Allis-Chalmers HD 6B User manual

Topic Title

Page

Air Pre-Cleaner

and

Air

Cleaner

..........

42

Avoid Unnecessary Engine Idling

..........

17

Cold

Weather

Engine Primer

..............

44

Cold

Weather

Operation

.................

19

Driving Instructions . . . . . . . . . . . . . . . . . . . . .

17

Electrical System

·.

. . . . . . . . . . . . . . . . . . . . . . 40

Engine Clutch

and

Clutch Brake . . . . . . . . . . . .

51

Engine Control Adjustments . . . . . . . . . . . . . . . 49

Engine Cooling System

.'

. . . . . . . . . . . . . . . . .

20

Engine Lubrication Syste.m·

.......•.......

36

Fuel

Storage

..........

,

.............

·.

. 9

I •

Fuel System~

...............

~

. . . . . . . . . . . 22

General

Description . . . . . . . . . . . . . . . . . . . . 4

General

Specifications . . . . . . . . . . . . . . . . . . 5

-Governor

......................

:..

. . . . . 34

Operating

C~~trols

and

Instruments .

-~

. . . . . . 13

Operating

in

Mud

or

Water

; . . . . . . . . . . . . . 19

Periodic Adjustment . . . . . . . . . . . . . . . . . . . . .

11

Periodic Lubrication·

and

Preventive

Maintenance

........................

10

Topic .

Tit.le

Periodic Service

.......................

.

Preparation

of

Tractor for

Storage

.......

\ .·

Preparation of Tractor for

Use

..........

: .

Routine Service

.......................•

10-Hour Service

...................

.

100.Hour

Service

...................

.

200-Hour Service

...................

.

400-Hour Service

1000-Hour Service

...................

.

Speciflcaflons of

Fu.el

....................

.

Specifl~ations of Lubricants

..............

.

StartintJ

and

Stopping of Engine

..........

.

Steering Brakes

.....

,.

.................

.

Steering Clutches

......................

.

T.-ack

and

Traek: l~ler Adjustment

...........

:

Tractor

and

Engine Serial Numper

.......

··

Valve Adjustment

and

Cylinder

Head

...

el(··

••

The/,Model

"HD

68"

Tractor

is

a 12,400 pound track·type tractor

p~,'l,(ered

with a

:f'~ylinder, 4 cycle

"DIESEL"

engine.

Power from the engine

is

transmitted' through a single plate, over-,center

type

,engine

clutch to the transmission through q universal ;oint drive shaft assembly.

From

the trans·

mission the power

is

transmitted

to

the bevel gear

and

from fhe bevel gear through the ·

steering clutches to the final drives

and

the track

driv!,!

·sprockefs.

The

transmission provides 5 forward speeds ranging

from

1.5

M.P.H.

in

low

gear

to

5.5

M.P.H.

in

high gear

and

a reverse

speed

of

2.0 M.P.H., under full governed e,n9ine

speed

of

i800

R.P.M.

·

Mechanical self.energizing brakes, wide operator's seat,

and

uno8structed view

of

the

front

of

both

tracks assure ea$y, positive

contro.l

of

the tractor

at

all times.

The

standard model tractor

is

equipped

with 24-volt electric starting

and

light equipment,

suction

type

cooling

fan,

muffler, full width crankcase guard, bumper, hinged.radiator

guard,

and

13° grouser track shpes. The truck wheels, track idlers,

and

track support

rollers have positive type seals.

TRACK

RHEASE

YOKli

AIR

PRE-CLEANER

TRUCK

WHEEL

OUTER

GUARD.

(SPECIAL·

EQUIPMENT)

TRUCK

WHEEL

INNER

GUARD

(SPECIAL

EQUIPMENT)

c.1------------------------ Model

HD

68 Tractor

-----------------

FIG.

1

~'GcEJ~

ER

A L/ ·SP

E,C:l

fI G.~,T

l;,G>;N'Sir

.

(STANDARD

TRACTOR)

General

Dimensions

and

Weight:

Overall Length

...

,

..........•.

x

.•.....

10ft.

73<6

in.

Overall Height (to

top

of exhaust stgck)

....

5 ft.

8%

in.

Overall Width (standard shoes)

..........

,6

ft.

63.4

in.

Ground Clearance

........................

111,4

in.

Drawbar Height (c:enter fine of jaw)

......

,

..

131

~6

in.

Lateral Drawbar Movement

.....•............

21

in.

Shipping Weight (approximate)

...

·

.......

12,400 lbs.

Tracks:

Width of

Standard

Track Shoes

...............

13 in.

Maximum Width Track Shoes Available

.........

20

jn.

Tread

Wid.th

(center-to-center)

.................

60

in.

Engine:

Make·

......................

"Allis-Chalmers" Diesel

Model

..................................

HD-344

Type

............................

.4

Strol<e

Cycle

(Naturally Aspirated)

Number of Cylinders

............................

4

Bore

.........•............................

4K6

in.

Stroke

........

·

............................

5'<6

in.

·Crankshaft Rotation (when viewed

from fan end)

........................

Clockwise

Number of Main Bearings

...

,

..............

·

.....

5

Piston Displacement

....................

344 cu. in.

L"ubrication

...........................•..

··•.

Pressure

Fuel

Used

...............

,

..............

Diesel

Fuel

Fuel

Supplied

By

..

"American Bosch"

Fuel

Injection Pump

Low

Idle Speed

..................

525 to"J50

R.P.M!+

High Idle Speed

.............

1930

R.P.M.

+or -25

Governed

at

Full

Load

.................

1800

R.P.M.

Steering:

,,.I}-.•

Method

..............

.-

..••................

Clute

Controls,

...................•

,

.........

Mechanical

Turning Radius

............................

8414Jn.

Capacities

(Approximate):

(U.

S.

Standard

Measure)

Cooling System

..........................

6~

gal:.'

Crankcase

and

Filter

.....•................

2~

gal~;

Air Cleaner

...........................

:

.....

2

qts.

Transmission

................

;

...•........

.5 gpj~.

Final Drives (each)

.........................

3,~(:t\

Fuel

Tank

..............................

.

40

>'v·

·

Support Roller (each) (Grease)

..............

, ;

Truck Wheel (each) (Grease)

...............•.

·

. Track Idler (each) (Grease)

.......•.........

11

Speeds (

at

Rated

Engine Speed):

1st

Gear

................

.

2nd

Gear

................

.

3rd

Gear

................

.

.4th

Gear

................

.

5th

Gear

................

.

1st Reversp

..............

.

2nd Reverse. ;

............

.

HD6B

l.5M.l~.

2.4M.P.H.

3.3M.P.H.

4.0M.P.H.

5.5

M.P.H.

2.0M:P.H.

The

Allis-Chalmers Manufacturing. Company reserves the

r,ieht

to make changes

in

the

above specifications

or

to

add

improvements at· any time without notice

or

obligation.

TRACT(!)R

A,ND

ENGINE

SP.IAL

NU,MBERS

1~11

all

parts

orders

and

in

all correspondence

'relatiy,e/to

the

tractor,

it

is

necessary that both

,<;)*t

1

fractor

and engine serial numbers be given.

