Brasch TRNS Generation 2 User manual

Brasch Environmental Technologies, LLC

140 Long Road, Suite 101

Chesterfield, Missouri 6 005

14-291-0440

www.braschenvtech.com

TRNS Generation 2

Installation / Operation Manual

Table of Contents

Introduction...................................................................................................................................4

General Description..................................................................................................................4

Features and Benefits..............................................................................................................5

Technical Specifications................................................................................................................6

Product Specifications..............................................................................................................6

Target Gas Specifications.........................................................................................................7

Carbon Monoxide.................................................................................................................7

Nitrogen Dioxide...................................................................................................................7

Description of Front Panel Indicators.......................................................................................8

Front Panel Indicators..........................................................................................................8

Operation Safety Notice................................................................................................................9

Types of Notices.......................................................................................................................9

Quick Start Guide.......................................................................................................................10

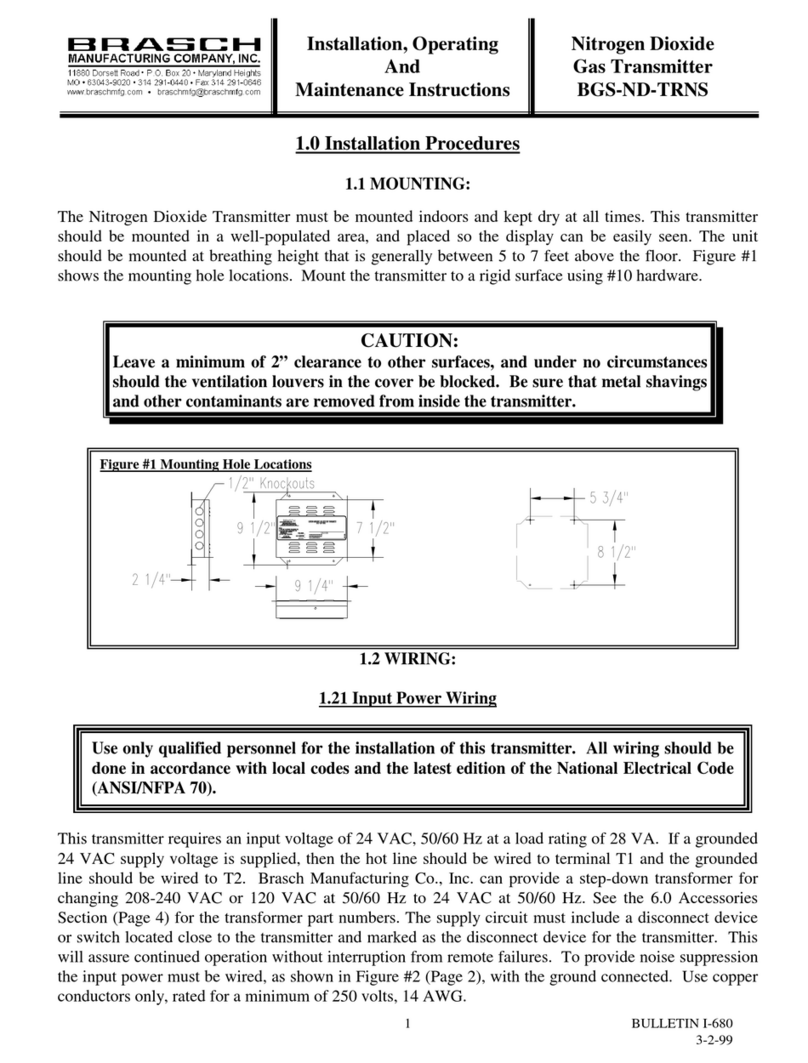

Step 1 – Mounting..................................................................................................................10

Step 2 – Input Wiring..............................................................................................................10

Step – Output Wiring...........................................................................................................11

Step 4 – Applying Power.........................................................................................................11

Installation...................................................................................................................................12

Mounting the Transmitter........................................................................................................12

Connecting the Power Supply................................................................................................1

Connecting the Voltage or Current Proportional Output........................................................14

Connecting the Modbus Output..............................................................................................15

Applying Power For the First Time.........................................................................................15

Installation Diagrams..............................................................................................................16

Operation....................................................................................................................................18

How the Transmitter Senses the Target Gas.........................................................................18

Factory Default Settings.........................................................................................................18

Using the Analog Proportional Output....................................................................................18

Adjusting the Proportional Output..........................................................................................19

Obtaining the Best Operation.................................................................................................19

Carbon Monoxide and/or Nitrogen Dioxide Transmitters...................................................19

Maintenance...............................................................................................................................20

Testing the Response to the Target Gas................................................................................20

Carbon Monoxide or Nitrogen Dioxide Transmitters..........................................................20

Replacing the Sensor.............................................................................................................21

