TROUBLESHOOTING

Problem Cause Remedy

Grease gun pumps little to no grease a. Air pockets in grease

b. Dense or Frozen Grease

c. Grease Gun Extension Blocked

d. Grease Gun Head Blocked

a. Prime Grease Gun (refer to steps 5-7 of grease gun loading)

b. Use a lower viscosity Grease / add some oil to grease to make it more

viscous / heat the Grease Gun Barrel to lower unfreeze the grease

c. Remove Extension Hose. If Grease gun pumps grease without the extension, then

the problem is with the extension, which should be cleaned / replaced

d. Dis-assemble the Grease Gun Head to check for any contaminants blocking the

passage of grease. Clean & Re-assemble the Grease Gun Head

Grease leaks from the connection between the Grease

Gun Head or the Extension hose or the Coupler

a. Loose Connection a. Inspect and tighten the connection using Teflon tape or another form of Thread

Sealant.

Grease leaks from the Coupler body joint or from in-be-

tween the Coupler Jaws & Grease Nipple

a. Damaged Grease Coupler a. Replace the Coupler

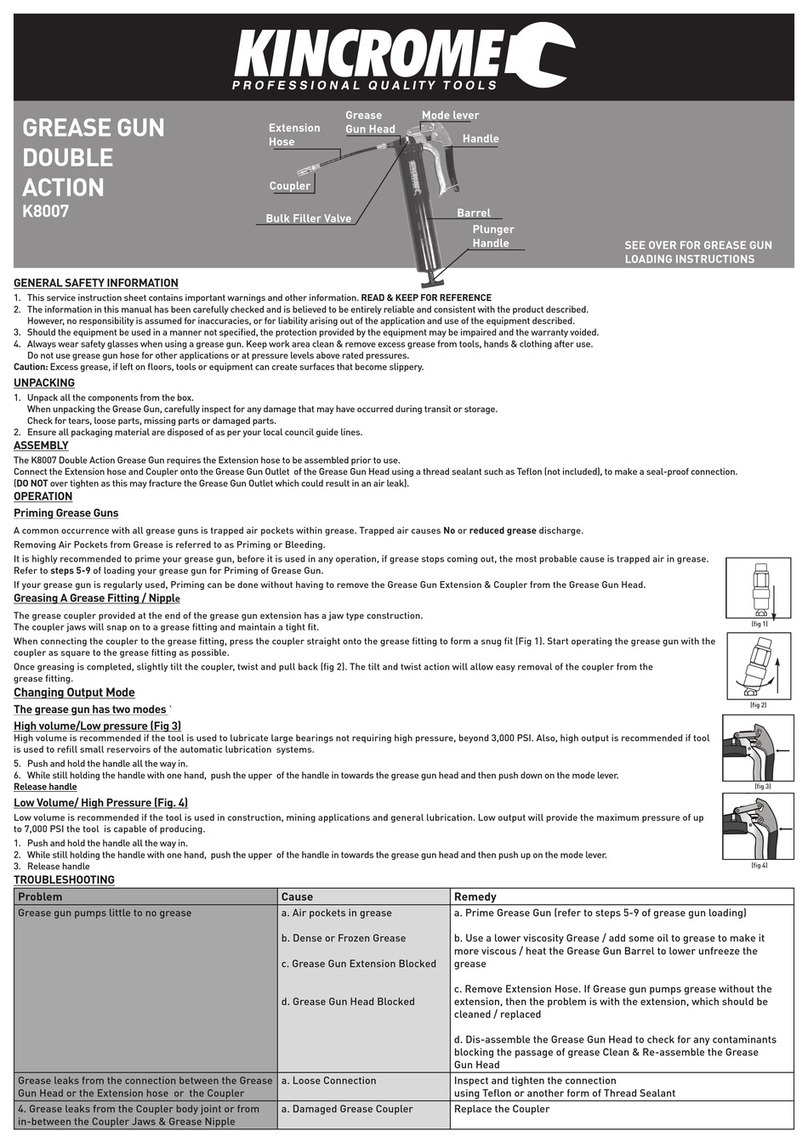

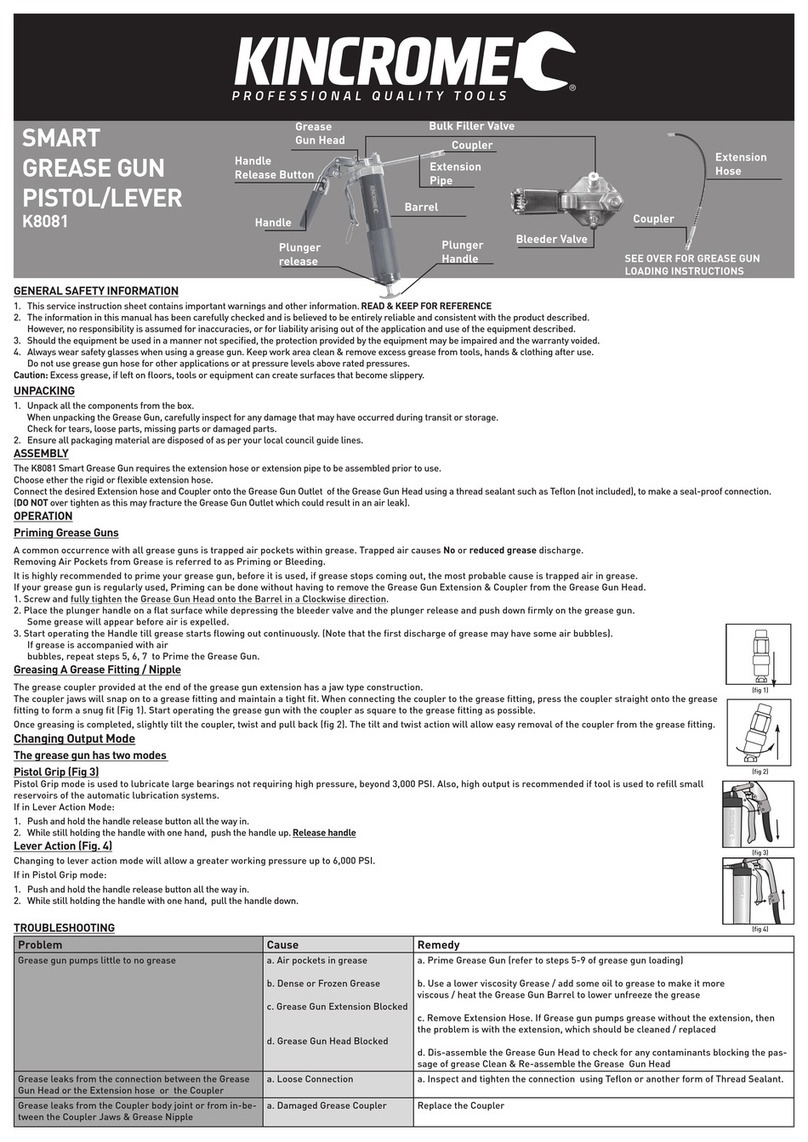

GREASE GUN LOADING

Caution must be observed when either unscrewing the barrel or unscrewing the pull handle from the follower rod as the large

follower spring inside the barrel is energised.

Grease guns have multiple loading options such as Cartridge Loading, Bulk Loading and Suction Loading

Cartridge Loading

1. Unscrew Grease Gun Head from the Barrel counter-clockwise.

2. Pull back the Plunger Handle all the way back until the plunger handle locks.

3. Remove the plastic cap from the open end of the Grease Cartridge & fully insert into the empty Barrel.

4. Remove the metal pull tab seal from the Grease Cartridge.

5. Screw and fully tighten the Grease Gun Head onto the Barrel in a Clockwise direction.

6. Place the plunger handle on a flat surface while depressing the bleeder valve and the plunger release. Push down firmly on the

grease gun. Some grease will appear before air is expelled.