;:ff{is

will

properly identify the particular tractor

and

will

assure obtaining the correct replacement

pq,rts

f'?r

it.

6

The tractor serial number

is

stamped

in

the rear

face of the steering

~lµtch

housing (near the upper

right corner)

and

is

also stamped , on a serial

number plate attached to the cowl.

The engine serial number

is

stamped on a plate

attached to the left

rear

side of the cylinder block.

FIG.

3

SPECIFICATIONS

Of

LUBRICANTS

A.

Engine Crankcase Lubricant

USE

NON-CORROSIVE "DIESEL" ENGINE

LUBRI-

CATING

OIL

CONlAINING

ADDITIVES

WHICH

WILL

PREVENT

SLUDGE

OR GUM DEPOSITS.

UNDER

NO

CIRCUMSTANCES

SHOULD

A CORRO-

SIVE

ENGINE

LUBRICA

"J:ING

OIL

EVER

BE

USED.

Use oils of

the

following viscosities:

Atmospheric

Temperature

Viscosity

90°

F.

and

above

Use

SAE

40

32°

F.

to

90°

F.

Use

SAE

30

0°

F.

to

32°

F.

Use

SAE

20W

0°

F.

and

below Use

SAE

lOW

Manufacturers of lubricants recognize the

im-

portance

of

the

qualities required for use

in

our

equipment

and

they

are

cooperating

fully

to

assure

the

use of only those oils which fulfill these require-

ments. The oil distributor

and

oil manufacturer

are

to

be

held respo11sible for

the

results obta.ined

from their products.

The outstanding lubricating requirements for effi-

cient operation of

the

engine

are:

The maintaining

of

piston rings

in

a clean,

free

condition;

absence

of

hard

carbon

and

"varnish" deposits on or within

engine

parts;

the

prevention of

bearing

corrosion;

and

the promotion of

general

cleanliness within

the

engine.

Proper

operation

and

maintenance

of

the

engine

are

necessary

to

9J,tain

the

desired results

fro11J

the

lubricating oil.

fr/

(l

7

B.

Air

Cleaner

Use

the

same

viscosity oil in.

the

air

cleaner

as

used

in

the

engine

crankcase. CAUTION:

Do

not.

use

an

oil that foams.

C.

transmission

and

Final

Drive

Lubricarit

Lubricate these assemblies with a

good

grade

of

engine

lubricating oil purchased from a repufoble

oil company.

Use oils of

the

following viscosities:

Atmospheric

Temper:ature

Above

32'\f

,,

32°

F.

and

below

Viscosity

Use

SAE

50

Use

SAE

30

D. Truck

Wheel,

Track

ldler,>an&:1

Tra

/•

Support

Roller

Lubricant

Lubricate these assemblies with''g

,€1

been

tested

ond

found

satisfactorfi

Allis-Chalmers Manufacturing Company\,.

A revised list of

approved

greases

is

issuec:1

periodicplly. Ask

your

nearest

"Allis-Chalmers"

authorized

Dealer for

the

latest list.

E.

Pressure Gun Lubricant

Use

a ball

and

roller

bearing

lubricant with a

minimum melting point of

300°

,F;

This

lubricaht

should

have

a viscosity

range

so

clito

assure e~sy

handling

in

the

lubricating gun

at

the prevailing

atmospheric

temperature,

and

MUST

be

water-

proof.

SPECIFICATIONS OF

FUil

'Mr·

The

'!OIESEL

11

fuel should

be

a natural distillate

~fr:oleum oil

and

must have certain qualities

in

"brder

to

ignite

and

burn

at

the

proper

rate

and

temperature. Field experience has ·shown

that

the

fuel best suited for this

engine

closely approxi-

mates the following specifications:

Gravity

API

.......................

30 -35

Viscosity

Saybolt

Universal

at

l00° F

...

35 -

40

Flash Point

.......................

150°

F.

Diesel Index

..................

48.5 to 65.5

Cetane

Number

...

;

..............

46 to 60

Pour Point

.........................

0°

F.

Volatil-ity

90%

...............

650°

F.

Max.

End Point

98%

Summer

...................

700°

F.

Max.

Winter

......

,

........

600°

F.

Preferable

Sediment

and

Water

.......

~

.........

Trace

Ash , . . . . . . . . . . . . . . . . . . . . .02 of l % Max.

':,•Geriradson

Corban

.........•

03 of l % Max.

},C~o)phur

..............

; . . .

V2

of l % Max.

satisfactory fuel flow through lines'

and

filters

. celd

weather,

the

pour

point

of

the

fuel must

fie.

at

least 10°

F.

below

the

prevailing atmos-

;fJ:iie

API

;gr'°vity of a fuel varies with

its

specific

gravity. The low

API

fuels

are

desirable because

they have a high specific gravity

and

more

heat

·units

per

gallon. H9wever~ 4

''the higher the

API

gravity, the

better

will

be.

th~ ignition quality of

the fuel.

'The ignition quality of a

fuel

is

expressed as; a •

"cetane

number." The higher

the

cefone number,

the

higher

the

quality of the fuel. The higher

cetane

. .

fuel shortens the ignition

delay

period

to

facilitate

starting

and

improve combustion. The

"DIESEL"

index number, which

is

a close approximation of

the

cetane

number,

is

a field method

to

represent

ignition quality. ·

The distillation

90%

point

and

the

end

point

are

important. High volatility

is

~equired to

enable

complete vaporization of

the

fuel, clean combus-

tion,

and

low residue formation.

The flash point of a fuel has no quality significance,

but

is

importcmt with respect to safety

in

storage

and

handling of the fuel.

It

is

important

that

the fuel

be

within the specified

limits for ash, carbon,

water,

and

sediment con-

tent, etc., to prevent excessive

wear

and

damage

to engine parts.

It

is

also important

that

the fuel has lubricating

properties so

that

the fuel injection pump

and

fuel

nozzles

are

adequately

lubricated. At times

it

may

be

necessary to use fuel with no lubricating prop~

erties.

If

this occasion arises,

add

one

quart

of

SAE

lO engine

oil

to every

10

gallons of fuel.

NOTE:

Distillates should be used only

in

emer:

gencies.

When

the proper fuel

is

again available,

the fuel system must

be

drained

and

cleaned before

the proper fuel

is

added.

CAUTION: The sulphur content

of

"DIESEL"

fuel

should

be

as low as possible. The fuel should not

contain a sulphur content

of

more than

V:z

of

1

%.

Generally speaking, a No. 2

"DIESEL"

fuel pur-

chased from a

reputable

oil

company

will

meet

the

above

specifications.

ll

fillers cmd eventi;,:i!iy

dicm10£1•::e

i;:mmi,

p,oi·t,01bl,:1

ston:ige

provid1:ts

th,e

meth:iJd

51i0,rin91

fu,e!

cm

the job,

in

Sl.lch

c,

i'cmk,

th,e

c1r,d

VJ'Cfl·er

.:r)m

easi"y

be

ccm

be

pumped

in1o

th,e

tn.:ictor

fo3!

lomk

¥ti~h

·

ne,;:ires'!·

this

ty,p,e

OCCU!I"

111

PERIODIC

LUBRICATION

AND

PREVENTIVE

MA1NTENANCE

LubricaJion

is

an

essential

part'

of

preventive main- .

ten~u{ce, _controlling to a

great

extent

the

useful

life of the tractor. Different lubricants

are

needed

and

some components

in

the

tractor

require more

frequent lubrication than others. Therefore, it

is

important

that

lhe

instructions

regarding

types

of

lubricants

.and

the frequency

of

their application,

as

given

in

this manual

and

on

the

"LUBRICATION

CHART,"

be

explicitly followed. Periodic lubrication

of

the moving

parts

reduces

to

a minimum the

possibility of mechanical failures.

