•

VEHICLE

IDENTIFICATION

NUMBER

(VIN) LOCATIONS

Vehicle

identification

numbers

are

used

to

identify

your

new

tractor

o',

'

,d

major

attachments.

These

numbers

should

always

be

referred

to

when

consulting

your

dealer

or

the

factory

concerning

service,

parts,

or

other

information

you

may

require.

If

these

plates

ore

removed

dvring

repair

operations

,

they

shou

ld

always

be

rep

l

aced.

The

tractor

vehicle

identification

number

plate

is

located

just

below

the

dash

ponel.

Engine

identification

number

plates

ore

located

on

the

engine

shrouding

and

indicate

the

model,

specification

or

type

number

and

the

seriol

number

of

your

troctor's

engi!1e.

Major

attachments

olso

have

a

vehic

le

identification

number

plate

attached

to

them

.

For

your

convenience

and

ready

reference,

enter

the

tractor

and

engine

numbers

below.

B & C

Series

VIN

Plate

location

Tractor

Identification

Number

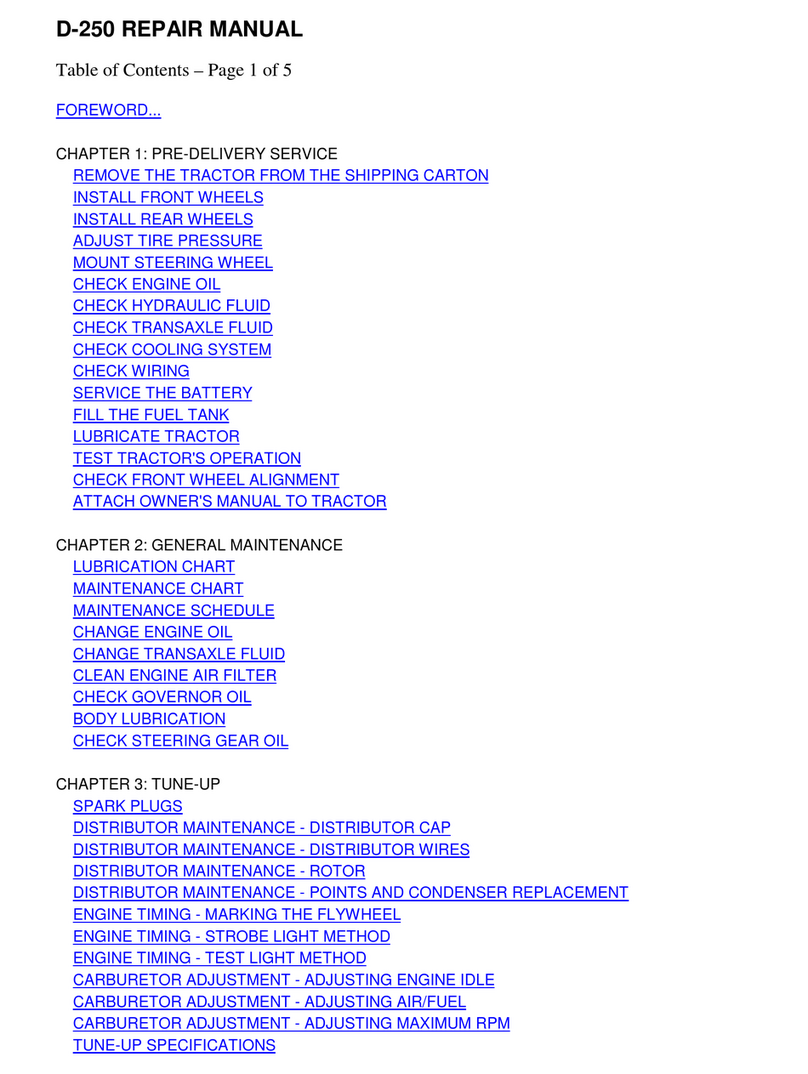

D-Series

VIN

Plate

location

Engine

Identification

Number

Model

_

Type

or

Spec

No.

Serial

No.

__

-

------------

OWNER REGISTRATION AND IDENTIFICATION

CARD

Service

and

wa

r

ranty

assurance

is

as

important

to

Wheel

Horse

as

it

is to

you

,

the

owner.

TO ASSURE

warranty

service

at

on

Authorized

Wheel

Horse

Dealer,

Wheel

Horse

provides

an

"OWNER IDEN-

TIFICATION CARD"

for

each

new

tractor,

or

mOlor

attachment

,

registered

with

the

factory.

To

receive

your

"OWNER I

DENTIF

ICATION CARD"

either

you

or

your

dea

l

er

must

fill

in

the

required

information

on

the

"NEW OWNER FACTORY

REG

-

ISTRATION CARD"

and

mail

immediately.

Your

"OWNER IDENTIFICATION CARD" will

be

returned

by

mail.

I~WHEEL

HORSE

I

lawn

&

garden

tractors

OWNER IDENTIFICATION CARD

PRODUCT 10

NUMB

ER

SELLI

NG

D

EA

LER

WAR~

A

"-I

TV

EXPIRES

Present

th

iS c

ard

to

an

a

ulh

C"

1

<'-

::

)ea

.

E"

10 Or:t8

111

warranty

serv

ice

PARTS MANUAL

A

separate

ports

manual

is

available

for

your

Wh

eel Horse

equ

i

pment.

To

obtain

a

ports

manual,

see

the

ordering

information

found

at

the

end

of

this

pub

l

ication.

BE

SURE

TO INCLUDE

THE

VEHICLE IDENTIFICATION NUMBER

OF

THE

EQU

IPMENT.

- 2 -

,