Brasch BGS-ND-TRNS Assembly instructions

BULLETIN I-680

3-2-99

1

1.0 Installation Procedures

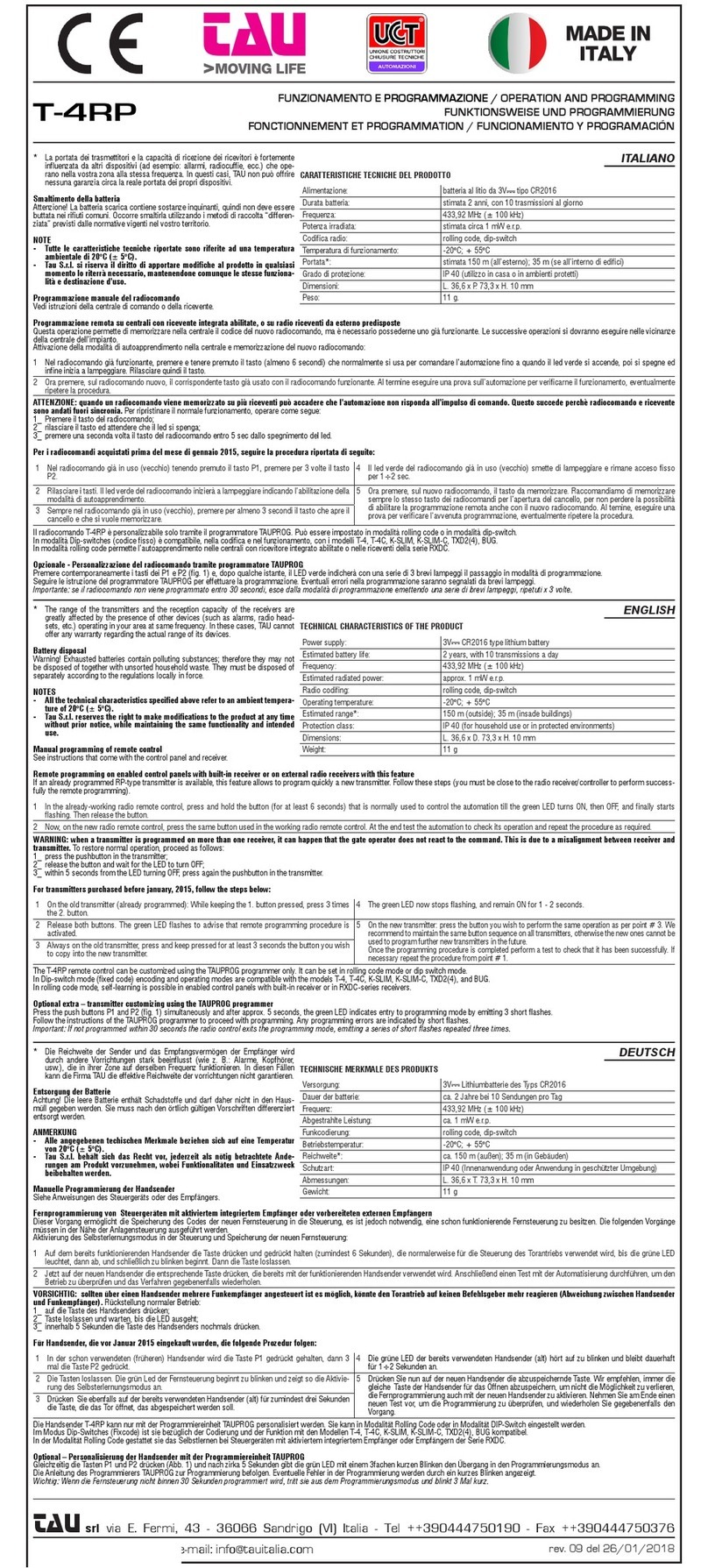

1.1 MOUNTING:

The Nitrogen Dioxide Transmitter must be mounted indoors and kept dry at all times. This transmitter

should be mounted in a well-populated area, and placed so the display can be easily seen. The unit

should be mounted at breathing height that is generally between 5 to 7 feet above the floor. Figure #1

shows the mounting hole locations. Mount the transmitter to a rigid surface using #10 hardware.

