Brasilisa CIAO + User manual

Ed. 07-2008

CIAO +

Instruction manual

EN Instruction Manual

Technical User

Rev 0 - 06-2008

CIAO +

GENERAL INFORMATION

Manufacturer.................................................

Model ............................................................

Stamp of local agent ....................................

BRASILIA S.p.A.

Strada Provinciale Bressana - Salice

27050 Retorbido (PV) Italy

Tel. +39.0383.372011

Fax +39.0383.374450

e.mail: [email protected]

www.brasilia.it

CIAO +

Rev. No.

Date Remarks

0 07/2008 Document issued

Rev 0 - 07-2008

ENGLISH / 1

Amable Señora, Estimado Señor:

Felicitaciones por haber escogido una máquina para café BRASILIA.

Su nueva máquina, provista de los componentes más innovadores garantizados por el Know-how y la

experiencia del Grupo Rossi, ha sido construida y ensayada con los métodos más avanzados de investiga-

ción y de la técnica moderna para garantizar su calidad y abilidad, en el respeto más profundo del medio

ambiente, para permitirle operar con la máxima eciencia y funcionalidad.

En las siguientes páginas encontrará las indicaciones para la instalación, el uso correcto y el mantenimiento

de la máquina, así como los consejos y advertencias para un uso práctico y seguro de la misma.

BRASILIA S.p.A.

Gentil Senhora, Prezado Senhor,

Nos cumprimentamos consigo por ter escolhido uma máquina de café BRASILIA.

A sua nova máquina, dotada dos componentes mais inovadores, garantidos pelo Know-how e pela ex-

periência do Grupo Rossi, é fabricada e testada com os métodos mais avançados da pesquisa e da técnica

moderna para garantir a qualidade e a conabilidade, no mais profundo respeito pelo ambiente, e para

operar com a máxima eciência e funcionalidade.

Nas páginas sucessivas são referidas as indicações destinadas à instalação, ao uso correcto e à manutenção,

bem como os conselhos e as advertências para um uso prático e seguro da máquina.

Cordialmente

Lieber Kunde, liebe Kundin,

wir gratulieren Ihnen zur Wahl einer Kaeemaschine BRASILIA.

Ihre neue Maschine, die mit den neuesten innovativen Komponenten ausgestattet ist, die durch das Know-

how und die Erfahrung der Gruppe Rossi gewährleistet sind, wurde mit den modernsten Methoden der

Forschung und der modernen Technik konstruiert und getestet, um Ihnen Qualität, Zuverlässigkeit unter

voller Berücksichtigung der Umwelt zu garantieren und um es Ihnen zu ermöglichen, diese mit größter

Ezienz und Funktionalität zu bedienen.

Nachfolgende Seiten enthalten Hinweise zur Installation, zur korrekten Bedienung und Wartung, sowie

Ratschläge für einen praktischen und sicheren Gebrauch der Maschine.

BRASILIA S.p.A.

Gentile Signora, Egregio Signore,

ci complimentiamo con Lei per aver scelto una macchina per caè BRASILIA.

La sua nuova macchina, dotata dei componenti più innovativi, garantiti dal Know-how e dalla esperienza

del Gruppo Rossi, è costruita e collaudata con i metodi più avanzati della ricerca e della tecnica moderna,

per garantirLe qualità, adabilità, nel rispetto più profondo dell’ambiente e permettendoLe di operare con

la massima ecienza e funzionalità.

Nelle pagine seguenti sono contenute le indicazioni rivolte all’installazione, all’uso corretto ed alla ma-

nutenzione nonché i consigli e le avvertenze per un uso pratico e sicuro della macchina.

BRASILIA S.p.A.

Dear Madame, Dear sir,

congratulations on purchasing a BRASILIA coee machine.

Your new coee machine is made with innovative components guaranteed by Rossi Group’s experience

and know-how. It was built and tested according to advanced research methods and modern technology,

in order to guarantee quality and reliability whilst respecting the environment, and in order to operate with

maximum eciency and functionality.

In the following pages you will nd the instructions regarding installation, the correct use of the machine

and its maintenance along with advice and warnings for practical safe use of this machine.

BRASILIA S.p.A.

Chère Madame, Cher Monsieur,

nous nous félicitons avec Vous pour avoir choisi une machine à café BRASILIA.