To

prevent minor irregularities from developing

10

into serious conditions

that

might involve shut-

down

and

major repair, several other services

are

recommended for the

same

intervals as the periodic

lubrication. The

purpose

of these services

or

in-

spections, which require only a few minutes,

is

to

assure the uninterrupted

operation

of

the

tractor

by revealing the need for adjustment caused by

normal

wear.

The need for some minor adjustment,

if

neglected, could result

in

failure

and

shut-down.

Refer

to

the

"LUBRICATION

CHART"

for relative

location of the service points of the

tractor

to

be

serviced.

For

added

conveniente,

listed below

are

the

lubri-

cation

points, adjustments, service items,

and

in-

spections

to

be

made

at

each

of the intervals (10-

l

00

-

200

-

400

-

1000

hours) shown on

the

"LUBRICATION CHART." Reference symbols given

below

refer

to

those given on this

chart.

10-HOUR

SERVICE

(Identified

by

Q

on

chart)

INSPECT:

Engine

Crankcase

-Oil Level

Air

Cleaner

Oil Cup -Oil

Level

Air Pre-Cleaner -Dust

Level

Radiator -

Coolant

.Level

Batteries -Check Electrolyte

Level

SERVICE:

Fuel Filters

First

Stage

-Drain Sediment

Second

Stage

-Drain

Sediment

Fuel Tank -Check Fuel Level

and

Drain

Sediment

LUB:a'UCA'IE:

Engine Clutch Shifting Bearing

100-HOUR

S~RVICE

(ldentilied

by

O

on

chart)

·

INSPECT:

Final ·Qrives -Oil

Level

Tr(msmission -Oil Level

SER~CE:

Engine

Crankcase

-

Change

Oil

Lubricating Oil Filter -Replace Element

Batteries -Test with Hydrometer

LUBRICATE:

Engine .Clutch

Shaft

Rear Bearing

Engine Clutch Camshafts

f'Rockford"

Clutch

only)

Engine

qutch

Shifting Sleeve

200-HOUR

SERVICE

(Identified

by

•

on

chart)

LUBRICATE:

Fan Idler Bearings

Fan Bearings

Generator

Brake Pedal Levers

400-HOUR

SERVICE

(Identified

by

O

on

chart)

LUBRICATE:,.

Drive

Shaft

Universal Joints

.

1000-HOUR

SERVICE

(Identified

by

•

on

chart)

LUBRICATE:

Truck Wheels

Truck Idlers

Track

Support

Rollers

SERVICE:

Transmission -

Change

Oil

Final Drives -

Change

Oil

PERIODIC SERVICE

Fuel Filters -Replace Elements

Cooling System -Drain

and

Flush

Fuel Tank -Drain

and

Flush

PERIODIC ADJUSTMENT

Eg.gine Clutch -Check

and

Adjust

Steering Clutch Linkage -Check

and

Adjust

Brakes -Check

and

Adjust

Tracks -Check .and Adjust

Water

Pump

and

Generator

Belt -Check

and

Adjust

· Fan Belts -Check

and

Adjust

Valve

Tappet

Clearance

-Chec:k

and

A:qJlist

Fuel Nozzles

.:....

Check

and

Adjust

··

,•

11

Cl·

cornp;'E:i)·lf;}

sure··

·~·J"~oiJ

no

Ihe

fr::,do,r i'o

make

lo:i:!'

or

m

the

1&nkr.mce

or

the

1:m

Ihe

engirie

soft

w,.~rr,er

or

c1

suit,c,b;e cmti-fre,,eze

'l'c,

lri

!'h1::e

Clip

is

(~ir

prs=

firi::ici'or

m,

i!'s

f'rCi1Cdk3

Vl·/2'1'..;~,.

p·:Jri~]0:5f~ly

()p,c!n.1,t12,

the

fr1::i1c:i'or

with

r,]

i

!9ht

hmirs. The

mo:£,!'

,edlld0nt

e•nr::3ini:':,

un1oi::1dinr1

rrw.st

T

t~7~

/.c\,

(~'

/(

cil:iirr,iin1ed

i'h<:i

ii:ln91in,r.1

terr,1~1,e1,,1hm:1

ci

n:mge

'ii

Jo

·i

i:35°

F,

Op:::'!rrcrtinti

the

,rmgine

th(.;;

,c,,:,•;)l,i::;ITTri·

temp"rcrl·urfi

hr:'ilov'I'

iihis

rcm,ge

vviil

rr~svit

irn:::011npleh::1

·co,mbuz;'l'r,:,n

stud

:1r._rts

dwck

hcmrs,

th•e,

,::mk:rging

th,~:

bolt

c!uti:!1

If

propet

ton:pe,

it

is

cibci

to

t1v2,

vi:..iive

lapp,ets

for

proper

,deGn:mc,e

(n?.fo:r

"\/Al

VIE

AD.HJSTMJ:],fl'

Ah!D

CYUl',IDER

HEAD"

fcH·

;nk1,:-rn,r:i;!,km).

The

1N!'ih

~,

!En{ijhlle

~i~'IDilJrtr~(JHY

knob

is

Th,e

shvt-oH

sh1.ri·"ciff

en,;1

inri

h;

to

,:1h::1rireJd;

puU

·~ht~

nor

sf'eip

the

fo idling

to

:;Jop

'l'hei

1,mgir,e,

C,~,UTiOl··,l:

D,o

firs, the

1

Itfo1!![ll~ll1).s,

Cfotdr

fJ~:J;,e:r,~i1l'~E'itl

le~,e~·,

Thi'.:!

12::;1~

g,iru~

ckrN::h

op

1

en:rling ,engine

dutch

frcin,

the

tH·,9drue

ti:,

~jGC!ir

rr:;rt·fio:

,,

posi'fo:m

h:,

'>.ii/hid,

·~h,,~

V\/h,;;;n

the

dutch

en,gc1gc:~

dutch., H

pc.:i5i~·fc1in

'I"rr:J

ns1Yt~fl;si()I~

1Q

.

Th,~

1:!11fJl11e

dutch

op1a:n:::rl°ing

1rmsr

io,r"'

n·ii:]ved

'frr::;.

rc

1

cs,Hion

1.x;,frw,re

l'hE:

'lran~m1ss.1.o,r,r

ccm

be

n'ilC1Vf.:1d

int,o

or

fo'h

..

,

(!!Kl'!h,E:f

pt1srnc:m.

h·""'"'''""

stoppinJ;1. hvc,

'Which

ccmnect the

'.'aL

31·,J·,rnfil

0

1l·,~a·

(jl11f.l:{~~·t:irtim1f]

Ritn.t.

