NOTE

For lightweight garage doors, make sure you have

installed the proper reinforcement (See Check Door

Condition and Thickness on page 5 in manual),

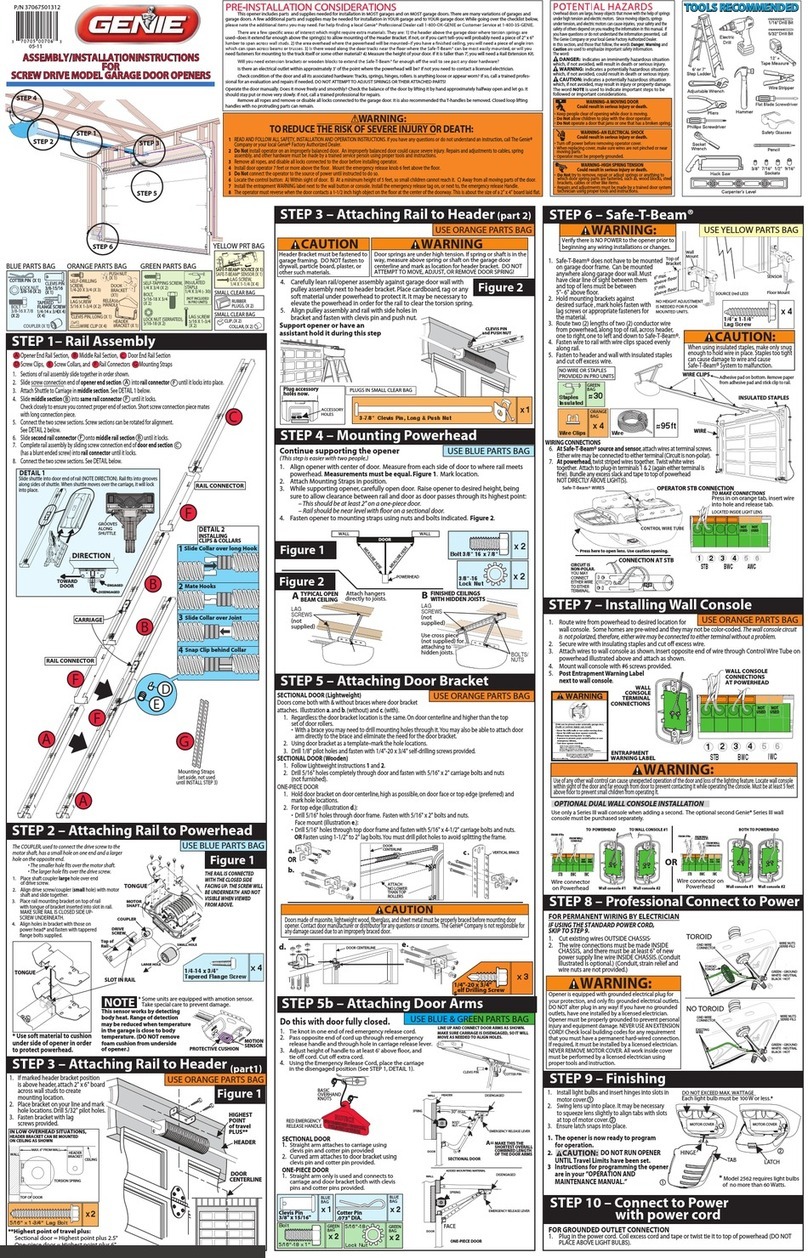

• TheHeaderBracketmustbefastenedtothe

mounting plate for the Header Bracket,The

Bracketcan then be mounted at the propel

location and have sufficient Support.

If a door springis inthe way place the Header

Bracketabove the spring, DoNot move the door

spdngi

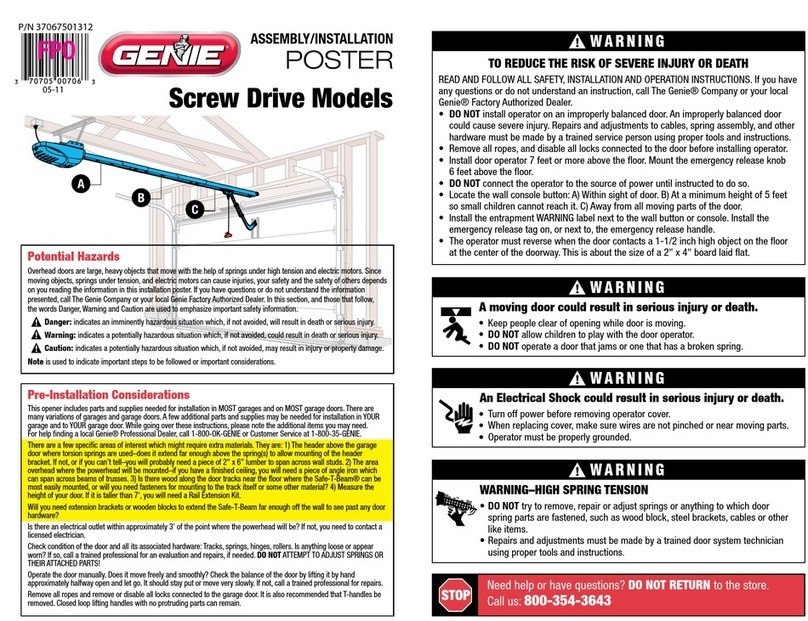

A Before mounting the header bracket, see CHECK

STEP4, in Operation & Maintenance Manual for

mounting instructions, ff needed, attach a 2"x 6"

board across wall studs where you made your

Header Bracket mounting point mark (Figure 8).

Transfer your mark from wall to board.

B Attach Header Bracket to header at your mark

above garage door.

NOTE

R is critical that point where Rail attaches to

Bracket be on centedine of Door.

Mark two Bracket hole mocations.

Drill 2 (5/32") pibt homes.

Attach Header Bracket using 2 (1/4"x 2") Lag

Screws.

DOoisrnadeofmas0nite:lightweightWOod, I

fiberglass,metN,orother lightweightmaterialsmust

be proper y braced before mount ng door Opener. J

For sectional doors:

A Place Door Bracket on door center line, no lower

than top roller, and mark holes (Figure gh

[3 Attach Door Bracket:

For metal doors, use 3 (1/4" =20x 3/4") Self_

Dri[ming Screws (provided).

For wooden doors, use 3 (1/4" x 2") Lag Screws or

_ (1/4" x 1=!/4") Lag Screws or 3(1/4" x 2=1/2")

arriage boks (not provided).j

Before installing, check length of the induded Lag

Screwsvs. the thickness of your garage door. For doors

thinner than 2", use 1ol/4" Lag Screws.Checkdoor

condition and thickness.See page3 in Operation &

Maintenance Manual

For one-piece doors:

A Position Door Bracket on door's center line, as high

as possible or on top of door.

B Attach Door Bracket:

For metal doors, use 3(1/4" =20 x 3/4'*) Serf=

DNlling Screws.

For wooden doors, use 3 (1/4" x 2") Lag Screws

or 3 (1/4" x 2")Carriage hefts (not provided).

