Branson 3015r User manual

PREFACE

This manual is to provide servicing personnel with extensive information on the structure, service procedure,

removal and installation procedure, disassembly, troubleshooting and more for the 3015R(h)/3515R(h)/

4015R(h) and F36R(h)/F42R(h) tractor with high-end technology to ensure precise and rapid service.

Most accidents are resulted from negligence in safety precautions and directions, so it is very necessary to

follow such precautions and directions to avoid any safety accident beforehand. Service technicians should

provide quality service to prevent any safety accident and enhance customer satisfaction so they should fully

understand the service procedure, methods, inspection points and safety precautions for accurate service.

To ensure optimum condition of your tractor, it is highly recommended to use only BRANSON genuine parts

which are manufactured under strict quality assurance policy for premium quality, durability and reliability.

BRANSON is always committed to provide best quality products through extensive research, study and

development.

Information in this manual is subject to change without notice for improvement of the product.

Please keep this manual in a safe place. If there is any typo, incorrect information or question about this

manual, feel free to contact BRANSON.

(Jan, 2016)

BRANSON TRACTORS Co. Ltd.

※Remark

This manual does not contain all accidents and preventive measures that can occur during ser-

vice. Make sure to have this tractor serviced only by professional technicians with care.

Useonlygenuineparts,includingengineoilandtransmissionuid,speciedinthismanual.Oth-

erwise, it can affect the tractor's performance seriously.

NeverattempttoduplicatecontentsandguresinthismanualwithoutpriorapprovalbyBRANSON.

Precautions and instructions described in this manual and safety decals, such as DANGER, WARNING and

CAUTION decals, are important for your and machine's safety. If these instructions are not followed, you and

the vehicle can be severely injured and damaged. Read such precautions and instructions carefully for your

safety.

If any DANGER, WARNING or CAUTION decal is damaged or missing, order it from your dealer and have it

attached to the original position.

Important safety instructions are described with various symbols throughout this manual. Make sure to follow

such instructions. Their design and meanings are as follows:

MEANINGS OF SAFETY SYMBOLS

This symbol indicates potentially hazardous situation which, if not observed, may

result in death or moderate injury.

DANGER

This symbol indicates the most serious hazardous situation which, if not observed,

may result in death or serious injury.

This symbol indicates potentially hazardous situation which, if not observed, may result in

minor or moderate injury. Also, this can be used as a warning for an unstable action.

This symbol indicates important procedures or information to perform work with

more ease and skills.

Notes This symbol indicates information useful to users.

WARNING

CAUTION

IMPORTANT

HOW TO USE THIS MANUAL

1. Target readers

This manual is intended for technicians with mid to high level of service knowledge and skills for BRANSON

tractors. Make sure to understand this manual fully for rapid and accurate inspection and service.

