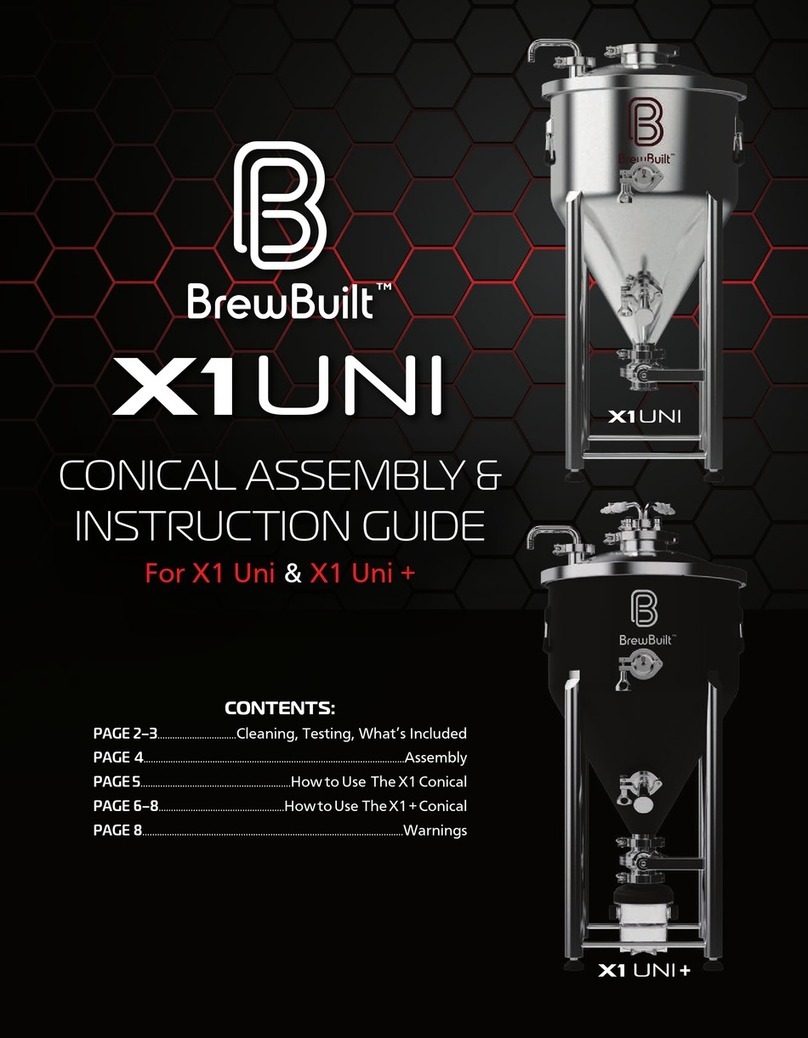

Pressure Package

The Pressure Pack, specically designed

to work with BrewBuilt X1 Conical

Unitanks, unlocks many possibilities.

Apply pressure before cold crashing

to eliminate sucking oxygen back

in. Start carbonating beer when

fermentation is done. Use it to

transfer nished beer to a keg in

a true oxygen-free environment.

With the Clear Float you will

allows being sampling, drinking

or transferring the clearest

possible beer from the top

down! In this guide we will talk

you through installing and

using your Pressure Pack.

CAUTION: Whenever

your X1 conical is under

pressure be aware that you will

need to relieve pressure before

removing any hardware that

is attached to your X1 fermenter.

If you are using a Flex Chamber

collection vessel, make sure the

bottom buttery valve is always in

the open position when in use and

when relieving pressure from the

conical.

INSTALLATION

Assemble the Pressure Pack lid per the

diagram. DO NOT USE TEFLON TAPE to

assemble threaded body connects as they seal with the

included o-rings. When attaching the Pressure Pack lid to

your X1 conical, be sure your tri-clamp gasket is properly

seated and then tighten down the TC clamp.

TIP: There is a welded hook on the bottom of your Pressure Lid. Use this

for hanging drawstring bags full of hops or whatever avoring additions

you want to extract avor from without directly pitching into your beer.

APPLYING PRESSURE

Before applying pressure you will need to replace the

u-shaped blow o with a tri-clamp end cap or tri-clamp

pressure relief valve with gauge. To apply pressure to your

conical, connect the gas-in ball lock QD on your CO2dra

system to the gas-in body connect located on the Pressure

Pack. The gas-in body connect has a notch on the side,

while the beverage-out body connect does not. Keep in

mind that your X1 Uni and Pressure Pack lid are rated at 15

psi and the PRV will start releasing pressure at that point.

We recommend setting the regulator on your CO2tank to

a maximum of 10–12 psi to ensure you do not exceed this

point.

Having head pressure on your X1 helps with dropping out

yeast & trub. However, if you’re using pressure to help

drop out solids, we recommend using no more than 2–4

psi. Prior to cold crashing, you can apply around 5 psi head

pressure to counteract the vacuum formed as the liquid

contracts when the temperature drops signicantly. This

would otherwise cause the tank to suck in oxygen via the

blowo. You also have the option to force carbonate your

beer while it’s still in the tank. Refer to a carbonation chart

to determine the proper pressure.

TRANSFERRING CLEAR BEER TO KEG UNDER

PRESSURE

Push your nished beer into a keg using CO2so it never

becomes exposed to oxygen—it’s simple and fast using

the Pressure Pack. Thanks to the Clear Float stainless steel

oating pick up, you’ll be transferring the clearest beer

from the top down.

Once your beer is ready to be packaged into a keg, follow

these instructions. NOTE: you will need a Corny Keg Ball

Lock Jumper Line (beverage tubing with bev-out ball lock

connectors at both ends).

1. Fill and sanitize a keg. Push the sanitizer out using CO2.

Open the keg pressure relief valve to let CO2exit the

keg.

2. Attach your CO2tank to the gas-in post on your

Pressure Pack lid and set it to around 10–12 psi

3. Attach the Corny Keg Ball Lock Jumper Line to the bev-

out post on your Pressure Pack lid.

4. Once you hook up the bev-out to the keg, beer will

start owing from the pressurized X1 Unitank into the

unpressurized keg.

5. Once your beer has transferred, unhook the bev-out

and gas-in connectors. Pressurize your keg.

6. Be sure to release any pressure from inside your X1

before opening it for cleaning.

FERMENTING UNDER PRESSURE

If you plan to ferment under pressure, you will need the

optional BrewBuilt Pressure Fermentation Hardware Kit.

You will also need to use a no-foam krausen reducer

such as CellarScience® Foam-Axe to eliminate krausen

from entering any of the PRV’s. The optional hardware

kit comes with a commercial-grade pressure relief that

connects to the 1.5” TC port on the lid. It also comes with

an adjustable spunding valve that attaches to the gas-in

body connect on the Pressure Pack lid. The spunding valve

allows you to set a safe pressure to ferment. With the

Pressure Fermentation Kit installed, there are three safety

relief valves: the standard pressure relief valve welded into

the lid, the commercial 1.5" TC relief valve, and the Ball

Lock Spunding Valve.

BREWBUILT.COM