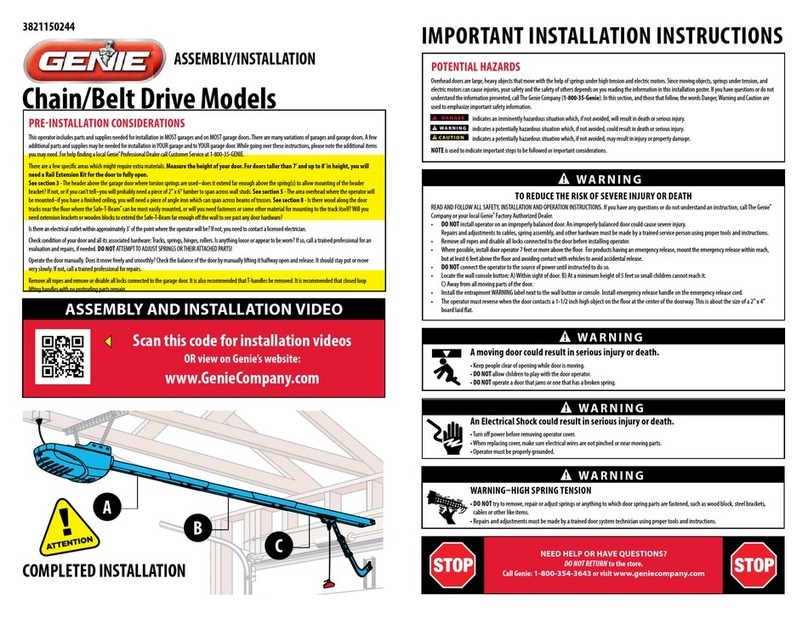

ATTACH RA|L TO HEADER

[}RACKET

A While supporting the Power Head, place threaded

end of Rail Strap Bolt through Header Bracket hole

(Figure lg).

B Attach (S/16"=18) FDnge Nut to Rail Strap Bolt.

Finger=tighten unti| |ater.

MOUNT'NOPowERHEA

Z UTnO

ounting Bracketsmust befastenedto garaqe fram!ng,De Ngt 1

fastento drywall, particleboard,plaster,or orbet suct_rhateriak

. Makesuretherailof yoursupportedPowerHeadisslightlyhigherthan

thehighestpointof doortravelbyraisingthedoortocheck.Adjustas

needed,

, MaterialsneededformountingOpenerPowerHeadtogaragemay

vary.Readallinstructionscompletely.

. Garageconstructionsdiffer.Extramaterialmaybeneeded,SeeCheck

PowerHeadMountingAreaonpage7in manual

A RaisePowerHeadand support it high enough that you can

manuallyraisethe garagedoor fulmyopen,

B Line up PowerHead and Railwith center of garagedoor.

C KeepingPower Headcentered,mount to ceiming:

At proper height;

a. For sectieea[ deers, mount power headat a height

whererail islevel with fleer or slightly bwer.

- Checkfor clearancebetween Railanddoor asit

opens(Figure 11).

b, For or.e-piece deers, mount power headso that

there is aminimum dearance of 2"betweenrail and

dooras it opens (Figure11 ).

D Using one ofthe preferredmethods shown (Figure12}, mount

PowerHead(Use5/1B'-18x 3/4 hexhead Boltsand S/16'q 8

FlangeNuts).(Itis possibb to useother mounting methods,The

critical point to rememberis that the mounting assemblymust

be solidlyattachedand ableto support the weightof thePower

Head.)DONOTATTACHTO DRYWALLORSUSPENDEDCEILING.It

must be anchoredto thegarage framework,

ASSEMBLEAND CONNECT

DOOR ARMS

For sectional doors:

A Attach short side of Curved Door Arm to Door

Bracket with Clevis Pin and Cotter Pin (Figure 13).

[3 Attach Straight Door Arm to Carriage with Clevis

Pin and Cotter Pin.

CAttach both Arms together with 2 (3/'8" x 7/8") Hex

Head Bolts and 2 (3/8") Serrated Flange Hex Nuts

so overal[ [ength is as short as possible. Securely

tighten fasteners.

D Adjust height of Emergency Release Cord Knob to

6' above floor:

Pull Cord through Carriage Release Lever until

Knob is 6' from floor.

Tie a new overhand knot in Cord at Carriage

Release Lever.

For one-piece doors:

A Attach Straight Arm to Door Bracket with CmevisPin

and Cotter Pin (Figure 14).

B Attach short side of Curved Arm to Carriage with

Clevis Pin and Cotter Pin.

CAttach both Arms together with 2 (3/8'* x 7/8") Hex

Head goffs and 2 (3/8") Serrated Fbnge Hex Nuts

so overall length is as |ong as possible_ Securemy

tighten fasteners.

D Adjust height of Emergency Release Cord Knob to

6' above floor:

Pull Cord through Carriage Release Lever until

Knob is 6' from floor.

Tie a new overhand knot in Cord at Carriage

Release Lever.

Do Not skip Step D above[

Failure to comply may leave Emergency

ReleaseKnob within reach of Children: ff the

Knob ispulled with ga[age door fully or

partially open, garage door may dose RAPDLY

without wamiDg!

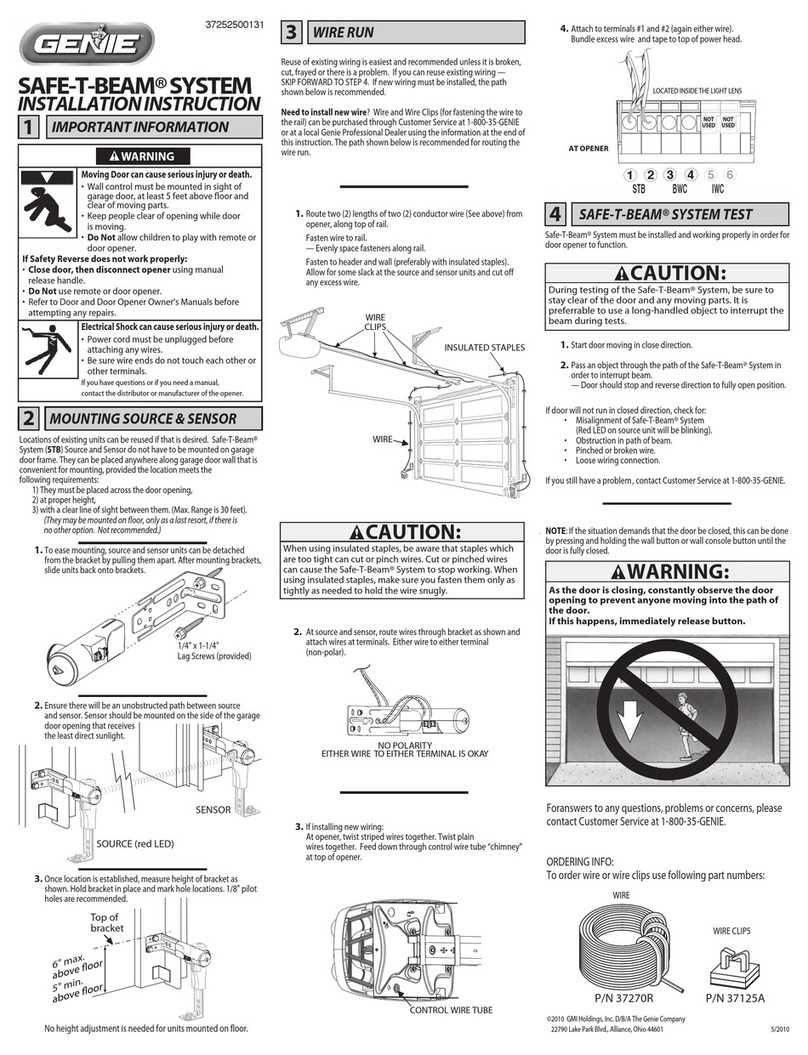

SYSTEM

ELECTRICAL WARNING-

Ensure there is NO power to the Opener before

installing Safe-T-Beam® System wires.!fOpener !s

plugged into outlet, Unplug it Now,

NOTE

The Opener will not dose the door automatically unless

the Safe-T-Beam ® System is installed.

