Breas Medical NIPPY+ Series User manual

Doc 0930 Technical Manual

for the

NIPPY+ Range of Ventilators

This manual covers all of the NIPPY+ range of ventilators

This manual contains confidential information

and it is supplied on the understanding that it

shall not be copied, loaned or distributed to any

other persons or organisations, in whole or in

part, without the written consent of:

Breas Medical Ltd

Unit A2, The Bridge Business Centre

Timothy’s Bridge Road

Stratford–upon-Avon

CV37 9HW

Tel: 01789 293460

www.nippyventilator.com

Version 10, December 2017

Contents

Introduction 1

Description 2 - 5

Service Menus

Time and Date 6

Service Period / Calibration 7

Diagnostic Screen 8

Alarm Log 9

Install Defaults 10

Fault Messages 11-12

Event Log 13

Opening the Case

Fig 1, Opening the Case 14

Fig 2, Inside the base 15

Fig 3, Inside the base –Control bd removed 16

Fig 4, Location of Components –Lid 17

Removal of Major Components 18-19

Preventative Maintenance Guide 20

Suggested Acceptance tests 22

Internal Battery 23

Replacement of Alarm Battery 24

Calibration 25

Theory of Operation 26

System Pneumatic Diagram 27

Block Diagram 28

Block diagram of Control Board 29

Block diagram of Command Board 30

Circuit Diagrams 31- 42

Specification 43

Spare Parts List 44

1

Introduction

The purpose of this manual is to enable suitably qualified competent technical

personnel to perform first line maintenance on the NIPPY+ family of

ventilators.

The NIPPY+ range consists of :- NIPPY 3+, NIPPY junior+, NIPPY St+ and

NIPPY S+. They all use the same hardware and service procedures.

Component level fault finding will not be considered. Due to the complexity of

the circuit boards used in the NIPPY+ range, it is not considered practical or

cost effective to try to trace faults to component level.

Second-hand or “service exchange” boards are not available.

This manual will deal with routine maintenance, calibration and replacement

of major components.

IMPORTANT

Read this manual before attempting service or repair of the NIPPY+

Please contact Breas Medical Ltd if training is required or you have any

questions.

NIPPY+ must be subjected to regular inspection according to Breas

Medical Ltd service instructions. Repairs shall be carried out in

accordance with this technical manual and any special service

instructions or bulletins provided by Breas Medical Ltd.

Before opening the case, disconnect the NIPPY+ from the mains supply.

Do not work on the NIPPY+ with the case open and the power supply

connected.

Make sure that all precautions to prevent Electrostatic Discharge (ESD)

have been taken.

Do not use explosive gases and/or fluids near the NIPPY+.

2

Description

The NIPPY+ range ventilators are intended to provide ventilation for non-

dependent, spontaneously breathing adult patients with respiratory

insufficiency, or respiratory failure.

The NIPPY+ range devices are pressure controlled, positive pressure

ventilators. They compress ambient air and deliver it to the patient through a

close fitting nasal mask or a tracheostomy. The output pressure, timing and

alarms can be adjusted by controls on the fascia panel. The Pressure,

estimated Tidal Volume, Rate and all settings are displayed on a colour LCD

(Liquid Crystal Display) screen.

The screen can be set to dim after a pre-set time (accessed via the user

preferences in the main menu). To restore the display, press any button once.

The basic ventilator settings can be achieved using the four buttons to the left

of the display. The four buttons to the right of the display adjust the alarms

and provide access to more advanced features and adjustments (accessed

via a menu).

NIPPY 3+ and NIPPY junior+ are normally supplied with an internal battery

fitted. This is available as an option on NIPPY ST+ and NIPPY S+.

All can run on an internal or external battery or both if extended run times or

extra back up is required.

All are capable of recharging their internal batteries and the external Lithium

ion packs. The internal battery has priority over the external one.

3

Modes of Ventilation

CPAP (Continuous Positive Airway Pressure) Constant

positive pressure is applied via the mask. No

respiratory support is given in this mode.

NIPPY 3+, NIPPY Junior+, NIPPY ST+.

Pressure Support IPAP (Inspiratory positive airway pressure) and EPAP

(Expiratory positive airway pressure) are set by the

physician. The ventilator augments the patient’s

spontaneous breathing.

Adjustable back-up rate takes over in the absence of

an inspiratory trigger.

NIPPY 3+, NIPPY Junior+, NIPPY ST+, NIPPY S+.

Pressure Control IPAP, EPAP and Ti are set by the physician. A timed

inspiration is cycled by the patients inspiratory effort.

Adjustable back-up rate takes over in the absence of

an inspiratory trigger.