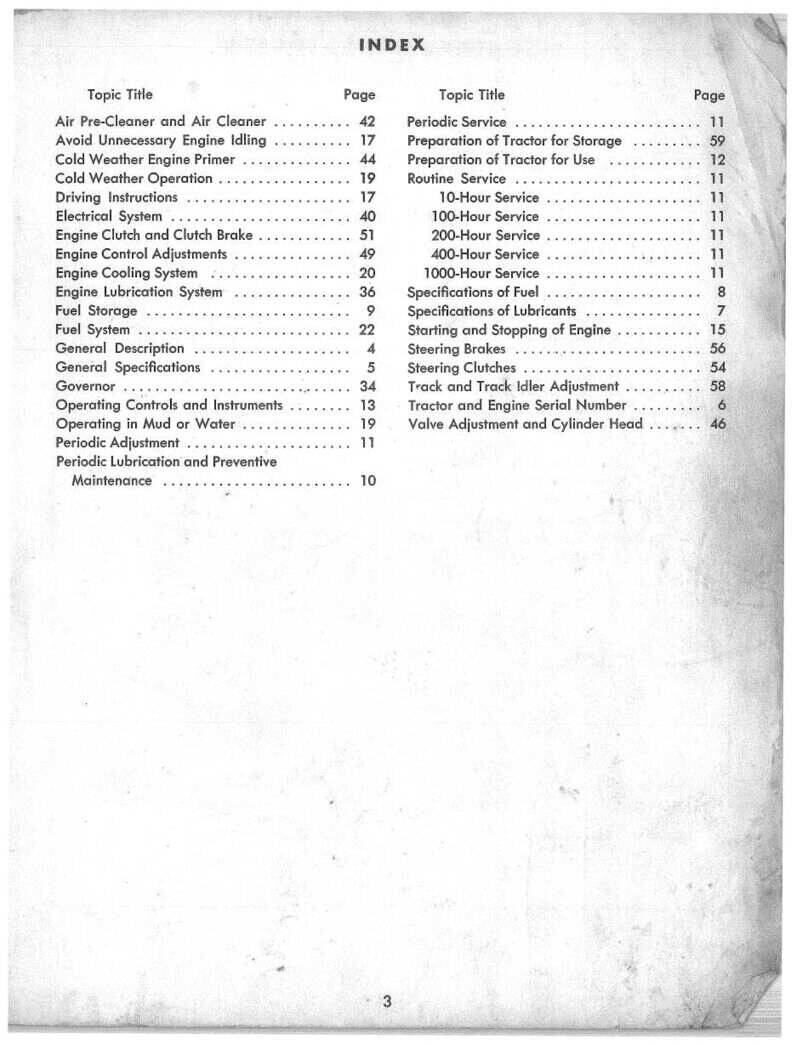

2. Order of contents

This manual is a single book for the 3015R(h)/3515R(h)/4015R(h) and F36R(h)/F42R(h) tractor and contains

several useful chapters such as General Information, Engine, Clutch, Transmission, Front Axle, Hydraulic

System, Electric System. Information and diagrams in this manual are described based on the standard model

so they may be different from your vehicle due to different specifications by models. However, the same

instructions should be followed for service.

3. Body structure of this manual

This manual is structured as follows:

< Lower section >

< Upper section >

CHAPTER 3 CLUTCH3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

3. DISASSEMBLY

3.1 CLUTCH HOUSING REMOVAL

1. Park the tractor on level ground and apply the hand

brake.

2. Disconnect the negative battery cable.

3. Drain the transmission fluid.

4. Remove the hood and propeller shaft.

5. Disconnect the hydraulic hose, wiring connector

and various cables between the vehicle body

and engine.

6. Place a stand under the clutch housing and a

portable jack under the engine oil pan.

3.2 CLUTCH DISASSEMBLY

K20W303A

3-8

42hW-201601

8. Unscrew the mounting bolt (1) from the cutch

housing and engine mounting flange. Then, push

the front axle section to separate it from the

clutch housing.

9. For more detailed disassembly procedures, refer

to the instructions for engine removal in Chapter 2.

ITEM TORQUE VALUE

M14 nut (10.9T) 16.5 kg.m (119.34 lbf.ft)

M14 bolt (10.9T) 16.5 kg.m (119.34 lbf.ft)

2. Remove the clutch disc.

K20W304A

1

2

3

45

HOW TO USE THIS MANUAL

① Chapter

This indicates the current chapter.

② Body

Generally,guresanddiagramsareplacedintheuppersectionofapagewhileinformationanddescription

are set in the lower section. However, a large table or diagram may take a whole page. Each gure is

assignedwithagurenumberandalargeguremaybesetinaA3-sizepagelikeacircuitdiagram.

③ Model name

This indicates the corresponding model.

④ Publication classification

This indicates the publication category and date of this manual.

⑤ Page number

Each page is given with the corresponding number:

Example: 3-8

4. Other information

Thecomponentnamesusedinthismanualaresettoreecttheirfunctionssotheymaynotbeconsistentwith

the ones in other materials, such as the part list and user's manual, labels and decals.

Also,astheguresanddiagrams inthismanualarebasedontheproductatthetimeofitspublication,so

theymaydifferfromyouractualproduct.Thespecicationandotherinformationinthismanualaresubjectto

change without notice for design change or improvement of the product.

TABLE OF CONTENTS

◆ ELECTRIC SYSTEM ......................................................................................

◆ HYDRAULIC SYSTEM ..................................................................................

◆FRONT AXLE ................................................................................................

◆TRANSMISSION ............................................................................................

◆CLUTCH [MEC. MODEL] ..............................................................................

◆ENGINE .........................................................................................................

◆GENERAL INFORMATION ............................................................................

1

2

3

4

5

6

7

◆INDEX ...........................................................................................................

8

CHAPTER 1 GENERAL INFORMATION

TABLE OF CONTENTS

1.