A [nsta[I Safe=T=Beam ® Source and Sensor

(Figure1S):

Mark both sides of garage door frame or waHH

6" above floor.

Hold Bracket against door frame or wall Check

if Bracket extends out from wall far enough so

tongue of Bracket is beyond door, tracks, or

any door hardware. Hfnot, Safe=T=Beam ®

Mounting Bracket Extensions are avaimabme

from a Genie Factory Authorized Dealer or

through the Accessories Order Form_

- Bmocksof wood, etc. may be substituted for

extensions.

Position top of Mounting Bracket at 6" mark

and fasten with 2 (#10=! 6 x 1=1/4") Phillips Hex

Head Screws per Bracket.

NOTE

Mounting Brackets can be attached to brick walls or

concrete floor using masonry anchors (not included).

B Attach Safe=T-Beam ® Source (Red LED) and Sensor

(Green LED) to Brackets (Figure 1S):

For s[ngle-door garages_

- Determine which side of garage receives

the most direct sunlight, and place Source

(Red LED) on this side whenever possible.

For multipb-door garages see (Figure 16).

Preventing crossed signals is critical

Place Source and Sensor modules on

adjacent doors facing in opposite directions.

[ NOTE

To help prevent interference from the sun, the Safe-T-

Beam ®Sensor (Green LED) may be placed further away

Ifromthe door opening,where it will spendmore time

in the shadows.

Slide the Safe-T-Beam ®Source and Sensor

onto the tongues of the Brackets until they

click into pbce,

Check final height of Lens (Figure 17).

CAUTmON

StapleswhicharetOOtight mayCutorpinch Wires.CUt

or pinchedWirescancausetheSafe-T-Beam®System

tostopworking,Wheninsta!lingtheBulated Staples,

makesureyoufastenthemOn!yastightlyas needed

to holdtheWiresecurely.

CInstall Safe-T-Beam ®Wiring: (Figure 18)

Route Wire and hsu[ated Stapmes

(F_gure lg, and 20).

- Securemyfasten Wires with hsuhted

Stapbs as you go. Stapbs should be snug

only.

- Wires between garage wall and Power

Head should be run on top of Rail and

underneath Wire Cmips.

Attach Wires to Safe=ToBeam ®Sensors.

- Spmitand strip Wire ends to be connected

as shown.

- Loosen Terminal Screws.

- insert each Wire under flat plate and

tighten Screw. It does not matter which

Wire, white or striped, goes on which

Terminal,

Attach Wires at Power Head.

- Wires are connected to Terminals #3 and

#4 on Power Head Terminal Block. ff does

not matter which WR'e, white or"striped,

goes on which Terminal

Check the following.

- Ensure that no part of door or its hardware

is in path between Source or Sensor

Lenses.

Ensure that tops of Lenses are between 5"

- 6" above floor. Brackets are flexibme and can

be adjusted sIightmy if needed.

NOTE

®

The Safe-T=Beam alignment check will be performed

following connection to eieEtriEal power. Do Not plug

in yet[

WALL CONTROL[NSTALLA_ON

[_ wAR.m.G

More than one lighted Wall Central per Opener will

causea maffunEtion.

WALL CONTROL (Figure 21 & 22)

AFinding the mounting location(Figure 22).

Pick a convenient location for mounting wail

control

- Location you choose should be in direct

sight of door.

-hshould be at least S'above floor to

prevent small children from operating

door.

- It must be away from any moving parts.

(You should not be able to reach the garage

door while standing at Wall ControL)

[} Wiring (Figure 22):

Run wire from Power Head to Wall Control.

Securemy fasten to ceiling and wall using

insulated staples provided.

SpHit and strip ends of wire.

On Power Head:

- Attach the striped wire to Terminal #1

and white wire to Terminal #2.

On back of Wa[I Control:

- Attach striped wire to Termlna|"B'[and

white wire to Term[naJ "W':

CMounting:

Fasten wail control to wail with 2 screws.

_ _ #6 x 1=1/4"

Remove protective backing from Entrapment

Warning Label

- Stick bbem on wall near Wall Control

CAUT[O

' Use of any wall Consoles other than the type

Jndudedwillpreventthelightfromworking

hold the Wiresnugly.

] A WA RNmN

To reduce the risk Of e[eEtrical Shock, this equipment

hasagroundedtype plugthat includesa third

(grounding)pin.Thisplugwi[[onlyfit a groundedtype

outlet, if you do not have a grounded outlet, contact a

qualified electrician to instal[ one. DO NOT aJter the

plug in any way. The door opener must be proper[y

groundedin order to preventpersonalinjuryand

damage to the components.

Connection with grounded plug:

A Checklocal building codes:

Does buimding code require permanent wiring?

ff yes, have an electrician perform

"Connection with permanent wiring" below.

ff no, pmugdoor opener into grounded

outlet.

.Perform Safe=T-Beam ® alignment check below.

Connection with permanent wiri#g

(Instructions for [kensed e_ectrician):

A Remove powerfrom circuit.

B Remove Motor Cover.

Remove 4 screws from Cover and slide down off

of Power Head (Figure 23).

Remove and discard power cord.

Cut power cord inside Power Head.

Remove and throw away power cord, strain

relief and knock uut.

D install suitable entrance bushing and power supply

wire.Connect permanent wiring to Power Head.

NOTE

There must be at |east 5 inches of black

and white wire inside of Power Head

(between splice and entrance bushing).

- Connect white supply line to white wire.

- Connect black supply line to black wire.

- Connect ground to green wire (ground).

NOTE

Use only UL recognized wire nuts.

Replace Motor Cover.

Slide Cover into place.

Replace and tighten 4 screws.

F Reconnect power to circuit.

Safe-T-Beam e Alignment Check:

After turning electrical power on, if STBs are not

properly aligned, red LED (source) will b_ink

continuously.

B To correct problem--STB mounting brackets are

flexible and may be adjusted slightly to bring the

system into alignment.

When STBsare brought into alignment--red

LED will stop b_inking and stay _it.

FORCE CONTROLS

Rough Setting of Limit Switches

A Setting Close Limit Switch (Pigure 24):

Check that Carriage Assembly is disengaged.

With garage door fully closed, slide Close Limit Switch

toward Carriage ueq it is aligned with

Carriage magnet.

Tighten Set Screw. Do Not over=tighten.

Setting Open Limit Switch:

Manually open garage door to full open

position.

Slide Open Limit Switch toward Carriage unti_

it is aligned with Carriage magnet.

Tighten Set Screw. Do not over=tighten.

Re=engage Carriage Assembly.