1.2 WIRING:

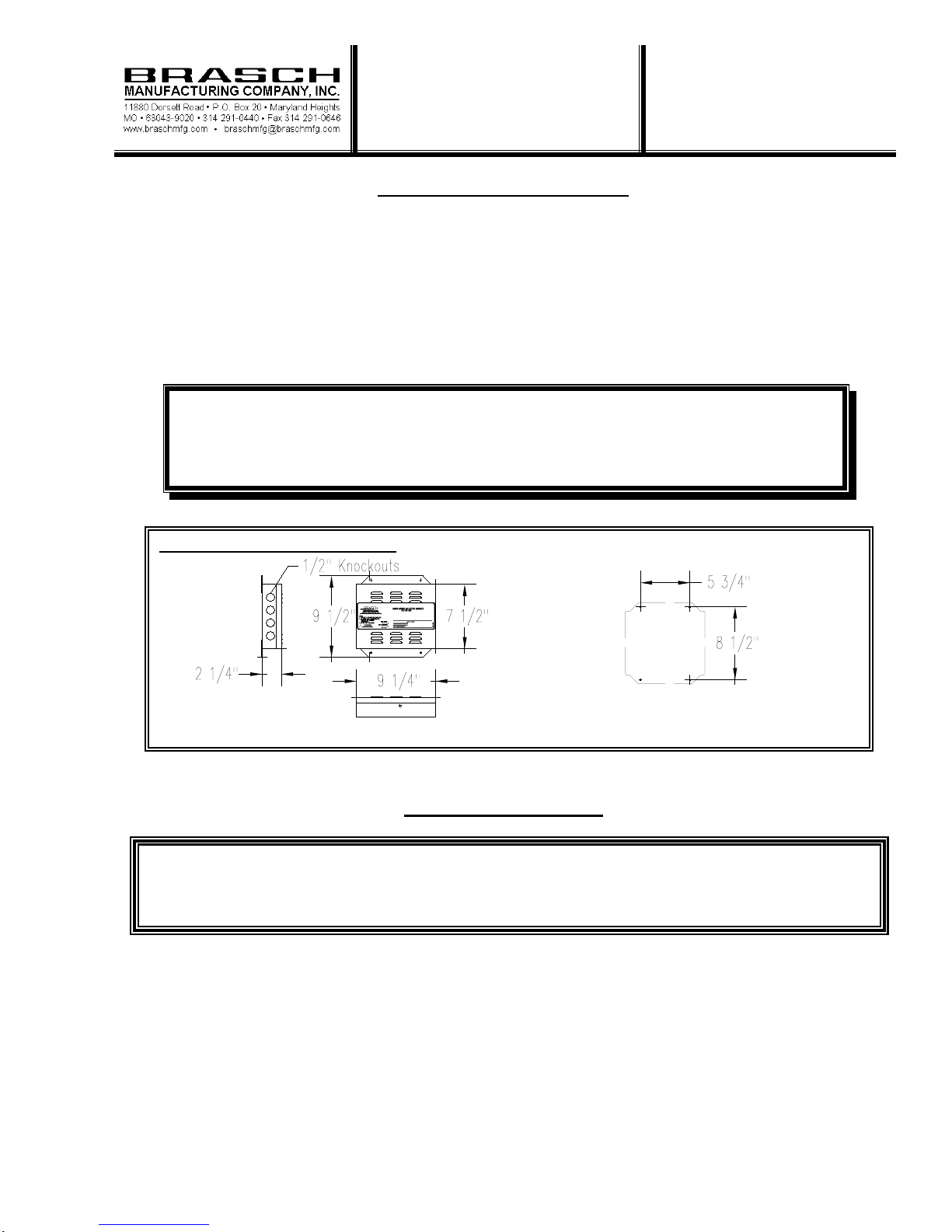

1.21 Input Power Wiring

This transmitter requires an input voltage of 24 VAC, 50/60 Hz at a load rating of 28 VA. If a grounded

24 VAC supply voltage is supplied, then the hot line should be wired to terminal T1 and the grounded

line should be wired to T2. Brasch Manufacturing Co., Inc. can provide a step-down transformer for

changing 208-240 VAC or 120 VAC at 50/60 Hz to 24 VAC at 50/60 Hz. See the 6.0 Accessories

Section (Page 4) for the transformer part numbers. The supply circuit must include a disconnect device

or switch located close to the transmitter and marked as the disconnect device for the transmitter. This

will assure continued operation without interruption from remote failures. To provide noise suppression

the input power must be wired, as shown in Figure #2 (Page 2), with the ground connected. Use copper

conductors only, rated for a minimum of 250 volts, 14 AWG.