NIPPY 3+, NIPPY Junior+.

IPPV (Intermittent Positive Pressure Ventilation) IPAP and

Ti are set by the physician. A timed inspiration is

cycled by the patient’s inspiratory effort. Patient

exhales to atmosphere via an exhale valve fitted in

the breathing circuit. EPAP is not used in this mode.

Adjustable back-up rate takes over in the absence of

an inspiratory trigger.

NIPPY 3+, NIPPY Junior+.

4

Alarms

Power Fail If the electrical power to the ventilator is interrupted, an audible

alarm will sound. This alarm will run for 5 minutes unless cancelled with the mute

button. Once cancelled the power fail alarm will not re-activate.

Low Internal Battery When running on its internal battery, the alarm will operate when

the battery is low. This could last for up to 1 hour. When the alarm becomes constant

there is approximately 10 minutes running time left.

Low External Battery When running on its external battery, the alarm will operate

when the battery is low. This could last for up to 1 hour. When the alarm becomes

constant there is approximately 10 minutes running time left.

Low Pressure A pre-set low pressure alarm is provided. If the control pressure falls

to below 50% of the set IPAP level for 10 seconds an audible and visual alarm will

operate.

High Pressure A pre-set high-pressure alarm is provided. If the pressure rises above

120% of the working pressure, an audible and visual alarm will operate after a 2 second

delay.

Breathing Circuit Disconnect A disconnection alarm is provided as a back up to

the high flow alarm. If the patients flow waveform indicates that a significant leak

maybe present in the breathing circuit an audible and visual alarm will operate.

The sensitivity of the alarm is adjustable.

Breathing Circuit Malfunction This alarm warns of a malfunction of the exhale

valve in the IPPV mode circuit.

High Flow alarm An adjustable alarm is provided to warn of excess inspiratory flow.

This is activated when the inspiratory flow exceeds the set high flow alarm level

for 5 seconds. An audible and visual alarm will operate.

Low Flow alarm An adjustable alarm is provided to warn of insufficient inspiratory

flow. This is activated when the inspiratory flow fails to achieve the set low flow

alarm level for 10 seconds. An audible and visual alarm will operate.

Apnoea Alarm An adjustable Apnoea alarm is provided. If an apnoea is detected an

audible alarm will sound with a visual indication on screen.

Max Breath Rate An adjustable maximum breath rate alarm is provided. If the max

breath rate is exceeded an audible and visual alarm will operate.

Fault The alarm may also be operated by an internal fault. In this case the fault will be

displayed on screen.

These alarms may be muted for approximately 2 minutes to allow for setting up of

the ventilator.

Low Internal Alarm/Memory Battery An intermittent alarm (short beep) with no

onscreen message indicates a depleted mains fail alarm battery. If the ventilator has

been stored for more than a few weeks the internal battery will self-discharge. In this

case the alarm will stop after the battery has recharged.

5

Estimated Tidal Volume

The estimated tidal volume is a calculated value, based on time and

calibrated flow values. The constant leak through the breathing circuit

exhalation port is subtracted from this calculation to give a reasonably

accurate estimation of tidal volume. If a different exhalation port is used (a

ventilated mask for example) this calculation may be affected by the possible

change in exhalation port flow rate. This must be taken into consideration

when reading the tidal volume.

A ventilated mask with a higher flow exhalation port will cause the estimated

flow reading to be slightly higher than normal.

Inspiratory Trigger

The NIPPY+ employs flow triggering, detecting the start of the patients’

inspiratory effort when the flow rate exceeds the level set by the Inspiratory

Trigger sensitivity.

Expiratory Trigger

The expiratory trigger is used in Pressure Support mode only. Towards the

end of inspiration, when the inspiratory flow rate drops to the baseline

(standing flow caused by exhale port leak) minus the expiratory trigger

sensitivity the ventilator will cycle into the expiratory phase.

The inspiratory and expiratory effort required to cycle the ventilator can be

adjusted via the Trigger option in the Menu.

For simplicity the trigger sensitivity is scaled 1 –10, with 10 being the most

difficult.

Battery Charging

Both internal and external batteries are of Lithium Ion construction. Charging is

fully automatic. When the ventilator is connected to mains power but not

running, batteries will be charged continuously. The internal battery is charged

to approx. 95%, and then the external battery (if present) is charged to the same

level, before switching back to internal to complete the charge. The charge will

be terminated when both batteries are fully charged.

Whilst the ventilator is running, the batteries are charged during the EPAP

period of the breathing cycle.

When the ventilator is switched off it is in standby mode. It will “wake up” every

16 seconds to check the state of its batteries and start a charge sequence if

necessary.

