Brano Industries Aladdin II Manual

When in doubt .........

.................. Read the Manual !!!

for

Aladdin II Domestic Garage Door Operator

Setup Instruction and

Users Manual

brano industries (pty) ltd.

October 2009

COPYRIGHT C

Manual AL - N01 Version 1

brano industries (pty) ltd.

p.o. box 277, bramley, 2018, rep. of south africa.

tel +27 (011) 887-0625 fax +27 (011) 887-7616

e-mail:- [email protected] ; web:- www.brano.co.za

INDEX

Garage Door Operator Installation Manual

Section Page Description

No. No.

00 Index

00 "brano" Distribution Centres

1 Technical Specifications

1 01 Technical Specifications

2 01 Operator Parts

3 02 Control Panel Layout

4 02 Terminals and Connctions

2 Programming The Operator

1 03 Applying Power

2 03 Setting The Open And Closed

Limits

3 03 Programming The Transmitters

4 04 Setting The Force Adjustment

5 04 Installing Infra Red Safety

Beams

6 05 Setting The Auto-Close Timer

7 05 Switching The Auto-Close

Function ON and OFF

8 06 Setting The Maintenance

Flashing Counter

3 Quick Reference Guide

1 06 Quick Reference Guide

Johannesburg brano industries (pty) ltd.

Head Office:- 22 - 3rd Street, Wynberg, Sandton.

and Factory PO Box 277, Bramley, 2018, RSA.

Tel (+27) 011- 887- 0625 / 6 / 7 / 8

Fax (+27) 011- 887- 7616

Cape Town brano cape (pty) ltd

Tel 021- 552- 5350 Fax 021- 552- 5350

Pretoria brano pretoria (pty) ltd

Tel 012 - 349 - 1494 Fax 012 - 349 - 2963

Westrand brano westrand cc

Tel 011 - 760 - 5773 / 3884 Fax 011 - 760 - 5774

For more information on your nearest

agent or distribution center

please contact us on our

Share Call Number:-

08600 - 27266

Dear Installer,

Thank you for choosing a "brano industries"

garage door operator for your installation.

This operator incorporates the very latest

features associated with this type of equipment

and complies with SABS - IEC 60335 - 2 - 95

and equivalent US, European, British and

Australian standards.

Only the very best materials have been used in

the manufacture of the machine. Extensive and

punishing testing of the door operator has given

us the confidence to offer a 1 year Limited

Warranty on the unit subject to the terms and

conditions contained herein.

We trust that you will find the operator to be

everything you could want in a garage door

operator and a profitable one to work with.

If you have any queries or simply would like to tell

us of your experiences with this operator please

contact us.

Yours sincerely,

brano industries (pty) ltd.

September 2009

page inside cover

SECTION 1

Technical Specifications

“brano” door operator installation manual"

page 01

1 Technical Specifications

1.1 Power Input

220 VAC - 50Hz

1.2 Electric Motor

24 VDC

1.3 Working Temperature

-20 to 50 Degrees Celsius

1.4 Opening and Closing Force

1000 N

1.5 Receiver

On Board - 433.92 Mhz - Rolling

Code

1.6 Lamp

24V - 5 Watt - Bayonet Type

1.7 Courtesy Light Time

3 Minutes

1.8 Programming Console

Soft Touch Push Button Control

Pad with LED Display

1.9 Functions

Soft Start and Soft Stop

Adjustable Overload Sensitivity

Connection Points for Safety

Beams or Pressure Sensitive

Edges

Optional Backup Battery

Optional Auto-Close function

IMPORTANT NOTE:

The Auto-Close function should not

be activated unless Infra Red Safety

Beams have been installed. An

external power supply is needed to

supply power to the Infra Red Safety

beams, power CANNOT be drawn

from the operator PC Board.

2 Operator Parts

page 02

SECTION 1

Technical Specifications

3 Control Panels Layout

4 Terminals and Connections

page 03

SECTION 2

Programming The Operator

1 Applying Power

Ensure that the traveller is in engaged

by moving the door until a click is

heard and the traveller is connected to

the chain.

