BREWHA BIAC User manual

BREWHA Equipment Co Ltd. www.brewhaequipment.com

BIAC User Manual

Dear Customer,

We are delighted that you have chosen a BREWHA BIAC for your brewing system! We trust that

it will bring you many fun-lled hours of brewing, and of course, many times spent enjoying the

fruit of your craft with your friends and/or customers.

This manual provides information on installation and setup, and its intent is to have you en-

joying brewing with your BIAC as quickly, safely, and condently as possible—please take the

time to read it carefully. The manual is organized into sections, identied by the numbered (and

colored) tab on the edge of the page to help you nd information easily:

1. red section discusses

safety

2. orange section discusses

installation

3. yellow section discusses

brewing

4. green section has

recipes

5. blue section is for warranty and returns

6. indigo section is

privacy and terms of service

In addition to the information in this manual, the ‘Learn’ section of the website contains lots of

videos and up-to-date information organized into categories at the top of the page, and each

website page contains a search bar that can help you nd what you are looking for quickly.

Sincerely,

BREWHA Equipment Co

1

2

3

4

5

6

WARNING!!

While BREWHA designs its systems with safety in mind, always keep the following in mind:

1. these vessels are not designed to withstand more than 3psi pressure in the 3-in-1

fermenter (14.9psi in the 4-in-1 fermenter) and 5psi in the 3-in-1 fermenter jacket (7psi

in the 4-in-1 jackets). Since municipal water is often supplied at over 60psi, care needs

to be taken when using municipal water to not allow the pressure to exceed the design

allowance. BREWHA will not be held responsible for deformation to the vessels due to

pressure or vacuum (do not let a vacuum occur)

2. the magnetic drive centrifugal pumps we supply are not designed to be ran empty

and should only be ran full of liquid; in addition, the exit should never be fully closed

while running or the pump may overheat and be damaged; damage due to improper

operation is not covered by warranty

3. immersion heating elements are not designed to be heated without water or they

will overheat and could be ruined; during mash, the pump outow (returning wort

from the bottom of the fermenter to the top of the Mash Colander) will very likely need

to be throttled/slowed with a valve (either on the exit port of the pump or the return

port on the Mash Colander), so that the pump does not remove water from around the

elements faster than it is replenished from the Colander above (see recirculation rate

recomendations in the Brewing section of this manual)

4. electrical devices (including the power controller, heating elements, sensors, sole-

noid, pump etc.) can be extremely dangerous and electrical systems need to be handled

with extreme care. Always unplug the devices anytime maintenance is required or the

system is not in use. Some devices such as the Power Controller may have multiple

power sources and all sources should be unplugged before servicing. For added safety,

a GFI/GFCI can be installed on the source power for the brewing equipment and an elec-

trician consulted for all electrical installations

5. contents of brewing vessels and hoses may be hot and/or under pressure so use

extreme caution

6. to reduce any risk of damage or harm, the vessels should only be moved when

empty or secured against tipping or falling; always move with them with caution and

only on smooth, level concrete oors

7. lifting the Mash Colander out can be dangerous so ensure there is a properly engi-

neered lifting device installed, and never operate beneath the Colander when it is sus-

pended.

8. our suppliers provide their own safety information and their manuals should be

read carefully

2

BIAC User Manual Safety

2

BIAC User Manual Safety

1

2

3

4

5

6

Safety Table of Contents

Reducing the risk of a potentially fatal shock by installing a ground fault interrupter

(GFI) ...... 4

Reducing the risk of ruining the electric heating element ....... 5

Installing a pressure relief valve to prevent overpressurizing the vessel and proper

use and installation of relief valve and lter discs ...... 8

Preventing damage to vessel jackets due to overpressurizing ...... 9

Securing sanitary clamps against accidental loosening ...... 10

If you have any questions about how to reduce the risk of harm, do not hesitate to

For additional information on safety consult manufacturer’s manuals, as well as the

‘Safety’ category at the top of the ‘Learn’ page on the website:

https://brewhaequipment.com/blogs/howtobrewbeer/tagged/safety

3

4

BIAC User Manual Safety

Ground Fault Interrupters

BREWHA recommends that brewers consider having a GFCI/GFI (Ground Fault Interrupter) in-

stalled on their power supply.

While most electrical panels will have fuses or breakers, they do not often have a GFI. Breaker

boxes (the electrical panel often found in laundry rooms) will prevent too much overdraw but a

GFI will respond much faster than a breaker or fuse to any deviation in electrical current.

A GFI can be installed in an existing breaker box (if not al-

ready there), or one can be added on the line servicing your

brewing setup. For home brewing systems, GFI panels that

service outdoors spas/hot tubs (240V/40A) are available at

Home Depot, Amazon or other electrical or hardware stores

and at around $200 are relatively inexpensive.

