BreakAir PH-90 User manual

P N E U M A T I C P I C K H A M M E R

O P E R A TI O N M A NU A L

PH-90

ver. 10.25.2016

www.diaber.nl

Ver 40-B, C, E. 11.1.2015

www.permon.cz

T A B L E O F C O N T E N T S

1

www.diaber.nl

BreakAir PH-90

TABLE OF CONTENTS

Obsah

TABLE OF CONTENTS .................................................... 1

LABOUR SAFETY - WARNINGS ...................................... 2

SAFETY INSTRUCTIONS................................................. 3

MATERIAL AND CONSTRUCTION................................... 4

APPLICATION .................................................................. 4

TECHNICAL DESCRIPTION............................................. 5

MODEL LABELLING ......................................................... 5

MAINTENANCE PRINCIPLES .......................................... 6

LUBRICATING .................................................................. 6

STORING.......................................................................... 7

DELIVERING .................................................................... 7

PARTS LIST...................................................................... 8

AXONOMETRIE / AXONOMETRIC VIEW......................... 8

L A B O U R S A F E T Y - W A R N I N G S

2

ver. 20.10.2016

www.diaber.nl

LABOUR SAFETY - WARNINGS

Every person to work with or service the hammer must

read or be familiarized with these instructions so as

to understand them completely.

Always wear safety shoes, goggles, ear defenders, gloves

and other safety equipment prescribed for the given task.

WARNING Noise and vibrations hazard

Prolonged exposure to noise and vibrations produced by

hammer operation puts the operator at risk of health issues.

Do not stay in a noisy environment without effective ear

defenders.

WARNING Electricity

The design of the product does not provide protection from

electric shock hazard.

WARNING Dust hazard

Operation may be accompanied by high dust nuisance.

The product has been designed and constructed to

comply with EN 1127-2+A1 and CLC/TR 60079-32-1

standards on use in locations of dangerous atmospheric

conditions 2, category M2, group I (mines).

The construction of the product complies with

requirements of Directive 98/37/EC of the European

Parliament and of the Council, as amended by technical

regulation –Government Regulation No. 24/2003 Coll., as

amended, requirements of harmonized technical

standards EN ISO 12100, standards on group I (mines),

category M2 machinery in accordance with Directive

94/9/EC of the European Parliament and of the Council,

as amended by technical regulation –Government

Regulation No. 23/2003 Coll., as amended, and

harmonized technical standards EN 13 463-1, and

conforms to standards on use in „dangerous atmospheric

conditions 2“ in compliance with EN 1127-2+A1 to the

extent limited by national regulation - CBU Decree No.

22/1989 Coll., § 232, section (1) c) of up to 1,5% methane

concentration.

Source of the supplied compressed air must be stationed

in a nonhazardous area.

Equipment

Do not blindly follow the

rules.

Read through the chapter to

learn why personal

protective equipment is

important.

S A F E T Y I N S T R U C T I O N S

3

www.diaber.nl

BreakAir PH-90

Only operate the hammer

with recommended,

approved tools. Work with

the recommended air

pressure and avoid heavy

impacts.

Do not get distracted –risk

of accident is always

present.

Make sure there is no

plumbing or wiring

(electricity, gas, ...) in place

of operation.

If you come across a

foreign object while

operating, put the hammer

aside and uncover the

object carefully to identify

it.

If you cannot produce

sufficient thrust on the

hammer (e.g. while

operating horizontally or

upward), choose another

type of machine or

technology. Insufficient

thrust increases vibrations

and risk of injury.

Supply hoses

• Fire-technical properties of hoses used for supplying

compressed air must comply with CBU Decree No. 22/1989

Coll., § 185, section (1), as amended.

• Supply hoses used in group I (mines) areas of higher

explosion risk I M2 must meet requirements set by CBU

Decree No. 22/1989 Coll., § 232, section c), as amended,

and comply with requirements of enactments EN 1127-1

and EN 1127-2+A1 6.4.7, EN 13 463-1 7.4.3, CSN 33 2030.