6

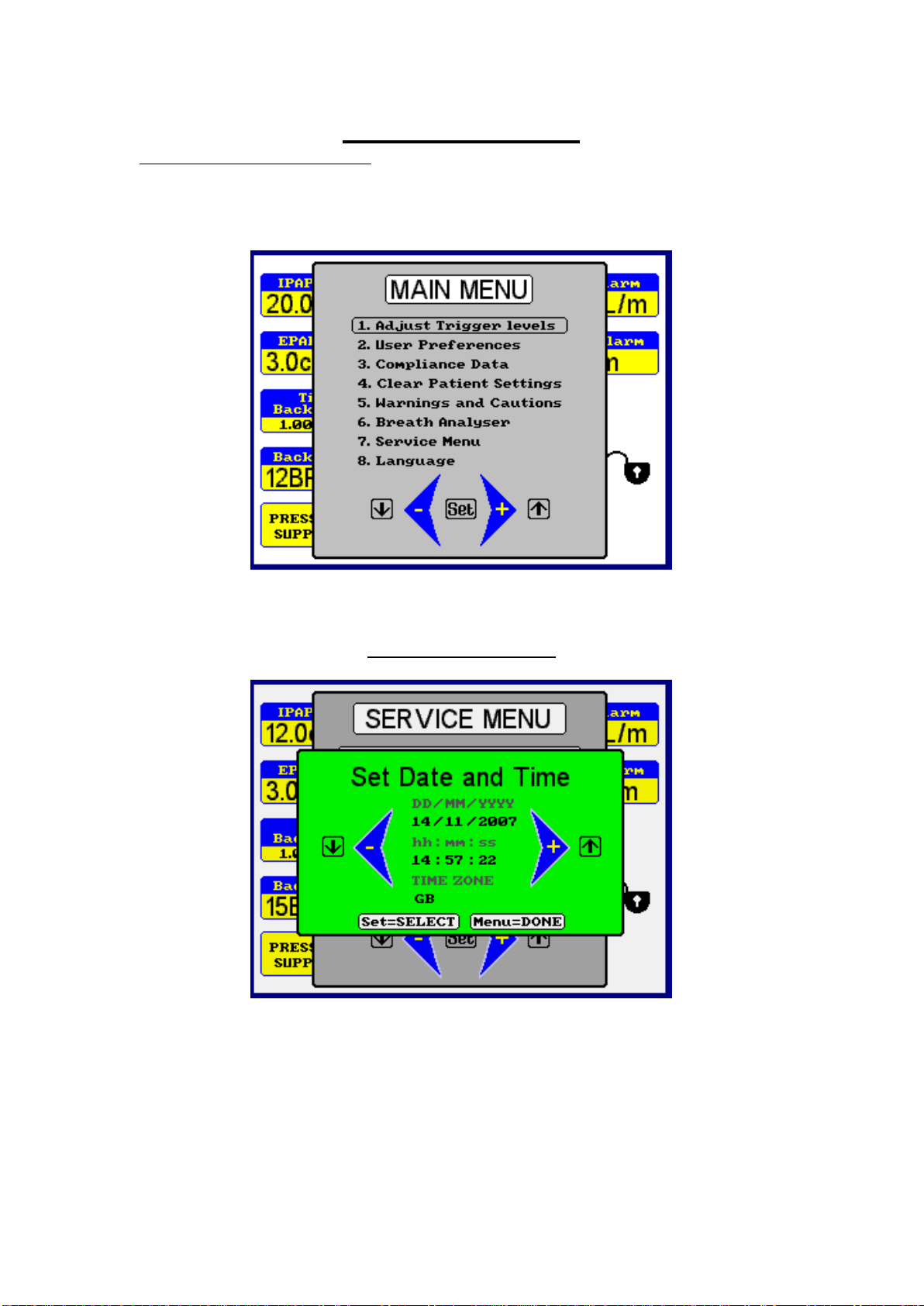

The Service Menu

Accessing the service menu

To access the service menu, power up the machine whilst holding down the

Hi and Lo alarm setting buttons (Menu and Mute on NIPPY S+ and ST+).

Press Menu and select Service menu from the main menu.

Set Time and Date

Press the set button to select the value and use the + and –buttons to adjust.

Time zone may be set for anywhere in the World.

Press menu to leave this screen.

7

Service Period

The service period screen shows the total running time and running time since

the last major service.

When a 10000 hour service has been completed, press the + and –buttons

together for 2 seconds. The current date will be entered into the service

record and the service indicator will be reset. This provides an on-screen

record of major services.