(*Some portable GFIs that are installed in between the Power

Controller and a heating element, do not work with the BRE-

WHA Power Controller on <100% power output as the power

output reduction causes the GFI to trip. It is recommended to

use a wall mounted GFI placed prior to the Power Controller.)

For commercial installations, consult a qualied electrician

for their recommendation on whether a GFI is necessary.

Electric Heating Elements

Immersion water heating elements must always be

completely immersed in water when operated to

ensure that heat is quickly dissipated. If not, the ele-

ment could overheat and melt. Many brewers have

brewed hundreds of batches of beer without a single

failure, but if it does occur, melting a heating element

by ‘dry-ring’ is not a fun experience, not to mention it

could ruin the batch. When they fail, elements some-

times have complete external failure (shown in the

picture to the right) or just fail internally as is often

evidence by a heat discoloration on the element (like

in the photo below). Having a backup replacement

element will come in handy if your element ever fails,

but here are a few suggestions on how to help avoid

failure in the rst place.

The most common period of failure is while recircu-

lating during mashing and/or vorlauf. In the BIAC,

wort from the Mash Colander drains into the fer-

menter and the pump pulls this wort out the bottom

of the fermenter and returns it above the grain in

the Mash Colander. This is useful for vorlauf and

for regulating mash temperature because the wort

can be heated as it exits the Mash Colander, passes

the heating element, and is returned to the top of

the grain bed. It is possible, however, if the pump is

operating too fast, to get ahead of the grain bed ow

rate, and pump all the wort out of the area under the

Mash Colander where the heating element is situat-

ed. This could remove all the water from around the

element and if the element is red at that point, lead to ‘dry ring’ of the element

and burn out. One needs to be most careful in the early stages of the mash before

the grain bed fully uidizes or if the grain crush is particularly ne, preventing good

ow through the grain bed and leading to a ‘stuck mash’. There are a few things

that can be done to help prevent a stuck mash.

First, increase the crush size for your grain by adjusting your roller width (or have

your supplier do it for you). A general width guideline is 0.04-0.048”/1-1.2mm. If you

still have a problem, go slightly wider. If you are experimenting with gelatinous or

4

BIAC User Manual Safety

1

2

3

4

5

6

5

Warning: heating elements must always be completely

immersed in water

gummy cereals (e.g. oats or rye) you can include rice hulls to help counter-act the ‘gummy’ eect

and keep the bed uid. Also, using a good grain mill to crush your grain evenly is important. We

recommend you consider the Crankandstein 328G (fully geared 3-roller mill) and have found the

factory setting (0.045”) to provide a good size for good uidity and conversion.

Second, if doing a single-step mash, if the strike temperature is properly calculated it is not criti-

cal to pump the wort during mash and it can be simpler not to. With the Mash Colander inserted

in the fermenter it is eectively surrounded by a water bath that will help maintain the tempera-

ture. The element keeps the water bath at the target temp for mashing, and warms the colander

which warms the mash. When mashing is almost complete, the pump can be operated to move

the water under the colander to the top of the grain bed for vorlauf. While care still needs to be

taken, during vorlauf it is less likely that your mash will stick or that you will run out of water in

the cone portion of the fermenter where the element is, especially if the next step is followed.

Third, if circulating during the mash, or during vorlauf, if the water level starts to rise in the Col-

ander, it means wort is being pumped out of the bottom faster than it is being replenished and

the pump outow should be slowed (in time, if the ow is not slowed, the element will be ex-

posed and could be damaged). To prevent the pump from moving wort to quickly, a valve must

be installed on the downstream side of the pump (either on the pump outlet or on the Mash Col-

ander port; on larger systems the latter might be an easier location for controlling the ow rate

and liquid level in the Mash Colander) and partially close it to slow the amount of wort moved

out of the bottom. (Don’t close or restrict a valve BEFORE the pump in any way as this ‘starves’

the pump and can damage it.) If grain that has fallen through the Colander plugs the pump line,

open the valve wide momentarily to move the grain into the Mash Colander or attach the pump

intake line to the cone side-racking port, rather than the bottom port of the fermenter (although

if possible it is better for uniform ow through the Colander to keep the pump line connected to

the bottom port).

Fourth, with the Power Controller, power output can be set to around 20-30% during mash

which is typically more than enough to maintain mash temperature, while minimizing the chance

that the element will be ruined if temporarily exposed.

