Brano Industries pro-alpha 2000 User guide

When in doubt .........

.................. Read the Manual !!!

for

Automatic Domestic Garage Doors

Installer's Instruction Manual

brano industries (pty) ltd.

August 1998 / April 1999 / January 2002

COPYRIGHT C

FILE:- CD10\PA2\InstalManVers3.cdr

Manual MAN - 02 Version 3

pro-alpha

door

light

brano industries

p

h

l

a

a

-

o

r

p

LRC

UTON

II

BA

C

OMAE

S

O O

O

E

S

DG

N

T

NUEM R

NAG

I

O B"

YBAO

-1

LD

UE"CN L

OURR

RN

ST O

L

L2

WPE"

PR

ER E

US

"-G

AT

T

L

OI

BR

L"AV"

M O AE8

brano industries (pty) ltd.

p.o. box 277, bramley, 2018, rep. of south africa.

tel +27 (011) 887-0625 fax +27 (011) 887-7616

"pro-alpha 2000"

electric garage door operator

i n d u s t r i e s

LUBRICATION

DO NOT USE COMMON GREASE

USE ONLY "BRANO LUBRICANT GDO-L1" OR

"LOW-TEMP LUBRIPLATE" OR "AVGREASE28"

"pro-alpha 2000"

Legal Notices

Important Notes for Dealers and Installers Regarding the

"Condition of Garage Doors and Door Operators"

1) As is the case with any installation of automatic garage door operators it is most important that the

doors are in good condition and are working in accordance with the manufacturers specifications. In

other words springs, lifting cables, pivot pins, pulleys, drums, hinges, in fact every component must

beingoodworkingorder.

2) The balance of the doors is vitally important. Before installing an automatic door operator, test the

doortomakesurethatitisproperlybalanced.

3) Ifthedoorsarenotinastateofgoodrepair,........ donotinstallanoperator!

4) If, for any reason, you fit an operator to a door which is dysfunctional or is not in sound mechanical

condition, or may be considered to be operating below the manufacturers specifications, and as a

resultthereofpersonsorpropertymaybeinjuredordamaged,......

You ! ... the dealer / installer may be held responsible and liable !

5) The responsibility for ensuring that the doors are in a condition which is acceptable for the

installation of automatic garage door operators remains solely with the dealer / installer. If the

dealerandinstallerarenotoneandthesame,thetwomaybeheldliablejointlyandseverably.

6) The law takes the view that you are the expert and therefore you should know best. You cannot

have the client indemnify you against any damages. This would be contrary to the individuals

"common-lawrights".Thelaw,now,isquiteclearinthisregard.

7) Thebestpolicyforallconcernedandespeciallyfordealers/installersissimplythis:-

Fix the door before you automate it !!!

It'sworthwhiledoing,besides,it'sgoodforbusiness!

SABS - IEC Standard No. 60335 - 2 - 95

This standard specification is now published and it's impact is being felt far and wide in the door and

gate industry. The most important aspect of this standard is that the minimum levels of safety for door

and gate operators have been set down and all installations are required to conform to this standard.

The responsibility for maintaining the standard is placed squarely on the shoulders of the installers /

dealers,inmuchthesamewayaselectriciansareresponsiblefortheworktheydo. DIY'erstakenote!

Ifsomethinggoes wrongandsomeone is injured byan automatic garage dooror gate and thecause is

deemedtobeduetoinferiorinstallationproceduresorworkmanship,orfailuretoobservethestandards

laid down, the blame will fall at the foot of the installer / dealer. The law assumes that if you install

automatic operators to doors or gates, you, the installer / dealer are familiar with the requirements

of this standard and will have satisfied yourself that the installation will comply with every

aspectofthe standard.Don'tunderestimatetheseriousnessofthesestandardsortheconsequences

thatmayresultfromanytransgressionthereof.

Be warned !!! You do so at your own risk !!!

In order to assist dealers and installers Brano Industries, from time-to-time, arranges training

courses covering the installation and maintenance of garage doors and door operators. Contact us for

details of when these courses will be run. It will be the best investment you can make in your business

andyourfuture.

Dealers & Installers ! ....... Read this section carefully !!!!

page 0 0 Inside front cover

"brano door operator installation manual"

INDEX

"pro-alpha 2000"

Installer's Manual

Section Page Description

No. No.

00 LegalNotices

01 Index

01 "brano"DistributionCentres

1 02-03 SuitableTypesofDoors

1 04 DoorsNotSuitableforAutomation

1 05 UnsafeInstallationPractices

2 06 Door Operator Terminology and

TechnicalSpecifications

3 07-08 Pre-installationPreparations

4SectionalGDOInstallation

4.1 09-10 "WorkingSpace"Tables

4.2 10-13 InstallationProcedures

ProblemInstallations-Low

Headroom

5Tip-UpGDOInstallation

14 "WorkingSpace"Tables

15 InstallationProcedures

16 ProblemInstallations-“Low

Headroom”

17 SingleAccessGarages

6 18 PCBoardConnections

19 ElectricalConnections

20 SafetyBeamConnections

7 Setting-upInstructions

21 TravelLimitSwitches

22 OverloadSensorAdjustments

8 23 OperatorFunctions

23 TestingandCommissioning

24 InformationLabelsand "Handing

Over"

9 25 ServicingandMaintenance

Lubrication

WearingParts

10 26-27 "pro-alpha2000"SpareParts

11 28-31 TroubleShootingGuide

12 32-33 TermsandConditionsofWarranty

BackCover Door Operator Equipment Details

andServiceRecord.

Johannesburg branoindustries(pty)ltd.

HeadOffice:- 22-3rdStreet,Wynberg,Sandton,RSA

andFactory POBox277,Bramley,2018,RSA.

Tel (+27)011-887-0625/6/7/8

Fax (+27)011- 887-7616

CapeTown branocape(pty)ltd

Unit 3, EXPO Centre, Koeberg Rd, ( Deliveries 35 Stella

Road), MontagueGardens,CapeTown.

Tel 021-552-5350 Fax 021-552-5350

Pretoria branopretoria(pty)ltd

Unit8-Block"B", ScientiaTechnoPark,

MeiringNaudeStr.,CSIR, Pretoria,

Tel 012-349-1494 Fax 012-349-2963

Westrand branowestrandcc

Shop No 2 Ontdekkers Centre, cor Louis Str. &

OntdekkersRd,Roodepoort,

Tel 011-760-5773/3884 Fax 011-760-5774

Bloemfontein branofreestate(pty)ltd

17MacKenzieRoad,EastEnd,Bloemfontein.

Tel 051-447-2850 Fax 011-447-7095

DearInstaller,

Thank you for choosing the "pro-alpha 2000"

garagedooroperatorforyourinstallation.

The"pro-alpha 2000" incorporates the verylatest

features associated with this type of equipment and

complies with SABS - IEC 60335 - 2 - 95 and

equivalent US, European, British and Australian

standards.

Only the very best materials have been used in the

manufacture of the machine. Extensive and

punishing testing of the door operator has given us

the confidence to offer a 3 year Extended Warranty

on the unit subject to the terms and conditions

containedherein.

We trust that you will find the "pro-alpha 2000" to

be everything you could want in a garage door

operatorandaprofitableonetoworkwith.

If you have any queries or simply would like to tell us

of your experiences with the "pro-alpha 2000",

pleasecontactus.

Yourssincerely,

branoindustries(pty)ltd.