Pt!!:.h

on

s.',',r::irl'er

op15•ra1ing

n:,d

IfJ

en,i;tClf!®'

s'tc1rt1Br

pinkm

the,

fly11vhe,e:

ring :;iecff to nperc:1te the

starter

1im,~

,:iep,r,es:s,ed

it

musl"

j'.'/OSIIk;,11

Hme

Io

ieec1s'E:1

stmter

open:tlfog rod

is

b1:;

rrJs,ad,

cmd

·wm

no'l

thc1

Z:n(Jirn:!,.

(\lC1

TE:

H

fhe

engine

rfo,es

dt;ihI,hand

turn;

'l"rc1ck

dr;ve, spn)ckets.

sh:.w?r1t1£1

l,&·rer

bc1d,;

!,::1H-hand

r.leer!ng,

dis-

'lhe

t,i,)

nDR'[V!hlG

INSTRUCTli'.Ji!•;Su).

} ,

it'll:ak@

P,e,Jl1:.!~S.

bn:ik1

3!

pr~i::kllis

r:11n?

1xsed

to

H,1~

sp,?.,.:!'d

or

h:1

fru::ilH.i:1h:,

i'rJrni:"'i{J

the

turn

ths

trncJ·or

t,,,

·~he

rk:ihl',.

,.,

(~r:d

right brake pedal; to turn the tractor to the left,

fully disengage the left steering clutch

and

press

on the left brake pedal. After the desired turn has

been made, release the

brake

pedal

and

return

the steering lever to

its

fqrward position.

CAUTION:

Never attempt

to

use the brakes to turn

the tractor without

first

pulling the steering lever

back

as far as possible on the side toward which

the turn

is

to

be

made.

8.

Parking

Brake

Lock Levers. The parking

brake

lock levers provide a means of holding the

brake

pedals

in

the applied position.

To

engage

the

parking brake lock levers, depress the brake pedals

and

move the lock levers forward.

To

disengage

the

.parking brake lock levers, further depress the

brake

pedals

and

move

the

lock levers toward

the

,rear.

FIG. 6

9.

Cold

Weather

Engine

Primer

Dispenser.

The primer dispenser, located on the cowl (to the

right of-the instruments),

is

used to hold

and

to

puncture a capsule containing starting fluid used

as

an

aid

in

starting the engine

in

cbld weather.

1

O.

Cold

Weather

Engine

Primer

Pump.

The primer pump, mounted

in

the

cowl with the

instruments,

is

used to force starting fluid through

a small nozzle

and

into

the

air

inlet elbow of the

engine. Refer to

"STARTING

OF ENGINE" for

full

ins~ructions on the use of the Cold

Weather

Engine

·'.Primer Pump

and

Primer Dispenser.

11.

.Light Switch. Move the switch lever to turn

on the lights. · · 14

B.

INSTRUMENTS

1. Engine

Temperature

Gage.

This

gage

indicates the engine coolant operating tempera-

ture, which should be maintained between 160°

and

185°

F.

at· all times.

2.

Engine

Oil

Pressure

Gage.

This

indicates

the pressure

at

which the engine lubricating

oil

is

circulated through the engine. At

full

throttle, the

oil

pressure should be between

30

and

55

pounds

at

normal engine operating temperature (160° to

185°

F.).

CAUTION:

If no oil pressure

is

indicated

by

the

gage,

the engine must

be

stopped immedi-

ately

and

the cause determined and corrected.

3.

Fuel Pressure

Gage

{Special Equipment).

This

gage

indicates the pressure

at

which the fuel

is

circulated through the low pressure fuel system.

Under normal conditions, with the engine operating

at

full

governed speed, the fuel pressure should

be

between 5

and

15 pounds.

4.

Ammeter.

The ammeter indicates the charg-

ing rate of the generator. When the batteries

are

in

a discharged condition, the ammeter should

indicate a good rate of

charge

until

the batteries

approach a fully

charged

condition. When the

batteries

are

fully charged, the ammeter

will

indi-

cate nearly zero except for a short time after the

starter has been used.

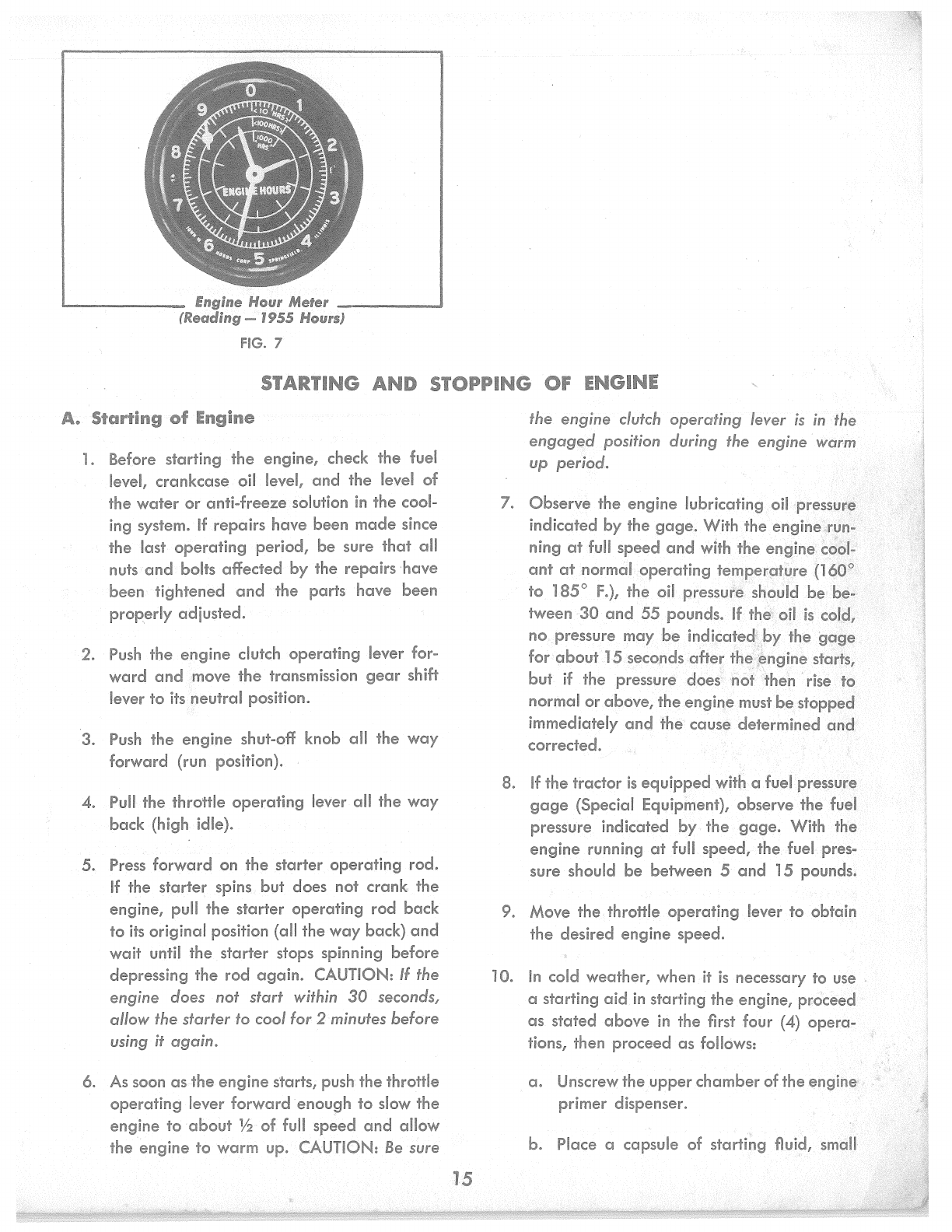

5.