Note 1: Throttling the pump (by partially closing a downstream valve) is also the best way to pre-

vent pump cavitation. Cavitation occurs when the pump is pushing liquid out faster than it can

draw it in. This creates a vacuum which causes a ‘cavity’ to form, which prevents ecient operat-

ing of the pump (a screeching sound from the pump is most often caused by cavitation). When

the ow is throttled back on the exit side by partially closing a valve, it prevents liquid from being

pushed out faster than it can be drawn in, preventing the cavity from forming.

Note 2: When brewing low volume batches, it is also important to be careful that the element is

not exposed during the boil. To ensure that the water level will not drop to the point where the

6

BIAC User Manual Safety

Caution: A ‘squealing’ sound in the pump often indicates a cavity and the pump

should be turned o immediately. See more information in ‘Installation’ section.

6

BIAC User Manual Safety

1

2

3

4

5

6

element is exposed, you need to rst observe/calculate the volume during lling at

which the element is fully covered (approximately 20% of the total volume of the

fermenter). Then add 10-20% volume as a safety buer and have this as your min-

imum water/wort level in the vessel. Then check all your recipes and ensure that

at no point during heating will the volume level ever be below this. And it is always

best practice to never be too far from your equipment on brew day. There have

been reports of customers leaving during the boil to run a few errands and return-

ing to nd their element dry-red and ruined.

Note 3: The same rules apply during fermentation as during mash and boil—keep

the element covered with water at all times. When using the element to keep the

beer warm during fermentation, it is important to keep the power output on the

Power Controller set to less than 3% to ensure that yeast that sticks to the element

does not scorch. This will also likely prevent dry-ring the element as at such low

power output the heat can dissipate. One should, however, still ensure the element

is fully covered at all times.

Note 4: To get the most longevity out of your elements, be sure to clean them

thoroughly after each brew. Once the beer is out of the fermenter, remove the el-

ements and clean them well with a stainless safe scrubber. A at scrub pad can be

fed around the element and moved up and down the element to ensure all sides of

the element are thoroughly cleaned. Cleaning right away before yeast has a chance

to dry on the element is certainly easiest, and removing all yeast/soil from the ele-

ment is the best thing you can do to ensure your element won’t scorch on the next

brew.

7

Use of a pressure and vacuum relief valve to prevent pressure build up

A vacuum breaker and pressure relief valve installed on a fermenter

lid port is a necessary accessory to help insure against damage to

a fermenter (and possible injury) caused by pressure or vacuum. A

vacuum, caused by a cooling of liquid or gas inside the fermenter

can pull the sides in, and pressure building up from expansion or

gas produced during fermentation can push the walls out. In either

situation, the fermenter can be damaged, possibly beyond repair.

The BREWHA Vacuum Breaker and Pressure Relief valve serves to

protect your investment by opening when either 25mmHg of vacu-

um or 3psig of pressure occurs in the 3-in-1 fermenter (14.9psig in

the 4-in-1 fermenters).

When a vacuum builds up, it pulls down on the valve, opening the

valve and letting air into the fermenter. When pressure builds up,

the relief valve is pushed open, letting gas escape. It is important

to note that a safety relief valve should always be used in ADDITION to a blow o hose or air

lock, and never be used as the primary means for release of gas; the reason, is that in the event

where a fermenter was overlled (and/or fermentation too vigorous) krausen (foam) could enter

the opening mechanism and prevent the valve from operating properly and this is more likely to

occur if used for primary gas relief.

8

BIAC User Manual Safety

Warning: Never use the pressure relief valve as primary means of gas relief;