July1999 / October2001/February2004

page 01

"brano door operator installation manual"

i n d u s t r i e s

1.4.1 "Trackless" Type Tip-up Door

With "Pantograph" Mechanism

"SPRING BALANCED" TIP-UP DOOR

Fig No. 3

Path of Door

SECTION 1

Suitable Types of Garage Doors

page 02

1.1 INTRODUCTION

First it is necessary to identify the type of door that is

to be automated. The most common types of

domesticgaragedoorsare:-

1.1.1 SectionalOverheadDoors.

1.1.2 One Piece "Tip-Up" Doors with Jamb

MountedDoorHardware,(tracklesstype).

1.1.3 One Piece "Tip-Up" type Doors (with

"overheadtrack").

1.1.4 One Piece "Pivot" type Tip-Up Doors,

(tracklesstype doors).

1.1.5 One Piece "Tip-Up" Counterweight

Balanced type Doors, ( vertically tracked

typedoors ).

1.1.6 Steel Roll-Up type Doors, ( flexible curtain

typedoors).

TakeNote:-

"Vertically” tracked Tip-Up doors, ( e.g.

Counterweight" Balanced types ), and "Steel

Roll-Up" type doors both require the assistance

of special "adaptor" kits in order to be

automated.Consultyour dealerforadvice.

Refer to the specific instructions for the

typeofdooryouwishtoautomate.

1.2 InspectionOfTheDoor

Inspect the garage door for signs of damage or

wornorfaultycomponents.

Repair the door as necessary !

TakeNote:-

It is very important that the door be in a

state of good repair and in proper working

order.

Do not automate a door that is not in good

working order. Should persons be injured

or property be damaged by a door that is

considered to be in a condition that is

below the specifications of the

manufacturer, then you, the installer /

dealer may be held jointly and severably

responsibleandliable.

Door with "Torsion" Type Springs

Door with "Tension"

Type Springs

Fig No. 1

Path of

Door

Door in "Open"

Position

Door

Track

Note:-

Torsion springs are normally

positionedabovethedoor.

Fig No. 2

1.3 Door Type 1

SECTIONAL TYPE DOORS

1.4 Door Type 2

“ONE-PIECE" TIP-UP TYPE DOORS

"brano door operator installation manual"

i n d u s t r i e s

1.5.2.1 VERY IMPORTANT NOTE:-

This type of door can only be automated

with the aid of a special adaptor system,

viz., the "Vertical Track Adaptor Kit". When

fitted with a "VTAK" system, the "built-in"

overload sensors of the door operator,

regardless of make or model, may be

compromised to the extent that local safety

standards may not be complied with.

SABS-IEC Safety Standards preclude the

use of this system for the automation of

domesticgaragedoors.

Check with your local operator dealer for

moreinformation.

IMPORTANT NOTES ON THE

CONDITION OF GARAGE DOORS

Nodoorshouldbeconvertedtoautomatic

operation unless it is in good working

order.

Before installing an automatic door

operator, inspect the door for signs of

worn, damaged or missing parts and

repair or replace as necessary. Test the

operation of the door to make sure that it

isproperlybalanced.

Pay particular attention to the springs.

Domestic garage door springs should be

replaced after every 10 000 operating

cycles, ( or approximately 4 to 5 years of

normalusage).

Fig No. 7

Steel "Roll-Up" Type Door

"One-piece" flexible

steel curtain.

"Stationary" Shaft

Door Roll

COUNTER-WEIGHT BALANCED

"PIVOT" TYPE DOORS

1.4.2 "Trackless" Type Tip-up Door

With "Horizontal Pivot"

Fig No. 4

Floor

Level

Lintel

Ceiling

"High-Rise"

Point of Door Path of Top

of the Door

Pivot

Bearing

Counter-

Weight

page 03

1.5.1 "Inclined Track" Tip-up Door

With "Pantograph" Mechanism

Track

Roller

Angled

Track

Fig No. 5

Spring

1.5 Door Type 3

"ANGLED TRACK" TIP-UP TYPE DOORS

Fig No. 6

Counter-

Weight Vertical

Guide Track

Guide

Roller

1.5.2 Door Type 4

"VERTICAL TRACK" TIP-UP TYPE DOORS

1.6 Door Type 5

“ROLL-UP" TYPE DOORS

“brano“ door operator installation manual"

Read note 1.5.2.1

Fig No. 8

Fig No. 9

SECTION 1.7

Doors Which Are Not

Suitable For Automation

Read this section carefully !

For reasons of safety, certain doors should not

be automated. One door in particular fails to

comply with the safety standards set out in

SABS/IEC 60335-2-95

This door is commonly referred to as a "Tip-In"

or"Cam-Spring"typedoor.

DISTINGUISHING FEATURES

A "one-piece" type door which has a "vertical"

guidetrack. The distinguishingfeatureofthe door is

theplacementoftheGuideRoller.

The Guide Roller is positioned at, or close to, the

bottom-most corner of the door panel. The effect of

this arrangement is that it causes the door to open

completelytotheinsideofthegarage.

At no stage during the opening or closing cycle

does any part of the door pass through or

protrudefromtheopening.

Whenthedoorisfullyopen,theentiredoorremains

completely insideofthegarage.

Thesedoors were intended for use in openingsthat

haveroundedor"arched"shapesandweresoldas

acheaperalternativetoSectionaltypedoors.

All warranties, whether stated or

implied, shall, "ipso facto", be

rendered null and void if “Brano”

products are fitted to such types of

doors.

Do not automate this

type of garage door!

"Tip-In" or "Cam-Spring"

Type Garage Doors

Track

Roller

Path of Door

Vertical

Guide

Track Door Open

Position

"Cam-Spring"

Door Mechanism

“brano” door operator installation manual"

page 04

CAUTION! CAUTION! CAUTION!

Thesedoorsareunsafeforautomaticoperation

as the force applied by the door operator is

magnified as much as 40 times under the door

due to the action of the door mechanism. The

operator is unable to sense reliably

obstructionsinthepathofthedoor.

IMPORTANTNOTE:-

These doors are classified as "Vertically

Tracked"typedoors.

Typical openings in which

“Tip-In" type doors are found.

i n d u s t r i e s

Two "One-piece" Tip-Up Doors Shown.

Two Sectional Doors With A Vertically

Mounted Motor between the doors.

( Similar to"side-mount" system

used for Steel Roll-Up Doors )

Single Door Operator Centrally Mounted

Between Two "One-Piece Tip-Up Doors

Which Are Rigidly Coupled Together.

Single Door Operator Centrally Mounted

Between Two Sectional Doors Which Are

Rigidly Coupled Together.

Unsafe Installation Practices

Do Not Install Door Operators In This Way

SABS - IEC 60335-Part 2 - 1995 sets down

certainsafetystandardsfortheautomationof

garage doors. When two Tip-Up type doors

are coupled together in the way shown

above, the built-in "overload" sensors of the

door operator, regardless of make and type,

may be severly compromised to the extent

that they may not respond quickly enough, if

at all, to any obstructions in the path of the

door.

Should any door which is automated in this

manner cause an injury, or worse, to any

person or damage to property, both the

owner and the installer may be held jointly

and severably responsible and liable and

maysuffertheconsequencesthereof.

Homeowners are advised to reject such

installations lest they be incriminated in any

claims.

The installation of door operators in this

manner will render all warranties, wether

statedorimplied,nullandvoid!

