Bray Small Weather Shield User manual

1

12/15/22

© 2022 Bray International, Inc.

Bray Commercial Division

13788 West Road, Suite 200A

Houston, Texas 77041

BCDSales@Bray.com

Phone: 1-888-412-2729

www.braycommercialdivision.com

Small Weather Shield

IOM Manual

Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Small Weather Shield Specifications................................................ 2

Tools Needed & Parts Included .................................................... 3

Mounting .....................................................................4, 5

FOR MORE INFORMATION ON THIS PRODUCT AND OTHER BRAY PRODUCTS

PLEASE VISIT OUR WEBSITE – www.braycommercialdivision.com

Table of Contents

Small Weather Shield - Installation, Operation and Maintenance Manual

Safety Instructions - Definition of Terms

Read, Follow and Save these instructions

WARNING

Indicates a potentially hazardous situation which, if not

avoided, could result in death or serious injury.

CAUTION

Indicates a potentially hazardous situation which, if not

avoided, may result in minor or moderate injury.

NOTICE

Used without the safety alert symbol indicates a potential situation

which, if not avoided, may result in an undesirable result or state,

including property damage.

2

Small Weather Shield - Installation, Operation & Maintenance Manual Continued

For ST2 Ball Valves with VA Series Actuators

Description

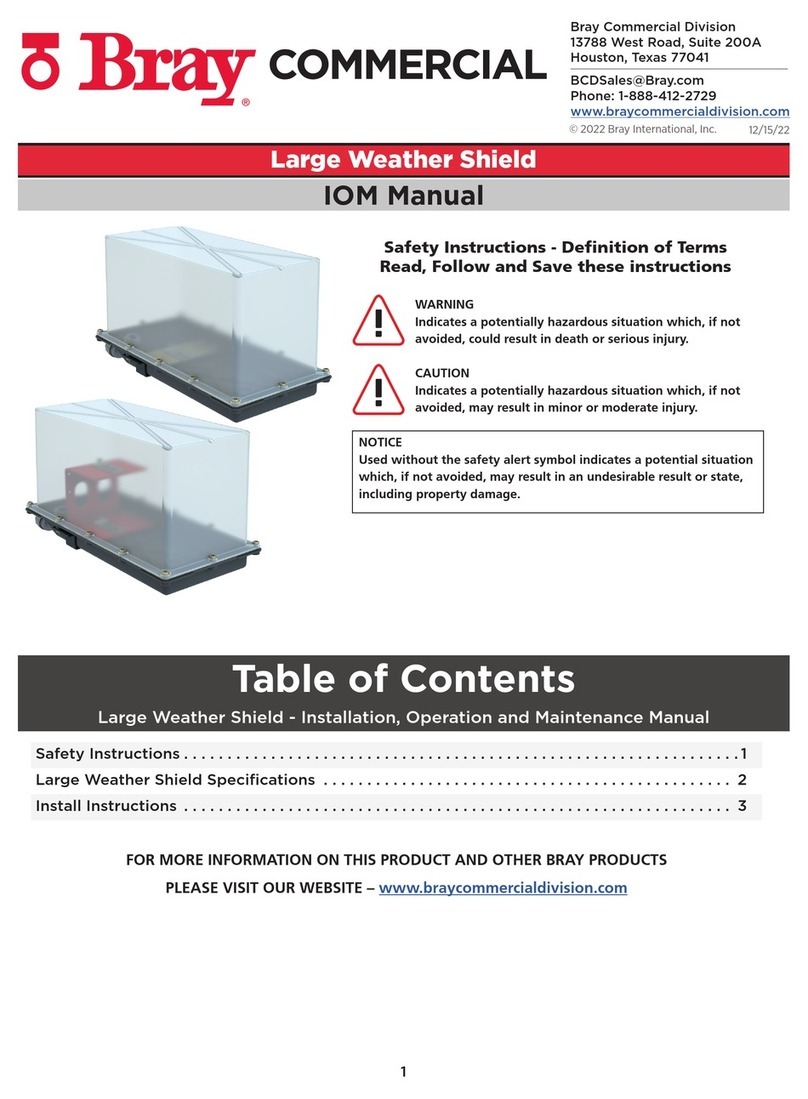

The Bray Small Weather Shield is an industrial grade, convenient,

and cost-eective method of protecting actuators from the harsh

elements and washdowns, not just weather.

Features

• Enclosure - constructed of impact-grade plastic that provides

excellent impact resistance.

• Fully Enclosed Design - Protects the electric actuator from

corrosion, rain, freezing rain, sleet, and snow.

• Strain Relief Conduit Fittings - Protect the electric actuator from

damage by preventing tension on the electrical connection.

Benefits

• UV inhibitors prevent cover from becoming brittle or damaged by the sun

or other environmental elements.

• Translucent Cover provides an unobstructed view of the electric actuator

without having to disassemble the enclosure.