GENERAL INFORMATION FOR SERVICE

..1-2

1.1 For safe operation.................................. 1-2

1.1.1 Work place...................................... 1-2

1.1.2 Working clothes and

other safety gears........................... 1-3

1.1.3 Tool ................................................. 1-3

1.1.4 Standard parts, lubricant,

grease and oil ................................. 1-4

1.1.5 Finishing up and checking.............. 1-4

1.1.6 Torque part ..................................... 1-4

1.1.7 Electric system ............................... 1-4

1.1.8 Safety during service...................... 1-5

1.1.9 Waste disposal ............................... 1-6

2. LOCATION OF DECALS..........................1-7

3. GENERAL INFORMATION FOR

MAINTENANCE .....................................1-11

3.1 Tightening torque..................................1-11

3.1.1 Hex. bolt.........................................1-11

3.1.2 Stud bolt ........................................ 1-11

3.2 Oil, grease, fuel and coolant

specications ....................................... 1-12

3.3 Electric device service......................... 1-12

3.4 Using standard part and adhesive....... 1-13

4. INSPECTION AND

CORRESPONDING ACTION.................1-15

4.1 Daily inspection ................................... 1-15

4.1.1 Checking work place .....................1-15

4.1.2 Checking condition around tractor...1-15

4.1.3 Checking when seating

on driver's seat ..............................1-15

4.1.4 Checking when turning

ignition switch ................................1-15

4.1.5 Checking when starting engine .....1-15

5.

GENERAL INFORMATION FOR SERVICE

...1-16

5.1. Machine history and information ......... 1-16

5.1.1 Serial number ................................1-16

5.1.2 Transmission serial number...........1-16

5.1.3 Engine number ..............................1-16

5.1.4 Hourmeter......................................1-16

6. COMPONENTS OF TRACTOR ..............1-17

6.1 Front and rear exterior view ................ 1-17

6.2 Interior view ......................................... 1-18

7. TRACTOR SPECIFICATIONS ............... 1-20

7.1 Exterior dimensions............................. 1-20

7.2 Majorspecications............................. 1-21

7.3 Driving speed....................................... 1-23

8. PERIODIC INSPECTION ....................... 1-24

8.1 Periodic maintenance schedule table.. 1-24

8.2 Inspection Description ......................... 1-26

8.2.1 Fueling into fuel tank..................... 1-26

8.2.2 Checking engine oil ..................... 1-27

8.2.3 Checking coolant amount ............ 1-27

8.2.4 Checking lamps ............................ 1-28

8.2.5 Checking seat belt ........................ 1-28

8.2.6 Cleaning radiator dust grill............ 1-28

8.2.7

Checking instrument cluster signals ....... 1-28

8.2.8 Changing engine oil...................... 1-29

8.2.9 Replacingengineoillter ............ 1-30

8.2.10

ReplacingHSTlter[HSTMODEL]

.. 1-30

8.2.11

Replacingtransmission/hydrauliclter

..1-31

8.2.12 Changing transmission

uid/hydraulicoil ............................1-31

8.2.13

Adjustingclutchpedal[MEC.MODEL] ..

1-32

8.2.14 Adjusting brake pedal .................. 1-33

8.2.15 Adjusting fan belt tension ............ 1-33

8.2.16 Checking fuel line ........................ 1-34

8.2.17 Cleaning air cleaner element....... 1-34

8.2.18 Battery ......................................... 1-35

8.2.19

Checking radiator and intake hoses ....

1-35

8.2.20 Applying grease........................... 1-36

8.2.21 Adding anti-freeze ....................... 1-37

8.2.22 Fuse and relay ............................ 1-38

8.2.23Tireinationpressure.................. 1-39

8.2.24 Checking toe-in ........................... 1-39

8.2.25 Adjusting front wheel toe-in......... 1-39

8.2.26 Tightening wheel bolt .................. 1-40

42hW-201601

1-2

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1. GENERAL INFORMATION FOR SERVICE

1.1 FOR SAFE OPERATION

1.1.1 WORK PLACE

6015W101A

CAUTION

CAUTION

6015W102A

CAUTION

When working in or under the machine, make sure

to have a protected lighting equipment.

6015W103A

CAUTION

Haveareextinguisherinyourworkplace.