Turn the power supply to the operator

on. The courtesy light will turn on for

several seconds while the LED display

counts from “99” to “11”.

Once the auto test cycle has completed

the courtesy light will switch off and the

operator will go into standby mode.

The operator is now ready to program.

2 Setting The Open And Closed Limits

With operator engaged to the door

ensure that the door in about 150 mm

above the floor. Press and hold “SET”

until the operator displays “P1”. Press

the “SET” button to confirm setup

mode.

The display changes to show “OP”.

Use the “UP” button to jog the door all

the way to the fully open position, the

display will show “OP” throughout this

operation. When the open position is

reached, press the “SET” button.

The LED display will change from “OP”

to “CL” to show that the up limit have

been set. Using the “DOWN” button,

jog the door to the closed position. The

display will show “CL” throughout this

operation. Once the closed position is

reached press the “SET” button. The

operator will open and then close the

door automatically to complete the

setup procedure. The LED display will

show “OP” during the up cycle and

“CL” during the down cycle. Once the

setup procedure is completed the

operator will return to “STANDBY”

mode.

3 Programming The Transmitters

With the operator in “STANDBY” mode

press the “CODE” button. The LED

display will change to display “SU”.

Press and release the button on the

transmitter that you want to program.

The “SU” on the LED display will flash,

then press and release the same button

on the transmitter again. The operator

will return to “STANDBY” mode when

the transmitter is successfully

programmed in.

The operator can store 20 transmitter

codes. When the receiver memory is

full the LED display will flash “FU” to

show that the memory is full.

page 04

SECTION 2

Programming The Operator

To clear the memory press and hold the

“CODE” button for 10 seconds. During

this time the display will change to

show “SU” and once the memory is

clear the display will show “DL”.

Important Note:

Always clear the operator memory on first

installation as the all the transmitter buttons

are coded in, in the factory for testing

purposes.

4 Setting The Force Adjustment

The operator is designed to sense

obstructions under the door. The

operator will stop and reverse

direction if it is obstructed in the down

direction. If it is obstructed in the up

direction the operator stop.

The operator has 9 sensitivity levels

with “F1” being the most sensitive and

“F9” being the least sensitive. The

default setting is “F5” and it should not

be necessary to adjust this setting if the

door is properly balanced.

To adjust the force sensitivity press and

hold the “SET” button until the display

shows “P1”. Press the “UP” button

once and the display will show “P2”.

Press the “SET” button to enter setup

mode. The display will show the current

setting. To increase the sensitivity

press the “UP” button and to decrease

the sensitivity press the “DOWN”

button. When the desired sensitivity is

reached press the”SET” button and

the operator will return to “STANDBY”

mode to show that the setting is

complete.

5 Installing Infra Red Safety Beams

The operator is designed to have Infra

Red Safety beams connected as an

optional safety device. The operator

must be set up to be able to function

correctly with this device connected.

PLEASE NOTE:- An external power

source is needed for the IR Safety

Beams. If a back-up battery is installed

the operator will not close the door

when the mains power is interrupted as

the IR Safety Beams will not be

functioning. The door will have to be

closed manually. If battery back-up is a

requirement it is suggested that IR

Safety Beams are NOT fitted to the

operator.

To install the IR Safety Beams press

and hold the “SET” button until the

display shows “P1”. Press the “UP”

button until the display shows “P3”.

Press the “SET” button to enter the

setup mode.

page 05

SECTION 2

Programming The Operator

To set the auto-close function press

and hold the “SET” button until the

display shows “P1”. Press the “UP”

button until the display shows “P4”.

When the desired setting is reached

press the “SET” button. The operator

will return to “STANDBY” mode to

indicate that the setup is complete.

5 Setting the Auto-Close Timer

Important Note:-

The Auto-Close function should not be

used unless IR Safety Beams are fitted

to the operator. Brano Industries

recommends that the Auto-Close

function be disabled. Using this function

is done entirely at the risk of the

installer and the home owner. Brano

Industries cannot be held responsible

for any damage to property and or

injury to persons.