Setting Force Controls e_d Final Adjustment

of Limit Switches

m

• Thegarage dooropens rapidly, and Can pause

sedous injury or death.

, Keep the path dear.

. Position the ladder to the side of the Power

Head so it isclear of all moving parts of the

Opener and the door.

- Set the door Opener to use the m!n!mum force

needed to open the door.

Little effort is required to turn the Force

Adjusting Knobs.

ffthe door stops moving while opening or

dosing, adjust the Open Force or Close Force

Controls slightly clockwise (to slightly

increase the force) and retry the step.

The Open Force and Close Force Controls

are tobe set to the mimimum force

necessary to ensure the door smoothly

opens and closes completely.

The garage door wi[[ move slowly the first

time it runs, until the Opener "learns" the

type of door.

Ensure the Carriage Assembly is engaged

and is between the two Limit Switches

before operating the Opener.

A

B

C

D

Pre=set Force Controls to midpoint between

LO and H[ (Figure 25).

Adjust the CHose Limit Switch:

Press Wall Console to close garage door.

- If door does not dose completely, measure

distance from bottom of door to floor. Move

Limit Switch same amount toward door.

- If door reverses after contacting floor,

move Limit Switch toward Power Head.

- If door reverses before contacting floor,

increase Close force.

Tighten Limit Switch Set Screw. Do not over=

tighten (strip) Limit Switch Set Screw.

Adjust Open Limit Switch:

Press Wall Console to open garage door.

- ffdoor does not open completely, move

Limit Switch toward Power Head.

- ffcarriage is crashing into power head,

move Limit Switch toward door.

Tighten Limit Switch Set Screw. Do not over-

tighten (strip} Limit Switch Set Screw.

Test Door Opener:

Run door up and down a few times using the

Wall Console and observe door travel

Repeat steps above as needed to set Limit

Switch positions.

Adjust Open Force to minimum needed

(Figure 2S):

Place door in dosed position using Wail

Console.

Gently adjust Open Force fully

counterc[ockwBe (minimum force).

Run Opener using VVaHConsole_

Observe that door runs to Open Limit Switch.

- if not, adjust Open ForceControl slightly

clockwise, dose garage door,and open it again.

Repeat steps above until garage door runs

smoothHy from Close Limit Switch to Open

Limit Switch.

Adjust C|ose Force to minimum needed

(Figure 2S):

Place door in open position using Wall

Console.

Gently adjust Close Force fully

counterclockwise (minimum force).

Run Opener using Wall Console.

Observe that door runs to Cbse Limit Switch.

- Ifnot,a_ust CloseForceControl slightly

clockwise, open garage door, and close it again.

Repeat steps above until garage door runs

smoothly from Open Limit Switch to Close

Limit Switch,

SAFE-T-BEA_ ® FUNCTmON

[

Limit Switch and Force Adjustments must be completed

|before checking the contact reverse function F sure 25).

A Open garage door using Wall Console.

Lay a 2" x 4" board flat in center of doorway

(Figure 26).

CCHosedoor using Wa[_ Console.

D Check that door stops and reverses within 2 seconds

after it contacts board:

o If door does not reverse, decrease Close Force

untiH door reverses.

,ff door still does not reverse, move Limit

Switch toward door.

E Check Safe=ToBeam ® System (STB) operation:

• ff beam is blocked, door will not dose (Figure 27).

NOTE

Thedoor must contact the2" x 4" board beforethe Carriageacti-

vatesthe CloseLimit Switch.If not,readjustthe dose Limit Switch.

Program Transmitter, install Light and Lens

A See Operation & Maintenance Manual.

I NOTA 1

[Pare puertasdesara ede peso[igeras,asegOresede queha

|instahdo los refuerzosadecuados(Veala secciBnsobre

[verificaciBn de lacondiciBn y espesorde la puertaen la pagina S)_

_ONTAR EL SOPORTE DE

TRAVESA£O

PRECAUTION

' E[ soportede[travesahodebeasegurarseaB estructurade[garaje.

NoIoasegureaparedesagdetadas,detablesdeaglomerado,yeso,u

otros materMessimilares.

o Puede sernecesadoer.samNarunatabBde2'x6"a b largodela

estructurameteilicade la paredbcalizadaperendma dd travesaho

dela puertaparaquesirvacome plata demontajedel soportedel

travesa_o.E[soportepuedeer.toncesmoetarseene[Dgar

adecuadoytenet refuerzosuficiente.

Siur.rosettede la puertainteffiere,coloqueeBoporte de[

travesa_operencimadel resorte.Nomuevaelresortede [apuert&

Siserequiere,ensambleunatabh de2"x 6"(Figure8) cona[menos

dos(cuatroesrecomendaNe)tornillosparamaderay rondanas

planas(noinduidasconelpaquete).

B Ponga el lade derecho de[ abrepuertas hacia arriba, y

sostenga [acaja del motor de manera de evitar el

romper los portal_mparas.

Lasvariaciones de montaje se muestran en ia Figure 8.

Cuaiquiera de esas puede usarse dependiendo dei espacio.

Sin embargo, escriticoque ei punto donde se ensambia ei

rid a_soporte del travesafro est_ en _aiinea de centre de _a

puerta.

•Marque Insposiciones de los 3agujeros.

•Barrene 3agujeros pibto de 5/32':

•Ensamble el soporte del travesaho usando 3 torni[Ios para

madera de t/4"x 2'.'

_ONTAR EL SOPORTE DE

LA PUERTA

PRECAUT[O

as puertas hechas de masonita, madera ligera, fibra de |

vidno, metal, u otros materia[es ligeros ddSen asegurarse

adecuadamente antes de insta[ar e[ abrepuertas. J

En el Case de Puertas Secci6nadas:

A Co[oque e[soporte de [apuerta en [alinea central de [apuerta,

procurando que no quede masabajode[ rodi[[o superior,y bs

agujerosguia hechos(Rgwa 9).

[} Acopbr el soporte de Hapuerta:

• Para puertas met_[icas, user 3 torni[[os autorroscantes

(de 1/4"=20 x 3/4") (que se proveen).

• Para puertas de madera, usar 3 pijas (de 1/4"x 2"6

3 pijas (de 1/4"x 1=1/4") (no se proveen).

[

Antes de instalar,verifique b Iongitud de bs tornillos para madera

induidos en elpaquete contrad espesor de la puerta de su garaie,

Para puertasm_s ddgadas a 2'; use tornillos para madera de -1/4'.

VerifiqueHacondkidn y espesorde la puerta.VeaHapggina3 en El

ManualdeMantenimientoyOperaci6n.

Pare Puertas de ann sole plezas:

A Coloque elsoporte de b puertaen la [ineacentral de B puerta,

tan alto come seaposiNeo en sucaseen b parte superiorde b

puerta.

B EnsamNeel soporte de b puerta:

•Parepuertasde metal use 3torni[[os autoroscarttesde

(1/4"-20 x 3/4") (induidos en el paquete).

, Parapuertasdemadera,use3tornillosparamaderadel/4"x2't

SOPORTE DEL TRAVESANO

A EnsambHeeHextreme roscadodellpernode Hacintadd rid en eH

agujerode[ soporte de[ travesaflo(Figure 10).