7. Start operating the Trigger until grease starts flowing out continuously. If grease is accompanied with air bubbles, repeat steps 5, 6, 7

to Prime the Grease Gun.

Note: that the first discharge of grease may have some air bubbles.

Bulk Loading

1. Unscrew Grease Gun Head from the Barrel counter-clockwise.

2. Pull back the Plunger Handle all the way back until the plunger handle locks.

3. Scoop out clean Grease from the Bulk Grease Container into the empty Grease Gun Barrel.

4. Once the Barrel is full, shake the Barrel to allow grease to settle down. Fill with more grease if Barrel is not completely full.

5. Screw and fully tighten the Grease Gun Head onto the Barrel in a Clockwise direction.

6. Place the plunger handle on a flat surface while depressing the bleeder valve and the

plunger release. Push down firmly on the grease gun. Some grease will appear before

air is expelled.

7. Start operating the Trigger until grease starts flowing out continuously. If grease is accompanied with air bubbles, repeat steps 5, 6, 7 to

Prime the Grease Gun.

Note: that the first discharge of grease may have some air bubbles.

Suction Loading

1. Unscrew Grease Gun Head from the Barrel counter-clockwise.

2. Insert the open end of the Barrel into the Grease bucket to about 2”(50 mm) deep.

3. Slowly pull the Plunger Handle all the way back, to draw in grease into the empty barrel and the handle plunger locks.

4. Shake the Grease Gun Barrel to allow the Grease to settle at the bottom of the Barrel.

5. Screw and fully tighten the Grease Gun Head onto the Barrel in a Clockwise direction.

6. Place the plunger handle on a flat surface while depressing the bleeder valve and the

plunger release. Push down firmly on the grease gun. Some grease will appear before

air is expelled.

7. Start operating the Trigger until grease starts flowing out continuously. If grease is accompanied with air bubbles, repeat steps 5, 6, 7 to Prime the

Grease Gun.

Note: that the first discharge of grease may have some air bubbles.

Filler Pump

1. Pull back the Plunger Handle all the way back until the plunger handle locks. Ensure the Grease Gun Head is screwed tightly onto the barrel.

2. Check compatibility of Bulk Filler Valve on your grease gun with your Filler Pump, to make sure they are compatible. Wipe the Bulk Filler Nipple clean of any

dirt before starting.

3. Insert the Bulk Filler Valve onto the Female Loader Valve of the Grease Filler Pump. Start operating the Filler Pump, keeping your hand on the Grease Gun,

lightly pushing it down onto the Filler Pump.

4. Disengage the Grease Filler Valve from the Female Loader Valve of Grease Filler Pump. Unscrew Grease Gun Head from the Barrel by a few turns, by

approximately 2-3 turns.

5. Once the Grease Gun Barrel is filled, pumping would get very hard. Stop at this time.

Warranty given by Kincrome Australia Pty Ltd of 3 Lakeview Drive, Caribbean Park, Scoresby, Victoria (Tel 1300 657 528). The applicable

warranty period (24 months) commences on the date that the product is purchased. If this product has materials or workmanship defects

(other than defects caused by abnormal or non warranted use) you can, at your cost, send the product to place of purchase, an authorised

Kincrome service agent or one of Kincromes addresses for repair or replacement. Your rights under this warranty are in addition to

any other rights you have under the Australian Consumer Law or other applicable laws. Our goods come with guarantees that cannot

be excluded under the Australian Consumer Law. You are entitled to a replacement or refund for a major failure and compensation for

any other reasonably foreseeable loss or damage. You are also entitled to have the goods repaired or replaced if the goods fail to be of

acceptable quality and the failure does not amount to a major failure. For further details please visit www.kincrome.com.au or call us.

Due to minor changes in design or manufacture, the product you purchase may sometimes differ from the one shown on the packaging.

YEAR

WARRANTY

2

SCAN FOR

HOW TO VIDEO

QR CODE