IB 328299 (11--2011) 1

EN English

INSTRUCTION BULLETIN

No. 328299

Machine: T16

Published: 11--2011

Rev. 00

English (EN) 1.................................................................

Deutsch (DE) 17.................................................................

Español (ES) 33.................................................................

Français (FR) 49.................................................................

Italiano (IT) 65...................................................................

Nederlands (NL) 81..............................................................

NOTE: Numbers in parenthesis ( ) are reference numbers for parts listed in Bill of Materials.

Installation instructions for kit number 322316

SYNOPSIS:

This kit contains the parts needed to replace the steering shaft on T16 scrubbers.

Please follow step-by-step instructions.

SPECIAL TOOLS / CONSIDERATIONS: 1--11/16 socket

(Estimated time to complete: 3 hours)

PROTECT THE ENVIRONMENT

Please dispose of packaging materials, old machine components, and

hazardous fluids in an environmentally safe manner according to local

waste disposal regulations.

Always remember to recycle.

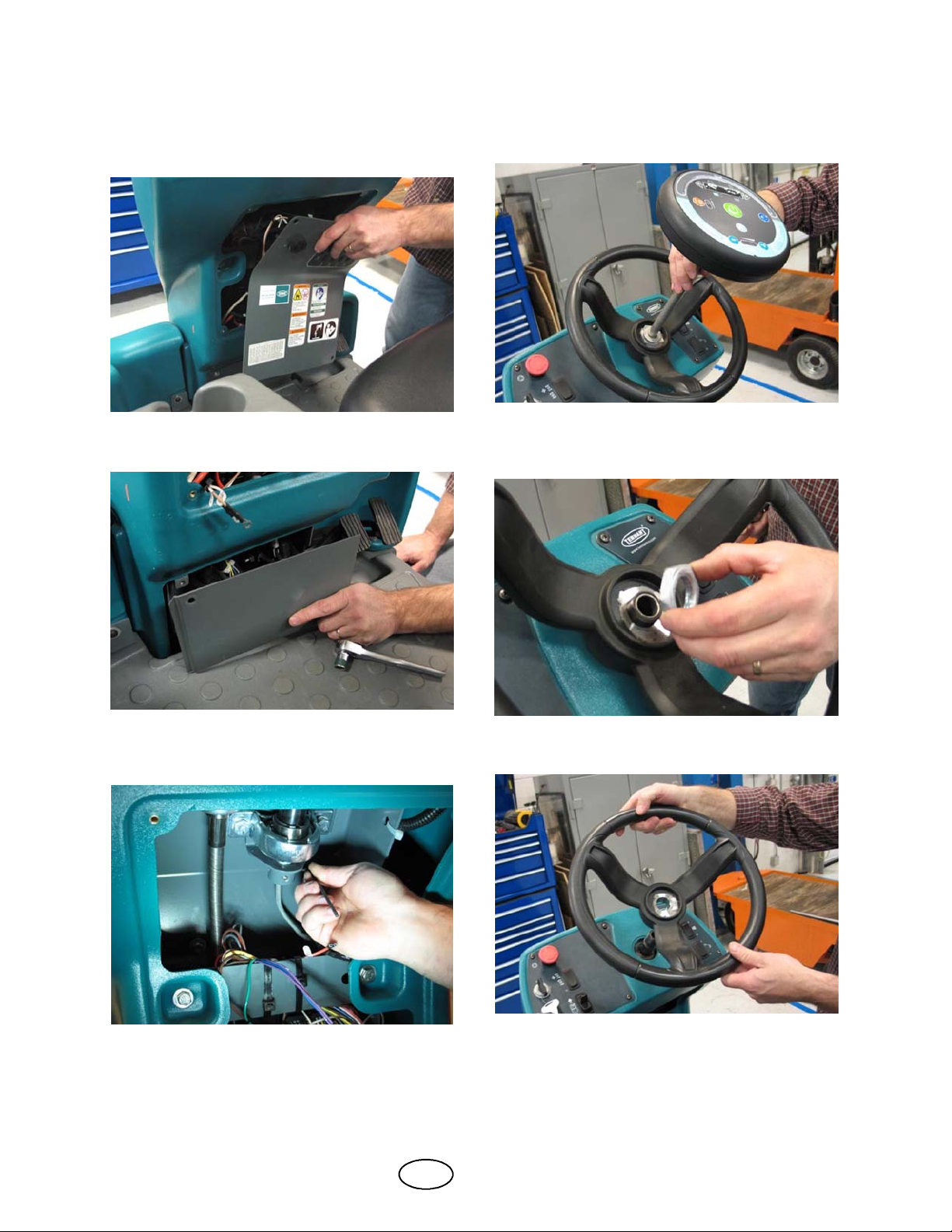

PREPARATION:

FOR SAFETY: Before leaving or servicing

machine, stop on level surface, turn off

machine, and remove key.