Suggested Repair Parts.........................................................................................................22

Troubleshooting..........................................................................................................................22

Fault........................................................................................................................................22

Checking and Replacing Fuses..............................................................................................22

Common Installation/Operation Mistakes..............................................................................2

Proportional Output Connected Incorrectly........................................................................2

Setting the Proportional Output Incorrectly........................................................................2

IOM02

Rev 1.0 – December 22, 2020 2

Using Improper Resistance/Impedance.............................................................................2

Transmitter Mounted in an Unsatisfactory Location..........................................................2

Limited Warranty.........................................................................................................................24

Warranty Statement...........................................................................................................24

Service and Repair Procedures.........................................................................................24

Appendix.....................................................................................................................................25

Model Numbers and Descriptions..........................................................................................25

Transmitter Model Number and Description......................................................................25

Figures and Diagrams............................................................................................................25

IOM02

Rev 1.0 – December 22, 2020

Introduction

General Description

The Brasch Environmental Technologies TRNS Generation 2 Gas Transmitter is designed to

function as a gas sensor and signal transmitter. The transmitter consists of a sensor and

digital control circuitry. A linear proportional output circuit is able to provide analog signals to a

customer-supplied building management controller or a variable-frequency drive. An RS-485

circuit is able to provide two-way digital communication using Modbus RTU. A microprocessor

monitors the signal from the sensor and transmits that signal to the output as either an analog

or digital signal.

The sensor used in the transmitter operates on the electrochemical principle. A current is

produced when the target gas reacts chemically with an electrode inside the sensor. This

small current is changed to a voltage by the transmitter’s circuitry, amplified, and converted to

the proper output signal. This signal is proportional to the target gas concentration present at

the sensor.

The transmitter’s circuitry consists of a printed circuit board mounted inside a polycarbonate

housing. The housing has a NEMA R rating. Vents are located on the bottom and side of the

housing to allow the sensor access to ambient air.

IOM02

Rev 1.0 – December 22, 2020 4

Features and Benefits

•Comprehensive Monitoring

◦Detects CO and/or NO2

•Greater Coverage

◦Monitors up to 9,000 sq. ft.