Votre nouvelle machine, dotée des composants les plus innovateurs, garantis par le Know-how et par

l’expérience du Groupe Rossi, est construite et rodée avec les méthodes les plus avancées de la recherche

et de la technique moderne, pour Vous garantir la qualité et la abilité, dans le respect le plus profond de

l’environnement et en Vous permettant d’opérer avec l’ecacité et la fonctionnalité maximale.

Les pages suivantes contiennent les indications concernant l’installation, l’utilisation correcte et l’entretien,

ainsi que les conseils et les avertissements

pour une utilisation pratique et sure de la machine.

ITA

Cordialm ente

ENG

FRA

DEU

BRASILI A S.p.A.

ESP

POR

Rev 0 - 07-2008 ENGLISH / 2

DECLARATION OF CONFORMITY

The company: BRASILIA SPA

declares under its own responsibility than the coffee machine (power supply 230 Volts -50

Hz) described in this folder complies with the following current standards: : UNI EN12100-

1, UNI EN 12100-2, UNI CIG 9886

CEI EN 60335-1, CEI EN 60335-2-15 and with the CE standards: 2001/95/CE, 98/37/CE,

97/23/CE, 2002/95/CE, 2006/95/CE, 2004/40/CE, 2002/96/CE 89/336/CE, 92/31/CE, 93/68/

CE as well as the Presidential Decree 547/55.

The machines ready for gas and/or gas fed also conform to the requirements laid down in the

directive 90/396/CE and to the standard UNI CIG 9886

Administrator

Rev 0 - 07-2008

ENGLISH / 3

DECLARATION OF CONFORMITY..................................................................2

INTRODUCTION............................... ................................................................5

1 - GENERAL WARNINGS .................................................................................... 6

1.1 - Description of the symbols........................................................................ 7

1.2 - Intended use ............................................................................................. 7

1.3 - Incorrect use ............................................................................................. 7

2 - UNPACKING AND POSITIONING ................................................................... 8

2.1 - Unpacking the machine............................................................................. 8

2.2 - Positioning the machine............................................................................ 8

3 - TECHNICAL FEATURES.................................................................................. 9

3.1 - Description of the machine...................................................................... 10

3.2 - Identication plate........................................................................... ........ 11

4 - CONNECTIONS ............................................................................................ 12

4.1 - General information regarding connections ............................................ 12

4.2 - Hydraulic connection............................................................................... 13

4.3 - Electrical connection ............................................................................... 13

5 - DESCRIPTION OF THE COMMANDS .......................................................... 14

Description of the push-button panel .............................................................. 14

6 - SUMMARY CHART OF PRELIMINARY OPERATIONS ............................... 15

7 - FIRST START-UP .......................................................................................... 16

7.1 Operating specications............................................................................ 16

7.2 Start-up...................................................................................................... 16

8 - REGULATIONS ............................................................................................. 17

8.1 - Pressure switch regulation ...................................................................... 17

8.2 - Bypass pump regulation.......................................................................... 17

8.3 - Grinder regulation ................................................................................... 17

8.4 - Version with Hyperwand.......................................................................... 17

CONTENTS

ENGLISH

Rev 0 - 07-2008 ENGLISH / 4

9- PROGRAMMING ........................................................................................... 18

9.1 - Description of the programming buttons ................................................. 18

9.2 - Access to programming .......................................................................... 18

9.3 - Diagram of the available menus.............................................................. 19

9.4 - Functions programming .......................................................................... 20

9.5 - Sequences programming........................................................................ 20

9.6 - Small-dose grinding programming .......................................................... 21

9.7 - Dose programming.................................................................................. 21

9.8 - Large-dose grinding programming.......................................................... 22

9.9 - Extra dose programming......................................................................... 22

9.10 - Medium grinding (X2)............................................................................ 23

9.11 - Medium dose programming................................................................... 23

9.12 - Medium counting programming............................................................. 24

9.13 - Milk delay programming ........................................................................ 24

9.14 - Pre-infusion programming..................................................................... 24

9.15 - Set default............................................................................................. 24

10 - PARAMETRES PROGRAMMING ............................................................ 25-26

11 - COMPONENT TESTING ............................................................................... 27

12 - COOLING CYCLE ......................................................................................... 28

13 - METRE READINGS ....................................................................................... 28

14- DRINK SUPPLIES ......................................................................................... 29

15 - TROUBLESHOOTING ..............................................................................30-31

16 - MAINTENANCE.............................................................................................. 32

17 - DISMANTLING .............................................................................................. 33

18 - HYDRAULIC DIAGRAMS .............................................................................. 34

NOTES ............................................................................................................ 35

CONTENTS

Rev 0 - 07-2008

ENGLISH / 5

2.2 - INTRODUCTION

“CIAO” automatic coffee machine, has been designed to combine extreme simplicity, rapidity of use and quality

of its products. “CIAO” makes a range of high quality coffee and/or milk based drinks (such as cappuccino,

American coffee, espresso, milk coffee, etc..) by simply pressing a button.