Press the “SET” button to enter the

setup mode and the display will show

the current setting. Using the “UP” and

“DOWN” buttons adjust the setting

until you reach the desired auto-close

time.

When the desired time is reached press

the “SET” button. The operator will

return to “STANDBY” mode to indicate

that the setting is complete.

7 Switching The Auto-Close Function

ON or OFF

The default setting for the Auto-Close

function is off. The function must be

turned on before the operator will close

the door automatically. To switch the

auto-close funtion “ON” or “OFF”

press and hold the “SET” button until

the display shows “P1”. Press the

“UP” button until the display shows

“P5”.

The display will show the current

setting - in the default setting “H0” the

IR Safety Beams are disabled. Use the

“UP” and “DOWN” buttons to switch

between “H0” - IR Beams disabled and

“H1” - IR Beams enabled.

“10” seconds is the minimum and

“90” seconds the maximum that the

timer can be set to.

Press the “SET” button and the display

will show the current setting. Press the

“UP” or “DOWN” button to switch

between “b0” - Auto-Close Disabled

and “b0” - Auto-Close Enabled.

When the desired setting is reached

press the “SET” button. The operator

will return to “STANDBY” mode to

indicate that the setup is complete.

page 06

SECTION 2

Programming The Operator

SECTION 3

Quick Reference Guide

8 Setting the Maintenance Flashing

Counter

The operator is equipped with

maintenance flashing counter that

enables you to set the courtesy light to

flash for 2 minutes after a preset

number of cycles have been

completed. This let the user know that

the operator needs a service. The

counter has 9 levels and each levels

accounts for 2000 complete cycles.

To set the maintenance counter press

and hold the “SET” button until the

display shows “P1”. Press the “UP”

button until the display shows “P6”.

Press the “SET” button to enter the

setup mode.

Functions

1 “P1” - Limits Settings

“OP” - Open Limit

“CL” - Closed Limit

2 “P2” - Closing Force Adjustment

“F1” - Most Sensitive

“F5” - Default Setting

“F9” - Least Sensitive

3 “P3” - Setting IR Safety Beams

“H0” - IR Safety Beams Disabled

“H1” - IR Safety Beams Enabled

4 “P4” - Setting Auto-Close Timer

“10” - 10 Seconds - Shortest Setting

“20” - 20 Seconds

“30” - 30 Seconds

“40” - 40 Seconds

“50” - 50 Seconds

“60” - 60 Seconds

“70” - 70 Seconds

“80” - 80 Seconds

“90” - 90 Seconds - Longest Setting

5 “P5” - Auto-Close ON and OFF

“b0” - Auto-Close Disabled (OFF)

“b1” - Auto-Close Enabled (ON)

6 “P6” - Setting The Maintenance

Flashing Counter

“C0” - Maintenance Flashing Disabled

“C1” - Flash after 2000 Cycles

“C2” - Flash after 4000 Cycles

“C3” - Flash after 6000 Cycles

“C4” - Flash after 8000 Cycles

“C5” - Flash after 10000 Cycles

“C6” - Flash after 12000 Cycles

“C7” - Flash after 14000 Cycles

“C8” - Flash after 16000 Cycles

“C9” - Flash after 18000 Cycles

7 “CODE” - Programming The

Transmitters

“Fu” - Memory Full

“dl” - Memory Cleared

“Su” - Search Unit - Waiting for Code to

be programmed

The display will show the current

status. Use the “UP” and “DOWN”

button to move between “C0” and

“C9”. When the desired setting is

reached press the “SET” button. The

operator will return to “STANDBY”

mode to show that the setting is

complete.

Important note:-

The counter is set in 2000 cycle increments.

“C0” - OFF

“C1” - 2000 Cycles

“C2” - 4000 Cycles Up to

“C8” - 16000 Cycles and

“C9” - 18000 Cycles.