always use a large diameter blow o hose for gas release and the relief valve as

a safety backup

8

BIAC User Manual Safety

1

2

3

4

5

6

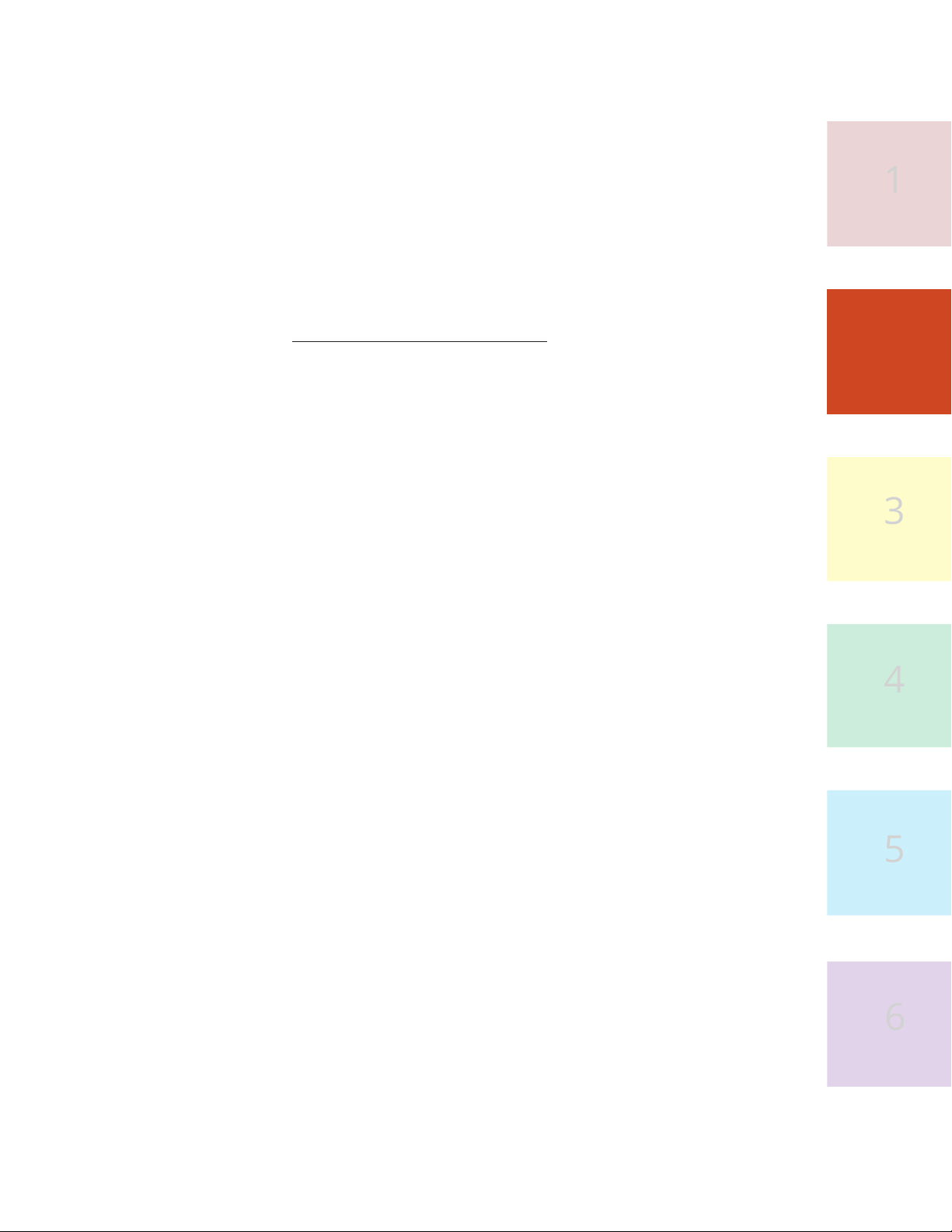

Preventing damage to vessel jackets

Every hose and tank is designed with a maximum allowable working pressure

(MAWP), which if exceeded, will cause damage and could even pose a safety hazard.

The BREWHA tank jackets have been designed to hold up to 5psi of pressure (7psi

in the MB 4-in-1s) which is more than enough pressure to allow adequate ow rates

for chilling wort and maintaining temperature during fermentation.

In many regions, municipal water is a cost-eective source of chillant. Ground, river

or lake water is often delivered at temperatures below what is necessary for pitch-

ing yeast so it provides a much less costly source of chilled water than an electric

chiller is able to provide. (Where municipal water temperature is higher than what

is necessary for yeast, or to conserve water, a combination of municipal water—to

perform the lion’s share of the cooling before switching to electrically chilled wa-

ter—can be a cost-eective way to chill.) Municipal water, however, is often sup-

plied at pressures well above the design tolerance of the BREWHA vessels, so if it

is fed directly into the jacket of a vessel, it could cause pressure inside the jacket to

quickly rise above the maximum limit, damaging the vessel. To ensure that pres-

sure doesn’t rise above the allowable limit when using municipal water (brewery

pumps can provide high pressure water too so caution is needed with them as well)

NEVER throttle or restrict the exit ow from the jacket in any way, and a water pres-

sure regulator should be installed on the feed line, prior to the vessel. The ¼” Watts

560 (which supplies approx 10L/min) or similar regulator can be used for maintain-

ing fermentation temperature, or for chilling post boil in the smaller tanks (up to

1.5BBL). For chilling where a higher volume of chilling water is needed for more rap-

id chilling, such as when chilling wort post boil in the 5 and 7BBL 4-in-1s, a ½” or ¾”

regulator on the brewery water lines could be sourced from a local plumber, and/

or a small plate chiller can be used in addition to the jacket to assist with chilling (a

pump can be used to circulate wort out a side port, through the plate chiller, and

back into the fermenter; run boiling

wort through for a few minutes to

sanitize the plate chiller, pump and

hoses, and clean thoroughly immedi-

ately after use). When installing any

regulator, for proper functioning it is

almost always necessary to ensure

the ow of water through the regula-

tor is in the same direction as indicat-

ed by the arrow on the side.