SAFETY INSTRUCTIONS

As the following instructions cannot cover all possibly

occurring cases, sound common sense must be employed

when working with the hammer and in the vicinity of this

machine.

Do not touch the trigger until you are ready to operate.

Always hold the hammer with both hands while

operating.

Stay on a safe and stable platform while operating.

Do not put the hammer close to your face and do not

rest it on your leg.

Do not use your leg to push the hammer down while

operating. The tool can break and cause serious

injury.

Stand with your legs safe out of the way of the tool

while maintaining balance.

Compressed air is dangerous! Do not aim an air hose

at yourself or other people. Do not use pressurized air

to clean the site or your clothing.

Make sure all hose connections are firm and airtight

and secure hoses to prevent loss of air or injury if a

hose gets loose or bursts.

Secure hoses using the prescribed number of

recommended hose clips and sockets prescribed for

the type of hose.

Do not release any joints that are under pressure.

Always switch off the air supply and bleed hoses first.

M A T E R I A L A N D C O N S T R U C T I O N

4

ver. 20.10.2016

www.diaber.nl

MATERIAL AND CONSTRUCTION

Main parts of the hammer are constructed of SAE grade 11,

12 and 14 carbon steels. No materials susceptible to

ignition spark formation are used on external parts.

The hammer is also free of materials with hazardous

electrostatic charging properties. The galvanized steel

surface also meets all of the requirements above.

APPLICATION

Pneumatic pick hammer is a versatile tool. It is designed for

breaking up low to medium strength rock and material

(concrete, bituminous roadways, coal etc.), in construction

works and mining or surface operations.