Coloqueuna tuercade reborde(5/16"-18) enel pernode la

cinta del rieLAprietemanualmente

ENSA_4BLELACAJA BEL MOTOR

[)ELGARAJE

PRECAUTION ]

Lossoporte_de moRtajedeber,asegurarse_ laestructuradel

garaje,No losasegure aparedes,de taNas de aglomerado,yeso,u

otros materia es slmi ares J

insulated Staples

(approximately 30 parts)

Grapes aisbntes (Approx 30 inidades)

#6=11/4"

Pan Head Screws

TorniI[os de cabeza

troncocBnica#6 = ]=1/4"

Hardware(red bag)

NOTA

. AsegOresedequeelridde[acaade[motorco[ocadaest_[igeramentem_s

altoquee[puntom_saltode[acarreram_ximadeviaede[apuerta,

mediante[ae[evad6nde[apuertaparaverificado.Ajustecomeseanecesado.

Losmaterialesparae[montajede[acajade[motorde[abrepuertaspueden

variar.Leatodaslasinstrucdonescomp[etamente.

, Lasconstrucdonesdelossaraesvarian.Sepuederequerkmaterialextra.Vea

[ap@ina7parevedficare[_reademontajede[acajade[motoc

A

B

C

Levante[acaja de control y sopBrtda suficientem entealto de

maneraque pueda levantarmanualmente lapuerta del garaje

abri_ndolatotalmente.

Alineela cajade control y el rid con el centrede b puerta.

Manteniendo centradala cajade control,monte al cielo raso:

A la altura cotrecta:

a. En_aspuertasensecciones,e[rid debe estara

nivd con el piso o ligeramentedebajo del nNeL

(Figura 11).

b. En_aspuertasdeunasoHapieza,eHrid no debe

interferir per unas2 pulgadas.(Figure 11).

Usandounode losm_todos preferidosque semuestra,

(Figure12),monte b cajadecontrol. (Esposibb usarotro

re@odedemontaje.E[punto crftico querecordaresqueel

conjunto dd montaje debeester sBlidamenteacopBdo y ser

capazde soportare[ pesode b cajade controL)NOACOPLEA

UNAPAREDDETABLAROCAO A UNCIELORASOSUSPENDDO.

Debeestarandado al entramado de b estructuradel garaje.

_ONTAR YCONECTAR

LOS BRAZOE DE LA PUERTA

Pare puertas secdo_es

A AcopBr el lade torte dd braze curvado de D puerta a_

soporte de b puerta con el pasador de horquilb y b

chaveta de dos pates (Figure 13).

[} Ensambbel brazerecto de _apuertaalensamNe dd eorredizo

magn@ico.

C EnsamNeambosbrazesjuntos usando2 pernosde cabeza

hexagonal(3/8 "x 7/8 ") y 2 tuercasde reborde hexagonal(3/8'!

demaneraque b Iongitudtotal quedetan corta comesea

posible.Apriete todos lossujetadoresmanualmente_

D Ajuste HaaHturadeHamanijade Hacuerdade Hiberaci6nde

emergenciaa6' sobre el nivd dd piso:

. Coloquelacuerdaa travSsdd ensambledd corredizo

magn@co hasteque la manijaquede a 6 'dd piso.

. Hagaun nuevo medionudeenla cuerdaen lalevadel

ensambledd corredizomagn@co.

Pare p_ertasde ann solepieza:

A Ensembled brazerecto a[soportede [a puertausandoe[

pasadorde horquilb y la davija ben@@(Figure 14).

Acop[ar el [ado corto del braze curvado de [a puerta al

corredizo con el pasador de horquiIB y la chaveta de

dos pates.

C EnsamNeambosbrazesjuntos usando2 pernosde cabeza

hexagonal(3/8 "x 7/8 ") y 2tuercasde reborde hexagonal(3/8 ")

de maneraque la Iongitud total quedetan [argacome sea

posible Apriete los sujetadoresmanualmente.

D Ajuste la altura dela maniia de la cuerdade liberaciBnde

emergenciaa6' sobre el nivel dd piso:

" CoHoqueHacuerdaatra%sdd ensambHedd corredizo

magn@co hastaque [a manijaquede a 6 'dd piso.

. Hagaun nuevo medionudeenla cuerdaen b levadd

ensamNedd corredizomash@ice.

_ede @jar [

[_os.Si b [

INSTALEELSISTEMA

SAFE-T-BEAM®

EHabrepuertas no cerrarg [apuerta autom_ticamente a

menos que elsistema Safe=T=Beam®est_ instabdo.

InstaBd6n de B fuente y e[ sensorde[Safe-T-Beam®(Figure 15):

• Ponga unamarcaen ambos_adosdd marcodepuerta del

garajeo en la pared a6"per encima del piSOa

° Sostengael soportecontra el marcode la puerta o la pared.

Verifiquesi el soportesobresalede la paredIo suficiente

come paraque la espigase extiendahacia lapuerta,sus

guiasde deslizamientoo algOnotro componente.

- Encaseque no, existendisponiblesextensionesde[

soportede montaje del Safe-T-Beam®con undistribuidor

autorizadode f_bRcaGenieo atray,s dd formatede

pedido de accesoriOSa

- Los bbques demadera etc puedensersubstituidos per

extensiones.

o Co[oque la partesuperior dd soporte de montaie en B

marcahecha 6"y asegurecon 2tornillos Phillips decruz

cabezahexagonal persoporte dd( #10-16x 1-I/4")

i NOTA ]

Lossoportes de montaje se pueden instabr en paredes de

ladrilb o de concrete usando andas para mamposteria (no

induidas en el paquete).

B EnsambHeb fuente(diode emisor rojo) y dd sensor(diode

emisorverde) del Safe-T-Beam®alos soportes(Figura 15):

o Paragarajesdeunasob puerta:

- Determinequ_ bdo dd garaje recibeb mayorcantidadde

bz dd soldirecta,y coloqueel foco( diodeemisor rojo)de

lacajadel motor en _stdadosiempreque seaposiNe.

o Paregarajesdepuertas mO[tip[esvea[a (F[gwa 16):

- Elprevenir lassehalescruzadasescritico.

- Cdoque losmBdulos de b fuente y d sensoren puertas

anexasapuntando haciadirecdones opuestasentresL

NOTA

Paraayudar a prevenir interferencia con el sol, el sensor dd

Safe=T-Beam®(diode emisor verde) puede colocarse lejos

del vane de la puerta, ee un Dgar ee donde est_ D mayor

parte dd tiempo a B sombre.

oDes[iceb fuerttedel motor y d sensordd sistemaSafe-T-

Beam®enlasespigasdelos soportes hastaqueatorenensu

[ugar.

o Verifiqueb alturafinal de bs bntes del sensor(Figure 17).

C Instalacionde Safe-T-BeameWiring (Figure 1B):

. Enrutee[ cablecon [asgrapas ais[antes(Figwa 19 y Figure 20):

- Sujetede manerasegura loscablescon grapesaisbntes

conformelos vayaenrutando.Lasgrapasdebenabrazar

sdamente bs cables.

- Loscables que vanentre la pared dd garajey b cajadd

motor deben guiarsesobre b parte superiordd rid yper

debajode los sujetadoresdeloscables.

• EnsamNeloscablesa lossensoresdd Safe-T-Beam®

- Separey pale bs extremesfinales de loscablespara conectar

los come semuestra.