DANGER

-

42hW-201601 1-3

CHAPTER 1 GENERAL INFORMATION

3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

WARNING

Use the specif ied too ls for disas sembly and

assembly.

[If hh huuff

, it can lead to an injury or

damage to equipments and parts.

1.1.3 TOOL

1.1.2 WORKING CLOTHES AND OTHER

6015W105A

6015W106A

CAUTION

DANGER

6015W104A

Never work on the tractor only with a wood support

or other type of block or jack.

Do not use any lift or crane with insufficient rated

load capacity.

Make sure to wear working clothes, safety hat,

safety gloves, safety goggles and other safety gears

for your safety.

42hW-201601

1-4

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1.1.6 TORQUE PART

lb

6015W109A

WARNING

WARNING

-

-

6015W110A

GREASE AND OIL

6015W107A

CAUTION

CAUTION

-

-

1.1.5 FINISHING UP AND CHECKING

6015W108A

Inspection

list

42hW-201601 1-5

CHAPTER 1 GENERAL INFORMATION3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

DANGER

K20W151A

WARNING

-

K20W150A

DANGER

-

-

K20W153A

K20W152A

CAUTION

-

42hW-201601

1-6

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1.1.9 WASTE DISPOSAL

K20W156A

WARNING

-

-

-

-

-

K20W155A

DANGER

CAUTION

-

-

K20W154A

42hW-201601 1-7

CHAPTER 1 GENERAL INFORMATION3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

14, 15, 16

12, 13

10, 11

1, 2, 3 4, 5, 6 7, 8

9

To ensure safe work, check the location of the safety decals and always keep the safety precautions.

Keep the safety decals intact. If any decals is damaged or missing, attach a new decal.

2. LOCATION OF DECALS

F42W105A

42hW-201601

1-8

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

(4)No.:TA00040603A[MEC.MODEL]

(1) No.: TA00036924A

(5) No.: TZE4190000C4

(6) No.: TZE5110000B4

(2) No.: TZE5130000C4

WARNING

HOT

SURFACE

75IH=CB

Clutch pedal

Stopper

Locker

For the long storage, please

lock clutch pedal in the both

Traction and PTO clutch are

disengaged position

TA00040603A

75IH=CB

DIESEL ONLY

TZE4190000C4

Start only from

seat in park or

neutral.

Starting in gear

kits.

DANGER

TZE5110000B4

75IH=CB

TZE5130000C4

(3) No.: TZE5180000C4

K5FB=B;

(7) No.: TZE5160000B3

TO AVOID PERSONAL INJURY:

1. Read and understand the operator’s manual before operation

2. Before starting the engine, make sure that everyone is at a safe distance from the

tractor and that the PTO is OFF

3. Do not allow passengers on the tractor at any time.

4. Before allowing ohterpeople to use the tractor, have them read the operator’s manual.

5. Check the tightness of all nuts and bolts regularly.

6. Keep all shields in place and stay away from all moving parts.

7. Lock the two brake pedals together before driving on the road.

8. Slow down for turns, or rough roads, or when applying individual brakes.

9. On public roads use SMV emblem and hazard lights, if required by local traffic and

safety regulations.

10. Pull only from the drawbar.

11. Before dismounting lower the implement, set the parking brake, stop the engine and

remove the key.

TZE560000B3

75IH=CB

42hW-201601 1-9

CHAPTER 1 GENERAL INFORMATION3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

(10) No.: TZE5120000B4

TO AVOID PERSONAL INJURY:

WARNING

1. Attach pulled or towed loads to

the drawbar only.

2. Use the 3-point hitch only with

equipment designed for 3-point

hitch usage.

TZE5120000B4

(9) No.: TZE5140000B3

BEFORE DISMOUNTING TRACTOR:

1. PARK ON LEVEL GROUND WHENEVER POSSIBLE.

If parking on a gradient. position tractor at right angles

to the slope.

2. ALWAYS SET PARKING BRAKE.

Leaving transmission in gear with the engine stopped will

not prevent tractor from rolling.

3. LOWER ALL IMPLEMENTS TO THE GROUND.

Failure to comply to this warning may allow the wheels to

slip. and could cause injury or death.

4. LOCK SHUTTLE SHIFT LEVER IN NEUTRAL

POSITION AND STOP THE ENGINE.

