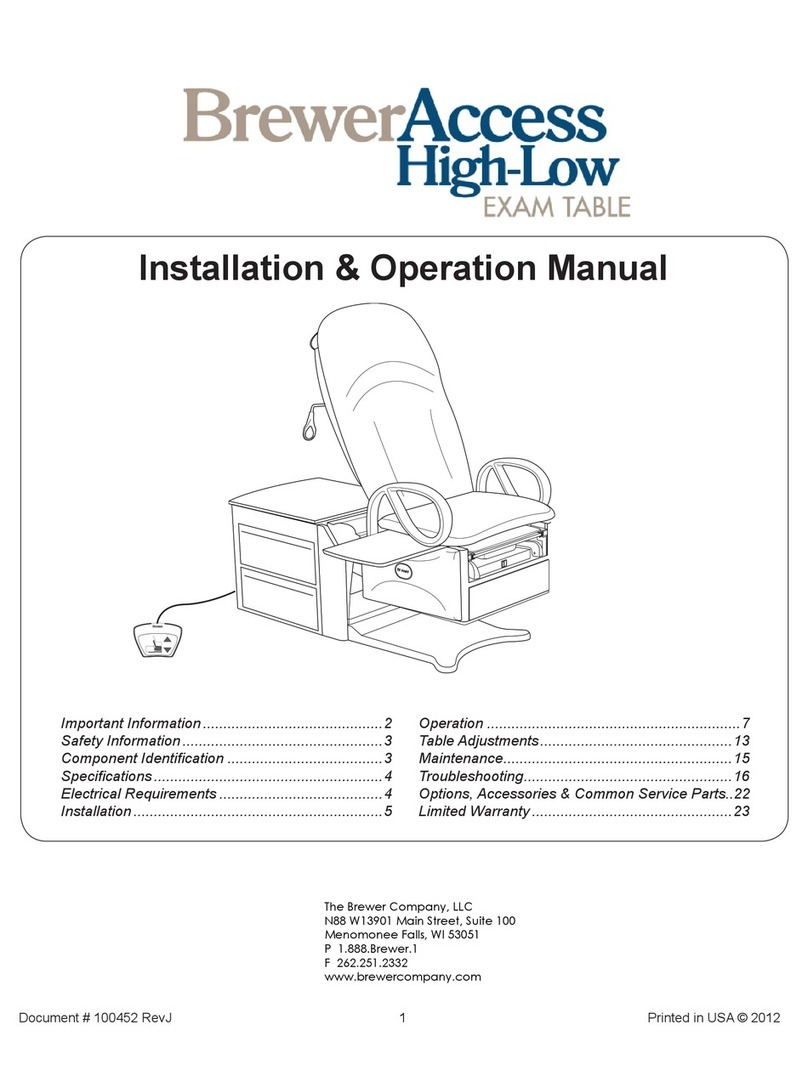

Document #100578 RevG 4 Printed in USA © 2010

CAUTION

This product has been evaluated with respect to

electrical shock, re, and mechanical hazards

only in accordance with UL60601-1; IEC60601-1;

CAN/CSA C22.2 No. 601.1

WARNING

When performing a cauterization or similar treat-

ment, the patient must be insulated from the metal

portions of the table by nonconductive material.

Failure to do so may result in electrical shock or

burns to the patient.

WARNING

Use 120 VAC, 60 Hz alternating current only. Failure

to do so may result in electrical shock to personnel

and will result in damage to the table.

WARNING

Do not use this table in an explosive or oxygen-en-

riched atmosphere. Failure to do so may result in

serious personnel injury or death.

CAUTION

Do not use any power supply other than that

listed on the rating label (Figure 1). Failure to do

so may result in serious injury and/or equipment

damage.