- Afloje los tornillos de lasterminJes.

- Inserte cadacableper debajo de lapbca pinnay apriete e[

torni[Io.No importa cualcable,blanco o rayado,va en cual

terminal.

, EnsamNeloscanes ala cajade potencia.

- Loscables seconectan alasterminales #2 y #3dd

Noque determinales de lacaja dd motor,Noimporta

cual cable,bBnco orayado,vaencual terminal

, Verifique[osiguiente:

- Que ninguna parte deB puerta o suscomponentes

interfiereentre lafuente y Ds lentes dd sensor.

, Aseg@eseque B pare superiordeBslentes est_

entre 5y 6"per encima dd piso.Lossoportesson

flexiNes y puedenajustarseligeramente sies necesano.

NO CONECTETODAVlA!

[NSTALAC_0NDE LACONTROL

DEPARE#

ZL ADVERTENC A

Verifiqueque no hayaenergia el@tricahacia el abrepuertasantes

deinsta[arloscanes de [aconsolede pared. J

NOTA

M_s de un control de pared iDminado per e_abre puertas

)rovocar5 un maffuncionamiento_

CONTROL DE PARED (Figura 21 y 22)

A Encontrar el [ugar montaje (Figura 22):

Escogerun Dgar conveniente para el montaje dd control

depared.

Elbgarqueescojadebeestarenb linenvisualdeb

puerta.

DebeestarperIomenosa5piesarribadelpisopara

impedirquelosnihospequehoshaganfuncionar[apuerta.

Debeestarabjadodelaspartesm6v@s(Usteddebeset

capazdeakanzarBpuertaestandoen e[controldepared.)

BCab[eado (Figure22):

Instabr el canede b cajade controlalcontroldepared.

Apretarde maneraseguraaHcido raso usandoHasgrapes

aisladasque seproveen.

Partu y pelar losextremes del cable.

Enla cajade control:

- Acoplar e[cable pdado altermmal #I y

e[ cane blaneo al terminal #2

Atr_sdel control de pared:

- Acoplar e[cablepdado alterm!nal '3",y

e[ cane blanco al terminal "W".

CMontaje:

Sujetare[ control de pared a la paredcon

2torni,,os _}_@ #6x1=1/4"

Quitar e[forro interne protector de [a

etiqueta de advertencia de"atrapamiento".(Figura 23).

- PegarB etiqueta en lapared,cerca dd

control depared

P AuTm.

*Elusode cua[quierconsolade pareddiferentea[tipo

ieduido en este paquete evitar_ que [a Dz trabaje

adecuadamente y podr[a causar que la puerta Opere sin

que se haya accionado intencionalmente.

o Los cable en cordo u opnmidos pueden causar que [a

console de pared no fuhcione. Siempre que use grapes

aisBntes asegOrese de co[ocadas tan distantes come se

requiera pare mantener os cab esjuntos,

_L

CONECTAR LA POTENCmA

C[A

, Conelfinde reducirelriesgodechequeel_ctBco,ekeequipotiene

unenchufetipotierraquecuentaconunatercerterminal.Esta

conexiBnseadaptar_solamenteaunatomedecorrientequecuente

_tipodeer.tradaadiciona.Sie enchufer.oentraen atoma

contacteunelectricistacertificado ueleinstalela

siemprequesetrabajeconlasinstalacionesel@tr[caL

CONEXI&N CON _OLmOTAPON

Co_ Enchufe Macho CuR Coeexi6_ ATierrao

AEnchufar e_operador de la puerta.

Vea Advertencia de arriba.

- Enchufar e_operador de la puerta en un tom

acorriente con clavija a tierra.

Realice cheque de alineaci6n de STB.

CONEX[ON CON EL ALA_BRADO PER_ANENTE

{|nstruc¢iones pare ememectridsta)

A Desconecte b a_imentad6n de[ drcuito deNvado.

B Quitar B tapa del motor.

Quitar 4 tornilbs de b tapa y resbabr abajo fuera

de b caja de control (Figure 23).

C Quite y deseche el cord6n de alimentaci6n existente.

Corte cuerda de poder dentro de caja de control

Quite y tire e_poder cuerda, e_alivio del esfuerzo

y knockout.

NOTA

Elcableado permanente adentro de la caja de

control debe 6" minimo.

InstaHeunaentradade manguito adecuada.

ConecteeHcabHeadopermanente adentrodeHa

cajadecontrol.

- Conectee[cable dealimentaciBnblanco al

aBmbre blanco.

- Conecteelcable dealimentaciBnnegro al

alambrenegro.

- Conectee[abmbre de tierraal abmbre verde(TIERRA).

NOTA

Elcableado permanente adentro de la caja de

CONtroldebe 6" minimo.

E Vudva a instaBr [atapade [acajadecontrd.

DesHice[atapa,recto.

Apriete loscuatro (4)tomilbs.

F ReconectelaalimentaciBnel_ctricaalcircuito derivado.

Verificar _aa[i_eadB_de[Safe-T-Beam®:

A Despu_sde conectar Haa[imentaci6nd_ctrica, s[d

STBnoest_alineado correctamente,e[DIODO

LUMNSCENTErojo (fuente) parpadear_continuamente.

B Paracorregir e[ proNema- bs cartdas son f[exiNesy se

pueden ajustarligeramente paraponer e[ sistemaenalineaciBn.

Cuandoe[ STBest_alineado el DIODOLUMINBCENTE

rojo dejar_de parpadeary permanecer_encendido.

m

FUAR LOS CONTROLE$ DE

LOS [NTERRUPTORES YLA FUERZA PosmcmoN DE AJUSTE

APRO×m_AOO DE LOS _NTERRUPTORESLm_|TADORES.

Aj_steaproximadode los intetrruptorsdem_mitBs

A PosiciBndeajusteaproximadode[interrupter[irrfitadordeCERRAR

(Figure24),

'Verificarqueconjuntodelcorredizoest_desenganchad.

Conlapuertade[garajetotalmentecerrada,resba[are[interrupter

[imitadordeCERRARhadae[corredizohastequee[mismoest_

a[ineadocone[magnetode[corredize

B Austede[interrupterdelimitepareapertura:

o Abraapuertadegarajemanuamentehastaque egueaa posiciBn

comp[etamenteabierta.

, Deslizere[intrruptorlimitadordeABR[Rhadae[corredizohasteque

e[mismoest_a[ineadoconelmagnetode[corrediz&

• Aprieteeltorni[[odefi aciBnde[ IfmiteNo[osobreapriete.

Vue[vaa conectarloscontro[esdeajustedefuerzade[ensamb[ede[

corredizomagn@coylosinterruptoresdeajustedelos[{mites.

LosCoRtremesPo_ieRtesdemaFuerzayUmiteQ_eAjustan

m

ADVERTENC[A

o La puerta del garaje se abre r_pidamente, y puede

.causar dahos severos o la muerte.

Despeje e[ _rea,

Co[oque la escalera aun costado de [a caja de[ motor"

con e[ fin de alejarla de todas [as partes en

, movimiento delabrepuertas y de la puerta.

Ajuste al abrepuertas de rnanera que use e[ minirno de

fufuerza pare abdrla.