Fig No. 10 Fig No. 11

Fig No. 12

page 05

“brano” door operator installation manual"

i n d u s t r i e s

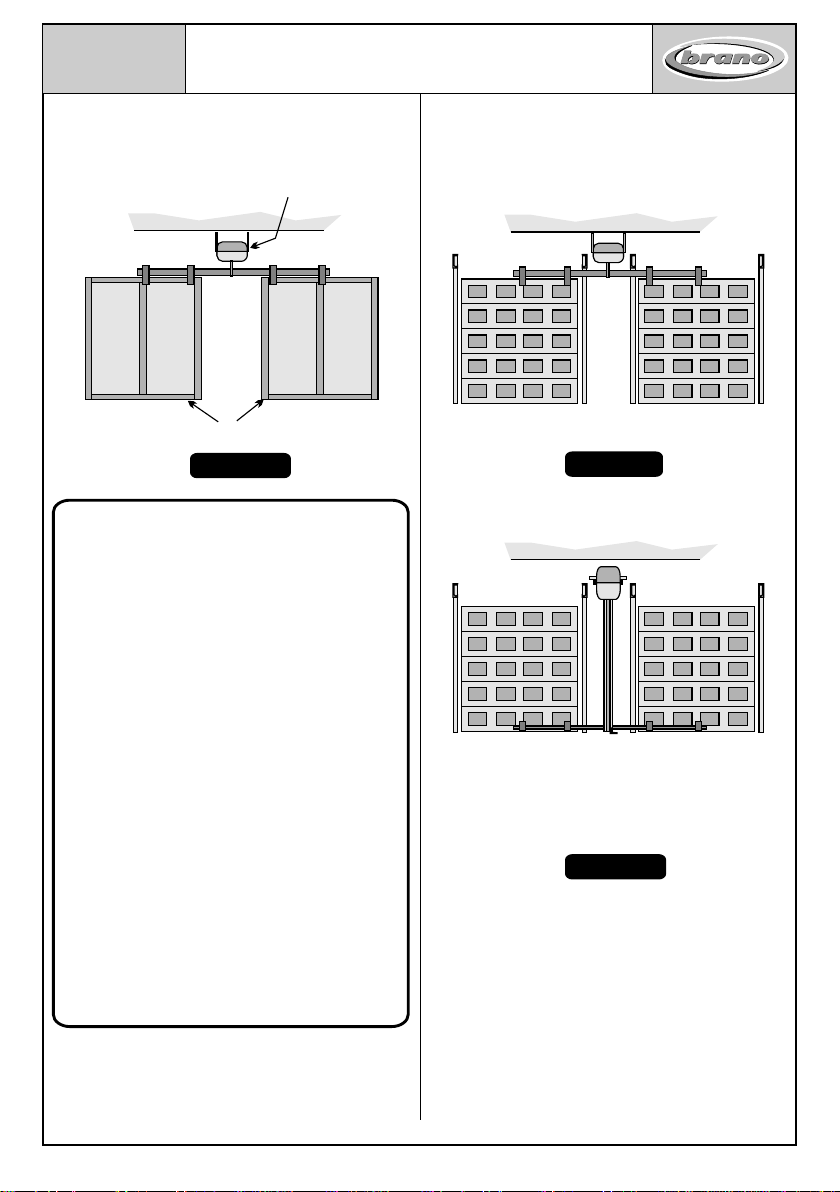

Electric

Motor

Motor

Capacitor

Rubber

Buffer

Base Plate

Lamp

Holder

"Opening" Sensor

Adjustor

"Closing" Sensor

Adjustor

Worm-shaft

Worm-shaft

Coupling

Wiring

Harness

Extrusion

Clamp P.C. Board

P.C. Tray

"Power ON"

Indicator Light

Power

Socket

Terminal

Connector

-pro alpha 2 0

00

LUBRICATION

DO NOT USE COMMON GREASE

USE ONLY "BRANO LUBRICANT GDO-L1" OR

"LOW-TEMP LUBRIPLATE" OR "AVGREASE28"

Serial Number

299 A 8 / 3478

Worm-shaft

Aluminium Housing

( Extrusion )

Emergency Pull

"Release Cord"

Light Diffuser

Lens Cover

Service

Cover

Lubrication

Label

Serial No.

Label

Traveller

Hanger

Bracket

"Open" Limit

Switch Wire

( Brown )

"Closed" Limit

Switch Wire

( Purple )

"Open"

Limit Switch

( "Closed" Limit

Switch not shown )

o

r

0

p

ha

p

al 2

0

-

0

LUBRICATION

DO NOT USE COMMON GREASE

USE ONLY "BRANO LUBRICANT GDO-L1" OR

"LOW-TEMP LUBRIPLATE" OR "AVGREASE28"

Serial Number

299 A 8 / 3478

GENERALDESCRIPTION

Electrically operated automatic garage door

operatorforuseondomestictypegaragedoors.

MAINFRAMEANDCOVERS

Galvanized steel frame supports the motor and

worm-screw housing. Moulded plastic cover

enclosesmotorandelectroniccontrolboard.

WORM-SCREWANDALUMINIUMHOUSING

Onepiecewormdirectlycoupledtothemotor.

O n e p i e c e a l u m i n i u m h o u s i n g .

ELECTRIC MOTOR

*Enclosed,fan-cooled,reversibletype.

*"SealedforLife"BallBearings.

*Singlephase-250W-50Hz-1450rpm-3,5A

POWERSUPPLY

*220V - singlephase - 50Hz

LIGHT

*Onelamp 100Wmaximumoutput.

*TypeBC-(Bayonetbase).

*Automaticcourtesylighttimer+/-3minutes.

*Light can be switched "ON" from the wall

pushbutton.

"pro-alpha 2000”

OPERATOR TERMINOLOGY

SECTION 2

Fig No. 13

brano industries (pty ) ltd

Copyright C

1998 / 1999 / 2001

page 06

“brano” door operator installation manual"

i n d u s t r i e s

3.6 Important Notes for Installers!

Always inspect the door first before

committingtoaninstallation!

Carefully inspect every component of the

garage door for signs of wear or damage. Be

particularlyvigilant formissingparts!

Checkfor .......

- stretchedorbrokenSprings,

- frayedorbrokenLiftingCables,(wireropes),

- wornrollers,pivotpinsandsheavewheels,

- damagedHinges,

- damaged Torsion Tubes and Support

Bearings,

- CableDrums,

- damagedLiftingandSteeringArms,

- damagedormissingStoppers,

- damagedormissinginternalLockingDevices,

- looseormissingnuts,boltsandscrews.

..... and repair or replace as necessary !

3.3 INSTALLATION PREPARATIONS

OnreceiptoftheDoorOperator,inspectthepackage

for any signs of shipping damage. If damage is

found, return the operator, complete with all

accessoriestoyoursupplier.

Insidethe package is a "packing slip". Stampedon

the slip will be a QC number, (Quality Control

number). Return this slip, or fax it directly to your

localagent withyourcomplaint.

BesuretoincludetheSerialnumberoftheoperator!

3.4 Check the contents of the package against the

"packing slip" to make sure it is complete. This

package contains all the hardware required to install

the operator onto a "standard" domestic garage

door. Also included are the Wall Push-button

Console, Kettle Plug Connector, "Safety" and

"Operation" information labels. If the door or the

garage itself does not conform to standard

specifications, special equipment may be required.

Contactyournearestagent/dealerforadvice.

The following items are not included in the

standardoperator hardwarekit:-

-a 3Pin-15Ampplugtop,

-lightbulb,(lamp)

-theelectricalpowersupplycable,

NOTE:-

"pro-alpha" Series 1 Door Operators

The installation techniques and especially the

electricalconnectionsandsetupproceduresfor

the Series 1 "pro-alpha" Door Operators is

different to those for the "pro-alpha 2000"

and“Aladdin”machines.

Refer to the specific instructions for the "pro-

alpha" Series 1 range of Door

Operators.