Engine

Hour

Meter.

The engine hour meter

is

installed

as

special equipment.

All

hands of the hour meter move clockwise.

The

small indicator (upper left) visibly turns when the

meter

is

recording. The meter records up to l0,000

hours

and

repeats. The four figures of the hours of

operation

are

read

from the three hands

as

follows:

l 9 5 5

Use

number passed on 1,000 hour

(inner) track here

-------...J

Use

number passed on l

00

hour

(middle) track

here---------J

Use

number passed on lO hour

(outer) track here

·-------------l

Use

number of marks passed beyond

last figure on 10 hour track here

_____

__.

Engine Hour Meter

____

__.

(Reading-

1955 Hours}

FIG.

7

STARTING

AND

STOPPING

OF

ENGINE

A.

Starting

of

Engine

1.

Before starting

the

engine, check the fuel

level, crankcase oil level,

and

the level of

the

water

or

anti-freeze solution

in

the cool-

ing system.

If

repairs have been

made

since

the last

operating

period, be sure

that

all

nuts

and

bolts affected by the repairs ·have

been tightened

and

the parts have been

properly adjusted.

2.

Push

the engine clutch operating lever for-

ward

and

move

the

transmission

gear

shift

lever to its.neutral position.

3.

Push

the engine shut-off knob all the

way

forward (run position).

4.

Pull

the throttle operating lever all the

way

back (high idle).

5. Press forward on the

starter

operating rod.

If

the

starter

spins but does not crank. the

engine, pull the starter operating rod back

to

its

original position (all the

way

back)

and

wait until the starter stops spinning before

depressing the rod

again.

CAUTION:

If

the

engine does not start within

30

seconds,

allow the starter to cool for 2 minutes before

using it again.

6.

As

soon

asthe

engine starts, pushthe thrott~e

operating lever forward enough

to

slow the

engine

to

about

1h

of

full

speed

and

allow

the engine

to

warm up. CAUTION:

Be

sure

15

the engine clutch operating lever

is

in

the

engaged

position during the engine warm

up period~

7. Observe the engine lubricating

oil

·pressur,~,

indicated by the

gage.

With the engine\r~n~ '

ning

at

full

speed

and

with the

er1gine:

c:doi'.:'

ant

at

normal operating temperip(~re

{l~Q.P:

to 185°

F.),

the oil pressuf@

..

should

be

bJi

tween ·30

and

55 pounds.

If

the'\.

ofl

is

cotq,

no. pressure may

be

indicate~.J:>y the

ga.e

for

about

15

seco,nds

after

tf:ie'.i}ngine

stal'fs,

but

if

the pressure does;

not

then

rise to

normal or above, the engine must

be

stopped

immediately

and

the cause determined

am:I.

corrected.

8.

If

the tractor

is

equipped with a fuel pressul:e

gage

(Special Equipment), observe the fuel

pressure indicated by.

the

gage.

With the

engine running

at

full

speed,

the fuel. pres-

sure should be between 5

and

15

pounds.

9. Move the throttle operating lever to obtain

the desired engine speed.

10.

In

cold weather, when

it

is

necessary to use .

a starting

aid

in

starting the engine, pi:oceed

as

stated

above

in

the first four

(4)

opera-

tions, then proceed

as

follows:

a.

Unscrew the.upper chamber of theengine,,

primer dispenser.

b. Place a capsule of starti~g flui~,

smciH

,..,,

or large, dependi~g upon

the

atmos-

pheric

temperature

and

the

requirements

established by trial,

in

the lower

chamber

or

body

of

the

primer dispenser.

In

ex-

. tremely low temperatures, one

large

and

one small capsule may

be

necessary.

c.

Pull

the plunger

to

the

top

of the

upper

chamber

and

screw

the

upper

chamber

tightly onto the primer dispenser body.

d. Push the plunger to

the

bottom,

thereby

puncturing the capsule

and

releasing

the

starting fluid so

it

can

be

picked up by

the

primer pump.

e. Push the engine shut-off knob all the

way

forward

(run position)

and

pull the throt-

tle operating lever all the

way

back (high

idle position).

f.

Depress the

starter

operating

rod to

crank the engine,

and

at

the

same time

~

operate

the primer pump to force starting

.fluid into the engine

air

intake system.

Continue pumping,

after

the engine

starts, until all of the starting fluid

in

the

dispenser has been injected into the

air

intake system. CAUTION: ALWAYS

BE

SURE

THE

ST

ARTER

IS

CRANKING

THE

ENGINE

BEFORE

USING

THE

PRIMER

PUMP

TO

INJECT

ST

ART/NG

FLUID

INTO

THE

ENGINE

AIR

INT

AKE

SYSTEM.

g. While

the

engine

is

warming up, unscrew

the

upper

chamber

of

the

engine primer

dispenser, remove the empty capsule,

and

reinstall

the

upper

chamber.

CAUTION: The starting fluid contained

in

the cap-

sule

is

essentially ethyl ether, highly inflammable

16

af!d should

be

treatf!d with the same caution

as

high octane gasoline. Gelatine capsules dissolve

in

water

and

soften

at

high temperatures. Therefore,

the following precautions must

be

taken:

1.

Avoid breathing

large

quantities of the

fumes from the starting fluid.

2. Avoid. cutting of the

hand

by

barbs

on the

~uncturing plunger.

3. Avoid proximity of

the

starting fluid

and

capsules

to

open flames, sparks, or hot

surfaces.

4. Avoid contact of the. capsules with water.

5. Avoid subjection of the capsules to high

temperatures (above approximately 120°

F.).

Obtain

starting fluid capsules from your nearest

"Allis-Chalmers" Construction Machinery Dealer.

The capsules

are

packed, 12 of the

17

c.c.

or

24

of the 7 c.c. sizes,

in

a can for safe storage

and

handling.

Obtain

the size

and

quantity most

suitable for your needs according to the prevailing

atmospheric temperature.

B.

Stopping

of

Engine

Push the throttle

operating

lever all the

way

for-

ward

(low idle position)

and

allow the

engine

to

idle for

at

least 5 minutes, so

that

the engine may

cool

gradually

and

uniformly, then pull the engine

shut-off knob all the

way

back to stop the engine.

IMPORTANT:

ALWAYS SLOW

THE

ENGINE ·To

IDLING

SPEED

BEFORE

PULLING

THE

ENGINE

SHUT-OFF

KNOB

TO

STOP

THE

ENGINE. Cover

the exhaust

pipe

at

the

end

of

each

day's operation

to

prevent rain from entering while the tractor

is

idle.