Main features:

• Doses and temperatures are electronically regulatable.

• 1 or 2 coffee bean hoppers: 1.3 kg. capacity each.

• 1 or 2 built-in high precision grinder-dispensers.

For models with 2 grinder-dosers, the differentiated use of the grinder-dosers according to the drink must be

programmed.

• The coffee is produced by an automatic group where the infusion and the output take place.

• The metal coffee and steam boiler alows to regulate the temperature rapidly preventing thermal imbalances

to the system (the heat source is provided by a resistance immersed in the boiler water that heats the boiler).

• Hot water to brew hot drinks, tea or chamomile tea.

• Steam nozzle.

• Refrigerator module to keep the milk fresh.

• A pump allows a perfect milk dose.

• B03-C milk frother.

• Immediate user interface.

• Cup-holder grille.

• Microprocessor control.

• Cup-rest for various drink containers.

• Hyperwand.

NOTE: The features may vary according to the model.

• Start up the machine as indicated in the “Use” section, lift the cup-heater (1) and remove it to access the

internal parts of the machine.

Rev 0 - 07-2008 ENGLISH / 6

1. GENERAL INSTRUCTIONS

BRASILIA S.p.A. has taken every possible measure to ensure that the equipment operates safely and efciently.

BRASILIA equipment comes with built-in safety devices to protect both users and authorised technicians.

• Read this manual carefully before installing the machine, starting it up and using it. Not doing so could cause

damage to the equipment, poor performance by the machine and health risks or personal injury.

• This manual should be treated as a part of the machine itself and should always be available to the user

and/or maintenance technician. If it gets lost, or you need further information, please get in touch with your

local retailer or with the manufacturer. The manual reects the state of the art at this time and any updates

will not imply that it was inadequate. The manufacturer reserves the right to change the manual with no

obligation to update earlier editions, except in unusual circumstances. The Figures in this manual are purely

explanatory and might not look the same as all the models referred to in the instructions.

You must not:

•operate the machine without complying with the safety regulations in force in the country where it is

installed;

• operate the machine without an earth connection. Not complying with this instruction could lead to electric

shocks;

• replace or remove the safety stickers and the specications plate afxed directly to the machine and its

packaging with a view to proper and safe installation and use;

• touch groups or nozzles while the machine is working. When handling the wands only touch them by the

grips. The beverages dispensed and some parts of the machine are hot and could cause burns or scalds;

• remove or tamper with any part of the machine; do NOT make arbitrary changes. Get in touch with the

authorised technician and specialist for your area;

• pull the line cord to unplug the electricity supply;

• allow children or unskilled staff to use the machine;

• expose the machine to the elements (sun, rain etc.);

• leave the machine in places where the ambient temperature is 0°C or lower because the water in the boiler

might freeze and cause damage;

• install the machine in places where jets of water that could reach the machine are used;

• operate the machine if any door or panel is not properly closed;

• stick spoons, forks or other utensils into the internal parts of the machine;

• operate the machine without water;

• to pour hot or boiling water into the machine;

•obstruct the air vents: you must leave a space of at least 10 cm between the machine and any walls and at

least 5 cm free on both sides, to allow proper ventilation.

For the machine to work properly you should use:

• only ground coffee, or, for models that have a special lter holder, cartridges.

• only cold tap water suitably softened (~7 French degrees).

• only original Brasilia S.p.A. spare parts

If these instructions are not followed, the guarantee does not apply and the manufacturer or the

maintenance technician declines all responsibility.

BRASILIA S.p.A. and the maintenance technician decline all responsibility in the following cases:

• if the machine is used in a manner other than as described in this manual;

• if the safety and maintenance instructions are not followed;

• if original BRASILIA spare parts are not used;

• if the INSTALLER, or the MAINTENANCE TECHNICIAN, is not authorised and specialised;

Rev 0 - 07-2008

ENGLISH / 7

• The INSTALLER or MAINTENANCE TECHNICIAN should inform the manufacturer about ANY

MALFUNCTIONS or improper uses that could adversely affect the original safety of the system.