•Enhanced Durability

◦Rainproof Water Resistance

◦Simple Service and Maintenance

•Simplified Installation

◦Preconfigured Wiring

◦Factory Calibration

◦Customized Programming

•Versatile Communication

◦Analog Output via User-Selectable Current or Voltage Loop

◦Digital Output via Modbus RTU Communication Protocol

•Effortless Upgrade

◦Works with New and Existing Building Controls Systems

◦Fully Backwards Compatible with TRNS Generation 1

IOM02

Rev 1.0 – December 22, 2020 5

Technical Specifications

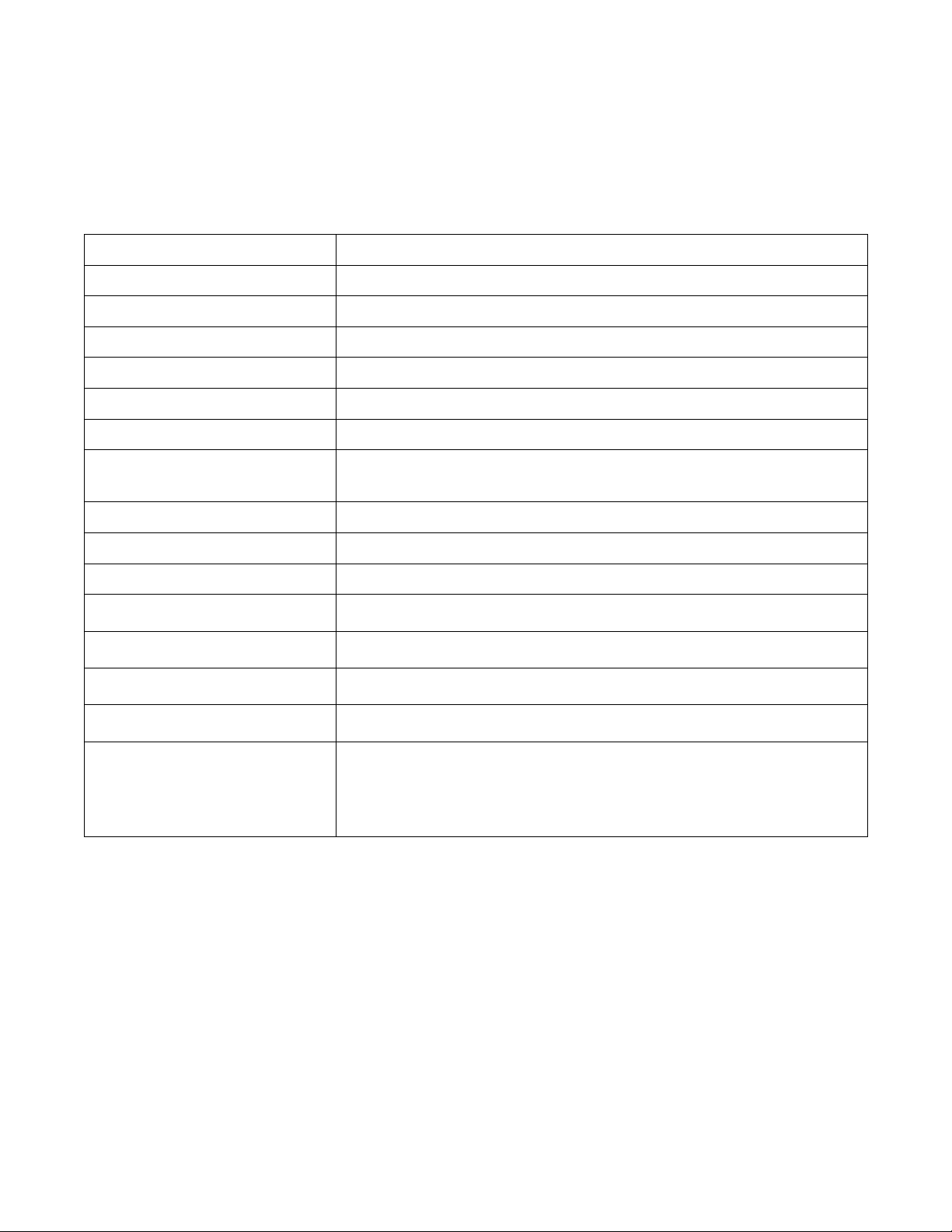

Product Specifications

Input Power 24 VAC, 50/60 Hz, 0.25 A

Installation Category II (local level, over-voltage transients less than 500V)

Storage Temperature -50°C to 120°C (-58°F to 248°F)

Operating Temperature -20°C to 50°C (-4°F to 122°F)

Humidity 10% to 90% (non-condensing)

Ventilation Control Relays None

Internal Alarm None

Front Panel Indicators Power (green LED)

Fault (yellow LED)

Display None

Selectable Fan Settings None

Alert Levels None

Delay Times None

Dimensions 4.8” W x 4.72” H x 2.16” D (12.2 cm W x 12 cm H x 5.5 cm D)

Weight 1 lbs (0.5 kg)

Housing Gray, NEMA R, polycarbonate plastic

Compliance ANSI/ISA 92.00.01-2010 (R2015)

EN 50270

FCC Part 15 Subpart B

RoHS

IOM02

Rev 1.0 – December 22, 2020 6

Target Gas Specifications

This Brasch Gas Transmitter is available for monitoring carbon monoxide and/or nitrogen

dioxide as target gases. Regulatory agencies have determined the threshold concentrations at

which the gases become dangerous. Brasch Environmental Technologies, LLC has designed

their transmitters so that the measurement ranges for each target gas meet the agencies’

requirements. Each target gas, for which Brasch currently produces a transmitter, is listed

below along with the relevant concentration specifications.

Carbon Monoxide

Full Scale Span: 200 PPM

Resolution: 1 PPM

Minimum Accuracy*: ± 10% or 6 PPM

Expected Lifespan 10 years

Recommended

Recalibration Time 2 years

Nitrogen Dioxide

Full Scale Span: 10 PPM

Resolution: 0.1 PPM

Minimum Accuracy*: ± 15% or 0.8 PPM

Expected Lifespan 10 years

Recommended

Recalibration Time 2 years

*Allowable tolerance for accuracy and repeatability criteria as defined in Annex A, Item 2 of ANSI/ISA 92.00.01-2010 (R2015)

IOM02

Rev 1.0 – December 22, 2020 7

Description of Front Panel Indicators

The front panel indicators convey to the user the operational status of the transmitter. The

following table describes the function of each indicator. Please refer to the transmitter’s front

panel label for the indicator’s location.

Front Panel Indicators

Indicator Color Description

Power Green Glows whenever power is on

Fault Yellow Glows when expected end-of-life is reached

IOM02

Rev 1.0 – December 22, 2020 8

Operation Safet Notice

Certain procedures and operations detailed in this manual require that specific precautions be

taken prior to beginning the procedure or operation. When precautions are required, a notice

will be printed in an appropriate location in the manual. The user is urged to read and

understand all such notices.

T pes of Notices

Three types of notices may be used in this manual to describe the severity of the situation

encountered.

WARNING: This notice indicates that conditions exist that could cause personal injury

or loss of life.

CAUTION:Conditions exist that could cause damage to the equipment or other

property.

Note: Special consideration should be given to the procedure or operation,

otherwise an unexpected operational result could occur.