'II.

AVOID

UNNECESSARY ENGINE IDLING

Prolonged engine idling causes the engine coolant

temperature

to fall below

the

specified·operating

range

of 160° to

185°

F.

Operating

with the

coolant temperature below this

range

is

detri-

mental to the engine, causing incomplete com-

bustion of fuel, which

in

turn causes crankcase

dilution

and

lacquer

or

gummy deposits ,to form

on valves, pistons, rings, etc.

It

also causes rapid

accumulation of sludge within the engine.

Since starting the engine

is

readily accomplished'

with

an

electric starter, there should

be

no reason

for prolonged engine idling. Stop the engine when

prolonged idling periods

are

necessary.

DRIVING INSTRUCTIONS

A.

Starting

of

Tractor

Start

the engine

and

allow it

to

warm up, then

slow the engine to idling

speed.

If

the engine

clutch has been

engaged,

disengage

it

and

push

forward on the clutch

operating

lever to force

the

clutch

brake

facing

against

the

brake

disc, thus

stopping the rotation of

the

transmission input

shaft. Move the transmission

gear

shift lever into .

the

required position· for

the

desired

speed

or

power.

Pull

the throttle

operating

lever

about

half-

way

back

and

pull back steadily on the engine

clutch operating lever until all slack

is

taken up ·

between the tractor

and

the

load, then pull the

lever back quickly to fully

engage

the clutch. After

the

engine clutch

is

engaged,

move the throttle

operating

lever to meet

the

operating

requirements.

Engagement of the engin~ clutch with

the

engine

running

at

half throttle

and

starting

the

load

in

the

above

manner

will

prevent excessi.ye

slippage

of

the

clutch, thus prolonging clutch life.

It

will

also

prevent "shock loading"

the

tractor.

To

shift to

another

speed

range,

push the engine

clutch operating lever forward

and

shift for

the

desired speed or power. When

the

engine clutch

operating

lever

is

pushed forward

it

forces

the

clutch

brake

facing

against

the

brake

disc, thus

stopping the rotation of

the

transmission input shaft.

Stopping the input shaft rotation enables

the

operator

to shift without clashing

the

gears.

To

shift to a higher

gear

after

the

tractor

is

in

motion, push the throttle

operating

lever forward

to the idle position

and

disengage

the engine

clutch. At the same time, shift to

the

higher

gear,

engage

the engine clutch,

and

pull the throttle

lever back to obtain

the

desired speed.

The engine dutch

operating.

lever controls

the

engine clutch which transmits power from the en-

gine to the transmission. Push the lever forward

to

disengage

the

clutch; pull it back

to

engage

the

clutch. The clutch

operating

lever also actuates a

shifting shaft locking device

in

the transmission.

When the clutch'operating lever

is

pulled back to

engage

the engine clutch it locks the transmission

"'

shifting shafts

in

the position to which

they

have

been moved

by

the transmission

gear

shift lever.

The clutch

operating

.Jever must

be

moved

tci

disengaged

position before the transmission

:~

.

shift lever

can

be

moved to shift the

gears

i~

neutral

or

into

another

position. '

Satisfactory

and

efficient ·operatron depends

largely on the operator's judgment

in

selecting .the

proper

gear

ratio

and

speed

for the various loads

or operation. Always

operate

the tractor

in

the

speed

range

that

will

permit the engine to

operate

at

full speed.

This

/will not only assure the most

power from

the

engine but will also allow the

engine to

operate

at

its highest efficiency.

CAUTION:

DO

NOT

SLIP

THE

ENGINE

CLUTCH

IN

AN

EFFORT

TO

PULL

AN

OVERLOAD;

SHIFT

TO

A

LOWER

GEAR.

The engine clutch should

engage

with a definite

over-center

"snap"

and

should require

an

appre-

ciable pull on the

operating

lever for

its

engage-

ment.

If

this

"snap"

is

not evident, or

if

the clutch

slips when under a load, adjustment must

be

made

immediately (refer to "ENGINE

CLUTCH

ADJUST-

MENT").

B.

Steering

of

Tractor

The

tractor

is

steered by disengaging the steering

clutch on the side of the

tractor

toward which the

turn

is

to

be

made.

This

is

do~e by using

the

steer-

.17

/

ing levers 101.ated directly

in

front of

the

tiperator.

To

mcike

a right turn, puU ,back the righ,t-hand

ste,efing lever;

to

make a left turn, pull back

.~the

left-hand steering lever. With

the

left steering

0

dutch

disengaged,

power

is

not delivered to the

, left track

and

the

track ~ill

·slow

down or stop.

Since power

is

still being delivered to the right

track, the right track.

will

keep turning

and

cause

the

tractor

to

turn to the left. When the right

steering

dutch

is

disengaged,

the

tractor

will

turn

to

the right

in

a similar manner.

If

a short turn

is

to

be

made,

pull the steering

lever back on

the

side

toward

which

the

turn

is

to

be

made

and

press down on the corresponding

brake

pedal;

this

will

stop

the

track completely.

Always pull

the

steering lever all the

way

back

when turning.

When

the

tractor

.has turned

as

desired,

return

the

lever immediat"ely to

its

forward

'position. Disengage

and

engage

the

steering

dutc;:h~st,smoothly

and

completely

to

avoid exces-

···•·

f?siv.el·~ar on

the

dutch friction discs.

~;,'

;':{

'}

'\)):/£'£:!:,

':

;

'>"

,J.''(:,'

,:,'4'.11

,:~:~~ti;steerfog

the

tractor

dc;,wn

steep

grades

with

.the lpqd

pushing·the

tractor,

the

use of

the

steer-

.ing levers

is

opposite to

that

when pulling a load.

lh

this case,

the

left-hand steering lever

is

used

to

mak,1a iright

twrn

and

the right-hand steering lever

to

make a left torn. Disengaging either steering

dutch

wiU

allow the

track

on

that

side

to

travel

faster, since

the

br.aking ,power of the engine

is

released from it, while the steering dutch remain-

ing

engaged

will

ad

as

a.

brake

for the opposite

.track.

During operation, observe the

amount

of

free travel

of

the

steering levers (the distance the levers move

before pressure

is

felt

and

disengagemenf

of dutch

begins).

This

free travel,. which assures complete

engagement

of

the

steering dutches, should

be

from l to 3 inches, measured

at

the tops of

the

levers, When'the free travel of either steering lever

becomes less than l inch,

the

steering dutch

linkc;1ge

requires adjustment (refer to "STEERING

CLUTCH

LINKAGE

ADJUSTMENT").

C.

Stopping

of

Tractor

To

stop the tractor, push

the

throttle operating

lever forward

and

disengage

the

engine dutch by

pushing the dutch operating lever forward, then

press on the

brake

pedals

to

apply

the brakes.

If

the

tractor

is

parked

on a

grade

where there

is

a

possibility of

its

rolling, lock

the

brake

pedals

in

their

applied

position by the use of the parking

brake

lock levers. Allow the engine to idle

at

least

5 minutes so

that

the engine

will

cool gradually

and

uniformly, then pull the engine shut-off knob

all the

way

back to stop the engine.