• CHECK ON the condition of the parts and, if they are faulty, stop the installation and ask for them to be

replaced.

• If the machine is going to be left unused for a long time the electric power and water supply should

be disconnected.

1.1 - EXPLANATION OF SYMBOLS

Information given in this manual about hazard operations is marked with the following symbols, indicating:

Danger due to electricity

General danger or miscellaneous information

Heat danger (burns or scalds)

Danger because of damage to the machine.

1.2 - USE FORESEEN

The machine for making coffee with powder is designed and made solely for dispensing espresso coffee and

for preparing hot drinks (tea, cappuccino etc.) by using hot water or by emitting steam.

These are the only purposes for which the machine should be used and use for any other purpose is

considered improper and therefore dangerous.

1.3 - IMPROPER USE

The coffee machine is made and designed for food use only and the following are therefore forbidden:

- use of the machine by unqualied workers;

- adding liquids other than water;

- heating up drinks or other non-food substances;

- putting powders other than coffee into the lter holders;

- placing anything except cups on the cup warmer;

- placing containers with liquids on the cup warmer;

- obstructing the air grilles with cloths or other materials;

- covering the cup warmer with cloths;

- touching the dispensing areas with your hands;

- using the machine if it is very wet.

N.B.

In this paragraph we have listed some foreseeable situations of improper use; however the use of the

machine must comply with the instructions set out in the “Use foreseen” paragraph.

Rev 0 - 07-2008 ENGLISH / 8

2. UNPACKING AND POSITIONING

IMPORTANT: The machine unpacking and positioning

operations must be performed by an authorised and

specialised technician.

HOW TO REMOVE THE MACHINE FROM THE PACKAGING

1 - Always check that the packaging is intact, and inform the

transporter of any damage.

2 - Open the top of the package and lower the aps (A). Extract

the accessories: the drainage basin, the cup-holder grille,

the hopper and the technical manuals.

3 - Open the cellophane (B) and LIFT OUT THE MACHINE

HOLDING IT AT THE BASE.

4 - Caution! the packaging materials (cardboard, cellophane,

metal clips etc.) may cut or injure if not handled with care,

of if used incorrectly; keep away from children or from

unsuitable persons.

5 - Place the machine in its nal position making sure that:

a) the support cabinet is sufently resistant and stable, bearing

in mind the weight of the machine and that it is not tilted.

b) there is a gap of at least 10 cm.between the machine and

any walls, to ensure a correct ventilation.

6 - Extract the detergent tablets, the lubricant tubes, the ON-

OFF key and the front panel key.

7 - Place the hoppers on the upper cover (C),assemble the

drainage tray, making it slide on the special support, and

place the cup-holder grille (D).

2.2 - POSITIONING OF THE MACHINE

Place the machine in its nal position making sure that:

1) the support cabinet is sufciently resistant and stable,

bearing in mind the weight of the machine and that it is not

tilted;

2) the machine feet are regulated correctly to prevent any

tilting.

3) there are at least 10 cm. between the machine and any

walls around, to ensure a correct ventilation;

4) the upper surface of the machine (cup-heater) must not be

more than 150 cm above the oor to allow easy access to

all operators;

5) near the machine there is an electrical connection board,

a water drain and a tap for water connection.

1

A

2

B

3

Rev 0 - 07-2008

ENGLISH / 9

3. TECHNICAL FEATURES

- Dimensions

** Technical Features Value Notes

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

Overall dim. (WxDxH mm)

Coffee boiler

Standard steam boiler

Steam boiler capacity

Hot water boiler

Supply group

Max. milk capacity

Supply height

Built-in refrigerator

Coffee grinder

Coffee bean hopper

Cleaning tablets

Coffee powder chute

User interface

Coffee ground drawer

Mains connection

Refrigerator temperature

indicator

Cup-holder

414x600x740

1.2KW (5.2A @ 230V)

1.3KW (5.7A @ 230V)

2.2KW (9.6A @ 230V)

1.5KW (6.5A @ 230V)