Installation, Operating

And

Maintenance Instructions

Nitrogen Dioxide

Gas Transmitter

BGS-ND-TRNS

CAUTION:

Leave a minimum of 2” clearance to other surfaces, and under no circumstances

should the ventilation louvers in the cover be blocked. Be sure that metal shavings

and other contaminants are removed from inside the transmitter.

Use only qualified personnel for the installation of this transmitter. All wiring should be

done in accordance with local codes and the latest edition of the National Electrical Code

(ANSI/NFPA 70).

Figure #1 Mounting Hole Locations

BULLETIN I-680

3-2-99 2

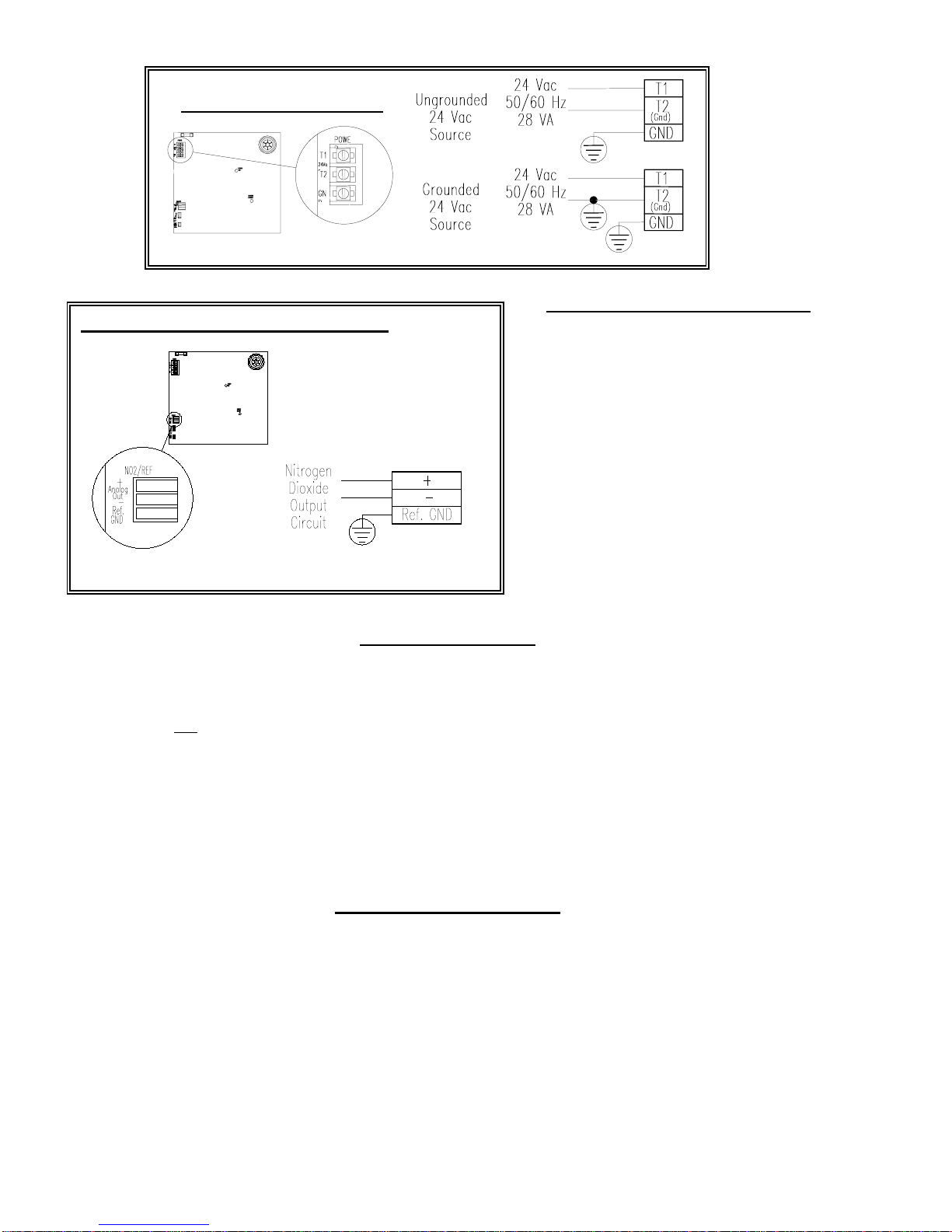

1.22 Proportional Output Wiring

See the 4.0 Specification Section (Page 3)

for minimum/maximum loads for the

proportional outputs. The wiring of the

proportional output signals is done by

lifting the white lever, inserting the signal

wire and pressing the white lever flat. Use

copper conductors only, rated for a

minimum of 250 volts, with a minimum

wire size of 26 AWG (22 AWG

maximum). Figure #3, Proportional

Output Wiring shows the wiring to a

remote Brasch Gas Detector Control

Panel, DDCS or BMS.

2.0 Unit Operation

When power is applied to the Nitrogen Dioxide Gas Transmitter the internal green power LED will

illuminate. This LED will stay ON as long as power is supplied to the transmitter. If the power ON

LED should go out, see the 5.0 Troubleshooting Section (Page 4) for help.

This Nitrogen Dioxide Gas Transmitter has one mode of operation, Normal. Upon the application of

power the unit will enter the Normal mode.

In the Normal mode the transmitter monitors the concentration of nitrogen dioxide (NO2) and generates

the proportional output signal.