Calibration Screen

In this screen the calibration of the flow and pressure transducers is

accessed. The machine then generates its own pressure or flow to be

compared to a calibrated standard. Altering the blower speed varies the

pressure and flow. Use the Set button to move from blower speed to pressure

or flow. Use the + and –buttons to adjust the values.

Press and hold Hi and Lo alarm buttons for 2 seconds to restore default

calibration values.

8

Diagnostic Screen

This screen shows the following information:-

Box internal temp The internal temperature. If this value rises above

60 degrees, an alarm will be activated.

Blower current Current consumed by the blower

Pressure Error The pressure servo loop error. This should ideally

be close to zero.

PSU Voltage The internal power supply voltage. Nominally 24V

dc

Int. Li. Batt. Vlt. The internal lithium battery voltage, if present.

Nominally 18.75V.

Int. Li. Batt. Curr. Charge or operating current of the internal battery.

Ext. Li. Batt. Vlt. The external lithium battery voltage, if present.

Nominally 18.75V.

Ext. NiMh.Batt.V The external Nickel Metal Hydride battery voltage,

if present. Nominally 24V.

Ext. Pb.Batt.Vlt The external Lead Acid battery voltage, if present.

Nominally 24V.

Ext. Batt. Cur External battery current in Amps. A positive value

represents a charge current and negative

represents discharge. Charging is only possible for

Lithium batteries.

Charge Voltage Battery charging voltage. 20.5V fully charged.

9

Alarm Log

The alarm log shows the number of alarm events and the time and date of the

last occurrence.

Alarm Log Entry

Explanation

“Over Pressure”

Pressure exceeded 120% of IPAP setting

"Under Press."

Pressure failed to reach 50% of set IPAP level

"High Flow"

Flow exceeded the high flow alarm level. Disconnected or excessive

leak.

"Low Flow”

Flow failed to reach low flow alarm level for more than 10 seconds.

Airway blockage.

"Low Bat.V."

External battery voltage low

"Disconnection"

Breathing circuit disconnection.

"Mains -> Batt."

Auto switch to internal or external battery after mains failure.

"Defs.Loaded"

Default values loaded.

"Power Lost"

Power failure.

"L.Saved.Ld."

Last saved values loaded

"Press.Meas.Flt"

Loss of pressure signal

“Safe mode”

Blower at minimum speed following Press.Meas.Flt

"Blower Flt."

Blower controller fault or blower stopped.

"Blower Spd.Flt."

Error between blower speed command and actual blower speed.

"Box Ov/Un Tmp."

Internal temperature below 5 degrees or above 60 degrees.

"Main Power Flt"

Internal power supply voltage out of spec. Less than 22 volts or

greater than 26 volts.

"Int.Coms.Flt."

Communication failure between internal micros.

"Alarm PIC Flt."

Communication error with alarm micro.

"Alarm PIC Bat."

Internal alarm / memory back up battery voltage low or high.

"B.Ram0.Flt.";

Battery backed-up memory access fault.

"B.Ram1.Flt.";

Battery backed-up memory access fault.

"B.Ram2.Flt.";

Battery backed-up memory access fault.

"EE.Mem.Flt.";

Eprom memory access fault.

Machine loads default values.