8 - 12 g

500 ml/min

80 – 170 mm

3 lt

200W

1.2+1.2 Kg

Yes

Yes

LCD16x2+14 buttons

40 dregs MAX

3/8”

Yes, on the main display

Yes, 18x2 cups

Fully automatic

Gear pump

Easy-to-set system

48 mm conics

Single hopper to be dened

*

* graphics display where available

Rev 0 - 07-2008 ENGLISH / 10

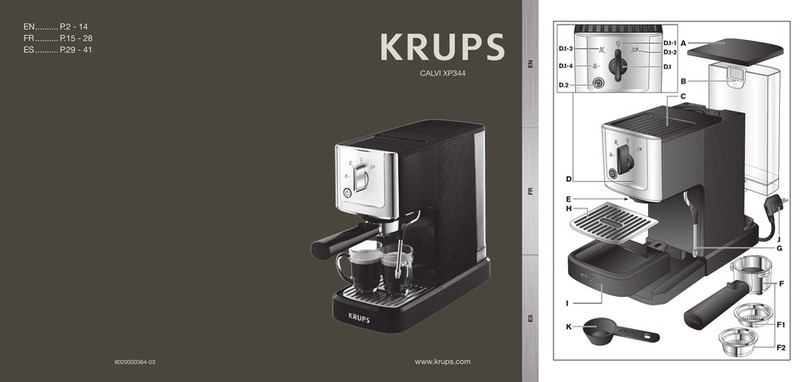

DETAIL N° FUNCTION

1 COFFEE HOPPER

2 UPPER COVER

3 WATER FILLING TUBE

4 WATER DRAINAGE TUBE

5 ELECTRIC CABLE

6 STEAM NOZZLE

7 TABLET SLOT

8 CONTROL HOLDER PANEL

9 PUSH BUTTON PANEL

10 CARTER (SUPPLY COVER)

11 CUP-HOLDER GRILLE

12 BAISIN

13 RIGHT UPPER COVER

14 REFRIGERATOR

15 LED

16 KEY

VERSION WITH HYPERWAND

17“ “CLEANING” BUTTON

18 HOT/FROTHED MILK BUTTON

19 “START STEAM” BUTTON

20 “HYPER WAND”

- TO CONTAIN COFFEE BEANS

- TO ALLOW WATER INTO THE MACHINE

- TO DRAIN THE WATER FROM THE DRAINAGE TRAY

- FOR ELECTRICAL CONNECTION

- TO SUPPLY STEAM

- TO SUPPLY HOT WATER

- TO INSERT DETERGENT TABLETS

- TO ACCESS AND USE THE INTERNAL COMPONENTS OF THE

MACHINE

- TO SELECT DRINKS AND FOR MACHINE PROGRAMMING

- SUPPLY COVER

- TO PUT THE CUPS DURING SUPPLY

- TO CONTAIN LEAKING LIQUIDS

- CUP-HOLDER

- TO CONTAIN MILK AND TO KEEP IT COOL

- SUPPLY LED INDICATION

- TO ACCESS PROGRAMMING BUTTON AND TO PERFORM MACHINE

MAINTENANCE.

- TO CLEAN THE HYPER WAND

- TO OBTAIN HOT/FROTHED MILK

- TO START UP THERMOSTATIC STEAM SUPPLY

- TO SUPPLY STEAM

3.1 DESCRIPTION OF THE MACHINE

2

3

4

5

6

1

7

8

9

10

11

12

13

14

15

16

Rev 0 - 07-2008

ENGLISH / 11

3.2 - IDENTIFICATION PLATE

The data shown on the identication plate is as follows:

A= Model

B= Serial number

C = Year of manufacture

D= Power supply voltage

E= Frequency

F= Power

1

Rev 0 - 07-2008 ENGLISH / 12

4. CONNECTIONS

4.1 GENERAL INFORMATION REGARDING CONNECTIONS

HYDRAULIC CONNECTION:

• The water from the water mains must be adequately softened (~7 French degrees).

• The input pressure range must be between 0,15 MPa (1,5 Bar) and 1 MPa (10 Bar).

• Water inlet: 3/8F connector Ø12/17 mm tube - Drain: two Ø 22 and 18 mm tubes.

ELECTIC AND ELECTRONIC CONNECTION:

• The machine has two circuits:

- power supply circuit for the operating electrical components (solenoid valves, pump, electronic control

units).

- power supply circuit for the heating element (boiler resistance).