3.0 Operational Settings

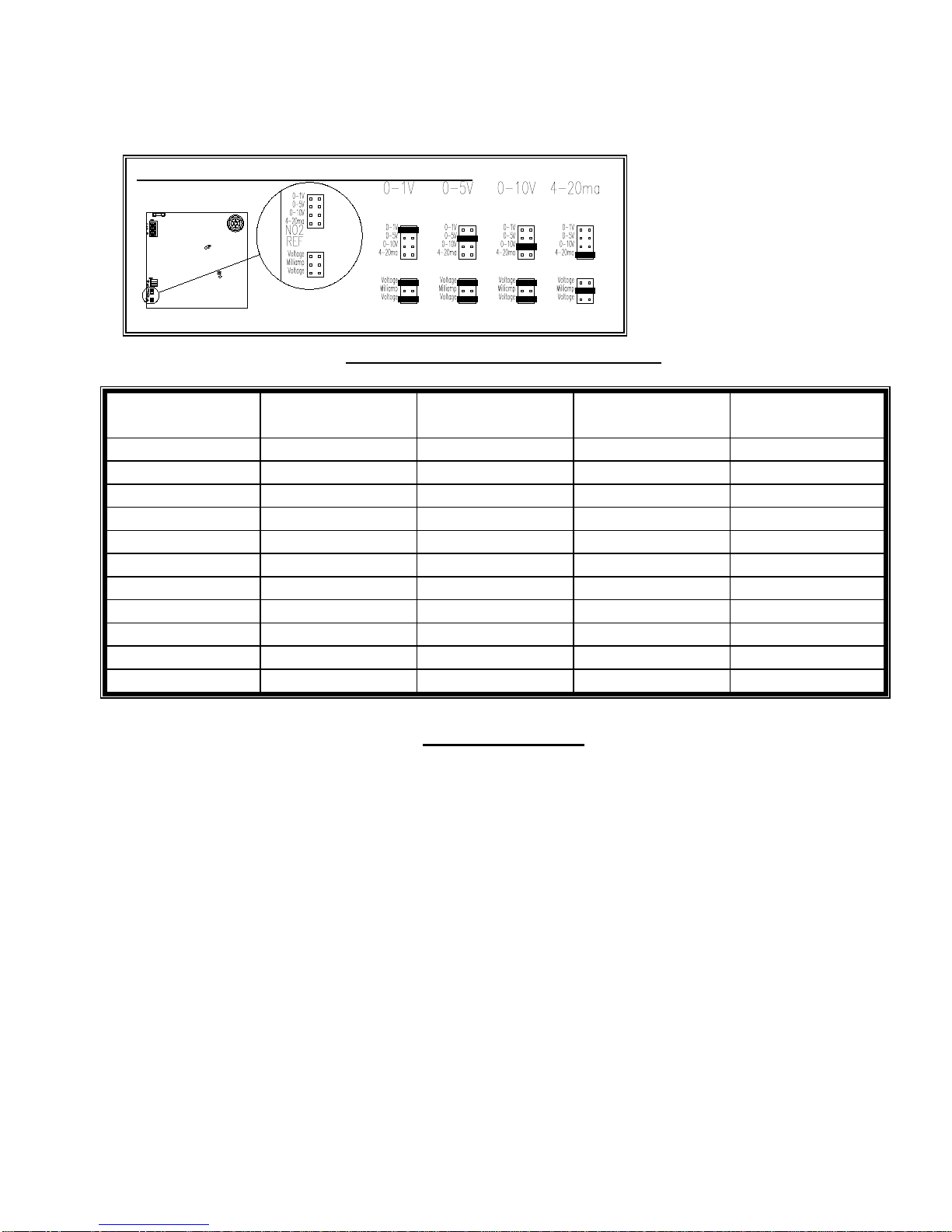

3.1 PROPORTIONAL OUTPUT OPTIONS

The gas transmitter has four different proportional output options that are selectable on the transmitter

board. The four options are 4 – 20 maDC current loop, 0 – 1 VDC voltage output, 0 – 5 VDC voltage

output and 0 – 10 VDC voltage output. The 4 – 20 maDC current loop is used with the Brasch Gas

Detector Control Panel. Any of the four options can be connected to a Direct Digital Control System

(DDCS) or Building Management System (BMS). See 4.0 the Specification Section (Page 3) for the

input impedance for each of the proportional outputs.

Figure #3 Proportional Output Wiring

Figure #2 Input Power Wiring

BULLETIN I-680

3-2-99

3

The output option is selected using a jumper and pin combination. See Figure #4 for location on the

transmitter board. To change the setting, turn off the power to the unit and remove the cover. Place

jumpers in the proper locations for the desired proportional output. Replace the cover and restore power