3.1 RECOMMENDED TOOLS

The tools required to successfully complete the

installationwilldependtosomeextentonthetypedoorto

be automated, i.e. is the door constructed of Steel,

Wood, Aluminium, Glass-fibre, or other material? The

more comprehensive the range of tools available, the

easier the job will be !!! Shown above is the range of

handtoolswerecommendyoushouldhave.

-Specialadaptororaccessorykits

-the Remote Controls. The remote controls

are not supplied as part of the basic operator kit

but are sold as optional extras as the type and

specificationsoftheremotecontrolswillvaryfrom

oneinstallationtoanother.

3.5 Ensure that you have the necessary tools to

complete the job. You are now ready to install the

dooroperator.

Turn to Sections 4& 5"Sectional" and "Tip-

UpDoorOperatorInstallationProcedures"

SECTION 3

PRE-INSTALLATION PREPARATIONS

Fig. 14

page 07

brano door operator installation manual"

i n d u s t r i e s

Low-Headroom Bracket for

Automatic Sectional Doors

1 KLHD - A

Description Product Code

SECTION 3

Locking Devices and Special Accessories

3.6.4 VeryImportant .............

If the door is balanced by means of

tension type springs, make sure the

Safety Cables are securely anchored.

If none are fitted to the door, insist that

these be fitted before the operator is

commissioned.

3.7 Locking Devices

It is necessary to render the locking devices

inoperative for normal automatic operation,

butdonotremovethementirely.

In the event of a malfunction of the door

operator, it is essential that the door may still

besecured.

The best way to do this is to pin the Lock

Cables or chains back with a screw or nail in

such a way that the Lock Catches are in the

"open"or"unlatched"position.

3.8 Garages Without Secondary Access

Doors

If there is no other means of access into the

garageexceptthroughthemaingaragedoors

themselves, it is necessary to install an

"Emergency Key-release" Kit for the door

operator.

It is also necessary to fit a normal outside "T"

Handle Lock to the door. In the event of a

malfunction of the operator system, the only

waytosecurethedoorwillbefromtheoutside

bymeansofthe"T"handleLock!

3.9 Special Accessories

Some doors may require the installation of

special equipment such as Low-Headroom

Bracketsinordertoallowthedoortowork.

Consult your “pro-alpha 2000"

dealerforadvice!

page 08

4 CABLE -SAFETY 1

"Spring Safety Cables" for

Tension Spring Systems.

1 KEYS

Emergency Key Release Kit

for Sectional and Tip-Up Doors

1 KEYPR

Emergency Key Release Kit

for Steel Roll-Up Doors

"Pro-Rola" System

Emergency Key Release Kit

for Steel Roll-Up Doors

"Side Mount" System

1 KEYR

“brano” door operator installation manual"

i n d u s t r i e s

ImportantNotes:-

The following table shows the minimum

amount of "Working Space" that is

required for the normal installation of

standard size Sectional doors. If the

space available is less than that stated

here, then special equipment may be

requiredtoundertaketheinstallation.

Certain assumptions have been made,

i.e.:-

1) Theopeningheightsare2135mmfor

standard doors or 2540 mm for

caravanheightdoors.

2) The structure is level, square, plumb

andtrueasthecasemaybe.

3) For Sectional Doors, the door panel

overlaps the opening by no more

than30mmatthetopandsides.

Contact your local dealer for advice

before committing yourself to a difficult

installation!

High-lighted Row Refers to a Standard Height 5 Section Door

( All dimensions in mm )

Floor

Level

Door Opening Height

Standard = 2135 mm

Back-reach of Door Operator

Hanger Bracket Position

Maximum Draw Length

Floor to

“Highrise" Level

Required

Headroom

Lintel

Ceiling

"High-Rise"

Point of Door

pro-alpha 2000

Path of Topmost

Section of the Door

12

3

Floor to top of

door operator

5

6

7

4

Opening No. of Track Headroom Highrise Hanger Top of Back-reach Draw

Height ( 1 ) Sections Radius Required ( 2 ) Level ( 3 ) Bracket ( 4 ) GDO ( 5 ) GDO ( 6 ) Length ( 7 )

2135 6 254 (10") 315 2380 2920 2445 3100 2350

2135 5 305 (12") 360 2420 2920 2500 3100 2350

2135 4 380 (15") 440 2500 2920 2575 3100 2350

2550 6 305 (12") 360 2840 3620 2910 3800 3160

2630 5 380 (15") 440 2925 3620 3070 3800 3160

Section 4

"Working Space" Tables for

Sectional Door Operators

All dimensions in mm

( Vertical scale is exaggerated)

Ceiling

0,0

40

80

120

160

200

240

280

320

360

400

0,0 100 200 300 400 500 700600 800 900 1000

..............

2200 2300 2400 2500

Lintel Level

Back-space

Recommended Headroom = 400 mm

Headroom

Minimum space required for

Door Operator Shaft = 75 mm.

page 09

Fig. 15

Fig. 16

4.1 Operator "Working Space”

“brano” door operator installation manual"

i n d u s t r i e s

Copyright C 1987 / 1990 / 1999 / 2001

brano industries (pty) ltd

20

60

100

140

180

220

260

300

340

380

0,0

400

Copyright C

1987 / 1990 / 1999 / 2001

SECTION 4

INSTALLATION PROCEDURES

SECTIONAL DOORS

4.2 Operator"WorkingSpace"

ApplicabletoAllSectional Doors!!!

Irrespective of the type or size of the

door that is to be automated, it is

absolutely essential to have adequate

"Working Space" for the equipment to

operatein.

The most important dimensions to

considerare:-

1) AvailableBackspace

2) AvailableHeadroom

3) Floor-to-"Highrise"point

4) Floor-to-TopofOperator

Inotherwords..........

.......theOperator"WorkingSpace"!!!

These 4 factors will determine the performance and

functionalityofthefinishedproduct!

Other useful information is included for installation

purposes. Refer to the relevant sections of this

manual.

Minimum Clearance Required

From Door "High-rise Point" to Ceiling.

75 mm

Sectional Doors

Operator- to-DoorClearanceat

"highrisepoint"approx.20mm

Fig. 17

Path of Topmost

Section of the Door

"High-Rise"

Point of Door

brano door operator installation manual"