• Master switch (E):

Two-position selector located at the back of the machine.

Position 0: no power supply to the internal components.

Position 1: power to commands and to resistance.

• Programming access button (F):

Enables access to programming and is generally located in the internal part of the control holder.

Notes:

• The machine is supplied with an electrical power cable without plug. If necessary, the plug must be installed

in accordance with the rules in the country of installation.

• If the power cable is damaged, it must be replaced with one which has the same characteristics, exclusively

by the authorized specialised installer/maintenance technician. The non-observance of this instruction may

cause damage to the machine and lead to electric shocks.

DETAIL N° FUNCTION

1 MACHINE DRAINAGE TUBE

2 GENERAL DRAINAGE TUBE

3 MACHINE FILLING TUBE

4 WATER SOFTENER

5 MAINS WATER TUBE

6 MAINS WATER TAP

7 ELECTRIC CABLE ORIGINATING FROM PROTECTED ELECTRICAL PANEL

8 CONNECTION WITH FUSES

9 ELECTRIC CONNECTING CABLE

Rev 0 - 07-2008

ENGLISH / 13

= YELLOW/GREEN N = GRAY

(*) 1 PHASE + NEUTRAL

(*) 2 PHASES + NEUTRAL

= YELLOW/GREEN N = GRAY L1 =BLACK

L2 = BROWN

4.2 HYDRAULIC CONNECTION

1 - Connect the water softener (detail 4) to the mains

water tap through the mains water tube (detail 5).

2 - Connect the machine lling tube (detail 3) to the

output connector of the water softener.

3 - Switch on the mains water tap (detail 6) and check

the resistance of the assembly.

4 - Check the ow of the general drainage tube (detail

2) and connect it to the machine drainage tube

(detail 1).

5 - If the machine is supplied with a refrigerator module,

connect the machine drainage tube to the fridge

drainage tube.

4.3 ELECTRICAL CONNECTION

1 - An earthing connection is compulsory, and the

system must also conform to current regulations in

the country of installation.

2 - Make sure that the power supply voltage (see

machine data plate) corresponds to that of the

locat mains.

3 - Do not use extensions or movable cables.The

working position is inevitably exposed to water and

humidity which compromise the system’s insulation

conditions.

4 - Check the integrity of the electric cable and its

section which has to withstand the maximum power

absorbed by the machine.

5 - Connect the connecting cable (detail 9) to the

electrical panel (detail 8) (*).

Note: The customer must see to the protection of the

electrical line with a safety switch (circuit breaker).

Rev 0 - 07-2008 ENGLISH / 14

5. DESCRIPTION OF THE COMMANDS

DESCRIPTION OF THE PUSH BUTTON PANEL

P1 - CLEANING: button to start the automatic cleaning cycle.

P2 - HOT WATER: button to select a dose of HOT WATER.

P3 - ESPRESSO: button to select 1 ESPRESSO coffee.

P4 - AMERICAN: button to select 1 AMERICAN coffee.

P5 - CAPPUCCINO: button to select 1 CAPPUCCINO.

P6 - FROTHED MILK: button to select 1 FROTHED MILK.

P7 - L: press this button before the chosen drink in order to have an increased dose.

P8 - 2X: press this button before the chosen drink in order to have a DOUBLE drink.

P9 - STEAM: button to select STEAM.

P10 - STOP: button to interrupt the supply.

P11 - COFFEE creme: button to select 1 coffee CREME.

P12 - DECAF: press this button before the chosen drink in order to have a drink with DECAFFEI-

NATED coffee.

P13 - LATTE: button to select 1 LATTE.

P14 - HOT MILK: button to select 1 HOT MILK.

P1 P2

P3

P4

P5

P6

P7

P8

P9 P10

P11

P12

P13

P14

Rev 0 - 07-2008

ENGLISH / 15

6. SUMMARY CHART OF PRELIMINARY OPERATIONS.

CHECKLIST OF THE OPERATIONS TO BE CARRIED OUT

YES NO

- The machine has been placed correctly in a rm position;

- There is enough space (10 cm) between the machine and the walls to

ensure a correct ventilation;

- The connection to the water mains and drain have been performed

correctly;

- The machine is connected to the electric mains correctly;

- The drainage siphon is connected correctly;

- There are no leaks from the connections and/or tubes;

- The machine and its body parts have been assembled correctly;

- The coffee hopper is secured correctly

CAUTION! Before proceeding with the machine start-up, make sure that all instal-

lation operations have been carried out correctly.