TZE5140000B3

WARNING

(8) No.: TZE5170000B3

TO AVOID PERSONAL INJURY OR DEATH FROM ROLL-OVER;

TZE5170000B3

1. BRANSON recommends the use of a Roll-Over Protective

Structures(ROPS) and seat belt in almost all applications

2. Remove the ROPS only when it substantially interferes with

operation or itself presents a safety risk. (Examples include work

in orchards and vineyards.) ALWAYS REINSTALL IT BEFORE

USING THE TRACTOR IN OTHER APPLICATIONS.

3. Never use just the seat belt or just the ROPS. They must be

used together. For further details, consult your Operator’s Manual

or your local dealer.

ZDUQLQJ

(11) No.: TA00015596B

WARNING

TO AVOID PERSONAL INJURY:

1. Keep PTO shield in place at all times.

2. Do not operate the PTO at speeds faster

than the speed recommended by the

implement manufacturer

3. For towing PTO-driven implements set

drawbar at towing position.

(see operator’s manual)

4. Keep hands, feet and clothing away.

TA00015596B

42hW-201601

1-10

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

(15) No.: NTE5210000C4

K5FB=B;

NTE5210000C4

DEATH OR INJURY MAY

RESULT IF THE TRACTOR

ROLLS OVER WITH THE

ROPS IN THE FOLDED

DOWN POSITION.

OPERATE THIS TRACTOR

WITH THE ROPS FOLDED

DOWN ONLY WHEN

NECESSARY.

(16) No.: NTE5220000C4

This structure’s

protective capability

may be impaired

by structural

damage, overturn,

or alteration.

If any of these

conditions occur,

the structure

must be replaced.

NTE5220000C4

K5FB=B;

(14) No.: NTE5150000C4

K5FB=B;

Use seat belt

NTE5150000C4

(12)No.:TZE4100000B4[MEC.MODEL]

WARNING

CONNECT THE LEFT

BRAKE WITH RIGHT

BRAKE WHILE ON THE

ROAD

DISCONNECT CONNECT

CONNECT ROD

TZE4100000B4

(13) No.: TZE5770000B3

75IH=CB

TO AVOID PERSONAL INJURY(OPERATING ON SLOPES)

1. If descending a slope, never disengage the clutch or shift levers

to neutral.

Doing so could cause the tractor to speed up out of control.

2. Slow down for slopes, especially when transporting heavy,

rear mounted equipment.

3. Before descending a slope, shift to a gear low enough to

control speed without using brakes.

TZE5770000B3

42hW-201601 1-11

CHAPTER 1 GENERAL INFORMATION3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

3. GENERAL INFORMATION FOR MAINTENANCE

3.1 TIGHTENING TORQUE

3.1.1 HEX. BOLT

ITEM

BASE TOLERANCE

N.m kgf.m lbf.ft N.m kgf.m lbf.ft

M8 11.8 ~ 15.6 1.2 ~ 1.6 8.68 ~ 11.5 8.82 ~ 11.8 0.90 ~ 1.2 6.51 ~ 8.67

M10 24.6 ~ 31.3 2.5 ~ 3.2 18.1 ~ 23.1 19.7 ~ 25.4 2.0 ~ 2.6 14.5 ~ 18.8

M12 29.5 ~ 49.0 3.0 ~ 5.0 21.7 ~ 36.1 31.4 3.2 23.1

3.1.2 STUD BOLT

ITEM NO GRADE OR 4 T 7T 9 T 8.8 T 10.9 T 12.9 T

M6

8.8

(0.9)

[6.4]

11

(1.1)

[8.1]

-

9

(0.9)

[5]

13

(1.3)

[10]

14

(1.4)

[9]

M8

20

(2.0)

[14.7]

25

(2.6)

[18.4]

14

(1.4)

[10.3]

23

(2.3)

[17]

33

(3.3)

[25]

40

(2.9)

[29]

M10

42

(4.3)

[30.9]

52

(5.3)

[38.3]

28

(2.9)

[20.6]

45

(4.5)

[33]

65

(6.5)

[50]

70

(7.0)

[50]

M12

68

(6.9)

[50.1]

84

(8.6)

[61.9]

44

(4.5)

[32.4]

80

(8.0)

[60]

115

(11.5)

[85]

125

(12.5)

[95]

M14

120

(12)

[88.5]

140

(14)

[103.2]

-

125

(12.5)

[90]

180

(18.0)