10

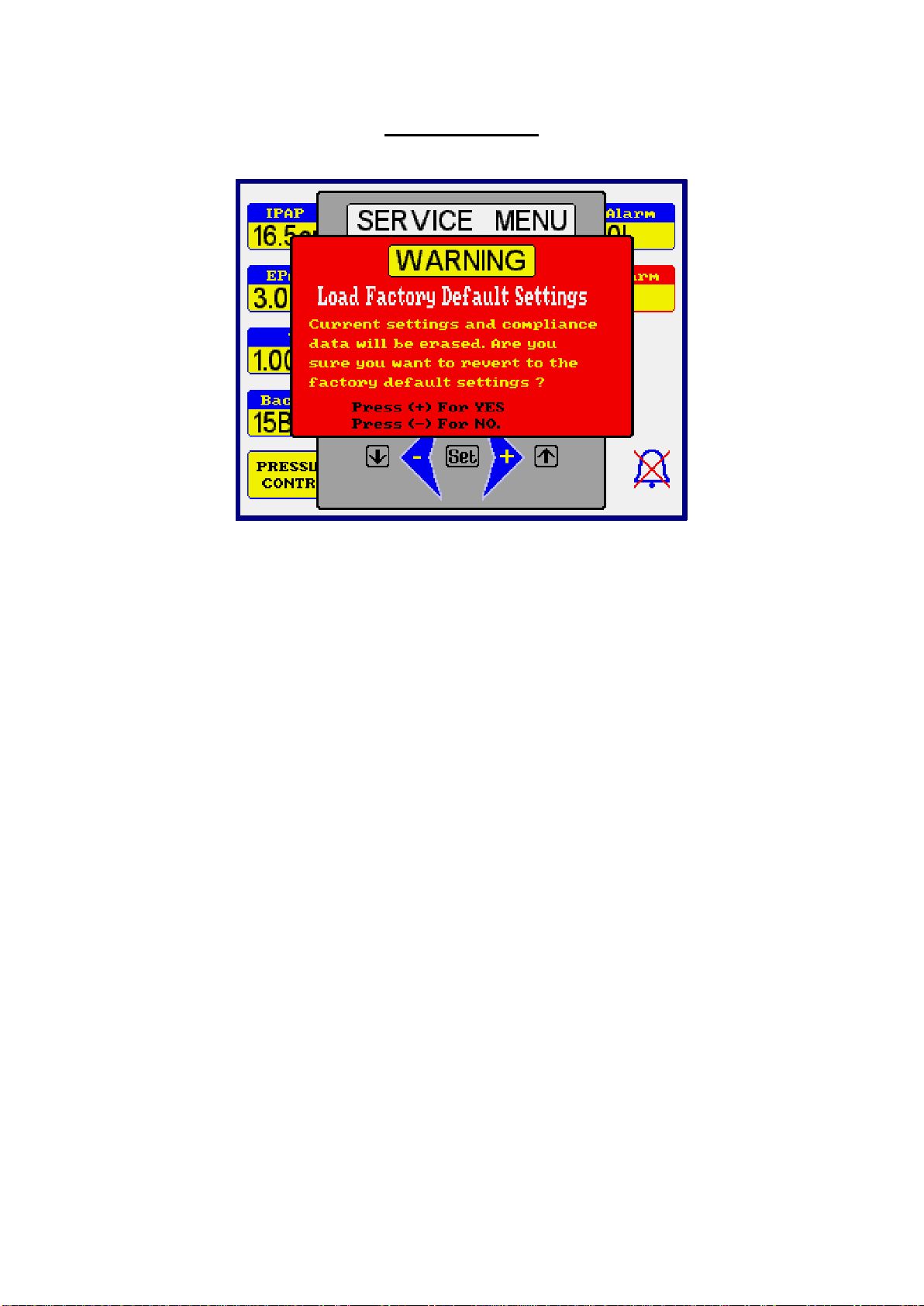

Install Defaults

If the ventilator is to be re-used for a different patient, the settings may be

restored to the factory defaults. These are:-

NIPPY 3+ NIPPY Junior+

IPAP 12cm 12cm

EPAP 3cm 3cm

Ti back-up 1.0 seconds 1.0 seconds

Mode Pressure Support Pressure Support

Hi Alarm 100L/min 60L/min

Lo Alarm 20L/min 20L/min

I Trigger 4 4

E Trigger 4 4

11

Fault messages

Fault Message

Fault Log Entry

Explanation

Probable Cause

Possible Remedy

Pressure Measurement

fault

"Press.Meas.Flt"

Loss of pressure signal

Pressure transducer pipe

disconnected.

Pressure transducer fault.

Reconnect pipe and restart

machine.

Replace power board.

Technical Fault

Vent Now in Safe Mode

Stop Using This Machine

Note 1

Safe Mode

Ventilator has set to minimum output

following a pressure measurement fault.

This prevents operation with no feedback.

Pressure transducer pipe

disconnected.

Pressure transducer fault.

Reconnect pipe and restart

machine.

Replace power board.

Blower Control fault

"Blower Flt."

Blower controller fault or blower stopped.

Seized Blower motor

Controller fault

Replace blower

Replace power board.

Blower speed fault

"Blower Spd.Flt."

Error between blower speed command

and actual blower speed.

Motor fault

Controller fault

Replace blower

Replace controller

Enclosure Temperature

fault

"Box Ov/Un

Tmp."

Internal temperature below 5 degrees or

above 60 degrees.

Machine covered, operated

in high ambient temperature

or cooling vents blocked.

Check operational

environment.

Check cooling fan operation

and vents.

Power supply fault

"Main Power Flt"

Internal power supply voltage out of spec.

Less than 22 volts or greater than 26 volts.

Power supply fault

Replace power supply

Control System fault

"Int.Coms.Flt."

Communication failure between internal

micros.

Failure of command micro

or power micro.

Replace command board or

power board.