IMPORTANT:

ALWAYS

STOP

THE

ENGINE WHEN

PROLONGED IDLING

PERIODS

ARE

NECESSARY.

This

will

not only save fuel

and

unnecessary

wear

on the engine but

will

also avoid operating the

engine below normal

operating

temperature.

If

it

is

necessary to keep

the

engine running, it.should

be

run

at

a

speed

fast enough

to

maintain normal

engine

oil

and

fuel pressure

and

with the engine

dutch

engaged.

While operating the tractor, observe

the

action of

the

b.rakes. The brakes

are

properly adjusted when

the

brake

pedals

each

have approximately l%

to

2 inches of free travel (refer

to

"STEERING

BRAKES").

The brakes require adjustment before

they become loose enough

to

allow the

brake

pedals

to strike the floor

plate

when the brakes

.

are

fully applied.

If

the

brakes

are

properly

ad-

justed,

and

still

do

not hold, it may

be

due

to

oil

on the

brake

linings

and

the brakes

will

require

washing.

Refer

to

"WASHING

STEERING

CLUTCHES"

for instructions on washing the brakes

and

steering dutches.

18

The

slee1dni.:1,

·

ceimp1:irtmerrb,

cire

dn::iino!:Je

,,;:,,f

i:::my

h,,ies

or·

wah':':i".

/~1;

si·eering diJ,tch

compartme1r11t

cfrc1in

hole (Fig. 52)

is

!oo::ited

fr,

th,a

boHom of

dutch

cornpo;rtmen't.

The

en•f1ine

rrienl'

cmd

1s

l",l',,"!i''IC•i"ii

in

the

bofh::itn ,:,f

"tl1•8

cm

(r0fr1r

to

hc,s1~~s

'io

pn:rJ·ecil' lt

frnffi

SYST!c':1\i\

1

').

und

-:md

r9,.

T1::isi·

pr,epc::1n2:

''C()LD

VV'E:ATHEl;i:

ENG!l,,iE

Pml,/lE!l'"

for

tD50

CJS

Sf)IXJ

CIS

indk,::r[·t'H,

ri!:iqi,iired.

Prrovide,

c1

rcidk~l·ot

(:,c::;rnpciri·nr,ent

H

the

to

mc1iurhc1in

i·he

,?n~

tr:crnnpernh.ir,a,

'Ntthin

ths

cmd fr,r sides

o-f

t!H':,

th1srir1os"!"u1"tr,.

gr,nie

rr.mge

e,i:framdy dusty

l),

scmdy

ci:::inditi::mz,

1/~

dro1n

p!VfJS

with lrc1d,cir) shou,ld be

V1

lhen

,o,p.ercrhn£i

wiih th~ drciin plug:ii im;tcdiad,

n,Hno·,i1,::i

Ih,e

piug.s

to

,oi!

Hm,·

,:1ccunmk:1ied

in

it

from

getl'ing on

brc;ke lining:s

..

if

'!'he

l'n'.:l,dC1l"

ren1ahls idki

c.1'!'

ge:o,d

pi·'(1:Ct2it:E~

t,(),

r1B:tT)

1

0,\1

1e

'!he d1J)' reinstc1l1

tn::1ctc,u'

the

mn,t

t,kir'l'ing

1:Jif

c1

"DIESEL"

,1:HJ1Jim'<

lTH,::rn,s

cc:m

be

d::rhJ11n~d

sp,aec!,

bcdt,edeis,

:,h::1ri"'2,r,

open:rted

in

y1r:,1JJ

r

nta(~

lft85'·t

1t:11

tJth

,c:1(li.1..:ed

t

11

~'°

for

!nform.::iticm1

rEJl}mdintJ

o::ivciik,,,

fhe

ope·rofin;\Ji

Nhiffe

frm:for

is

idle,

sr...ffidiy

f.'J

ihe

gn:nm,d,

or

fr·,adrs,

ccruss:d

by

cm ,,:,iff&mpf

1c,

trnci<s.

ENGINE COOLING

SYSTEM

A.

Qp~,ription

of

System

The engine cooling system includes the

water

pump,

radiator,

engine

oil cooler, thermostats, engine

temperature

gage,

cooling fan,

and

the

water

passages

in

the cylinder block

and

cylinder

head.

The

water

pump

draws

the

coolant

from the bottom

of

the

radiator

and

circulates it through the engine

oil cooler

and

through the

water

passages

in

the

engine. The

coolant

is

discharged

from the cylinder

head

into the

water

outlet manifold

and

passes

througn' the thermostat housing

and

the

radiator

inlet elbow to the

upper

part

of the radiator. The

fOolant

is

cooled

as

.it

passes from the

top

to the

bottom,of the

radiator

core by

air

drawn

through

\h~

radiator

co.re

by

the suction-type cooling fan.

Th,~

th~ric1nristats,

located

in

the thermostat housing

t.if

the front of

the

water

outlet manifold of the

engine,

operate

automatically to maintain a normal

coo.lant

operating

temperature

of

160°

to

185°

F.

'B.

General

Maintenance

Jn

warm weather, keep the cooling system filled

with

dean

sofrwater

or

rain

water

whenever pos-

sibie.''llf softw!!iler

is

not

available

and

hard

water

must

be

used, tire

hard

water

should first

be

treated

with a

water

softener. A commercially reliable rust

inhibitor should

be

added

to the cooling system for

warm

weather

operation. A rust inhibitor (soluble

oil), available

in

half pint

or

quart

containers, can

be

ol:itained from "Allis-Chalmers" Dealers

and

should

He

added

to

the cooling system

in

propor-

tions

of

1·pint of soluble

oil

to every 15 quarts of

water.

C!>,UTION:

NEVER

ADD

AN

ANTI-FREEZE

SOLUTION

TO

A COOLING

SYSTEM

THAT

CON-

TA/NS A

RUST

INHIBITOR. Drain, flush,

and

refill

the

cooling system with clean

water

before

adding

an

anti-freeze solution for cold

weather

operation.

In

winter

weather,

use

an

ethylene glycol anti-

freeze

solution

in

the system to protect

against

damqge

from freezing.

This

type

of anti-freeze has

a much higher boiling point

than

water. After

any

addition of

water

or

anti-freeze compound, test the

solution

after

the

added

quantity has become

thoroughly mixed to make sure it

will

withstand

the

prevailing or anticipated

temperature.

A

mix-

ture

of

60%

ethylene glycol

and

40%

water

will

20

provide maximum protection;

the

use of more

than

60%

ethylene glycol

in

the

solution will raise the

freezing point

and

provide less protection

against

freezing.

Keep the

radiator

air

passages

free from leaves,

trash,

and

other material which will restrict the flow

of

air

through

the

radiator.

All

leaks

in

the cooling system must

be

corrected

as

soon as they

are

evident. The fan drive. belts

and

the

water

pump

and

generator

drive belt must

be

kept properly adjusted.

The most efficient engine operation

is

obtained

with the coolant

operating

temperature

held within

a

range

of

160°

to.

185°

F.

Operating

the engine

with the coolant

temperature

below this

range

will

result

in

incomplete combustion

of

fuel, higher fuel

consumption with less power,

and

will

cause harm-

ful

deposits within the engine.