WARNING: Always disconnect battery

cables from machine before working on

electrical components.

NOTE:Do Not discard removed parts unless

instructed to do so. Set removed parts aside.

Most of these parts are reinstalled onto the

machine.

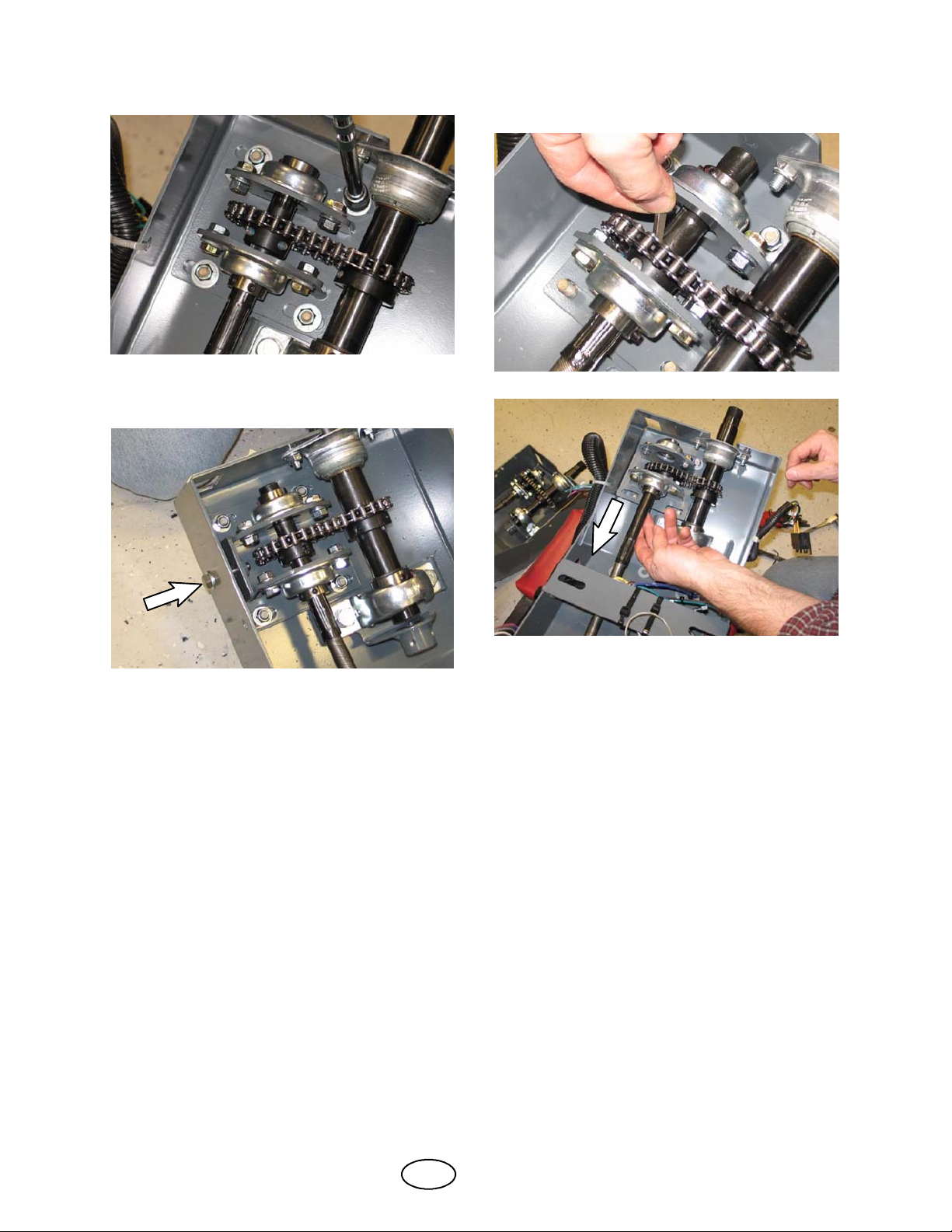