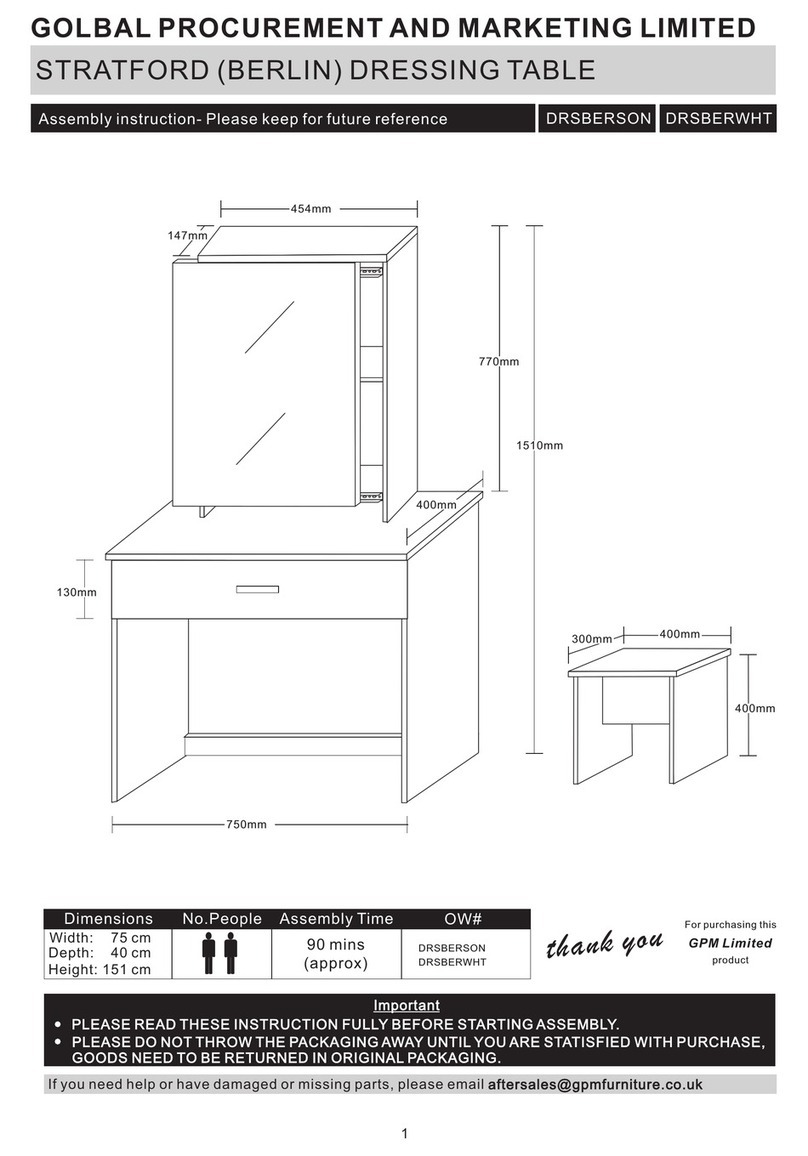

SPECIFICATIONS

Electrical Requirements

... .........120 VAC nominal, 60 Hz, 3 amps maximum

... .........including maximum 2 amp accessory outlet

Fuse rating.................................3 Amp/250V/P/N 100091

Power Cord

................................ Extends 78 in. (Minimum) from table

................3 conductor, 120VAC. With hospital grade plug

Type of protection against electrical shock........... Class 1

Type of protection

against electrical shock ............................ B applied parts

Type of protection against ingress of water……. Ordinary

Can accept paper rolls of..................... 21 in. x 3.5 in. dia.