If you have answered no to even one of these questions, do not start up the machine until the

problem has been solved.

Rev 0 - 07-2008 ENGLISH / 16

7. FIRST START-UP

7.1 OPERATING SPECIFICATIONS:

PRESSURE:

• Working pressure → 0,1 ÷ 0,3 MPa (1 ÷ 3 Bar).

• Coffee pressure → 0,9 MPa (9 Bar): regulated through by-pass pump (see "REGULATIONS" section).

• Steam pressure → 0,15 MPa (1,5 Bar): regulated through pressure switch (see “REGULATIONS” section).

BOILER TEMPERATURE:

• Normally between 92° and 98 °C (according to the type of coffee used).

7.2 START-UP

1 - Switch on the mains water tap and ll the hopper exclusively with coffee beans.

Make sure that the closing mechanism of the hopper does not obstruct the spout. If so, push the “A” lever towards the

rear of the machine.

2 - Make sure that the ON-OFF switch (B), in the internal part of the control holder, is in position 0 (zero).

3 - Switch on the machine: press the ON-OFF switch to “ON” position, in order to activate the functions of the machi-

ne.

• The start-up of the machine is carried out, and for about 2 seconds the eeprom used by the machine is displayed

“…………… Ciao vers. 1.xx“

• Subsequently the word “Heating” will appear on the display.

4 - Access programming by pressing the “C” button, located in the internal part of the control holder. When “Password”

appears on the display, press the “C” button once again.

• The display shows the word “Select”

5 - Run a cleaning cycle by pressing the “CLEANING” button for at least 10 seconds.

• Once the cleaning cycle is over, switch the machine off.

6 - Switch the machine on again, by turning the switch in position 1, and access programming by pressing the “C” but-

ton.

Follow the instructions in the "PROGRAMMING" section to check and/or set up the machine parametres in

the"PARAMETRES PROGRAMMING" menu.

7 - Exit programming by pressing the "C" once again.

8 - Press the "ESPRESSO" button until water comes out of the spout.

This operation allows the complete relling of the coffee boiler (the steam boiler is controlled by the auto-level).

• Once the supply is over, the display will show the word “Select”.

Rev 0 - 07-2008

ENGLISH / 17

1

8. REGULATIONS

ALL THE REGULATIONS CAN BE PERFORMED ONLY BY AU-

THORIZED PERSONNEL!

8.1 PRESSURE SWITCH REGULATION (Fig. 1)

To be carried out when the machine is hot and under pressure.

To obtain the right pressure in the steam boiler, it is necessary to turn

the pressure switch toothed ring nut.

• turn to the right to increase the pressure and turn to the left to reduce

it.

8.2 BY-PASS PUMP REGULATION (Fig. 2)

To be carried out during the coffee supply phase.

CAUTION! HOT LIQUID!

To obtain the right ow it is necessary that the by-pass pump is regu-

lated correctly.

Remove the coffee ground drawer and insert a screwdriver in the ap-

posite slot (A) until the by-pass screw is reached:

• turn to the right to increase the ow.

• turn to the left to reduce the ow.

CAUTION! THE SUBSEQUENT REGULATIONS MUST

BE CARRIED OUT EXCLUSIVELY WHEN THE MA-

CHINE IS COLD.

8.3 GRINDER REGULATION (Fig. 3)

In order to obtain a good result, it is necessary to turn the grinder ring

nut one notch at a time.

• Turn to the right to reduce the granulometry.

• Turn to the left to increase the granulometry.

After every regulation always carry out 2 or 3 test supplies.

IMPORTANT: THE GRANULOMETRY MUST BE REGULATED

ACCORDING TO THE TYPE OF COFFEE.

• IF THE COFFEE COMES OUT TOO QUICKLY:

a) make the ground ner by turning the ring nut to the left

b) increase the grams of grounds

• IF THE COFFEE COMES OUT TOO SLOWLY:

a) make the ground more coarse by turning the ring nut to the right

b) reduce the grams of grounds

8.4 VERSION WITH “HYPER WAND”

AIR FLOW REGULATION

Act on the air tap knob located inside the machine:

• turn clockwise to reduce the air ow

• turn anti-clockwise to increase the air ow.

Fig. 1

Fig. 2

Fig. 3

Table of contents