM LED –OFF

VALVE LED –OFF (no discharge)

3

The VALVE LED and the automatic stopping device output has reversed logic. Hence when VALVE LED is lit the

automatic stopping device is NOT active (overboard valve in discharge position) and vice versa.

140613 09:50:24

PPM>30.0 SPL

Simulation SPL

PPM>30.0 SEP_OFF

Simulation SPL

PPM>30.0 SEP_ON

Simulation SPL

PPM=14.0 SEP_ON

Simulation SPL

PPM=16.0 SEP_ON

Simulation SPL

PPM=16.0 SEP_OFF

140613 09:50:24

PPM>30.0 SPL

BilgMon488 Instruction Manual vAD 19(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

10.6 FORCE AUTOMATIC STOPPING DEVICE ACTIVATION

When the separator is running and the PPM value is below 15.0 ppm the automatic stopping device

can be temporarily activated by pressing and holding for approx. 2 sec.

After 10 seconds or on a press of BilgMon488

returns to normal operation.

10.7 ACKNOWLEDGE ALARM2

If separator is running (separator status input is closed, BilgMon488 in ACTIVE mode) and the PPM

value goes above 15.0 ppm the unit will generate an alarm2 (alarm2 output terminal and LED). The

alarm2 can be acknowledged

4

by pressing , or . This means that the alarm2 output

terminal will be put in no alarm position but the alarm LED on the front will still be lit.

4

Automatic stopping device output cannot be acknowledged (only alarm2 output).

Force valve

close: 10s EXIT

BilgMon488 Instruction Manual vAD 20(38)

BRANNSTROM SWEDEN AB

www.brannstrom.se

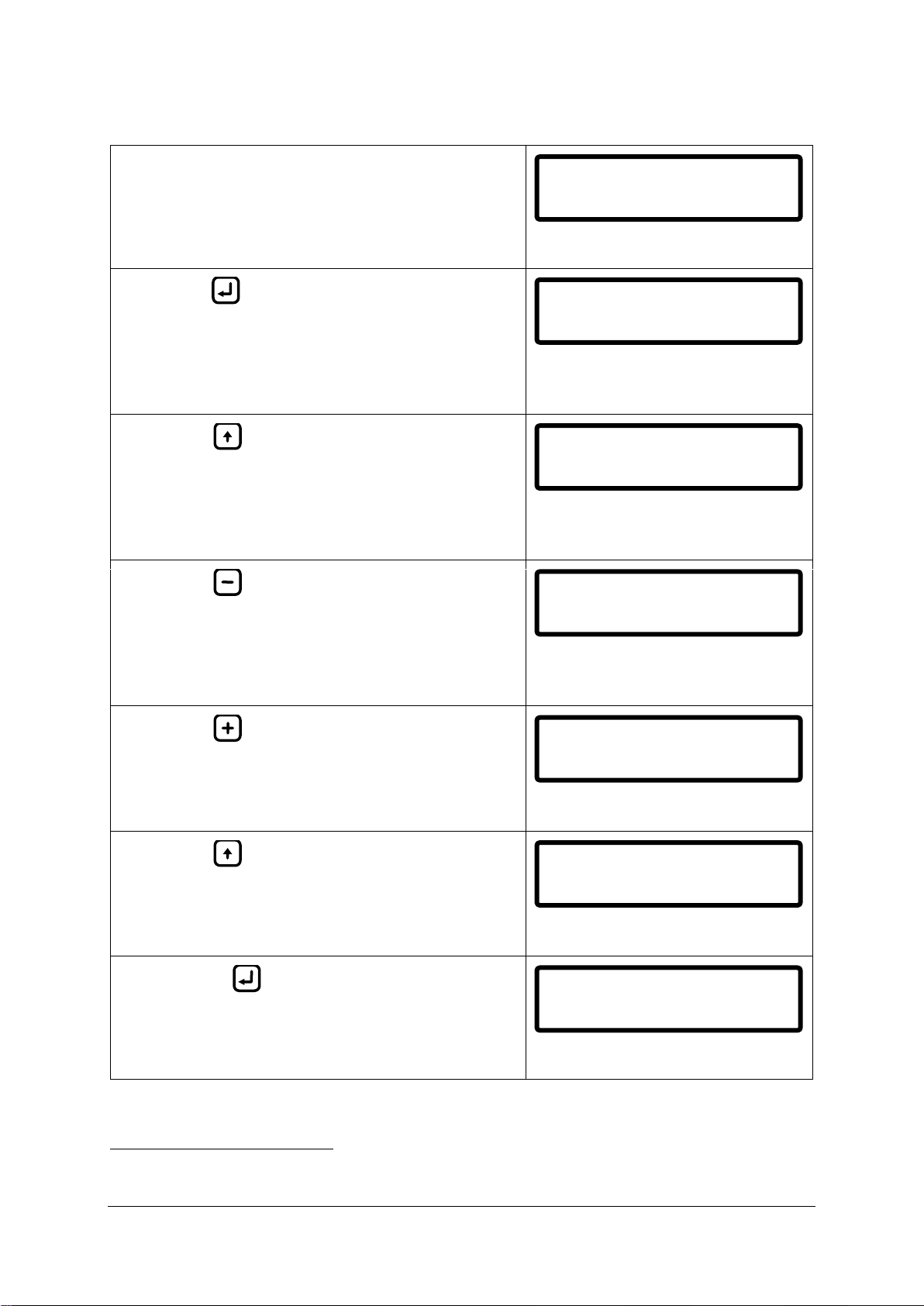

10.8 INFORMATION MENU

The information submenus will display

5

information about the MASTER and the SENSOR unit of

BilgMon488 according to examples below:

10.8.1 Master info

Cycle 0:

Menu name.

Cycle 1:

Serial number.

Cycle 2:

Software version.

Cycle 3:

Master unit lid power supply voltage. Should be approx.

5V.

Cycle 4:

RTC backup battery voltage. Should be approx. 3V. If

lower than 2.5V, replace battery ().

Cycle 5:

Internal time reference (RTC). Should be UTC time and

date (approximately).

10.8.2 Sensor info

Cycle 0:

Menu name.

Cycle 1:

Serial number.

Cycle 2:

Software version.

Cycle 3:

Factory calibration date.

Cycle 4:

Calibration check date.

Cycle 5:

SENSOR internal measurements (temperature, moisture,

voltage etc.).

5

Information is continuously cycling (cycle 0, cycle 1, … , cycle n, cycle 0, …).

Master info

Master ID:

000A-4567

Master SW ver:

00C3

Master voltage:

5V supply=5.3V

Master voltage:

RTC battery=3.0V

Master UTC:

140427 18:23:34

Se nsor info

Se nsor ID:

00 0B-4325

Se nsor SW ver:

00 B6

Se nsor date:

14 0112 13:23 :10

Ca l. checked:

14 0427 1 0:43:12

T:25.3 Dry:60

V3:3.20 V03:.312

Table of contents