Certications..................................... UL Classied 60601

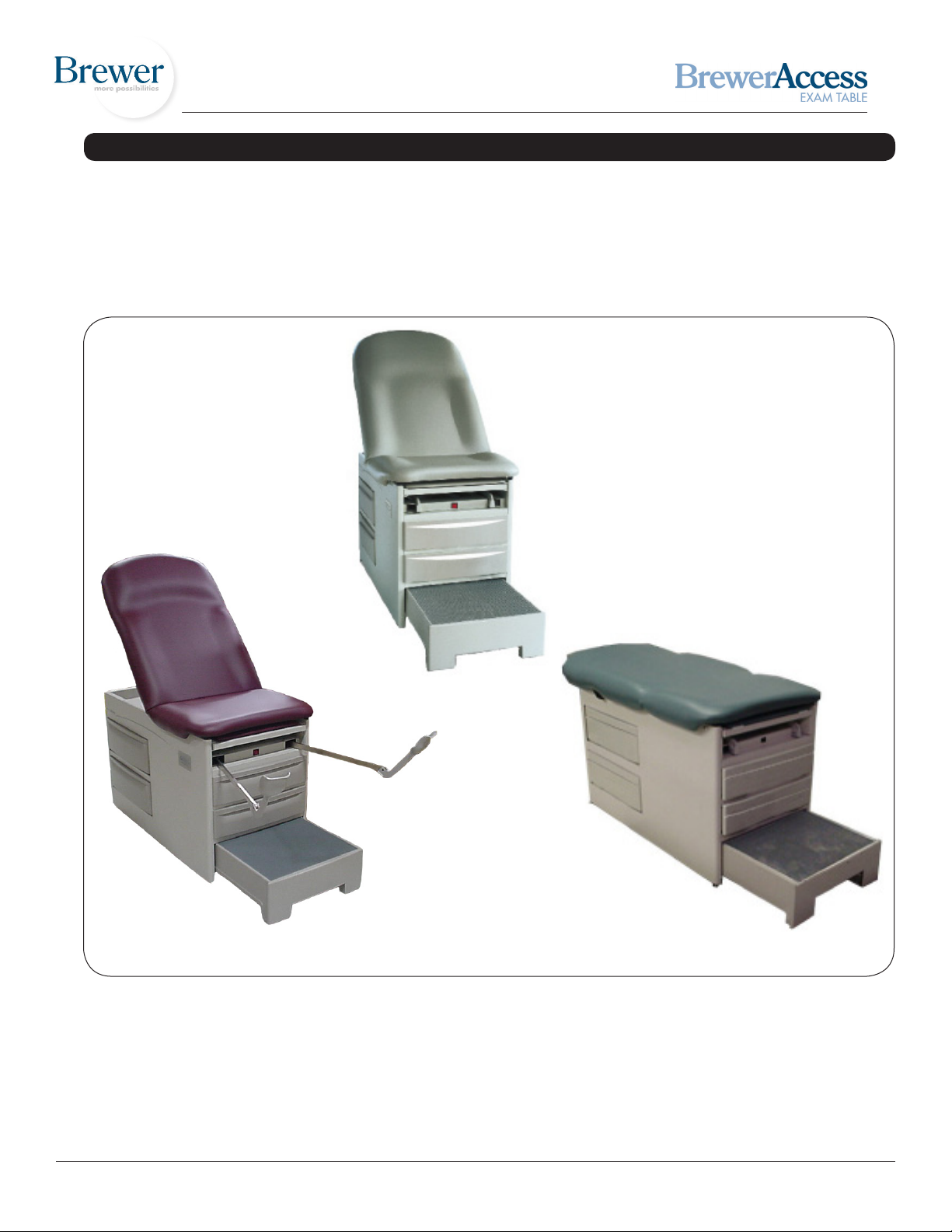

Pelvic Tilt ...............................................................5° Rise

Drawer Warmer ..................120 VAC, 65 watts, 0.5 amps

Weight of Table.....................................................220 lbs.

(With carton and skid)...........................................265 lbs.

Table Weight Capacity..........................................500 lbs.