Note 1: The technical fault message informs the user that the ventilator has switched to safe mode to protect against operation

without pressure feedback. The output is sufficient to clear exhaled gas only. If the original fault (pressure measurement fault) is still

present, this message will alternate with the pressure measurement fault message with each press of Mute. If the original fault has

cleared, only the technical fault message will be shown. Mute time in this configuration is reduced to 10 seconds. The pressure

measurement fault should be investigated.

12

Fault Message

Fault Log Entry

Explanation

Probable Cause

Possible Remedy

"Alarm PIC Flt."

Communication error with alarm micro.

Power interruption has

caused communication

error.

No action required. Unless

there are multiple occurrences,

then change command board

Alarm back up battery

fault

"Alarm PIC Bat."

Internal alarm / memory back up battery

voltage low or high.

Battery self discharges

when not in use.

Faulty battery

Run machine for 12 hours to

recharge battery.

Replace battery.

"B.Ram0.Flt.";

Battery backed-up memory access fault.

Machine failed to access

memory, probably because

of sudden power down.

No action required. Alternative

memory location will have

been used.

"B.Ram1.Flt.";

Battery backed-up memory access fault.

Machine failed to access

memory, probably because

of sudden power down.

No action required. Alternative

memory location will have

been used.

"B.Ram2.Flt.";

Battery backed-up memory access fault.

Machine failed to access

memory, probably because

of sudden power down.

No action required. Alternative

memory location will have

been used.

"EE.Mem.Flt.";

Eprom memory access fault.

Machine loads default values.

Machine failed to load from

Eprom memory.

Change command board.

13

The Event Log

The ventilator automatically stores every event during its lifetime. This event

log is not displayed on-screen but may be downloaded to a PC using

download lead part no. 0858.

The following events will be stored in the memory:-

Power on / off

Power interruptions

Any button push

Any adjustment

Any alarm event

Switching to battery and/or back to mains

Battery voltage when running on battery

Viewing of the service menu

Any calibration alteration

Pressure, and settings are logged at intervals when there are no other events

to log

These events are stored in chronological order.

To view the event log, the PC must have NIPPY for Windows software

loaded.

With the software running and the RS232 download lead connected, go to the

Tools menu and select Event Log.

Click on Get Latest to view the most recent events. Click on Previous or Next

to scroll through the events.

0086

100 - 240V

0.4 - 1.0 Amperes

47 - 63Hz

Fuse 2 x T1.6A SN

RS 232

Cooling Vent

1

2

3

1. Aux. Power - 24 Volt connection for external battery. Connect only

recommended batteries, part no 0910

2. RS232 Port - For connection to remote alarm or personal computer.

Isolated to 1500 Volts.

3. Power Inlet - Input mains power connector. Double fused and

fitted with connector retaining clip.

14

Opening the Case

IMPORTANT Disconnect the ventilator from the mains supply and / or

any external battery.

Invert the ventilator and remove the seven recessed, hexagon socket screws.

Stand the ventilator on its base and ease the lid upwards, away from the rear

panel. When the rear of the lid is clear of the rear panel, lift it from the left

hand side. Disconnect the RS232 connector (4) and the board to board ribbon

cable (3).

1

2

3

4

Fig 1.