page 10

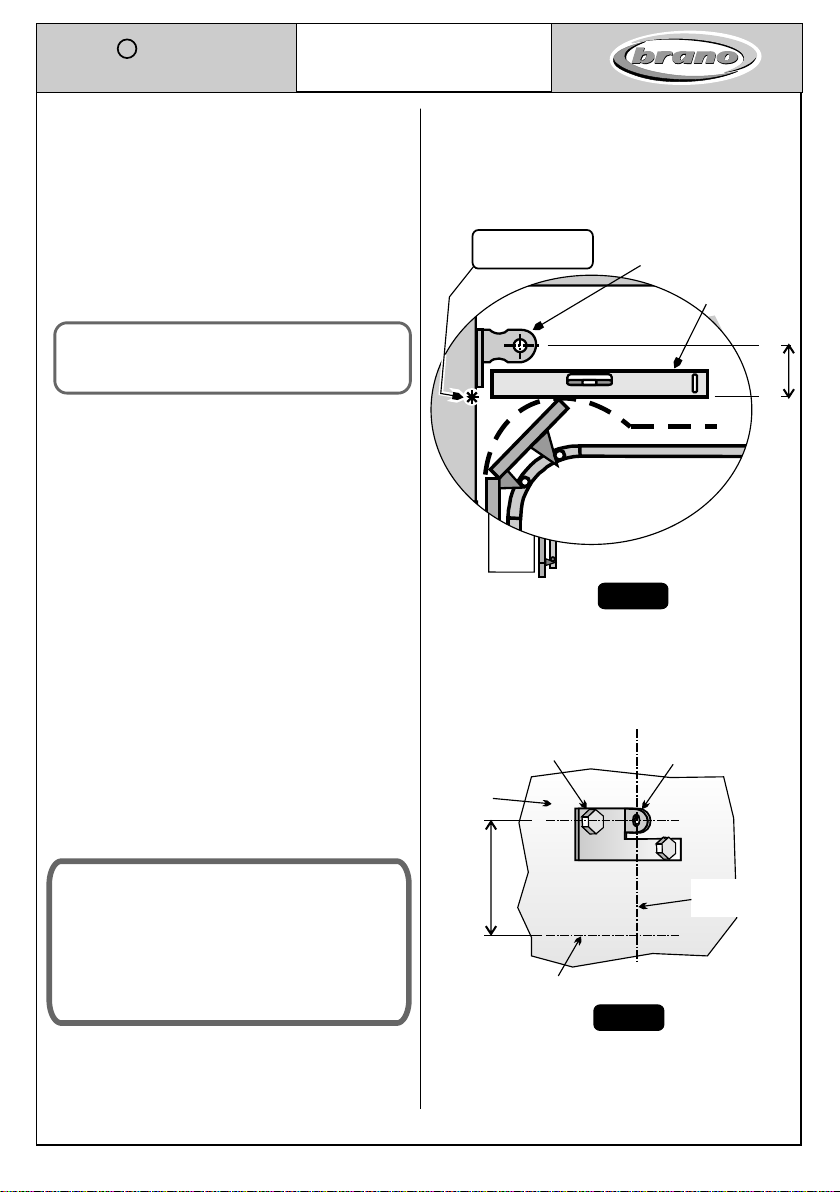

DoorTowingBracketandTopRoller

Bracketmustbeapproximately

inlinewitheachother.

Dimension "X"

*

Fig. 18

Wall Anchor

Bracket

Door Towing

Bracket Top Roller

Bracket

*

"X"

approx.

Centre Line of Door

4.3 Mounting the "Wall Header

Anchor Bracket"

Door

Track

View of Door From Inside

Header Bracket Position

Dimension “X”

( approximate value )

Track Horizontal Dimension

Radius Track “X" (approx)

Colour

250 mm Orange 300 mm

305 mm Green 360 mm

380 mm Blue 430 mm

i n d u s t r i e s

4.3.1 First ......Establish the centre-point of the

door.Mark-offthecentrepointalongthetop

rail.

4.3.2 Next..... Draw a vertical line on the wall

abovethedooratthecentre-pointposition.

4.3.3 Then..... Slowly raise the door taking note

of the highest position reached by the door

asitmovestothe"full-open"position.

Note:- Sectional Doors rise above

their "closed" positions as

theyopen.

4.3.4 Measure the height above the floor of the

"high-rise point" of the door. This

measurement is necessary in order to

establish the position of the Header

AnchorBracket.

4.3.5 Make a mark on the wall corresponding to

the "high-rise point" of the door. The

HeaderAnchorBracketisfixedabovethis

mark.

4.3.6 Position the Header Anchor Bracket, on

the wall in such a way that the right angle

face of the bracket coincides with the

centre-linemarkofthedoor.

4.3.7 Mark the positions for the fixing screws and

drill 10 mm dia. holes approximately 100 mm

deep. Insert the 2 "Green" plastic wall plugs

into the holes and fix the Header Anchor

Bracket in place using the two M 8 x 90 mm

Hex-head Washer-faced Lag Screws

supplied.

Note:-

It is very important that the Header

Anchor Bracket is well secured as

this fixture takes all the forces

actinginthesystem.

Fig. 19

Spirit Level

Wall Header

Anchor Bracket

"High-Rise"

Point of Door

Wall

M 8 x 90 Hex-Head

Coach Screws Wall Anchor

Bracket

Fig. 20

Centre Line

of Door

"High-rise"

Level of Door

80 - 130 mm

80 - 130 mm

door operator installation manual"

page 11

Copyright C 1987 / 1990 / 1999 / 2001

SECTION 4.3

Installation Procedures For

SECTIONAL DOORS

i n d u s t r i e s

Path of Topmost

Section of the Door

Ideal Clearance 20 - 50 mm

4.4 Mounting the "pro-alpha"

GarageDoor Operator.

4.4.1 For all overhead type garage doors, the

operatorissuspendedfrom the ceiling of the

garage by means of 2lengths of Punched

Angle which are attached to the Hanger

BracketsfixedtothePower-Head.

4.4.2 First..... Attach the Aluminium Extrusion

of the operator to the Header Anchor

Bracket using the M 8 x 25 Hex-head Set

Screwsupplied.

4.4.3 Next..... Temporarily support the Power-

head from the ceiling by means of a suitable

rope or prop it up with a ladder as shown in

Fig.21

4.4.4 Then..... Openthegaragedoorfully. This

willassist you to position the operator on the

"centreline"ofthedoor.

Preferred

Arrangement

Not

Recommended

4.5.1 MountingthePower-head

4.5.2 Establish the position of the nearest roof

beams or other suitable overhead structures

from which the operator may be supported.

Using the lengths of Punched Angle and

Fasteners supplied, suspend the operator

fromtheceiling.

4.5.3 Take care to ensure the operator is

positioned along the extended centreline of

thedoor.

Note:-

For all Overhead Track type doors, the

operator is mounted in such a way that it

is"horizontal",i.e."parallel"tothefloor.