IOM02

Rev 1.0 – December 22, 2020 9

Quick Start Guide

Please read this entire manual before attempting to install and operate this gas transmitter.

This guide is only intended to provide the basic steps necessary for installation and operation.

Each step will reference the portion of the manual where more complete information can be

obtained.

Step 1 – Mounting

Determine the location for mounting your transmitter(s). The location(s) may be indicated on

the architectural drawing. Also, the owner or designer of the facility may be consulted.

Mounting guidelines can be found on page 12 of this manual.

Step 2 – Input Wiring

Provide a dedicated circuit at the required 24 VAC and 6 VA at each transmitter mounting

location. Follow all national and local wiring codes. The wiring should be at least 14 AWG. A

conductor connected to earth ground should also be provided. The circuit must include a

disconnect switch located within easy reach of the transmitter.

Color-coded wires exiting the transmitter housing through the top conduit connector are

provided for connecting the operating voltage to the transmitter. Therefore, it should not be

IOM02

Rev 1.0 – December 22, 2020 10

WARNING

This transmitter may require the use of voltage levels high enough to cause fatal injuries.

Proper procedures must be followed any time work is performed on this unit.

Only qualified personnel should attempt to install, maintain, or service this equipment.

CAUTION

Operating this transmitter with the incorrect voltage and power requirements can cause

internal electrical components to overheat and fail. Operation with the wrong power

requirement will void the manufacturer’s warranty and the installer will be responsible for any

damage that occurs.

Contact Brasch Environmental Technologies, LLC before connecting power to the transmitter

if you are unsure of the correct power requirement.

necessary to remove the front cover from the transmitter when connecting the voltage supply.

Connect the hot power conductor to the black wire and the neutral conductor to the white wire.

Refer to page 1 for further information.

Step 3 – Output Wiring

The transmitter conveys its sensor signal over two wires. Use a two-conductor shielded cable

for each transmitter in the system. As with the input power connections, color-coded wires exit

the transmitter housing through the top conduit fitting so removal of the front cover should not

be necessary. When using the analog output, the positive conductor connects to the red wire

and the reference conductor connects to the green wire. When using the digital output, the

positive conductor connects to the brown wire and the negative conductor connects to the blue

wire.

See figures 1 and 2 on page 16 for wiring diagrams.

Step 4 – Appl ing Power

Once you are sure that the wiring connections are correct, apply power to the transmitter

circuit. When power is first applied, the green power indicator will glow, indicating the

transmitter is active. The unit will begin transmitting its signal through the output immediately;

however, you should wait at least 2.5 minutes before taking any gas measurements as the

sensor will still be warming up.

See page 15 for more information concerning the initial startup.

At this point, the transmitter is now ready to monitor for the presence of the target gas.

IOM02

Rev 1.0 – December 22, 2020 11

Installation

Mounting the Transmitter

The ability of the transmitter to sense the target gas depends greatly upon proper selection of

the mounting location. This transmitter monitors the area around it by sampling the air that

passes by the sensor. Since the sensor is mounted inside a housing, air must diffuse through

the intake vent and pass by the sensor on its way out the exhaust vent. Therefore, the

transmitter should be positioned where it can sample air that contains a target gas

concentration representative of the average value in that area.

When determining the mounting location, give special consideration to the following guidelines.

•Use one sensor per target gas for each area to be covered.

•Always prioritize locations with the highest occupation density.

•The types of gases each unit is designed to monitor have densities approximately equal

to that of air. For maximum safety, mount the unit at the average breathing height –

approximately 5 to 7 feet from the floor.

•Avoid mounting locations that would not be representative of the average gas value in

that area. These include but are not limited to locations near doorways, fans, ventilation

inlets and outlets, and areas with air velocities in excess of . ft/s (1 m/s).

•Avoid locations that would allow direct contact with water. Mounting the unit near

outside garage doors may allow rain to hit the unit when the door is open.

•Avoid locations that are directly in the outlet air vents of heaters or air conditioners.

•Avoid mounting locations with normal ambient temperatures below -4°F (-20°C) or

above 122°F (50°C).

•Do not allow exhaust from engines to flow directly on the unit. Each unit is designed to

sense gas concentrations that are 00 to 1000 times less concentrated than the gas

levels found in engine exhaust. Also, engine exhaust contains high levels of other

components. These components can shorten the useful life of the sensor if they contact

the sensor before being diluted by the room air volume.

•Avoid mounting locations where the unit may be hit by passing vehicles. If the unit must

be mounted in these locations, provide a shielding cage around the unit for protection.

•Do not restrict the air flow to the unit housing.

•Do not mount the unit in a corner.

IOM02

Rev 1.0 – December 22, 2020 12

•Do not mount the unit near containers of chemicals such as gasoline, kerosene, alcohol,

or other cleaning fluids. High level concentrations of these chemicals may be mistaken

as the target gas by the sensor and cause false readings. Also, some welding gases

may cause false readings.