Opening the NIPPY

1. Command board

2. Control Board

3. Board to Board Ribbon Cable

4. RS 232 Connection.

15

1

23

4

5

6

7

8

910 11 12

13

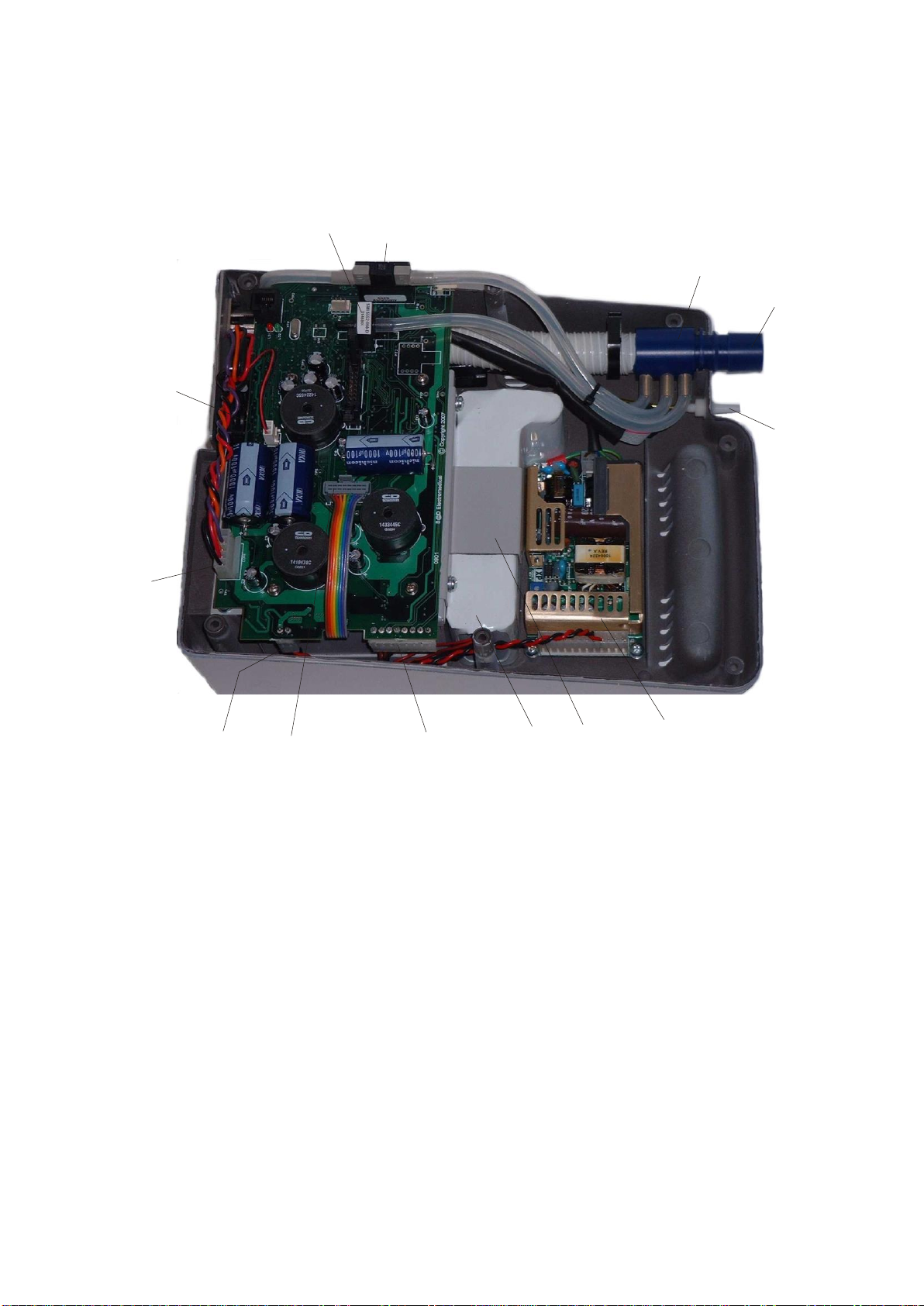

Fig 2.

Inside the Base

1. Mains Power Supply

2. Battery Clamp

3. Battery

4. Internal Battery Connector

5. Blower Connector

6. PSU Connector

7. External Battery Connector

8. Cooling Fan Connector

9. Pressure Transducer

10.Flow Transducer

11.Flow Head

12.Patient Outlet Port

13.IPPV Exhale Valve Control Line

(NIPPY 3+ and jnr+ only)

16

Fig 3.