9

Caution: When installing a Water Pressure Regulator, ensure the ar-

row on the regulator points in the direction of ow or it will not oper-

ate correctly and may cause damage or injury.

10

BIAC User Manual Safety

Securing sanitary clamps against accidental loosening

Caution needs to be taken when loosening the san-

itary clamps to ensure that the correct clamp is be-

ing loosened, or instead of removing a hose tting,

one might remove the entire valve and suddenly

have contents spilling out of the fermenter. It is bad

enough if this occurs at the end of fermentation

and some beer is wasted, but it can be very danger-

ous if this occurs during the boil.

If one is concerned this may happen to

them, the simplest way to ensure an import-

ant clamp is not removed, is by replacing

the wing nut (which is easy to remove quick-

ly by hand) with a standard hex nut which

requires a tool (most nuts on BREWHA

clamps are 5/16” and can be purchased

from most hardware stores but bring one

with you to ensure it ts before purchase).

If all the clamps that should not be loos-

ened until brewing is completed have a hex

nut, and only the clamps that can be safely

loosened without consequence have a wing

nut, the risk of loosening the wrong clamp is

greatly decreased.

10

BIAC User Manual Safety

1

2

3

4

5

6

11

12

BIAC User Manual Installation

12

BIAC User Manual Installation

1

2

3

4

5

6

Installation Table of Contents

Cleaning and sanitizing stainless brewing equipment ...... 14

Assembling the BREWHA BIAC ....... 17

Assembling the Sanitary Ball Valve ...... 26

Installing the Water Heating Element ...... 27

Installing the Brewing Power Controller ...... 29

Programming the BREWHA ETC ...... 34

Installation and Operation of the Water Chiller ...... 38

For additional information on installation and operation select the ‘Installation’ category at the top of

the ‘Learn’ page on the website:

https://brewhaequipment.com/blogs/howtobrewbeer/tagged/installation

For product manuals or for specic instructions for a particular accessory, refer to that product page

on the website, or select the ‘Instruction Manuals’ category at the top of the ‘Learn’ page on the web-

site: brewhaequipment.com

https://brewhaequipment.com/blogs/howtobrewbeer/tagged/instruction-manuals

For information on what other items are needed for your brewery, refer to this page:

https://brewhaequipment.com/pages/what-else-is-needed-for-my-brewery

13

14

BIAC User Manual Installation

Cleaning and sanitizing stainless brewing equipment and preventing rust

One of the very useful features of the BREWHA BIAC is that the fermenter is boiled in which

makes perfect sanitation much easier to achieve—the heat of the boil will sanitize the fermenter

so chemically sanitizing the vessel is not necessary. All that is needed is to clean the fermenter

out well with water and a soft cloth after the beer is removed, disassemble and clean out the

valves and ports, and clean the elements well and it is ready to go for the next batch.

However, when having just purchased a new BREWHA vessel (including the 3-in-1 and 4-in-1)

or if beer stone builds up after several brews, deeper cleaning might be necessary. With a new

vessel it is important to remember that the vessel comes direct to you from the shop where it

is hand-made. This means that there could be a small amount of oil or welding stains on the

vessel and there could be welding material or polish inside the jacket so a thorough cleaning of

your vessel and ushing out of your jacket should be completed before starting to brew. (It is

especially important to clean out your jacket well if you will be using it for providing sparge water

during mashing.)

For keeping your equipment clean we strongly recommend cleaning immediately after brewing

(or with the fermenter, as soon as you transfer beer out) as residue will be much easier to re-

move before it dries. Use a soft cloth or stainless steel safe scrubber and don’t use steel wool

to scrub the pot as this will scratch the mirror polish nish. A non-abrasive scrubber such as a

100% copper scrub brush can be helpful to clean scorched or caramelized sugar o the heating

element. It is also recommended to disassemble the valves when cleaning and wipe out any

visible sediment (heat from the boil will take care of the rest), and take care not to stretch the

silicone lid or valve gaskets as they may deform.

The best sanitizer is heat. If chemical sanitation is necessary or

preferred, we recommend STAR SAN. Since the lid is generally o

during boil, it is benecial to put the lid on the fermenter for the

last few minutes of boil to let the steam heat it up (be careful to

allow steam to escape and that foaming up does not occur), and

to run a little boiling wort through the valves/racking arm and/or

to spray a little Star San on the lid and ports and hoses. Chemicals

only sanitize surfaces so it is important to have items clean.