Sectional Doors

Operator - to - Door Clearance

at "high-rise point" 20 - 50 mm

Fig. 21

Fig. 23

Fig. 22

Fig. 24

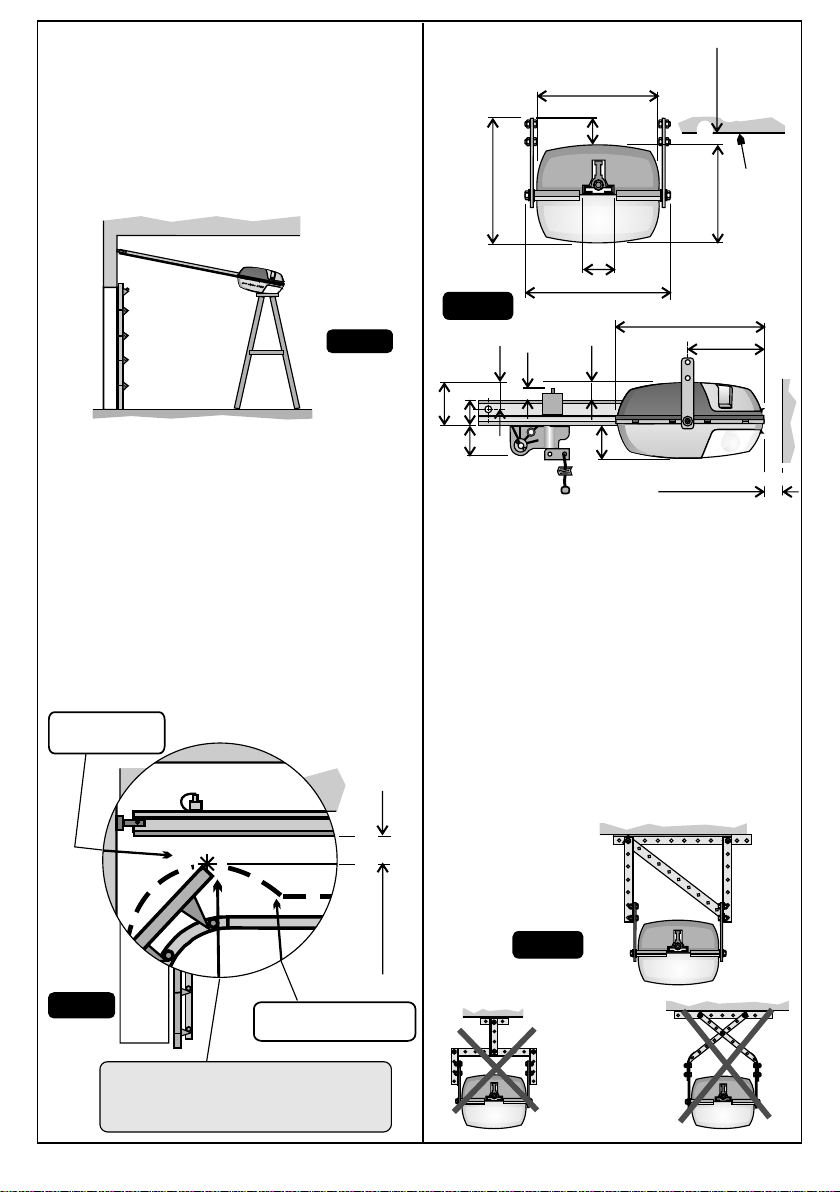

4.5 Useful Dimensions

370

10

60

93

67

58

46

190

Minimum

Back Clearance

20

35

230 Over-all

200

43

200

160

40

Ceiling

Minimum

Top Clearance

page 12

"High-Rise"

Point of Door

10 mm

Pro-alpha 2000

4.6 Restricted Headroom Installations

The Hanger Brackets are designed to be readily

adaptable for "low-headroom" installations. Make a 90

degree bend in the Hanger Bracket through the centre of

the lower of the two holes as shown. The bracket may

then be fastened directly to the ceiling. The clearance

between the ceiling and the operator will be sufficient to

allowtheremovaloftheoperator'sServiceCover.

Bend Line

09

Ceiling

minimum 10 mm

4.7 AttachingtheDoorBracket

- SectionaltypeDoors

4.7.1 TheDoorBracketisattachedtothedooratthe

centreline position in such a way that the

Clevis Pin in the Door Bracket is

approximately in line with the topmost

Rollersof thedoor.

4.7.2 Usethe threeNo 12 x 30 mm slotted pan-head

head screws provided to fix the Door Bracket

tothedoor.

4.8 AttachingtheTowingArms

OntoSectionalTypeDoors.

4.8.1 Use both the "L" Shaped Towing Arm and

theStraightTowing Armtocouplethedoorto

the traveller as shown in Fig 27. The "L" Arm

isattachedto thedoorwhilst theStraight Arm

isconnectedtotheTravellerasshown.

4.8.2 Use the two 10 mm dia. Clevis Pins and 2,5 mm

Split-Pins to couple the towing arm to the door

bracketandtraveller.

IMPORTANT NOTES:-

4.8.3 The towing arm should make an angle of

between75 and 80 degrees to the horizontal

whenthedoorisintheclosedposition.

4.8.4 The security of the locked door is a

function of the angle which the "Towing

Arm"makeswiththehorizontal.

15 degrees off the vertical is the optimum

angleforSectionaltypeDoors.

Door Towing Bracket Position

Roller Axis

Top Rail

of Door

Centre Line

of Door

Door Towing

Bracket

C/Line of

Clevis Pin

ptTo Sec ion

door

light

brano industries

CAUTION

Multi function

Push-button Console

and Label

Fig. 25

Fig. 27

Fig. 26

Approx.

15 Angle

75 - 80

Garage

Access

Door

page 13

Now turn to Section 6, page 18

forPCBoardconnections!

Brano door operator installation manual"

SECTION 5

"WORKING SPACE" REQUIRED

FOR TIP-UP DOOR OPERATORS

Tip-Up Doors

Op er ato r t o Do or

Clearance at "high-rise"

point 20-50mm

2575 mm - Standard height Tip-UP doors

Hanger Bracket Position

Fig. 29

i n d u s t r i e s

"brano door operator installation manual"

page 14

5.1 Operator"WorkingSpace"

ApplicabletoAllTip-Up Doors !!!

The same criteria as for Sectional doors apply

toTip-Uptypedoors.

See the diagram above and the relevant door

installation manuals for specific information

anddimensions.

Path of Top of Door

"HIGH-RISE"

Point of Door

150 mm

Minimum Clearance

Door's "Hig-hrise Point" to Ceiling

Floor

Level

Height of Door Opening

Standard = 2135 mm

Floor to "High-rise" Point

( +/- 2310 mm for std height door )

Top of Door, ( closed ).

Underside of Door Operator

Floor to Top of Wall Anchor Bracket.

Path of Top of Door

"High-Rise"

Point of Door Ceiling

"Highrise"

Level

Back-reach of Door Operator.

Minimum = 2760 mm for Std height door.

Available

Headroom

Lintel

2210 mm Maximum Draw Length

Max. distance Traveller can move.

Fig. 28

250 to 300 mm

Headroom Required for Tip-Up Doors

( All dimensions in mm. )

Steering Optimum Minimum

Arm Headroom Headroom

Setting Required Required

"Low" - 1 Not suitable for automation !

"Normal" - 2 300 200

"High" - 3 400 325

*Note:-If the Headroom Available is less than

theminimumrequired, specialequipment and

/ordoorsmayberequired.

Headroom

( See Table )

Required

NowturntoSection6,page18forPC

Boardconnections.

5.4.2 Use the two 10 mm dia. Clevis Pins and 2,5

mm dia. split-pins to couple the towing arm

tothedoorbracketandtravellerassembly.

5.4.3 IMPORTANT:- Theanglebetweenthe

Towing Arm and the horizontal plane

shouldbeasfollows:-

Tip-Up Doors - between 15 and 30

degreestothehorizontalwhenthedoorisin

theclosedposition.

5.4.1 AttachingtheTowingArm

Use the "Straight" Towing Arm, (Part

2TOWT),tocouplethedoortothetravelleras

showninFig.32.

If the "L" shaped towing arm is to be used,

(Part 2TOWLS ), use the arrangement

showninFig.33.

5.2 One-piece Trackless and Pivot Type Tip-

UpDoors

5.2.1 The Door Bracket is attached to the door at

the centre-line position as close to the top of

thedooraspossible.

5.2.2 Use the three # 12 x 28 mm hex head Lag

Screws provided to fix the Door Bracket to

thedoor.

5.5 Alternative Towing Arm

Arrangement for TIP-Up Door

Door Towing

Bracket

"L" Shaped Towing Arm Arrangement

Door Towing

Bracket

15 - 30

Straight Towing Arm Arrangement

SECTION 5

INSTALLATION PROCEDURES

TIP-UP DOORS

Position3

"High-headroom"Position

Best position for automatic

operation. Minimum Headroom

required=350mmabovedoor

Position1-"Low-Headroom"Position

Notsuitableforautomaticoperation.

Position2-"Normal"Position

Most commonly used position for

automatic operation. Minimum

Headroom required = 250 mm

abovedoor

Door Jamb

Mounting Channel

12 3

5.3 Steering Arm Settings

Jamb Mounted

"Power Plate"

Fig. 30

Fig. 31

Fig. 33

Fig. 32

VIEW OF INSIDE OF DOOR

Fix the Door Towing Bracket

ascloseto thetopof thedoor

aspossible.