Inside the base with the control board removed

17

1

2

3

4

5

6

7

8

9

10

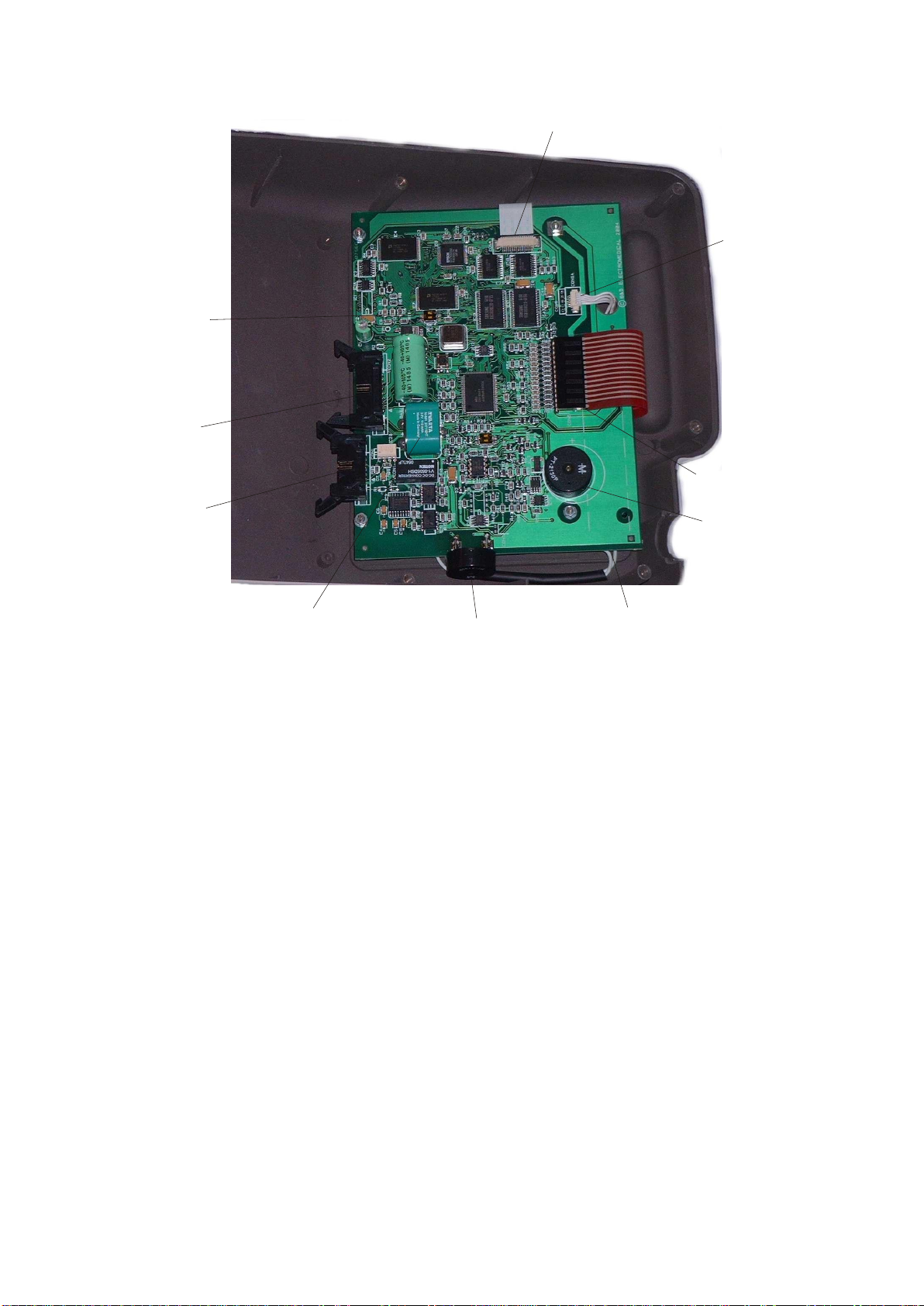

Fig 4.

Inside the Lid

1. RS 232 Port

2. Board to Board Ribbon

Connector

3. Memory Battery Switch

4. Display Connector

5. Display Back-light Connector

(Input)

6. Keypad Connector

7. Alarm Sounder

8. Display Back-light Connector

(Output)

9. Second Alarm Sounder

10.Alarm and Memory Back-up

Battery

18

Removal of major components

IMPORTANT Before opening the case, disconnect the NIPPY+ from the

mains supply.

Do not work on the NIPPY+ with the case open and the power supply

connected.

Make sure that all precautions to prevent Electrostatic Discharge (ESD)

have been taken.

Do not use explosive gases and/or fluids near the NIPPY+.

Unscrew the 7 case screws to separate the two halves of the case.

Disconnect the board to board ribbon cable and the RS232 lead (fig 1). Lay

the ventilator lid next to the base.

The Battery

Refer to fig 2

Disconnect the battery connector (4). There is no need to remove the board to

do this. Support the corner of the board with thumb and forefinger and gently

wiggle the connector downwards until it comes free.

Remove the battery clamp by removing the 2 M4 x 10 screws.

Remove the battery.

Reverse this procedure to refit.

The Power Supply

Refer to fig 2.

Disconnect the 2 way mains connector and the earth terminal.

Disconnect the 12 way output connector.

Remove the 4 securing screws and lift the power supply out of the case.

Reverse this procedure to refit.

The Control Board

Refer to fig 2.

Disconnect the internal battery first.

Disconnect the 3 Molex connectors. (Int Battery, PSU, Ext Battery, Cooling

fan).

Disconnect the blower connector.

Disconnect the 4mm silicon tubes from the pressure and flow transducers.

Disconnect the green and yellow small bore tubes from the Exhale valve

control solenoid. Located on the underside of the board.

Remove the 4 securing screws.

To refit:-

Connect the 2 small bore tubes. NOTE: the green tubes fits on the port

nearest the back edge of the board. The yellow tube fits on the adjacent port.

If the ends of the tubes are stretched, trim off approx. 2mm of tube.

Connect the PSU and connector.

Place the board into the lid and fit the 4 mounting screws.

This manual suits for next models

4

Table of contents