The transmitter is attached in the mounting position in one of three ways.

•Attach the housing to conduit using appropriate conduit fittings. If you use this method,

make sure that the conduit is securely attached to a solid support. Firmly tighten the

threaded nuts on the conduit fittings inside the transmitter housing so they will not

loosen over time.

•Attach the housing to a four inch square conduit box using the ½ inch fitting provided

with the transmitter. Make sure that the conduit box is firmly fastened to the mounting

surface with screws. Securely tighten the fitting nut on the inside of the conduit box so it

will not loosen over time.

•Attach the housing to a solid support base using screws through the internal housing

mounting holes. This method requires removal of the housing cover to gain access to

the mounting holes. A mounting hole is located at the top and bottom of each housing

end wall.

Find a flat area at least 6 inches high by 6 inches long and place the back of the open

housing flat against it. Using a pencil or other slender marking tool, mark the location of

the four mounting holes using the housing as a template. Start the screws without the

housing in place to avoid any possibility of damage to the housing or circuit boards.

Remove the screws, place the housing in position, and install the mounting screws. Do

not over-tighten the screws as this may crack the plastic housing. Be careful not to

damage the printed circuit board. Carefully replace the housing cover and securely

tighten all four of the cover retaining screws.

Connecting the Power Suppl

While this transmitter does not require much power to operate, it is usually located near

machines that do consume large amounts of power. When these large machines operate, they

IOM02

Rev 1.0 – December 22, 2020 1

WARNING

This detector may require the use of voltage levels high enough to cause fatal injuries.

Proper procedures must be followed any time work is performed on this unit.

Only qualified personnel should attempt to install, maintain, or service this equipment.

cause large voltage spikes to appear on the AC wiring. These spikes can interfere with the

proper operation of the transmitter. The easiest way to avoid much of this interference is by

providing power to the transmitter through a dedicated circuit from the service panel. In some

very noisy situations, a line filter can be connected in the power supply circuit just ahead of the

wiring connections at the transmitter.

Provide a dedicated circuit at the required operating voltage at each transmitter mounting

location. Follow all national and local wiring codes. The wiring should be at least 14 AWG. A

conductor connected to Earth ground should also be provided. The circuit must include a

disconnect switch located within easy reach of the transmitter.

Be sure that the step-down transformer provides 24 VAC and has at least a 6 VA rating. The

power requirements for the transmitter are also listed on the label on the left side of the unit.

Color-coded wires exiting the transmitter housing through the top conduit connector are

provided for connecting the operating voltage to the transmitter. Therefore, it should not be

necessary to remove the front cover from the transmitter when connecting the voltage supply.

Connect the hot power conductor to the black wire and the neutral conductor to the white wire.

Connecting the Voltage or Current Proportional Output

The Brasch Gas Transmitters include circuits that provide either a current loop or voltage

proportional output for each gas sensor. Each output produces a linear response over the full

scale range of the sensor. A detailed description of these outputs can be found starting on

page 18.

IOM02

Rev 1.0 – December 22, 2020 14

Note

Do not operate the transmitter on the same AC circuit with the ventilation components.

Doing this will almost always cause improper transmitter operation.

CAUTION

Operating this transmitter with the incorrect voltage and power requirement can cause

internal electrical components to overheat and fail. Operation with the wrong power

requirements will void the manufacturer’s warranty, and the installer will be responsible for

any damage that occurs.

Contact Brasch Environmental Technologies, LLC before connecting power to the transmitter

if you are unsure of the correct power requirement.

The transmitter conveys its sensor signal over two wires. Use a two-conductor shielded cable

for each transmitter in the system. As with the input power connections, color-coded wires exit

the transmitter housing through the top conduit fitting so removal of the front cover should not

be necessary. At each transmitter, the positive conductor connects to the red wire and the

reference conductor connects to the green wire.

See figure 1 on page 16 for a wiring diagram.

Connecting the Modbus Output

The Brasch Gas Transmitters also include a circuit that provides digital communication via

Modbus RTU protocol. This output allows a client device to read the firmware version, gas

sensor type, gas sensor value, and any error codes associated with the transmitter. Color-

coded wires exit the transmitter housing through the top conduit fitting so removal of the front

cover should not be necessary. At each transmitter, the positive conductor connects to the

brown wire and the negative conductor connects to the blue wire.

See figure 2 on page 16 for a wiring diagram. A more complete description, including

instructions on setting up the client, is available in the dedicated Modbus Setup Guide.

Appl ing Power For the First Time

Once all the wiring connections are complete, the transmitter is ready for power to be applied.