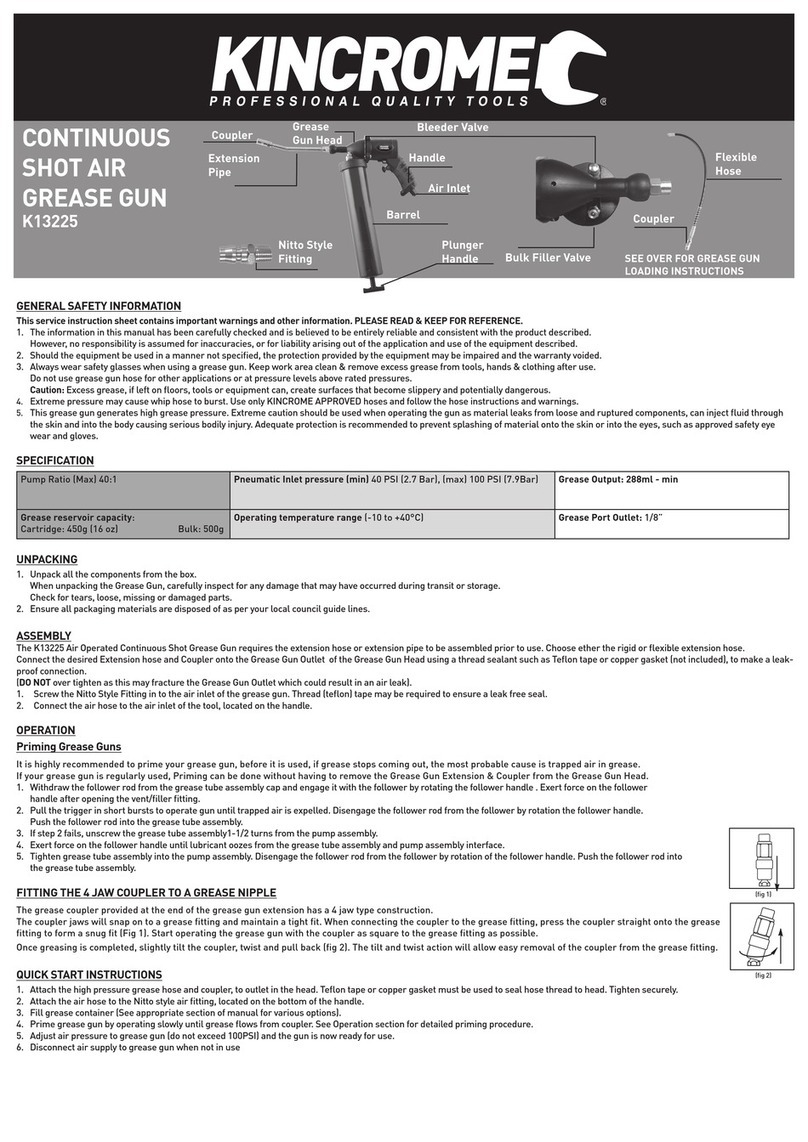

Technical data and main dimensions

ISO unit

PH-90 Ø25x75

PH-90 #22x82

Weight

kg

9.5

9.5

Impact energy

J

26

Impact frequency

Hz

28

Air consumption

m3min-1

1.1

Operating air pressure

MPa

0.4 –0.7

Effective value of weighted acceleration

m.s-2

9.1

Measured sound power level

dB

104.2

100.8

Guaranteed sound power level

dB

105

102

Length

mm

470

Width

mm

180

Supply hose

mm

Js 13, 16, 20

Connecting thread

''

G 3/4''

Tool shank size

mm

Ø25x75

#22x82

Mean values (±10% tolerance) at 0.6 MPa air pressure.

Air pressure

The hammers are

constructed for operating air

pressure of 0.4 –0.7 MPa.

0.4 –0.7 M P a

T E C H N I C A L D E S C R I P T I O N

5

www.diaber.nl

BreakAir PH-90

Machine type and serial

number are embossed on

the handle.

TECHNICAL DESCRIPTION

The hammer is constructed for operating air pressure of 0.4

- 0.7 MPa. Compressed air is in turns filling spaces below

and above floating piston head in hammer cylinder, setting

piston into linear reciprocating motion. In power stroke,

piston transfers its kinetic energy to a tool that disrupts

material. The tool is retained by screw retainer Exhaust air

leaves through a series of holes in silencer. Silencer can be

rotated into arrested positions, directing exhaust air to

ensure safety and comfort.

MODEL LABELLING

Machines are fitted with labels containing important

information. Keep these labels clean and readable at all

times and order new ones as necessary.

The main label should be found on the handle.

The 'CE' symbol states that the product is EC-approved

(see EC-Declaration of conformity).

Maximum permitted compressed air pressure is stated in

the top right corner.

The opened book symbol states that user has to read and

understand the manual before using the machine for the

first time.

The headset symbol reminds user to wear effective ear

defenders.

The last symbol reminds user to wear safety goggles.

Guaranteed noise level in accordance with Directive

2000/14/EC is indicated by a label under silencer, and a

mark on the silencer marks the group and category the

machinery falls under in accordance with Directive 94/9/EC

–ATEX.

BreakAir PH-90 93/0516

M A I N T E N A N C E P R I N C I P L ES

6

ver. 20.10.2016

www.diaber.nl

MAINTENANCE PRINCIPLES

Only personnel properly acquainted with the structure and

function of the hammer can service the tool.

All repairs are to be performed by the manufacturer or

authorized trained personnel.

Dry, clear air of the appropriate overpressure

(see Technical data) must be available in

sufficient volumes.

Supply hose must match the prescribed dimensions.

To avoid excessive frictional pressure loss, do not use

hoses of over 15 meters in length (in case of a Js16

hose). If necessary, hose of a larger diameter can be

used over greater distances.

Protect the hammer from dirt and other harmful

particles getting in. Always keep the input and output

openings clean.

Blow the hose clear to get rid of potentially harmful

particles before attaching it to the hammer.

Properly tighten all joints and re-tighten after 3-5 hours

of first operation.

Check-up on the state of the hammer regularly.

Hexagonal chuck in PH90 #22x82 makes use of chisel

type tools possible. The open screw retainer can be

used for wider chisels and facilitates faster tool

replacement. If the hammer operates without sufficient

thrust, the screw retainer can crack under heavy

impacts of the tool!

LUBRICATING

The hammer must be in good condition and lubricated

properly to provide maximum performance, service life and

proper functionality. Ensure sufficient lubrication with an

oiler or a water-separator/oiler unit.