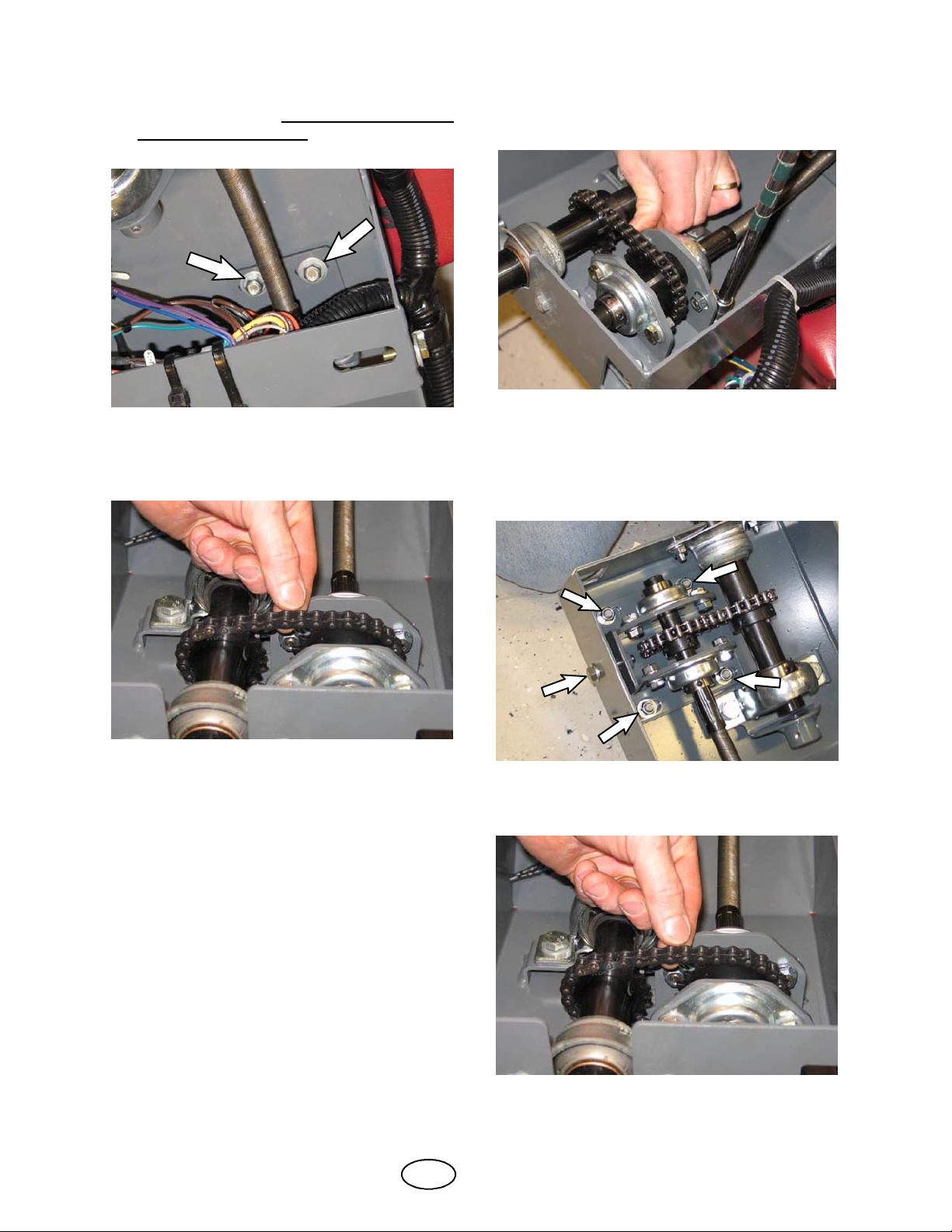

NOTE:Refer Fig. 54, Fig. 55, and Fig. 56 for

exploded views / part locations on the machine.

ATTENTION: Do Not bend the steering shaft

except for the slight bend necessary to install

it onto the machine.