Door Towing

Bracket

Door Jamb

Mounting Channel

*

Wall Anchor

Bracket

Centre Line

of Door

page 15

i n d u s t r i e s

5.6 Installation Of Door Operator On A Jamb-Spring

System Tip-Up Door Using An Extended Towing Arm

Path of Door Insufficient clearance available

between door and ceiling for an operator.

Installation In Garage With “Low

Headroom”

“TracklessTip-Up”DoorsOnly!!!

If there is insufficient clearance

between the path of the door and the

ceiling, it is permissible to move the

motor back away from the door and fix

the "Anchor Bracket", (or Header

Bracket),to the ceiling andmakeuse of

an "Extended Towing Arm" to couple

thedoortotheoperator.

*

po

r

0

0

a

-0

h

p

a

l2

SECTION 5

PROBLEM INSTALLATIONS

i n d u s t r i e s

Fig No. 34

" H i g h r i s e " P o i n t .

Nor mal P ath o f Doo r wit h

standard type “Adjustable Top Roller

Bracket" Installed Door Clearance Increased

by approximately 60 mm

Door in fully

"Opened Position"

"Highrise" Point.

Path of Door with

"Low-headroom"

Brackets Installed.

Door

Track

"Low-headroom" Bracket

Rollers

Automatic Door Installation

5.7 Installation Of Door Operator On A Sectional Door

Having Insufficient Headroom For A Door Operator

Fig No. 35

page 16

Fig No. 36

Ifyouexperiencea problem......... ChecktheInstallation!

Ifthatdoesn’thelp ......... ReadtheManual!

Iftheproblempersists ........ Book yourself into one of our

TrainingCourses!

Thereisnosubstitutefordoingitrightthefirsttime!

Fig No. 37

5.8 “Emergency Key-Release” Mechanism For Sectional and Tip-Up Doors

The "Emergency Key-Release" is a

specialmechanism whichisfittedtoa

doorwhen....

..... the only access into the garage

is through the garage doors

themselves, i.e. there is no back or

sidedoorentranceintothegarage.

This special release mechanism

permits the manual operation of the

door in the event of a power failure or

otherbreakdownofthesystem.

The Installation procedure for both

Sectional Doors ( shown ), and Tip-Up

Doorsisthesame.

PULL

STEEL CABLE

TRAVELLER LEVER

in "normal"

operating position

LOCK LOCK

CYLINDER

1/4 TURN

KEY

"pro-alpha 2000"

SECTION 5

PROBLEM INSTALLATIONS

i n d u s t r i e s

page 17

C

BEAM

11

LIGHT

BEAM

LOCK

TRIGGER

COMMON

COMMON

12 V +

Fig. 40

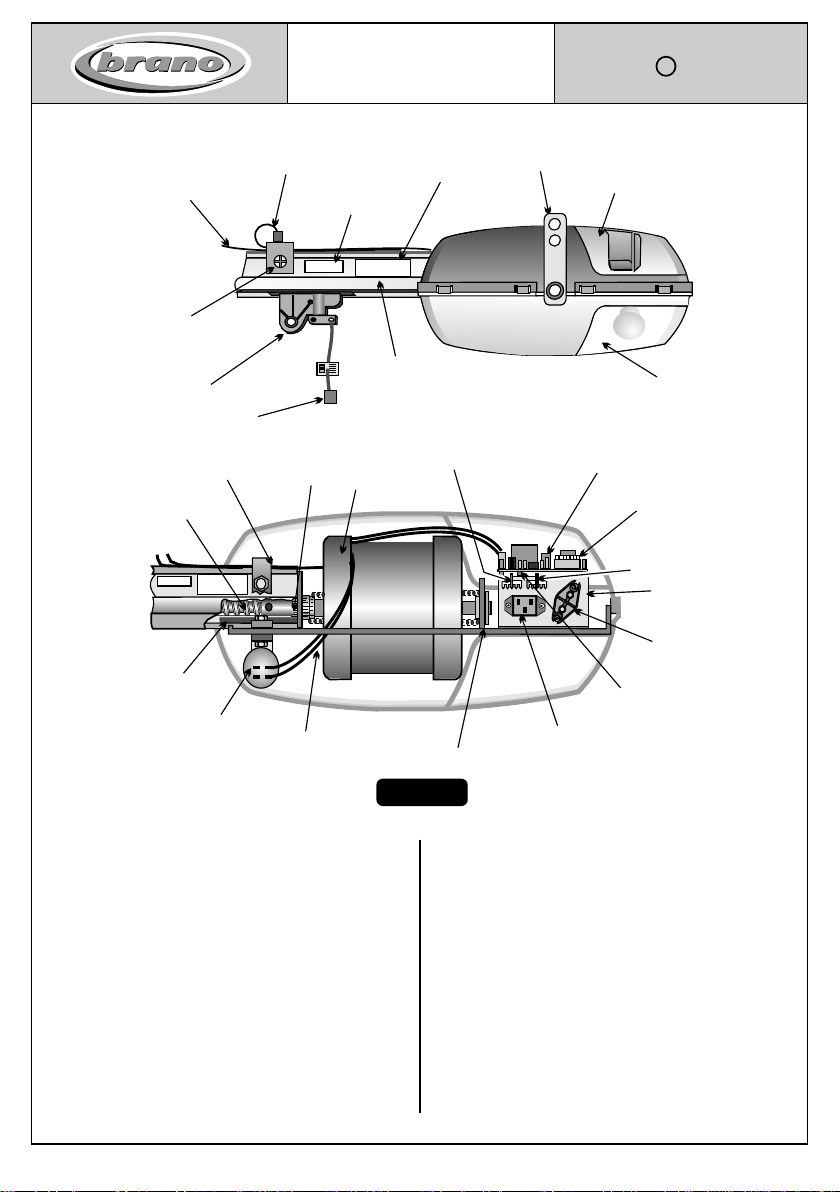

SECTION 6

"pro-alpha 2000"

PC Board Connections Rev 2 April 1999

Rev 3 October 2001

CONNECTING THE RADIO RECEIVER

Aerial - Do not cut

or remove

Dipswitch

Block

( Simple Dipswitch Type )

Radio Connections

to Door Operator's

PC Control Board

Operator PC Board

Typical Radio

Receiver Board

Terminal

Block

( Red )

( Green )

( Black )

( Blue )

1

2 3 4 5 6 7 8 9 10 1 12

1

ON

OFF

--

COMM

++

12 V

NO

NC

NON-LATCH

LATCH

GND

A

brano

Note:-

PC Board jumper switch is

set to "NORMAL" position.

Connect the Radio

Receiverasshown.

TakeNote:-

1) If no "Safety Beams"

are to be fitted then the PC

Board "jumper switch"

must be set to the

"Normal"position.

2) The wire colours as

supplied may vary from

thoseshown.

Fig. 38

"DOWN Over-load"

Sensor Adjustment.

( Sensitivity )

"UP Over-load"

Sensor Adjustment.

( Sensitivity )

Terminal Block for

connection of Radio Receiver,

Wall-Pushbutton and

Safety Beams.

"pro-alpha 2000" PC BOARD - GENERAL LAY-OUT

brano industries (pty) ltd.

PC Board Lay-out

FORCE ADJUSTMENT

CLOSING OPENING

DOWN

UP

LED

+

OVERL.