Alternatively, pour about 100 cm3of oil into the air supply

hose (at the entry point) by the compressor unit and 5 cm3

into the air inlet at the beginning of each work shift and

repeat every 2-3 hours of operating.

Do not use hydraulic oils or unstabilized coleseed oils

for lubrication.

Before storing the tool for over three weeks, conserve

it using mineral oil (see Storing).

Do not use ecological oils for conservation.

Thrust

With regards to vibrations

and manipulation of the

hammer, the optimal thrust is

between 150 –200 N.

The thrust must prevent the

hammer from working idly,

which increases wear and

chance of breakdown.

Tool insertion

Unscrew retainer with ring.

Always check the state of

rubber ring. Insert tool into

cylinder and screw retainer

back on.

Never start a hammer

without a tool inserted!

S T O R I N G

7

www.diaber.nl

BreakAir PH-90

Recommended ecological oils:

BP BIOHYD SE 46, ÖMV BIOHYD M 32,

TOTAL HYDROBIO 46

Recommended mineral oils:

PARAMO PNEUMAT 46

STORING

Before storing the tool for over three weeks, it needs to be

conserved.

Conserve the hammer by pouring cca. 50 cm3(0.5 dcl)

of mineral oil into the air inlet and running it shortly to

coat its internal parts with oil.

Store the hammer in dry conditions –protected from

weather factors and relative humidity below 75%.

Do not store the hammer close to corrosive chemicals

or gases.

In proper storage conditions, the hammer can be stored for

a year and spare parts for a year and a half without re-

conservation.

DELIVERING

The hammer is delivered separately, including this manual

and a certificate of warranty.

By default, we deliver the ¾'' Quick Coupling as the joint

for the supply hose. Alternatively, the quick coupling can be

replaced by a cap nut with a socket, which can be attached

to the ¾“ threaded socket.

The cap nut (item no. 319 257) can be combined with:

Ø13 socket (item no. 319 264)

Ø16 socket (item no. 319 255)

Ø20 socket (item no. 319 256)

Following items are also for sale:

tools

oilers, water separators

recommended ecological oils

hoses and hose ends, adapters, nuts, sockets, clips

Low temperatures

Presence of condensate in

air coupled with low

temperatures can cause the

hammer to freeze up.

Add a water separator or

before the hammer and as

far away from the

compressor unit as possible

(min. 20 m).

Ordering spare parts

All hammers are

manufactured in accordance

with drawing documentation

to ensure interchangeability

of all components.

Please state the hammer

type, name, quantity and

item no. of the desired

component in your order

form.