to the transmitter.

The proportional output is

controlled by the concentration of

nitrogen dioxide (See Table #1).

If at any time a value of 0 maDC

or 0 VDC is measured at the

output, the gas transmitter has

had a power or sensor failure (See

5.0 Troubleshooting, Page 4).

TABLE #1 Proportional Output Values

Nitrogen Dioxide

PPM 4 – 20 maDC

Output Level 0 – 1 VDC

Output Level 0 – 5 VDC

Output Level 0 – 10 VDC

Output Level

0.0 4.0 0.20 1.0 2.0

0.2 5.6 0.28 1.4 2.8

0.4 7.2 0.36 1.8 3.6

0.6 8.8 0.44 2.2 4.4

0.8 10.4 0.52 2.6 5.2

1.0 12.0 0.60 3.0 6.0

1.2 13.6 0.68 3.4 6.8

1.4 15.2 0.76 3.8 7.6

1.6 16.8 0.84 4.2 8.4

1.8 18.4 0.92 4.6 9.2

2.0 20.0 1.00 5.0 10.0

4.0 Specifications

Proportional Outputs: 4 – 20 maDC 250ΩMaximum

0 – 1 VDC 1000ΩMinimum

0 – 5 VDC 1000ΩMinimum

0 – 10 VDC 1000ΩMinimum

Proportional outputs are field selectable.

Calibration: The main transmitter module should be re-calibrated every two years.

Contact the factory for re-calibration information and pricing.