It is important to note that ‘stainless’ steel is a bit misleading as it

doesn’t mean it will never stain or rust. It should actually be called

‘harder-to-stain’ steel. The following is an interesting excerpt by

General Electric on taking care of stainless steel.

The largest single component of stainless steel is steel. Steel

will rust. The chromium in stainless steel when exposed to oxygen in the atmosphere forms a

thin invisible layer called chromium oxide. This invisible layer covering the entire surface gives

stainless steel its ability to resist stains and rust. If this layer is damaged rust is formed on the

surface at the point of that damage. The good news is, with a little cleaning and care the chro-

14

BIAC User Manual Installation

1

2

3

4

5

6

mium oxide layer is self -healing...

Stainless steel and the chromium oxide layer actually thrive on proper cleaning.

For everyday cleaning of non oxidized soils, dust, dirt and ngerprints, a mild

soap/detergent (dish detergent) and warm water solution should be used. Use

the solution to remove the soil, rinsing with fresh water and a clean cloth, and dry

completely.

To clean spots (cosmetic) from the stainless

we recommend using Bar Keeper’s Friend, and

it also works well to remove rust spots and to

‘heal’ areas that might be open to rust. A period-

ic full vessel cleaning with an acid such as citric

acid or is in Bar Keeper’s Friend can also help

preserve the entire fermentor and is recom-

mended for getting greatest longevity from your

stainless steel.

While stainless is fairly durable, it needs to be

treated with care. Some chemical cleaners can

actually attack and degrade stainless steel. John

Palmer in his book How to Brew provides the

following summary:

For general cleaning, mild detergents or per-

carbonate-based cleaners are best for steel

and aluminum. Bleach should be avoided because the high pH of a bleach solu-

tion can cause corrosion of aluminum and to a lessor degree of stainless steel...

the corrosion inhibitor in stainless steel is the passive oxide layer that protects the

surface. The 300-series alloys (a.k.a. 18-8 alloys) commonly used in the brewing

industry are very corrosion-resistant to most chemicals. Unfortunately, chlorine

is one of the few chemicals to which these steels are not resistant. The chlorine in

bleach acts to destabilize the passive oxide layer on steel, creating corrosion pits.

This type of attack is accelerated by localization and is generally known as crevice

or pitting corrosion.

Many brewers have experienced pinholes in stainless-steel vessels that have been

lled with a bleach-water solution and left to soak for several days. On a micro-

scopic scale, a scratch or crevice from a gasket can present a localized area where

the surface oxide can be destabilized by the chlorine. The chlorides can combine

with the oxygen, both in the water and on the steel surface, to form chlorite ions,

depleting that local area of protection. If the water is not circulating, the crev-

ice becomes a tiny, highly active site relative to the more passive stainless steel

around it and corrodes. The same thing can happen at the liquid surface if the pot

is only half full of bleach solution. A dry stable area above, a less stable but very

15

16

BIAC User Manual Installation

large area below, and the crevice corrosion occurs at the waterline. Usually this type of corro-

sion will manifest as pitting or pinholes because of the accelerating eect of localization.

A third way chlorides can corrode stainless steel is by concentration. This mode is very similar

to the crevice mode described above. By allowing chlorinated water to evaporate and dry on a

steel surface, those chlorides become concentrated and destabilize the surface oxides at that

site. The next time the surface is wetted, the oxides will quickly dissolve, creating a shallow pit.

When the pot is allowed to dry, that pit probably will be one of the last sites to evaporate, caus-

ing chloride concentration again. At some point in the cleaning

life of the pot, that site will become deep enough for crevice

corrosion to take over and the pit to corrode through.

It is best to not use bleach to clean stainless steel and other

metal. There are other cleaners available that work just as well

without danger of corrosion. The percarbonate-based cleaners

like PBW are the best choice for general cleaning.

If you have a particularly tough stain, liked burned malt ex-

tract, then you may need something stronger. There are oxalic

acid based kitchen cleansers available at the grocery store that

are very eective for cleaning stains and deposits from stain-

less. They also work well for copper. One example is Revere

Ware Copper and Stainless Cleanser, another is Bar Keeper’s

Friend, and another is Kleen King Stainless Steel Cleanser. Use

according to the manufacturer’s directions and rinse thorough-

ly with water afterwards.

To clean spots (cosmetic) from the stainless we recommend using Bar Keeper’s Friend, and it

also works well to remove rust spots and to ‘heal’ areas that might be open to rust. For passiv-

ating a larger area, or in areas that are hard to reach (such as between wedge wire or in jackets)

circulating for 30-60 minutes with a 10% citric acid solution (other acids can be used but citric

acid is food safe and readily available) at 65C/150F and letting the area fully air dry for 12 hours

before rinsing is generally all that is needed to mend any damaged areas to help preserve the

fermentor and get the greatest longevity from your stainless steel. Five Star’s Acid Cleaner #5

is also eective for passivating stainless as well as removing stubborn stains and deposits (it is

available at most brewing supply stores).