A Pre-fijarloscontro[esdefuerzaene[puntomedioentreBAJO(LO)y

ALTO(HI)(Figure25),

BAjustede[interrupterde[[[mitedederre:

,Presioneb consdadeparedparecerrarhpuertadelsarae.

- Silapuertanoderracompletamente,mida[adistanciadesdela

parteinferiorde[apuertahastaelpBo.Muevae[interrupterde

[Hmitelamismadistandahacialapuerta.

- Si[apuertaseregresadespu_sdeestab[ecercontactocone[piso,

muevae[interrupterde[[mitehada[acajade[motet

- Si[apuertaseregresaantesdeestab[ecercontactocone[piso,

klcremente[afuerzadecierre.

o Aprieteeltorni[10defijadBndelinterrupterde[[imiteNo[0sobreapriete

CAjustedelinterrupterde/limitedeapertura:

o Presione[aconsoladeparedparaabrir[apuertade[garae

- 5i[apuertanoseabrecomp[etamente,muevae[interrupterde

[imitehacialacajadelmotor.

- Si[apuertaabrecomp[etamente,petee[motorcontinOa

trabaando,muevae[interrupterde[imitehada[apuerta.

o Aprietee torni odefijaciBnde imite.Noo sobreapdete.

Serequiempocoesfuerzoparegirar[asperi[lasdeajustedefuerza.

Encasedeque[apuertasedejedemovermientrasest_abriendoe

cerrando,a uBeloscontro[esdefuerzadeaperturaofuerzadederre

ligeramentegirandolaperi[[aene[sentidodelasmaned[[asdelrelo(para

incrementar[igeramentelafuerza)yvue[vaaliniciode_stepunto.

Loscontro[esaefuerzadeapertureyfuerzadederre@benajustarsea[as

necesidadesminimasdefuerzacone[findegarantizarque[apuertaabrey

cierracomp[etaysuavemente

Lapuertade[garae semover_[entamente[aprimeravezque@ere,hasta

quee[abrepuertas'programe"e[ripedepuertaqueest_acdonando.

AsegOresequee[ensam_o[ede[corredizomagn@coest_enganchadoy se

encuentraenmediodelosdosinterruptores8e[[miteantes8eoperare[

abrepuertas

f

A

B

C

D

NOTA

Pareprotegersunueva inversion,suPOWERMAXest5equipado

con un rolei de tiempo y con un contador decidos,[os cua[es

trabajan untos paraprevenir cuakNier daho generadoper

taler a loscircuitos el_ctricosdebido aun excesode cidos en

un periodo detiempo muytorte. Sisuabrepuertas

repentinamentesedetiene comerespuestaauncomandodela

consda depared- NO DESCONECTELA UN[DAD-

simplemerlteespere10 minutes hastaque e_relo de tiempo /

contador de cidos reinicienuevamente.

LadesconexiBnde_aunidadevita que el rebj de tiempo /

contador de cidos sevueha a programac

Pruebade[abrepuertas: ., ,

, Accione[apuertaparequeabrayderreunascuantasvecesusando[a

consoledeparedyobservebcarrerade[apuerta.. ....

, _epltalospasosarnDamenclona_osseqOnserequleracone[rmoe

ajusta[[asposicionesdelinterrupterde][mite.

ustedelaruerzaaeaperturaalm[nimonecesario(Figura25}:

Co[oque[apuertaenposkbndecerradausande[aconso[adepaled.

Suavementeajuste[afuerzadeaperturagirandocompletamen_e_a

peril[aen sentldocontrarioalasmanedl[asde[reloj fuerzaminima.

Accioneelab[epuertasusandolaconsoladepared.

Observequelapuertaseaccionaoeacuerdoalospar_metros

estab[edoosparqe[interrupterde[[[mitedeapertura. , ,,

- SinoajusteelcontroldefuerzadeaperturaqirandoRperil[a

[geramenteene[sentdodelasmanec[[asde[re[oj,derre[a

R puertade[garaje,y_bra[anuevamente_ , ....

epdalospesosantenoresnastaquelapuertadegaraprunaone

suavementedes@e[ interruptoroe[[imitedecierrehastae[

interrupterde[[imitede aperture.

ustelatuerzadecJerreaimmJmonecesario.(Figura25):

Coloque[apuertaen[aposidBnabiertausan[Jolacons@depard,

Suavemen!eajuste[afu?rzadecierregirandolaperi[[aene[sentido

contradooe[asmaneci,asuelreloj(fuerzaminima).

Accionee[ab,repuertasusando[acons@d,epareu.

ObservequeRpuertaseacdonadeacuerdoalospar_metros

estab[eddosparae[interrupterde[[[mitedederre

- Sinoa ustee[controldefuerzadecierregirando[aperi[[a

geramenteene sentdode[asmaned[[asde[ e[oj,ce e apueta

nuevamente.

Repitalospesosantedoreshastaq.u.elapue[tadelgarajefuncigne

suavementedes@e[interruptordellimitedeaperturahastael

interrupterde[I/mitede cierre.

VER_FmQUELAFUNOON DE

REVERSAPORCONTACT{:)

Abra [apuerta de[ garaje usando[a conso[ade pared.

C0[0queunatablade 2"x 4" pinnaenel centrede[clarede[a puerta.

Cierre[a puerta usando[aconsolede pared.

Verifiqueque [a puerta se detieney regresa2 segundosdespu_s

de que Nzo contacto con la tabla.

o Si [apuerta no regresa,disminuya[afuerza de cierre hasta

que [apuerta regrese

• Si aunasi [apuerta no regresa,muevae[ interrupter de

hmite hacia la puerta.

Vedfique [aoperadBn de[ sistema Safe-ToBeame :

° Si e[ hazde [uz est_ b[oqueado,[apuerta no. (Figura 27),

NOTA

La puerta debe tocar Hatab[a de 2" x 4" antes que el

corredizo active el interrupter de limite de derre. Si no,

reajuste e[ interrupter de _imite de cierre.

ElPasoFinal

El tra_smisorde[ programa, i_sta[a [as [uzes y el lento.

Vea El Manual de Mantenimiento y Operaci6n.

CenterLineaf doer CenterLiceofdoor

La[Rleacentrald epuerta Lalineacentraldepuerta

',

o0a0,dir.0tl;- __!

intoHeader

Monte

directamente.:S2 _ g:-:_ _,\>ZLe-:cJL

enelPar_ntesis":-- --- "__' ._:::e:_. derBracket

depared _____ " .::_= oard

Tableadicionaldeapoyo

Figure 8 Attach Header Bracket

Figure 8 Conecte e[ par_ntesis de pared

SECTmONAL DOORS ONE-PmECE DOORS

LASPUERTASDESECC[ONADAS LAS PUERTASDE UNO PEDAZO

CenterL_neaf doer

La[[neacentraldepuerta Ceeter L_neafdeor

La[ineacentra[depuerta

Figure 9 AttachDoorBracket

Figure 9 ConecteParBntesisde Puerta

Rei[ Strap

La correa de

la baranda Elpar6ntesis de

encabezamiente

Figure 10 AttachRailStrapto HeaderBracket

Figure 10 Conectebarandacorreaa[par_ntesisde[ encabezamiento

SECTIONALDOOR/Puerta Seccional

CHECKEORCLEARANCE/VeBfiqueparae_espacio[ibre.