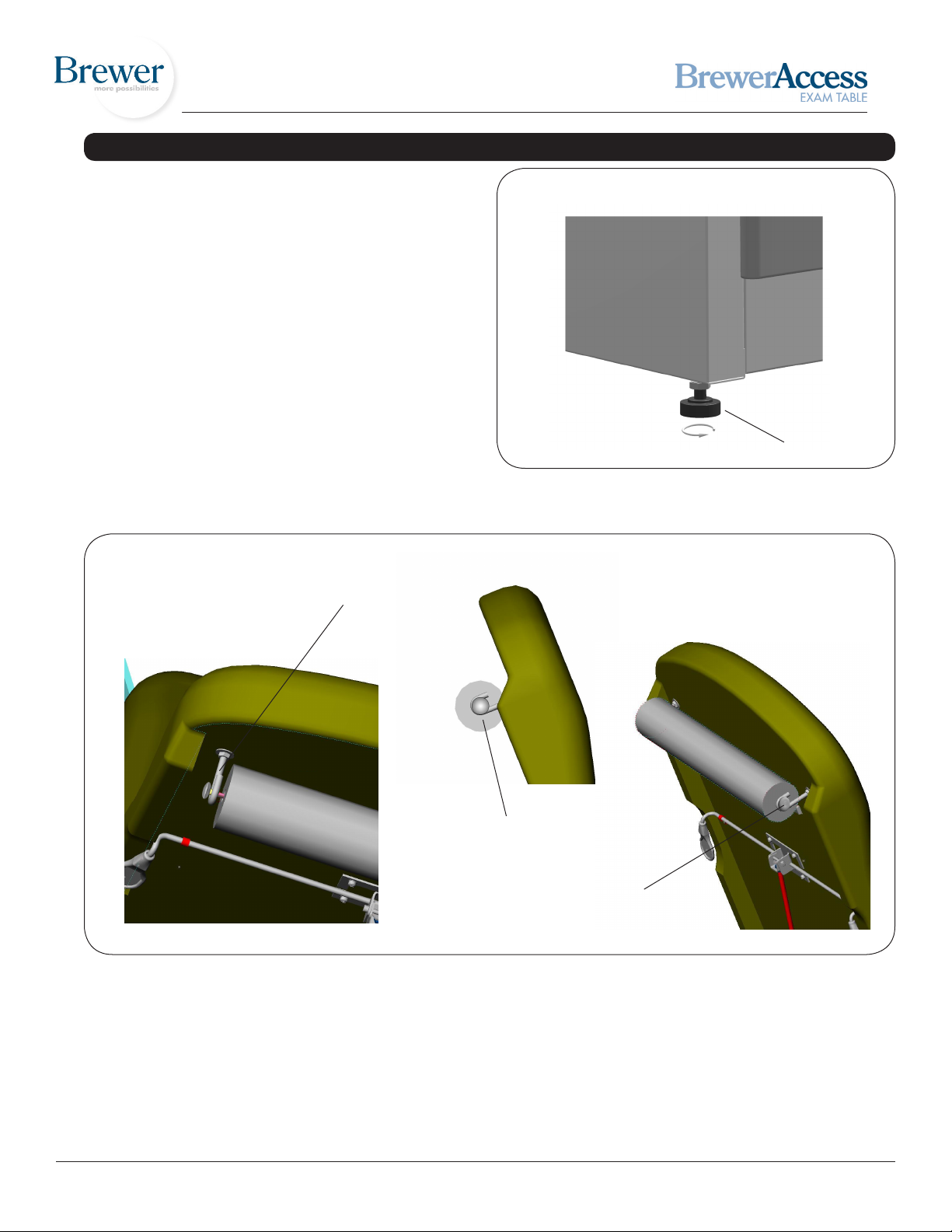

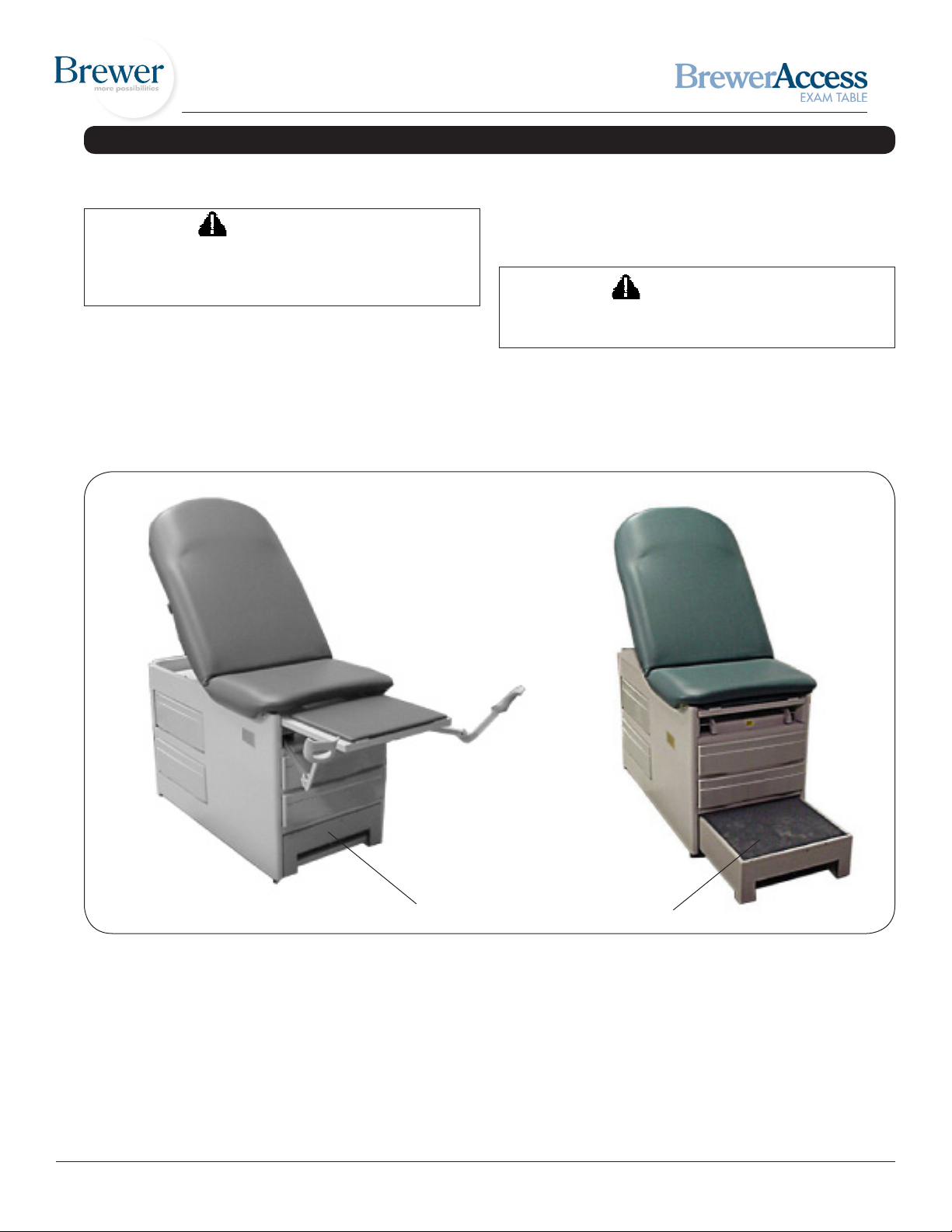

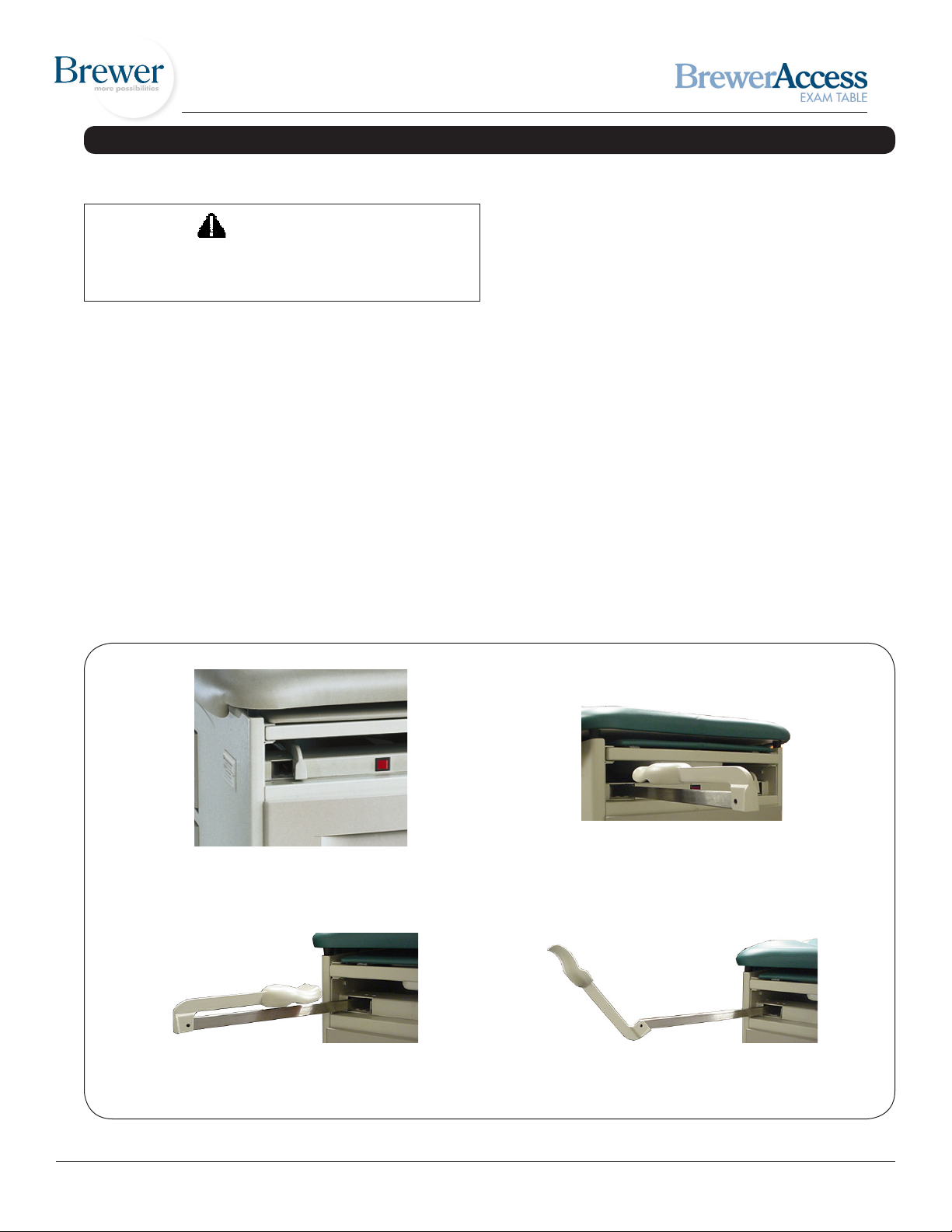

Stirrup Extension (maximum): ................................. 16 in.

Stirrup Lateral Positions ......................4 Lateral Positions

Leg Extension (maximum)....................................... 15 in.