Maintaining the normal

coolant

op~rating tem-

perature

(160° to

185°

F.)

depends

mostly on

proper

functioning of the thermostats.

If

the coolant

te,;,perature remains consistently below normal,

the thermostats should

be

removed, checked for

proper

operation,

and

replaced

if neces;;ary.

C.

Draining

of

Cooling System

Remove the

radiator

filler

cap

and

open the cyl-

inder block

drain

cock, located on the right

rear

side of the cylinder block.

Open

the

radiator

drain

cock, using the extension tool (included with 'the

tools fur~ished with the tractor) inserted through

the hole

in

the lower right corner of the main frame.

CAUTION: When draining the cooling system

in

freezing weather,

make

certain that the coolant

flows freely from all drain cocks

and

that the

system drains completely.

D. Filling

of

Cooling

System

Close the

radiator

drain cock, located

at

the lower

right corner of the

radiator

(in the

water

outlet

elbow). Close the cylinder block drain cock, located

in

the right

rear

side of the cylinder block.

Fill

the

cooling system through the

radiator

filler

cap

opening until the coolant level

is

within approxi-

Cylinder

B.lock

Drain

~q~/$

~1',J

Radi~tor

Drain Cock location.

FIG.

8

FIG.

9

mately 2 inches of the

top

of the

radiator

and

install the

radiator

filler

cap.'

E.

Fc~an

Drive

Belt

Adiustment

The fan drive belts

are

correctly adjustic:1 when

the

straight side of the belts

can

be

pressed inward

by

hand

approximately

Y2

to % inch

at

a point

half-way between the crankshaft

and

the fan

.

21

~=;;..:

Water

Pump

and

Generator

Drive

Self

·

Adjustment

foc~tion

FIG.

10

pulleys.

To

adjust the drive

bE!lts1

loosen. th

idler

bracket

clamping capscre~."~'J-\9~en

the

nut on the adjusting screw

and

turn/lf~:~:adj.ust

....

screw

in

or

out

as

necessary to obtain'.fli}c;_orr~c:t

tension on the drive belts, then tighte~;tthti.fifdjost-

ing screw jam nut. Tighten

the

..

fall

idJiji'li

btfu9~1et

clamping capscrew.

F.

Water

Pump

and

Genercator

Dri

e

Belt

Adiustment

The

water

pump

and

generator

drive. belt

is

prof

erly adjusted when the belt ~an

be

pressed inward

by

hand

approximately

Y2

inch

at

a point half-way

between the

generator

and

water

pump pull,eys.

To

adjust the drive belt, loosen the

generator

adjusting

arm

capscrew, move the

generator

up

or down to

obtain

the correct tension of the drive

belt, then tighten

the

adjusting arm capscrew.

FUEL

SYSTEM

A.

DESCRIPTION

OF

SYSTEM

The engine fuel system consists of a fuel tank, first

stage

fuel filter, fuel transfer pump, second stage

fuel filter, fuel injection pump, fuel nozzles, and

the fuel· lines. There

are

two fuel pressure systems;

the low, pressure system

and

the high pressure

system.

The

low

pressure system consists of the fuel tank,

first

stage

fuel filter, fuel transfer pump, second

stage

fuel filter, fuel leak-off

header,

and

the fuel

return line leading from the fuel sump of the fuel

injection pump to the fuel tank.

The high pressure

sy;~tem.

consists of the fuel

in-

.d!~!ion pump, fuel n~zzles,

and

aU high pressure

'•

fpll'Jines connecting tlie fuel injectfor, pump to the

(uei

no:µles.

The

high pressure fhel

lin~s

are

s~c:imles!i

ste.el

tubing

and

each line

is.

the same

l~ngth. These. lines being the same length assures

·

thil$tQper

timing

and

the

proper

amount of fuel

·tq~.ach fuel nozzle. These lines

are

not interchange-

·~i,fo;

when ordering lines·

for·

replacement, specify

,f\•,.:•.i

.,.

\ . /

'f9r

;~~ic;h

cylit!d~r the line

is

ordered.

. .

Tl,e,f~~Fis draWh from the fuel tank, through the

Ji:r~fstag(?. f~eF;filter, by the fuel transfer pump.

·The fuel tis th~n .forced by the transfer pump,

through the second stage}uel filter

and

to the fuel

inj~ction pump.

The

amount of fuel required for

~o,:nbustion.

is

forced under high pi:essure by the

fuel injection pump, through the high pressure fuel

FUEL

PRESSURE

RELIEF

VALVE

ENGINE

lines to the fuel nozzles, from which the fuel enters

the engine combustion chambers

in

the form of a

fine cone-shaped spray.

There

is

a certain amount of fuel

seepage

between

the

lapped

surfaces of each fuel nozzle

va.lve

and

its

body, which

is

necessary for lubrication.

This

leakage

of fuel accumulates around the spindle ·

and

in

the spring compartment of each fuel nozzle,

and

is

returned through the leak-off

header

to the

fuel return line, extending to the fuel tank.

The

excess fuel delivered to the fuel injection pump by

the fuel transfer pump

is

returned to the fuel tank

through the fuel return line. A pressure of 5 to 15

P.S.I.

is

maintained within the low pressure fuel

system by a fuel pressure relief valve installed

in

the fuel return outlet of the fuel injection pump.

The heavy-duty fuel injection pump

is

of the con-

stant-stroke, distributing-plunger, sleeve control

type, the plunger being actuated by a cam

and

tappet

arrangement

which also carries the gearing

for the distribution function.

Its

purpose

is

to meter

the fuel accurately

and

deliver

it

precisely

at

a

definite moment

in

the engine cycle

and

under

high pressure to the fuel nozzles.

The

fuel injection

pump plunger

is

9

M.M.

in

diameter and the pump

is

controlled by

.a

mechanical-centrifugal type

(type·

"C'?

governor).

The function of the fuel nozzles

is

to direct the

metered quantity of fuel, received from the fuel

injection pump, into the engine combustion cham-

TO

FUEL

PRESSURE

GAGE

(SPECIAL

EQUIPMENT)

r1 1

SECOND

ST

AGE

FUEL

FILTER

FUEL

TRANSFER

PUMP

FIRST

STAGE

FUEL

FILTER

-

FUEL

TANK

Loo--------------

Fuel Flow -Schematic

Diagram

--------------'

FIG.

11

..

22

Table of contents

Other Allis-Chalmers Tractor manuals

Allis-Chalmers

Allis-Chalmers G User manual

Allis-Chalmers

Allis-Chalmers B Install guide

Allis-Chalmers

Allis-Chalmers HD-5 User manual

Allis-Chalmers

Allis-Chalmers regent hydro 14 User manual

Allis-Chalmers

Allis-Chalmers H 4 Specifications

Allis-Chalmers

Allis-Chalmers 10 hp User manual

Allis-Chalmers

Allis-Chalmers WD Use and care manual

Allis-Chalmers

Allis-Chalmers ac130 series User manual

Allis-Chalmers

Allis-Chalmers HD-4 Specifications

Allis-Chalmers

Allis-Chalmers G User manual