Dimensions

Specifications

Top Cover Transparent UV resistant polycarbonate plastic

Enclosure Seal Nitrile

Body UV resistant polycarbonate plastic

Cover Gasket Polyurethane

Electrical

Connections

Strain relief conduit fittings with 1/2 in. (13 mm)

National Pipe Straight Mechanical (NPSM) exit

Ambient

Temp. Limits -40 to 176°F (-40 to 80°C)

Dimensions See Below

Protection Rating NEMA 4X, IP66

Weight 4.2 lb (1.9 kg)

Warranty 5 Years limited from time of shipment

Model Number Description - Actuators Covered

M9000-342 ST2 Direct Mount

(VA Series) Actuators

B

D

C

E

A

Dimensions - Small Weather Shield - in. (mm)

in. mm A B C D E

- ()

-

()

-

()

-

()

-

()

- ()

- ()

()

- ()

- ()

3

Small Weather Shield - Installation, Operation & Maintenance Manual Continued

Special Tools Needed:

• 8 mm (5/16 in.) open-end wrench

• 6 mm (1/4 in.) flat-blade screwdriver

• No. 1 Phillips screwdriver

• No. 2 Phillips screwdriver

21 mm and 22 mm open end wrench

(or two adjustable wrenches)

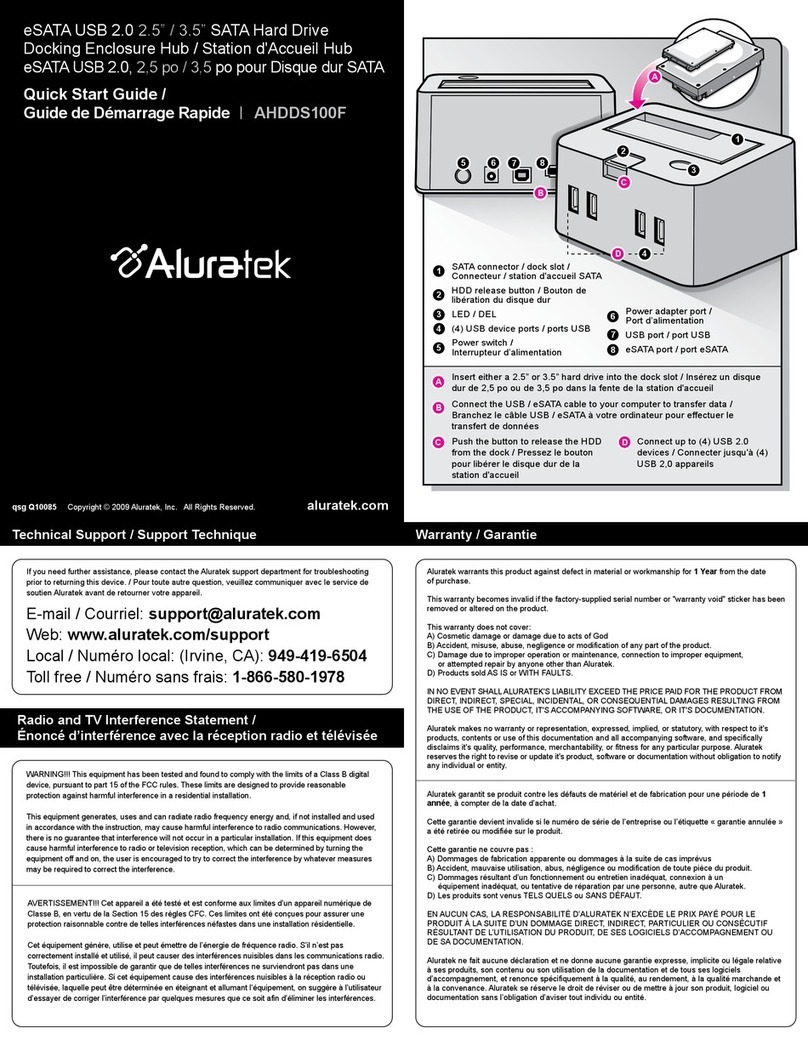

Parts Included:

Table 1: Parts Included in Small Weather Shield Enclosure Kits

Callout Quantity Description

1A 1 Base, enclosure

1B 1 Clear enclosure cover

1C 4 Screw, cover (factory-installed)

5 1 Bearing, seal carrier (factory-installed)

6 1 Seal, lip (factory-installed)

7 1 O-Ring, RoHS (factory-installed)

8 1 Plate, inner (factory-installed)

9 4 Screw, button head Torx, RoHS (factory-installed)

1024Screw, M3 x 0.5 x 8 mm long, Phillips, oval countersink

1124Washer, flat, M4, plain steel, 4.3 mm ID x 9.0 mm OD x 0.8 mm

1221Bracket, Anti-rotation, weather shield

13 1 Bracket, mounting

14 4 Screw, machine, #6-32 x 1/2 in. long, cross-recessed pan head, RoHS

15 4 Nut, #6-32 hex, flanged, serrated tooth, RoHS

16 1 Bracket, valve

17 1 Bearing, plastic, flanged, split, 20 mm ID, RoHS (factory-installed)