UP

DOWN

LAMP

220 V

COMMON

NORMAL

C

BEAM

LIGHT

BEAM

LOCK

TRIGGER

COMMON

COMMON

12 V +

11

NORMAL

Fig. 39

CONNECTING THE WALL PUSH-BUTTON

Lock

( White )

( Brown )

( Blue )

( Black ) Light

Trigger

Common

Door

Push-Button

Light

Push-Button

Operator PC Board

pro-alpha

door

light

lock

off on

brano industries

Wall Mounted

Push-button Console

C o n n e c t t h e W a l l -

Pushbuttonasshown.

TakeNote:-

1) If no "Safety Beams"

are to be fitted then the PC

Board "jumper switch" must

be set to the "Normal"

position.

2) The wire colours shown,

( White, Brown, etc. ), are

typical only. The colours of

the wires as supplied may

varyfromthoseshown.

Note:-

PC Board jumper switch is

set to "NORMAL" position.

C

11

LIGHT

BEAM

LOCK

TRIGGER

COMMON

COMMON

12 V +

BEAM

NORMAL

i n d u s t r i e s

"brano door operator installation manual"

page 18

Door Lock

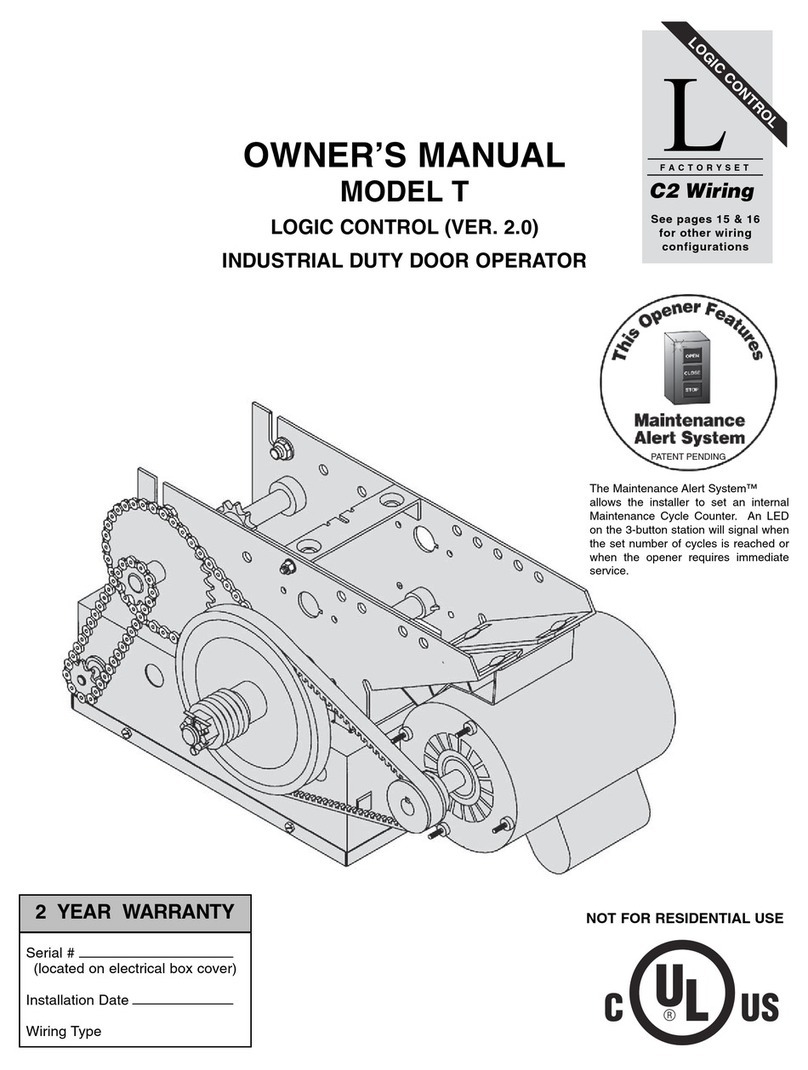

Table of contents

Other Brano Industries Garage Door Opener manuals

Popular Garage Door Opener manuals by other brands

Garaga

Garaga SECURITY+ 3265GCM 1HP owner's manual

Chamberlain

Chamberlain Whisper Drive SECURITY+ WD822K Series owner's manual

Chamberlain

Chamberlain T owner's manual

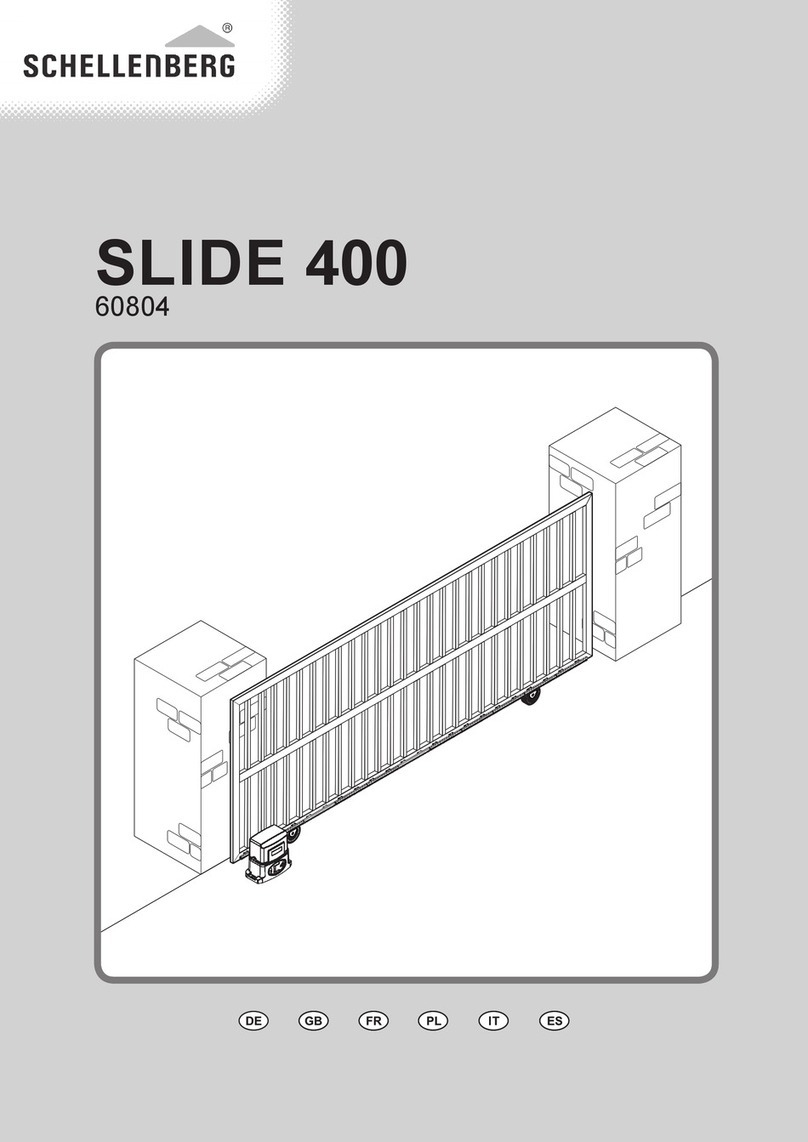

Schellenberg

Schellenberg STA Slide 400 instructions

Chamberlain

Chamberlain Merlin Professional MT230 Installation and operating instructions

Abloy

Abloy DA460 Installation and commissioning manual

BFT

BFT KR92522800003 Installation and user manual

Raynor

Raynor 3245RGD 1/3 HP owner's manual

Whisper Drive

Whisper Drive 248739 owner's manual

Chamberlain

Chamberlain ATS 211 owner's manual

Chamberlain

Chamberlain C450 owner's guide

Comunello Automation

Comunello Automation RAMPART 600 Installation and user manual