H SLIGHTLYBELOW

Figure 11 Adjust the power head height

Figura 11 Ajuste [aa[tura de cabeza de poder

ONE=PiECEDOOR/Puerta de una p[eza

MNMU/I OF2"/E[ minimo de 2"

Mounting Straps

Las xorreas que montan

UNFiNiSHED CEiLiNGS

supportbeardaddedformo.gerspa_s

Sostengalatabla agregadapare

espaciosrn_slargos

Perforated Aegme[ren/not in_muded)

Elhierro perforado del angulo

(no induy6)

F|N|SHED CE|L|NG$

Locateceiling joists

ortrusses using a stud

finder or similar device.

Attach angle iron

(net included) te

joists or trusses

through finish material

using Lag Screws

LOS TECHOS TERM_NADOS

Locabceviguetasde techo o

braguerosque utilizana un

descubridor de semenralo

disposaivo semejante.

Acople un perEI de hierro

_ngulo (no se incluyeen

redes losmode[os)alas

viguetas a trav#sdel mateRa[

acabado usando[aspijas(30).

Figure 12 Mounting methods for open beam andfinished ceilings

Figura 12 LosMBtodos que montan para el rayo abierto y terminaron techos

®???

5/!6=18 x 3/4"

Hex Head Bolts

La cabeza hexagonal

cierra de 5/16"=18 x 3/4"

5/16=18 x 3/4"

Hex Serrated FHangeNuts

5/16"=18 Las nueces serradas

hexagona_es de reborde

Header 1/4"x 2" Door Bracket

Bracket Lag Screws

E[parantesis de La demora encrosca E[par_ntesis de puerta

encapezamiento de 1/4"x 2"

1/4"=20 x 3/4"

Self=Drilling Screws

Los torni[[os que auto

ta_a@ando de t/4"-20 x 3/4" Safe-T-Beam ®

(STB) Brackets @

Supportes de_ Safe-T_Seam

As short as poaaibme

Tan brevemente come /*_,

sea )osibHe_m, qR3k-_)

It_1 /_ "'L _StraightDoorArm

,.-" _/' _'(g_h Elbrazo recto de

(3_z ":_' lapuerta

Curved Door Arm

ElbrazecurvodeHapuerta

Figure13 Assemble Arms (SECTIONAL)

Figure13 Arme armamentos (local) de puerta

Aaioegaa poasibie

Tanlargo como seaposible

El braze curve de la puerta

\ 5@lraight Door Arm

El braze recto b puerta

Figure 14 Assemble Arms (ONE=P_ECE)

Figure 14 Arme armamentos (uno pedazo) de puerta

®

Safe-T-Beam Sensor

Green LED @

ElSensor (Verde LED)

Safe-T=Reem ®Sourceaf_'_

Red LED

La Fuente (Roio LED)

Figure 1S install Safe=T=Beams ®

Figure 15 [nsta[e Safe-T-Beams ®

_ lide onto

tongue of

Bracket until

it dicks into

place

Desliceen lengua

de par_ntesis hasta

que hagadic en

el lugar __

Topof

// / I":: [ B:racket 6"

.above

'_(47_ I floor

,_ _ ." _ La alma de

._ , H.'[' parBntesis-6"

i_AI]l'i'-L enc,ma de piso

IIIlfi_!t#_ljI,LLL_

#10=16x 1V4"

Phillips Hex Head Screws

Torni_[o Phillips de cabeza 3/8" Hex Serrated

hexagonal #10-16 x 1-1/4" Flange Nuts

Tuercas de reborde serradas

hexagona_es de 3/8"

Garaje con u_a puerta Garaje con dos puerra

Gara N con tres puerta

Figurer5 Source!sensor Locations

Figure16 Locaci6n de Fuente/Sensor

Top edge of Lens

5" = 6" above fbor

La cima de

par_ntesis =5"-6"

endma de piso

Figure 17 Final Check Safe-T-Beams ®

Figura 17 El cheque final de Safe=T=Beams ®

3/8" x 7/8" _. Cotter Pins

Hex Head Bobs _ ChavetadePernos de cabeza dos pates

hexagona_ de 3/8"x 7/8" Clevis Pins

Pasadores de horqui[[a

aHambra _-_

..... Aprox. [ H

A r x _< Peb_prox

"_ ,i,/J//Rrip

Wire /// approx.

1 2'"

@ j

Figure 18 Wire the Safe-T-Beam ®System

Figure 22 Wail Control WMng

Figure 22 A[ambrado de Control

Security Vacation Lock Switch

TerminalAttachment at PowerHead

LasRjaciBnesterminales en cabezadepoder

Mbw sDck/Permita r_ojo

White Wire to

Termioam2

E"a[ambreb,anco l\\\/11

a,oterm,n._2%

Etriped Wire %,

toTermina[ 1 _'_j

Elalambre pdad t _

a[aterminal 1

Termieal Attachmeetat Wall Control

Lasfijaci6nes termina[es en [a Central de Pared

TERMINALS

Striped Wire t<_

Te_mina_"B"

Elal ambr e

pelado

terminal "B"

White Wire to

Terminei "W"

Elal ambre

blanco

a [a

terminal"W"

Force

Contro[e

La Fuerza Contro[a

Figure 25 Making Force Adjustments

F_gura 25 Los ajustes de _aFuerza

E_transmiser de[ programa,insta[a _as[oaesyel lento.

Veaa Du@o's/Manua[de Conservaci6n pagiea 11.

Knockout pmug/Tap6nmaraviRoso el_ctrico

Cut w_res here.

Elcorte

®

Figure 18 A[ambre el Safe=T-Beam Sistema

Wire cmips/Ela[ambresujeta

!

F

Figure 19 Wiring Method A

Figure lg E[ re@ado que a[ambre A

mnsalatedStaples

Termieai attachments

at Safe-T_Beam®

Lasfijacidnes terminales

en SafeoT-Beame

Wire C[ipe Ela[ambre sujeta

@

Figure21 ConsoB de Pared ............... o ............... Bot6n de pared.

insulatedStaRlet/

Losgrapesaisladas

Te_miea_attachments

at PawerHead

Lasfijacidnes terminales en

cabeza de poder

Figure 20 Wiring Method B

Figure 20 E[m_tado que a[ambreB

Aliewsleekfor

_djustmeRt Rojopare

el ajuste

Terminal attachments

at SafeoT-Beame

Lasfijaddnes termina[es

en Safe-T-Beame

alambra aqui.

Figure 23

Remove screws

Figure 23 _ I

Quita bs TorniHos _, Screw

Tornillo

Open Limit Switch

(deer felly open)

E[ Interrupter

abierto dd I[mite

(puerta abre

completament) Elcoche (salt6)

ClosedLimit Switch

(door fury dosed) _[_[ ....

EHInterruptor cerrar

de[ [[mite (puerta cerrd

comp_etamente)

Figure24 Settin 9 Limit Switches

Figura 24 El L{mite poniente cambia

2" x 4" board

[aid flat

2"x 4"table co[oc6 [a p[anicie

Figure 26 Checking Contact Reverse

Figure 26 Verificar b Fuerza Inverse

Figure 27 Biock Safe=T=Beame

Figure 27 BHoquee e[ Safe-T-Beam ®