The green power LED will glow immediately and the output will begin transmitting. However,

the first 2.5 minutes after the power is applied should be considered a warm-up period as the

sensor readings will not be fully stabilized yet. After this time, the transmitter is ready to

monitor the area for target gas.

IOM02

Rev 1.0 – December 22, 2020 15

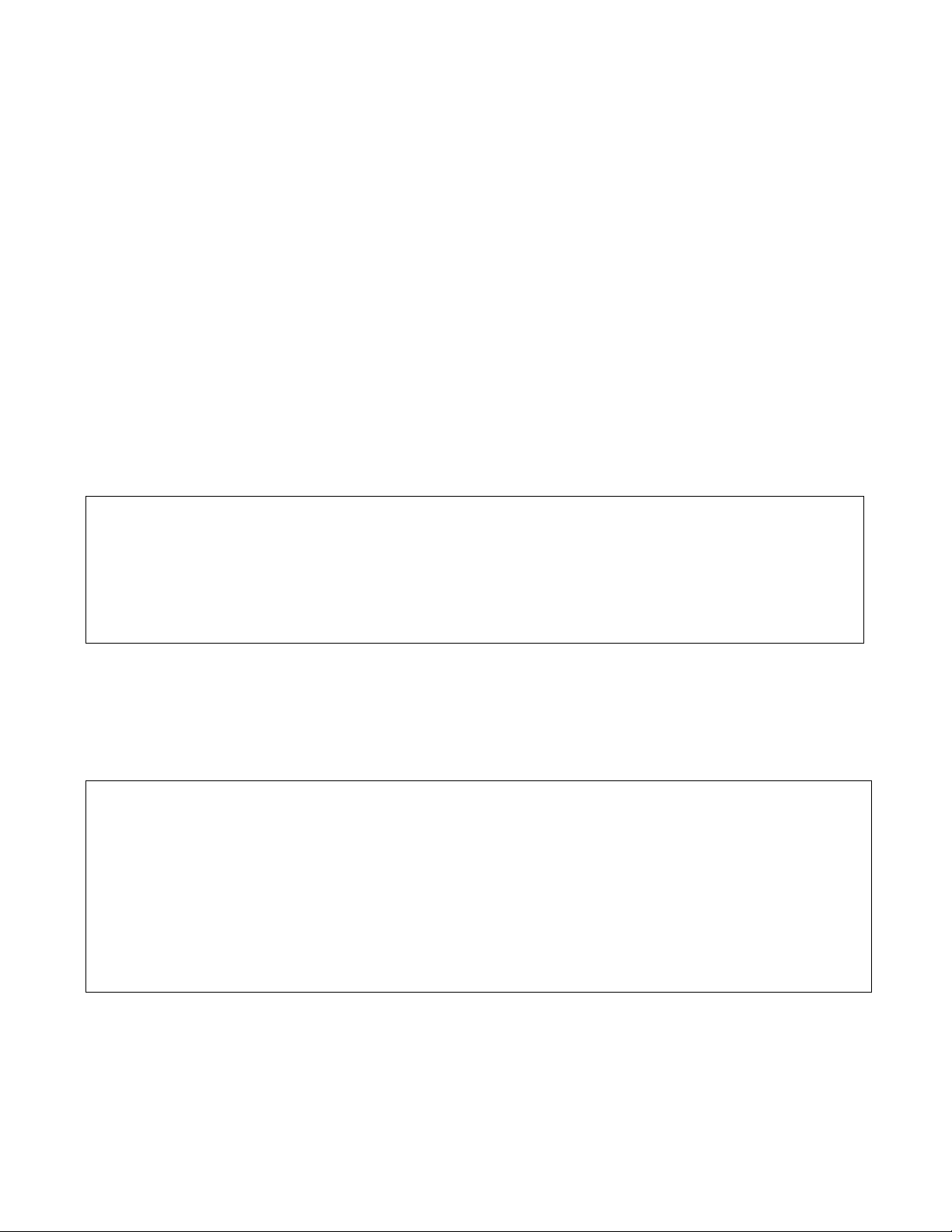

Installation Diagrams

IOM02

Rev 1.0 – December 22, 2020 16

Figure 1: Wiring – Analog Output Configuration

Figure 2: Wiring – Digital Output Configuration

IOM02

Rev 1.0 – December 22, 2020 17

Figure : Wiring – Remote Sensor Configuration

Operation

How the Transmitter Senses the Target Gas

Ambient air surrounding the transmitter housing diffuses inside the housing where it comes

into contact with the sensor. Although the transmitter’s circuitry dissipates very little power, a

small amount of heat is produced inside the housing. This heat causes air to rise up through

the bottom vent, past the sensor, and out the upper vent. Any target gas present in this air

causes a response from the sensor. If the transmitter is located properly, the sensor will

respond to the average amount of the target gas present in the area. For help in properly

locating the transmitter, please read the mounting guidelines on page 12. This transmitter

monitors the actual concentration of the target gas exposed to the sensor. This actual value

may be different than the time-weighted-average values displayed by many personal gas

monitors. Please take this difference into account when comparing the response of the two

units.