[133]

195

(19.5)

[145]

M16

180

(18)

[132.2]

220

(22)

[162.2]

-

195

(19.5)

[140]

280

(28.0)

[200]

290

(29.0)

[210]

M18

260

(27)

[191.7]

290

(30)

[213.9]

-

280

(28.0)

[200]

390

(39.0)

[285]

400

(40.0)

[290]

M20

360

(27)

[265.5]

400

(41)

[295.0]

-

400

(40.0)

[290]

550

(55.0)

[400]

-

Unit:N.m(kgf.m)[lbf.ft]

42hW-201601

1-12

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

ITEM

SPECIFICATION REMARKS

MEC. MODEL HST MODEL

Fuel 27ℓ(7.13u.s.gal) Diesel fuel (KS 2) Summer: S, Winter: W

Engine oil 4.3ℓ(1.14u.s.gal) SAE15W-40

3015R(h)/3515R(h)/4015R(h) (Final Final Tier4):

Grade CJ or higher

F36R(h)/F42R(h) (StageⅢA):

Grade CG or higher

Grease Small amount High load No. 2 of

KSM 2130 Multi-purpose

Coolant Radiator:5.0ℓ(1.32u.s.gal)

Reservoirtank:0.45ℓ(0.12u.s.gal)

BRANSON genu-

ine anti-freeze No. 2 of KSM 2142, permanent use

Transmissionuid

and steering oil

34ℓ(8.98u.s.gal) 37ℓ(9.77u.s.gal) TF500 Texaco TDH oil, 1893

Chevrontractorhydraulicuid

Front

axle oil 6.4ℓ(1.69u.s.gal) SAE#90 Gear oil

※If the ambient temperature is below 50°F (10°C), use diesel fuel for winter season.

3.3 ELECTRIC DEVICE SERVICE

1. When disassembling or repairing any part

applied with voltage, disconnect the negative

batterycablerst.

2. W he n d i sc o nn ec t in g t h e b at t e r y c a b le s,

disconnect the negative c able f irst. When

connectingthem,connectthepositivecablerst.

3. Apply grease to the battery terminals and cover

them securely after connecting the batter y

cables.

4. When charging the battery, it produces hydrogen

gas and chlorine. Therefore, disconnect the

battery and move it to an isolated well-ventilated

area with no f lammables and flame before

charging.

6015W165A

42hW-201601 1-13

CHAPTER 1 GENERAL INFORMATION3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

1

3.4 USING STANDARD PART AND ADHESIVE

When replacing a worn or damaged part, use a

new part that meets the international standard.

When replacing a packing or O-ring, fit a new

one. Before installation, apply grease to the

O-ring or oil seal ring.

When assembling a snap ring on a shaft or in a

hole, ensure its sharply angled side to point the

directionofforceasshownintherstgure.

When installing a spring pin, inser t its split

portion in the direction to be forced as described

inthesecondgureabove.

1.

2.

3.

4.

When the oil grooves are engaged with the

thrust washer, be careful with assembly.

6.

6015W114A

Replace the split pin with a new one and fix it

rmly.

5.

6015W115A

6015W116A

Oil groove

6015W113A

Snap ring for shaft Snap ring for hole

Section applied

with force

42hW-201601

1-14

CHAPTER 1 GENERAL INFORMATION 3015R(h)/3515R(h)/4015R(h)/F36R(h)/F42R(h) TRACTOR

Use a liquid sealant removal scraper (flat) to

remove any sealant left on the case. Make sure

not to make any scratch bigger than 0.3 mm

(0.012 in). If the surface is scratched, grind it with

an oil grinder.

7.

6015W117A

Scraper

CAUTION

-

6015W118A

Liquidseal-

ant

Cut second step

Mating surface

3 - 3.5 mm

CAUTION

-

-

6015W119A

Apply

Tool

3 - 3.5 mm

Liquidsealant

This manual suits for next models

9

Table of contents

Other Branson Tractor manuals

Branson

Branson 8050 User manual

Branson

Branson 00 Series User manual

Branson

Branson 9550C User manual

Branson

Branson 25 series User manual

Branson

Branson 2000 series User manual

Branson

Branson 20R series User manual

Branson

Branson 6640C User manual

Branson

Branson F36r User manual

Branson

Branson 00 Series User manual

Branson

Branson 00 Series User manual