P A R T S L I S T

8

ver. 20.10.2016

www.diaber.nl

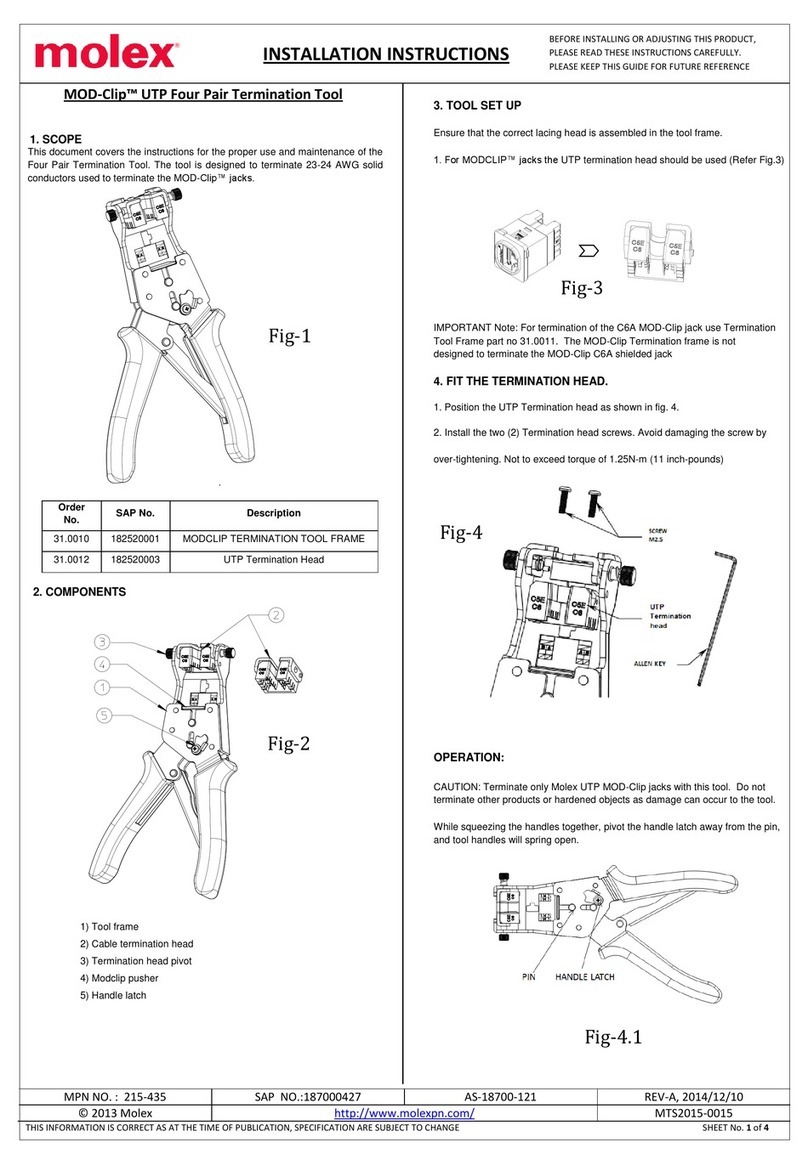

PARTS LIST

Pos.

Item No.

Title

Qty

Standard

9410 350

BreakAir PH-90 Ø27x75

9410 360

BreakAir PH-90 #22x82

1

8323 590

Cylinder Assy. Ø25x75

1

J

1

5095 572

Cylinder

1

J

2

2005 280

Chuck Ø25x75

1

J

1

8323 600

Cylinder Subassy. # 22x82

1

J

1

5095 572

Cylinder

1

J

2

2090 220

Chuck #22x82

1

J

3

273 123

273 123

Rubber Sealing 4202-050

1

J

4

273 129

273 129

Rubber Ring 4201-311

1

J

5A

8042 291

8042 291

Closed Screw Retainer

1

J

5B

8042 300

Open Screw Retainer

1

N

15

5003 475

Piston

1

J

16

3908 060

Distribution Ring

1

J

17

1511 281

Cover

1

J

18

3051 011

Pin

1

J

19

273 406

Silencer

1

J

20

4771 050

Safety Ring

1

J

21

8040 140

Handle Assy.

1

N

22

5259 483

Handle

1

J

23

1411 172

Trigger

1

J

24

311 038

Spring Pin 8 x 28

1

J

25

722 094

Ball 17 (plastic)

1

J

26

315 007

Spring 4500-240

1

J

27

311 376

Plug

1

J

28

319 282

Threaded Socket G 3/4''-3/4''

1

J

29

414 259

Quick Coupling 3/4''

1

J

30

3081 271

Trigger Pin

1

J

*

319 264

Socket Js 13

1

N

31*

316 255

Socket Js 16

1

N

*

319 256

Socket Js 20

1

N

32*

319 257

Cap Nut 3/4''

1

N

-

8040 160

Handle Assy. (bottom triggering)

1

N

-

5259 591

Handle

1

N

-

562 015

Trigger

1

N

-

311 377

Spring Pin 6 x 28

1

N

25

722 094

Ball 17 (plastic)

1

N

26

315 007

Spring 4500-240

1

N

27

311 376

Plug

1

N

28

319 282

Threaded Socket G 3/4''-3/4''

1

N

29

414 259

Quick Coupling 3/4''

1

N

30

3081 271

Trigger Pin

1

N

J = Standard N = On Demand * = Replaces Quick Coupling (29)

Ver 40-B, C, E. 11.1.2015

www.permon.cz

AXONOMETRIE / AXONOMETRIC VIEW

PARTS LIST

PAGE 8

BreakAir PH-90

Table of contents