Table of contents

Other Brano Industries Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

SVS

SVS SHR-7 FUGA operating instructions

Chamberlain

Chamberlain LiftMaster 3275C owner's manual

Chamberlain

Chamberlain RollerLift CR655MYQ Installation and operating instructions

Chamberlain

Chamberlain LiftMaster LM3800A instructions

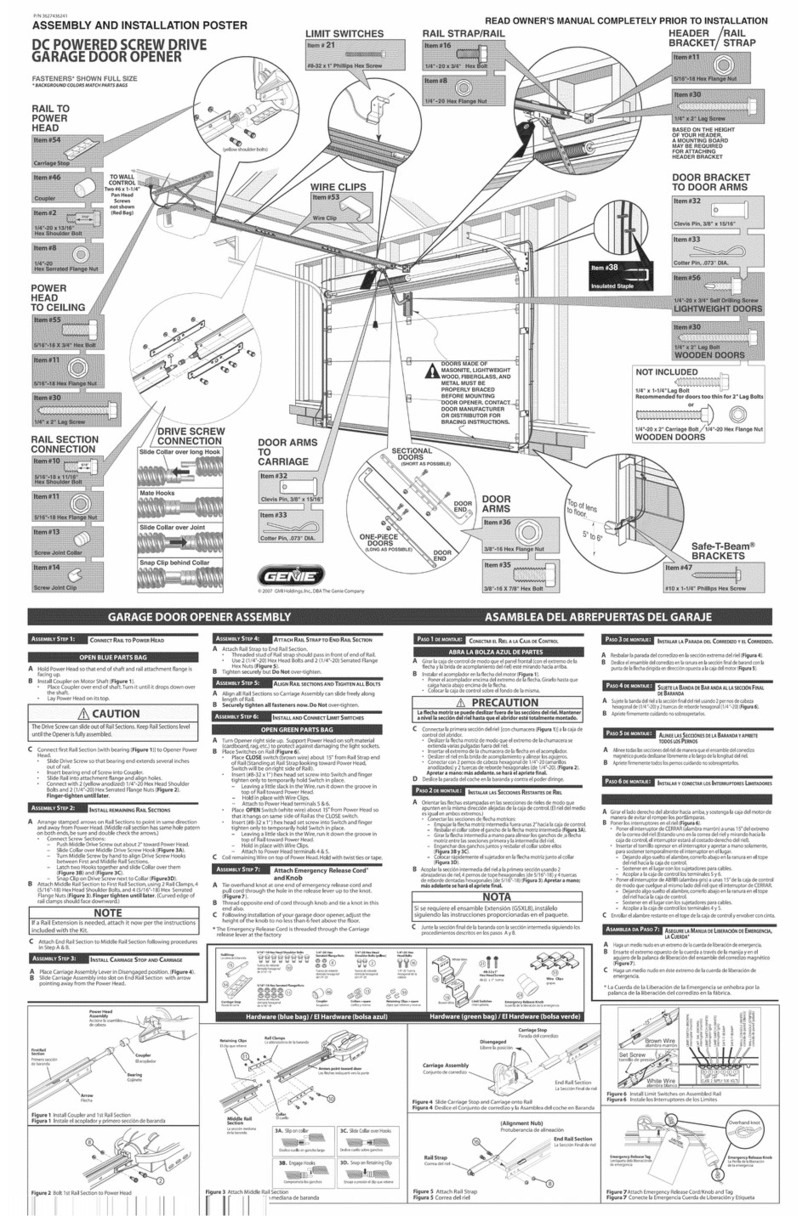

Genie

Genie 3627436241 Assembly and installation

Chamberlain

Chamberlain GT owner's manual

jcm-tech

jcm-tech ML8NF user manual

quiko

quiko MOOVY QK-M300B Use and maintenance manual

Genie

Genie 1035 Operation & maintenance manual

Delta Electronics

Delta Electronics VFD-DD Series user manual

Overhead door

Overhead door RSX installation instructions

B&D

B&D Panelift Storm-Shield installation instructions