Ratings: Input Power: 24 VAC, 50/60 Hz, 28 VA

Humidity: 10% to 90% (Non-Condensing)

Temperature: Storage: -50oC to 120oC (-58oF to 248oF)

Operating: -15oC to 40oC (5oF to 104oF)

Installation Category: II (local level, over-voltage transients less than 500 volts)

Indicators(LED Type): Green LED: Power ON

Figure #4 Selection of Proportional Output Option

BULLETIN I-680

3-2-99 4

Dimensions: 7 5/8”H x 9 1/8”W x 2 1/4”D

Weight: 4 pounds

Fuse Rating: Main Supply: 5x20MM, Time-Lag, 1.25 Amps

5.0 Troubleshooting

1. Power LED not on: A. Check for 20.4-26.4 VAC at terminals T1 & T2 (see Figure #2,

Page 2).

B. Check circuit board fuse for continuity. If the fuse needs to be

replaced use only the rated fuse listed in the 4.0 Specifications

Section.

C. Consult the factory.

2. Sensor failure light is on: A. Remove sensor and reinstall.

B. Replace transmitter board (includes sensor and calibration).

C. Consult the factory.

3. For any other situation please consult the factory.

6.0 Accessories

Transformers: *

120 VAC to 24 VAC @ 36VA 36T120N1

120 VAC to 24 VAC @ 75VA 75T120N1

208-240 VAC to 24 VAC @ 36VA 36T240N1

208-240 VAC to 24 VAC @ 75VA 75T240N1

Other voltage levels are available upon request.

* Transformers supplied in a NEMA 1 enclosure intended for indoor use.

Sensor Re-calibration: Factory re-calibration of transmitter board including new sensor.

Contact the factory for complete information and pricing.

Brasch Manufacturing Company, Inc.

2310 Millpark Drive

Maryland Heights, MO 63043

(314)291-0440

fax: (314)291-0646

CAUTION:

Only qualified personnel should attempt to service this equipment. All power

sources must be disconnected before removing the cover of this transmitter.

BULLETIN I-680

3-2-99

5

Brasch Manufacturing Co., Inc warrants gas transmitters, gas transmitter control panels and accessories

for a period of one year from the date of shipment against defects in material or workmanship. Should

any evidence of defects in material or workmanship occur during the warranty period, Brasch

Manufacturing Co., Inc will repair or replace at its own discretion, without charge. The company shall

not be held responsible for any charges in connection with removal or replacement of allegedly defective

equipment, nor for incidental or consequential damages.

Limited Warranty

Brasch Manufacturing Co., Inc warrants gas transmitters, gas detectors,

gas detector control panels and accessories for a period of one year

from the date of shipment against defects in material or workmanship.

Should any evidence of defects in material or workmanship occur

during the warranty period, Brasch Manufacturing Co., Inc will repair

or replace at its own discretion, without charge. The company shall not

be held responsible for any charges in connection with removal or

replacement of allegedly defective equipment, nor for incidental or

consequential damages.

Table of contents

Other Brasch Transmitter manuals

Popular Transmitter manuals by other brands

Cypress

Cypress VEX-E2502T Operation manual

Soundstream

Soundstream BLT Owner's manual and installation guide

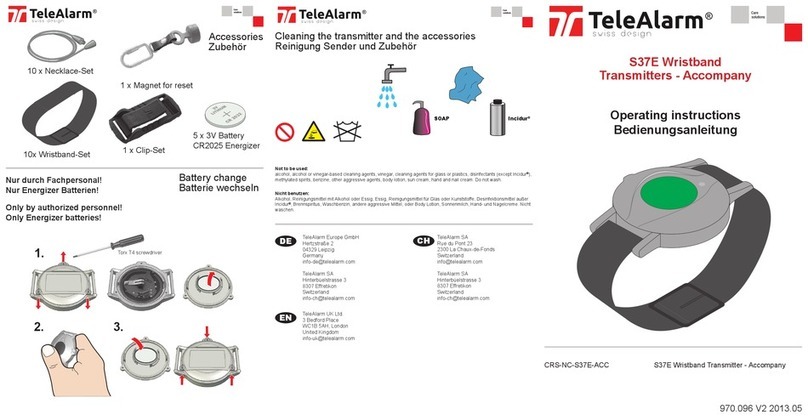

TeleAlarm

TeleAlarm S37E operating instructions

SVS

SVS SHT-12 C8D operating instructions

Philips

Philips Lightolier Controls CLMIR Programming and operation instructions

Tekon

Tekon DUOS inCO2 installation guide