18 1 Shaft, valve

19 3 Screw, tapping, hex washer head, type F, RoHS

Figure 2: Parts Included (See Table 1)

20 1 Thermal barrier

23 2 Gland, cable, PG11 to 1/2 in. NPSL

24 1Cap plug, PG11 with O-Ring, RoHS

25 2Nut, hex, single chamfer, PG11

26 1Label (factory-installed)

3021Screw, tapping, hex washer head, type SW, RoHS

3121Shaft, valve, 1 in. diameter

3221Screw, M4 x 0.7 x 60 mm long, Torx.slotted pan head

1. We recommend using a 1/2 in. liquid-tight conduit and 1/2 in. National Pipe Thread (NPT) liquid-tight fittings (purchased

locally) to terminate the control wiring to the weather shield enclosure strain relief conduit fittings.

4

Small Weather Shield - Installation, Operation & Maintenance Manual Continued

Mounting:

Mount the valve in a location with sufficient clearance

to remove the weather shield cover and actuator.

Before installing the electric actuator, use an adjustable

wrench to manually rotate the valve stem several

times. Rotating the valve stem breaks the torque that

may have built up during long-term storage.

To mount the Small Weather Shield Kits:

1. Position the valve ball and stem to the preferred

spring return position. To mount the actuator to

Spring Return Port A (Coil) Open, turn the valve

stem to the position in Figure 4. To mount the

actuator to Spring Return Port A (Coil) Closed, turn

the valve stem to the position in Figure 5.

Note:Position the valve ball stem to the position in

Figure 4.

2. Place the Teflon® thermal barrier on the ball valve

actuator mounting flange by inserting the alignment

rib on the bottom of the thermal barrier into the

recess on mounting flange (Figure 6).

3. Install the valve adapter bracket over the thermal

barrier and attach the valve adapter bracket to the

valve using the four M6 screws and flanged nuts

(Figure 7). Tighten screws to a recommended

torque of 35 to 44 lb·in. (4.0 to 5.0 N·m).

Note:Before you fully tighten the screws, temporarily

install the valve shaft through the adapter bracket and

engage the valve stem. This action ensures proper

alignment with the valve stem and adapter bracket.

Figure 4: Positioning the Valve Stem -

Spring Return Port A (Coil) Open

3 Way2 Way

2 Way 3 Way

Figure 5: Positioning the Valve Stem -

Spring Return Port A (Coil) Closed

Figure 6: Mount the

Thermal Barrier

Figure 7: Install Valve Bracket

5

Small Weather Shield - Installation, Operation & Maintenance Manual Continued

Continued:

4. Secure the weather shield enclosure mounting

bracket (Figure 8) to the valve adapter bracket by

using the raised alignment aids (Figure 9) for

positioning and the three 12-24 x 1/2 in.

self-tapping screws. Tighten the screws to a

recommended torque of 31 to 40 lb·in.

(3.5 to 4.5 N·m).

5. Install the strain relief conduit adapters in the

weather shield base. Use one adapter for actuators

without switches or two adapters for actuators with

switches. If you only use one adapter, seal the

remaining hole with the cap plug and nut. Tighten

the strain relief and cap plug nuts to a torque of 27

to 35 lb·in (3 to 4 N·m).

6. Align marks on top of the valve stem extension

shaft with marks on the valve stem and install the

weather shield base and seal assembly on the

weather shield enclosure mounting bracket.

Secure tightly using the four 6-32 x 1/2 in. screws

and nuts. Tighten the screws to a recommended

torque of 9 to 12 lb·in. (1 to 1.4 N·m).

7. Set up the valve actuator linkage according to the

instructions supplied with the actuator.

8. Install the valve actuator into the weather shield

feeding the electrical cables through the strain

relief conduit adapters and position the actuator on

to the internal bracket.

9.

Tighten the screw in the center of the fixed pointer

to valve stem extension to a torque of 10 to

12 lb·in. (1.1 to 1.4 N·m). Tighten the conduit fitting

to a torque of 25 to 30 lb·in. (2.8 to 3.4 N·m) to

secure the electrical cord in place.

10. Install the weather shield cover and gasket

assembly using the four cover screws supplied

with the kit. Tighten the screws to a recommended

torque of 9 to 12 lb·in (1.0 to 1.4 N·m).

Repair Information

If the Small Weather Weather Shield

Enclosure fails to operate within its specifications,

replace the unit. For a replacement weather shield,

contact the nearest Johnson Controls representative.

Figure 8: Weather Shield on

Mounting Bracket

Figure 9: Raised Alignment Aids

Alignment

Aids

?g:alignment

Figure 10: Actuator within Small Weather

Shield Kit

Table of contents

Other Bray Enclosure manuals