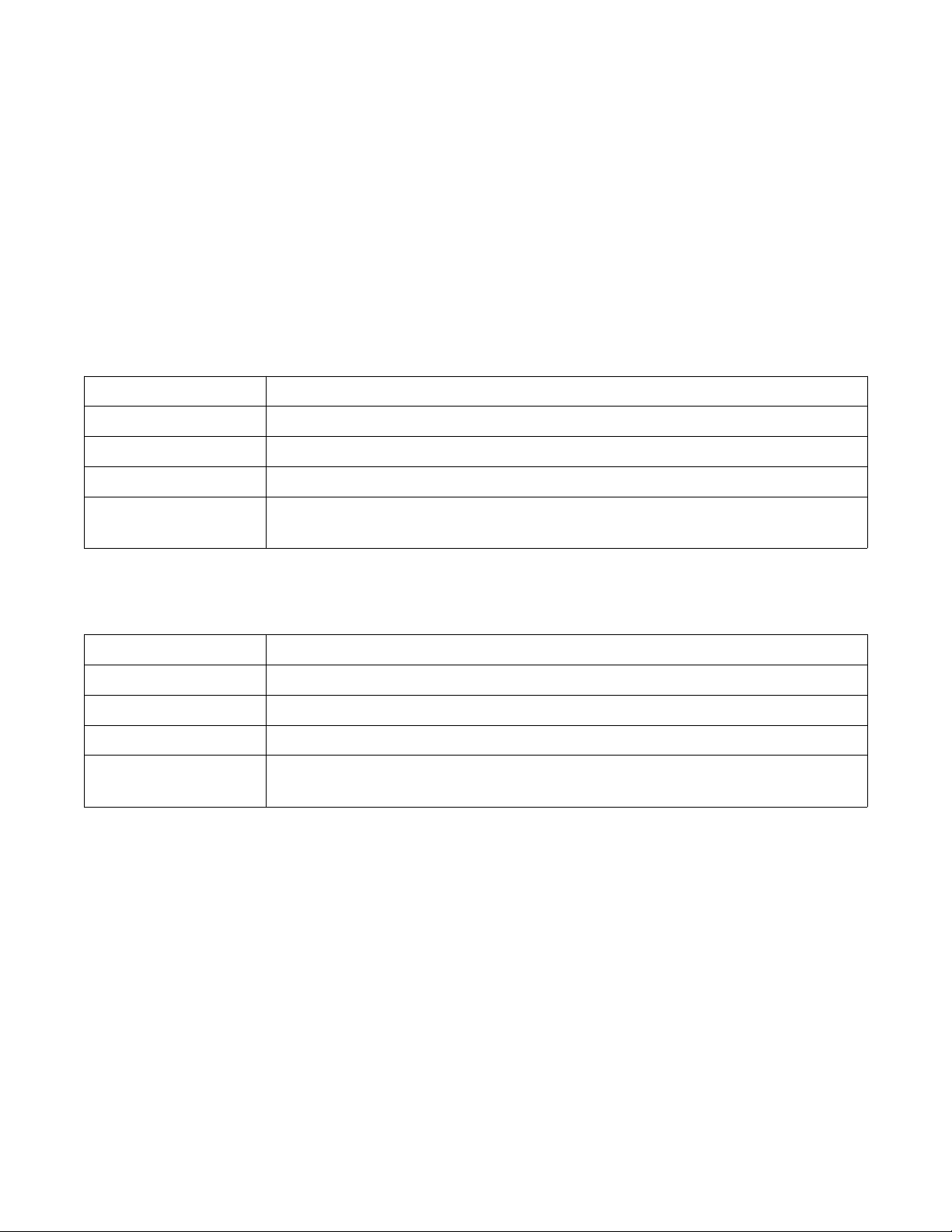

Factor Default Settings

Unless otherwise specified on the order form, the following settings will be used to configure

the analog proportional output of the transmitter.

Setting Default

Analog Proportional Output Units mA

Analog Proportional Output Signal 4-20 mA

Using the Analog Proportional Output

This Brasch Gas Transmitter is supplied with a linear proportional output that can be

connected to a building management controller or variable-frequency drive. This output can

produce either a current or voltage signal that is proportional to the concentration of the target

gas present at the sensor. By moving jumpers, located on the bottom, right corner of the

printed circuit board, the user can select from 4-20 mA, 2-10 VDC, 1-5 VDC, and 0.2-1 VDC

signals. This signal is available at the terminal strip TS , located at the bottom, right corner of

the board. See figure 6 on page 26 for the terminal strip locations and signal mode selection

jumpers.