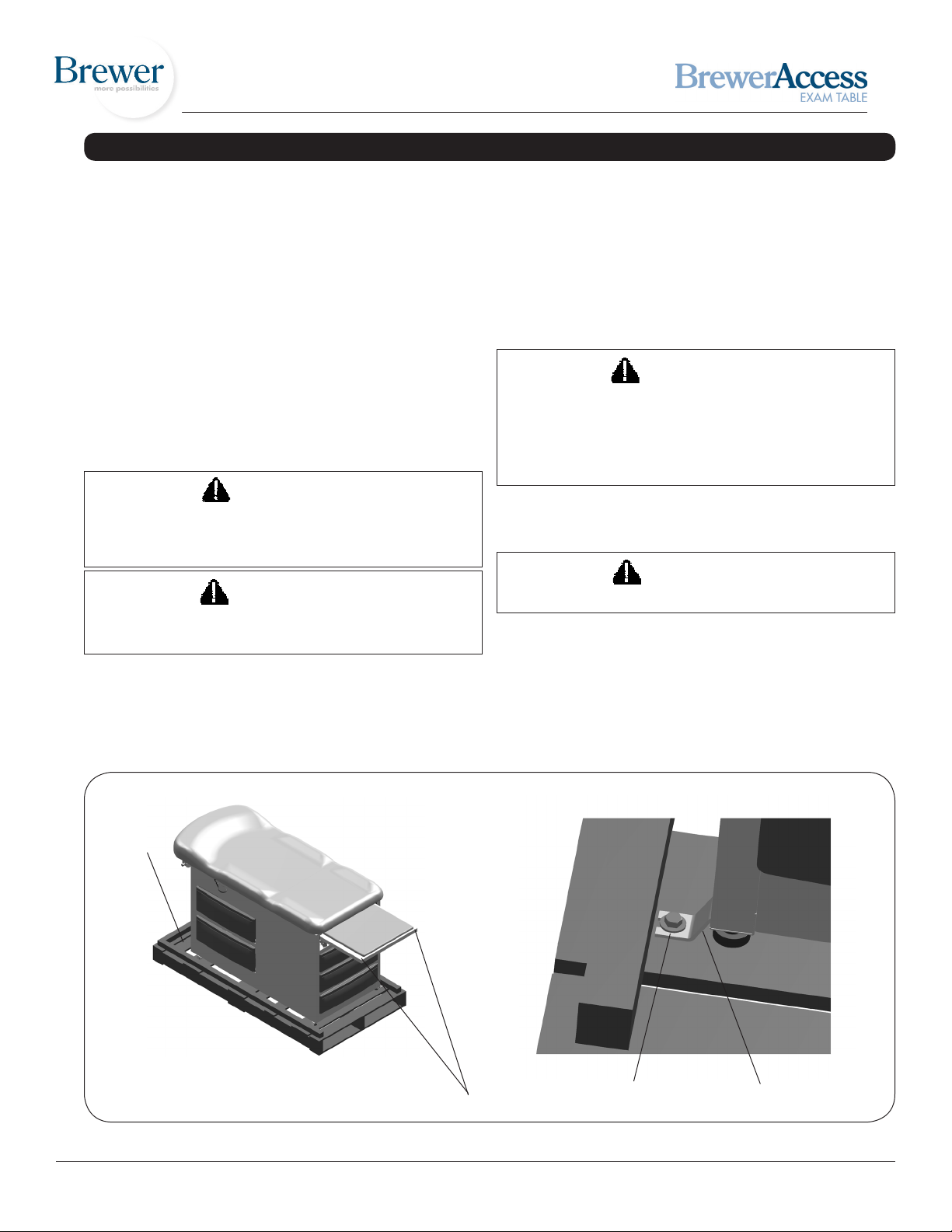

Dimensions:

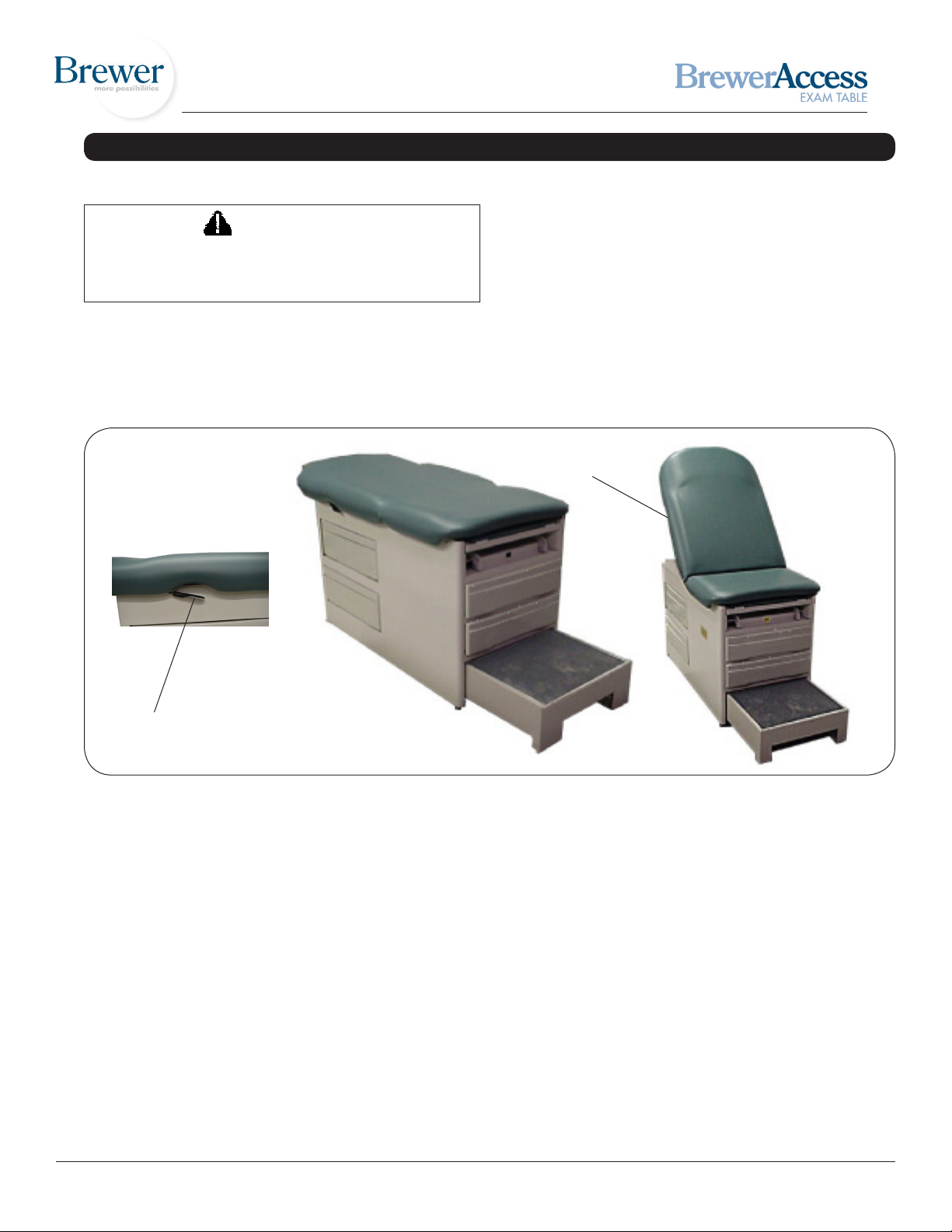

Upholstered Top ....................28.0 in. wide x 57.3 in. long

With Leg Extension Fully

Extended .............................................................. 71.0 in.

Seat Height...........32 in to top of upholstered seat at foot

Step .................. 7.2 in. high x 20.38 in. wide x 11 in. long

Step Capacity .......................................................500 lbs.

Base ............ 28.2 in. high x 23.25 in. wide x 46.0 in. long

Transportation and Storage

Temperature .............................................18°F to 176°F

Humidity......................................................-10% to 90%

Operation

Temperature .............................................50°F to 104°F

Humidity.......................................................30% to 75%

ELECTRICAL REQUIREMENTS

Electromagnetic Interference

This product is designed and built to minimize electromagnetic interference with other devices; however, if interfer-

ence is noticed between another device and this product, remove the interfering device from the room or plug this

product into an isolated circuit.