Additional instructions on care of stainless can be found at the following link to the Specialty

Steel Association of North America’s guide to ‘Care and Cleaning of Stainless Steel’.

A detailed discussion on care of stainless is the Nickel Development Institute’s ‘Cleaning and

Descaling of Stainless Steel’.

16

BIAC User Manual Installation

1

2

3

4

5

6

Assembling the BREWHA BIAC

Assembly of the BIAC is relatively intuitive and straightforward and can be assem-

bled and ready to brew in just a few hours. A brewer may want to substitute or

alter a few parts, which is entirely acceptable, but this description explains how to

assemble it in the typical manner. The BIAC being shown here is the Small version;

larger models are almost identical. The Microbrewery 4-in-1s (MB) are almost iden-

tical to the Homebrewery 3-in-1s (HB) for almost all aspects of the install (special

note will be made where they dier).

1. The BIAC will arrive in two wood-

en crates. The fermenter (3-in-1 fer-

menter with Homebrewery systems

and 4-in-1 fermenter with Micro-

brewery systems) in one crate and

the Mash Colander in the other. Re-

move the screws and withdraw the

vessels. The ttings and accessories

are packaged inside bags inside the

vessels or in separate boxes. Be-

fore emptying the ttings out of the

bags, look at the packing list inside

the bag as it may help you identify

where the ttings from that bag

should be installed.

2. The lift beam (or cable) included with

the complete accessories package can be

used to help remove the vessels from the

crates (the larger vessels have lift lugs for

this purpose). Ensure your hoist or lifting

mechanism is securely installed accord-

ing to manfuacturers instructions and at

no time operate underneath the vessel in

a way that could cause bodily harm if the

hoist fails. The Colander Tipping Cable

(with 1.5-7BBL) that will be used to dump

the mash can be installed. It comes with

the upper end already nished (connect

to hoist trolley) with an hourglass sleeve

and thimble and extra cable on the lower

end. For the lower end, adjust the cable

to the length you need so that when the

Colander is tipped, the bottom will be

above your grain disposal receptacle so

17

18

BIAC User Manual Installation

the spent grain can be easily unloaded. Then cut the

cable and securely fasten the hourglass sleeve once

the thimble is in place.