Unless otherwise specified, the transmitter is shipped from the factory with the selection

jumpers set in the 4-20 mA current loop mode. To change the mode to one of the voltage

modes, the JP2 selection jumper must be moved to the “Volts” pins. After this, the JP jumper

IOM02

Rev 1.0 – December 22, 2020 18

may be moved to the desired output. To return to the 4-20 mA mode, replace the JP jumper

on the “mA” pins and the JP2 jumper to the “4-20 mA” pins. Ensure that power to the

transmitter is off before attempting to change these settings.

The output signal is connected using a two-conductor shielded cable. The resistance of the

total cable length must be less than 250 Ω if the 4-20 mA current loop mode is selected. For

the voltage modes, the input impedance of the controller must be greater than 100 kΩ.

Ground the shield of the signal cable at an earth grounding point only to avoid noise conditions

created by ground loops. Although the positive signal lead can be shorted to ground without

causing damage, this condition should be avoided. Also, do not route the signal cable in

conduit containing other wiring to avoid unwanted noise pickup.

The linear outputs produce a signal based on the full scale response of the transmitter. As an

example, a Brasch Carbon Monoxide Transmitter has a full scale output of 200 PPM CO. For

the 4-20 mA output mode, 0 PPM CO would equal 4 mA while 200 PPM CO would equal 20

mA. Follow the instructions supplied with your controller to adjust the controller’s input for the

proper scaling of the signal. Consider a 0 mA or 0 VDC output as a fault condition. See figure

7 on page 27 for details.

Adjusting the Proportional Output

To adjust the output, set the jumper at JP2 on the bottom, right of the sensor board to the

desired unit – “Volts” or “mA”. Then set the jumper at JP , just above JP2, to the desired

output signal – 2-10 V, 1-5 V, 0.2-1 V, or 4-20 mA. Be sure to follow the instructions on page

18 to ensure proper functionality of the proportional output.

Obtaining the Best Operation

Carbon Monoxide and/or Nitrogen Dioxide Transmitters

These transmitters are placed in areas to monitor for a rising concentration of the target gas.

No two installations will be exactly the same. The number of gas producing sources, air flow

patterns inside the room, the total room volume, and the exact location of the transmitter(s)

influence how effective each is in sensing the target gas concentration.

IOM02

Rev 1.0 – December 22, 2020 19

Note

Power to the transmitter must be turned off in order for any changes made to take effect.

With most installations, the only variable that can be changed is the location of the transmitter.

In some cases, you may find that a target gas source is too close to the transmitter. Consider

other mounting locations for the transmitter or move the gas source farther away.

Maintenance

Testing the Response to the Target Gas

Carbon Monoxide or Nitrogen Dioxide Transmitters

Testing these transmitters requires that the target gas be applied to the sensor using one of

two methods. Gas can be applied from a tank of air containing a known concentration of the

target gas or from the exhaust of an operating engine to produce a level of target gas sufficient

to activate the control system. For the latter method, use a gasoline or petrol engine to

produce CO and a diesel engine to produce NO2.

Of the two methods of obtaining test gas, the simplest is operating an engine in the vicinity of

the transmitter under test. The engine should be placed about 10 feet away from the

transmitter so that exhaust gases will not contact the transmitter directly.

The engine should be allowed to operate until a level of the target gas is sufficient to activate

the ventilation system. Depending upon the volume of the area where the transmitter is

located, this may take from 10 to 0 minutes.

Using test gas applied from a tank has the advantage of speed as well as assurance that the

transmitter is responding accurately to the target gas. However, the gas must be applied

directly to the sensor if the response is to be close to the value present in the tank. The test

gas cannot be allowed to become diluted by the air in the room before it comes in contact with

the sensor. This reduces the concentration to a level too low to give the desired result.

IOM02

Rev 1.0 – December 22, 2020 20

CAUTION

Allowing the transmitter to come in direct contact with undiluted exhaust gases will decrease

the expected useful lifetime of the sensor. The high concentration of acids and other

components in the exhaust gas will overload the activated carbon filter inside the sensor and

will increase the effects of interfering gases on the accuracy of the sensor.

If the sensor becomes damaged, it must be replaced with a new sensor calibrated at the

factory.

This manual suits for next models

3

Table of contents

Other Brasch Transmitter manuals

Popular Transmitter manuals by other brands

Dwyer Instruments

Dwyer Instruments DSGT Series Installation and operating instructions

Auto-T

Auto-T 540312 manual

RKI Instruments

RKI Instruments AirLink 6940XP Operator's manual

TEKO Broadcast

TEKO Broadcast SYNAPSE30 user manual

WIKA

WIKA CPT-2x series operating instructions

Z-Band

Z-Band Z-Light 6TX operating manual