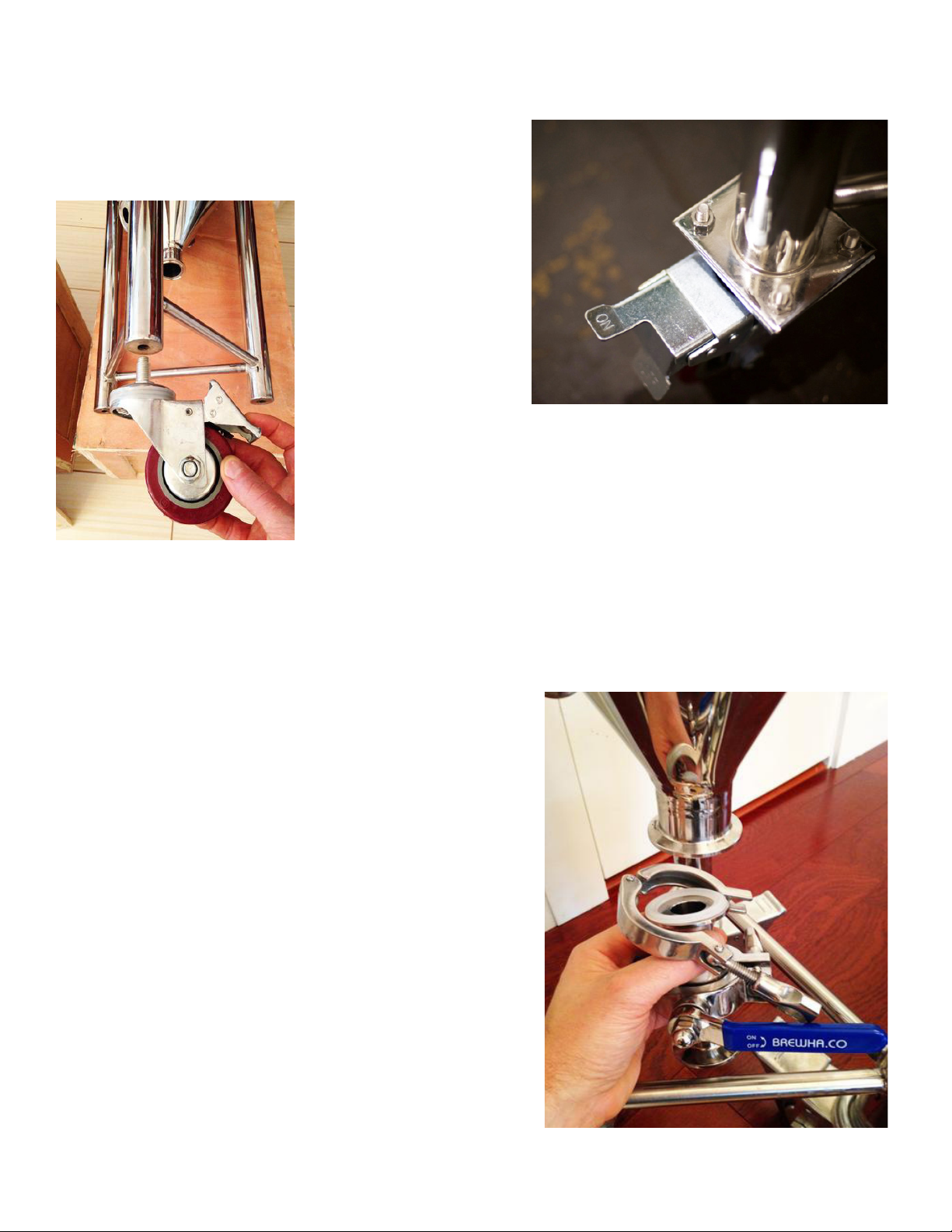

3. The fermenter is

shipped without the

casters installed to pre-

vent damage in transit.

To install the casters

for the smaller fermen-

ters, rst lock the wheel

which will allow the

caster/bolt to be turned

in manually. The cast-

ers on the larger mod-

els attach with four M8 bolts and there are two swivel casters and

two xed casters for each fermenter. The xed casters should be

installed on the side opposite of the fermenter push bar. The bolts

should be installed through the caster plate and fermenter leg plate

with the nut side up, so the bolt does not impede movement of the

swivel caster. Only use the fermenters on a at, smooth surface and use wheel chocks to pre-

vent rolling. To minimize risk of accidental tipping, fermenters should not be moved when full or

moved with extreme care.

3. Attach the rst of the four sanitary valves (ve with the 1.5BBL, 3BBL, 5BBL and 7BBL) to the

bottom port of the fermenter by placing a gasket

between the vessel and the valve and attaching a

clamp; use the large valve (1-3/8” dump) here if you

purchased one with the smaller tanks, or the 2” but-

tery valve with the larger tanks. The valve can be

installed in either direction and it will not aect per-

formance. (With the large dump valve and the Small

fermenter, the handle may need to turn up to fully

open the valve.) During fermentation if using the Yeast

Harvester with the Small BIAC use only the standard

7/8” valve. Tighten the valve clamp manually until it is

snug. Over-tightening (e.g. with a tool) could damage

the silicone gasket. (It is good to ll the fermenter with

water to check for leaks before each brew day. If a

valve is leaking, wiggling the handle while tightening

may help, or the valve may need to be reassembled

to ensure the gaskets are properly seated.) One can

attach a hose barb to the outer side of the valves to

connect your own hose (generally a large hose barb

will go on the bottom port to assist in draining of trub/

18

BIAC User Manual Installation

1

2

3

4

5

6

19

yeast cake from the fermenter). During fer-

mentation, the brewer can dump yeast/trub

out the bottom port when primary fermenta-

tion is ending (after about 3-4 days with ales)

to prevent the yeast ‘cake’ from getting too

hard (be sure to rinse the port thoroughly

with water and sanitizer after every use so

that microbial growth doesn’t occur).

4. There are two sizes (1.5” and 2” or 3”) of

TC ferrules/ports (‘TC’ stands for Tri-clamp

or Tri-clover compatible ttings which are

very common in sanitary applications) on

the cone portion of the fermenter. The 2”

TC ports (3” on 7BBL only) are for heating

elements—one each on the fermenters up

to 90L/24gal, two on the 1.5BBL, four on the

3BBL, six on the 5BBL and ve (3 phase) on

7BBL (see the section later in the manual for instructions on installing the heating

elements). The uppermost 1.5” port on the side of the cone is for the temperature

sensor. The middle 1.5” port on the side of the cone is for a valve (since it sits above

the level that trub/yeast normally settles during fermentation it can be used to

transfer/rack beer to kegs—other ports can be used as well for racking if desired). A

racking arm can be inserted here before the valve; when using such a tting, a tef-

lon gasket will rotate more easily than silicone but is harder to seal. The lower 1.5”

Table of contents