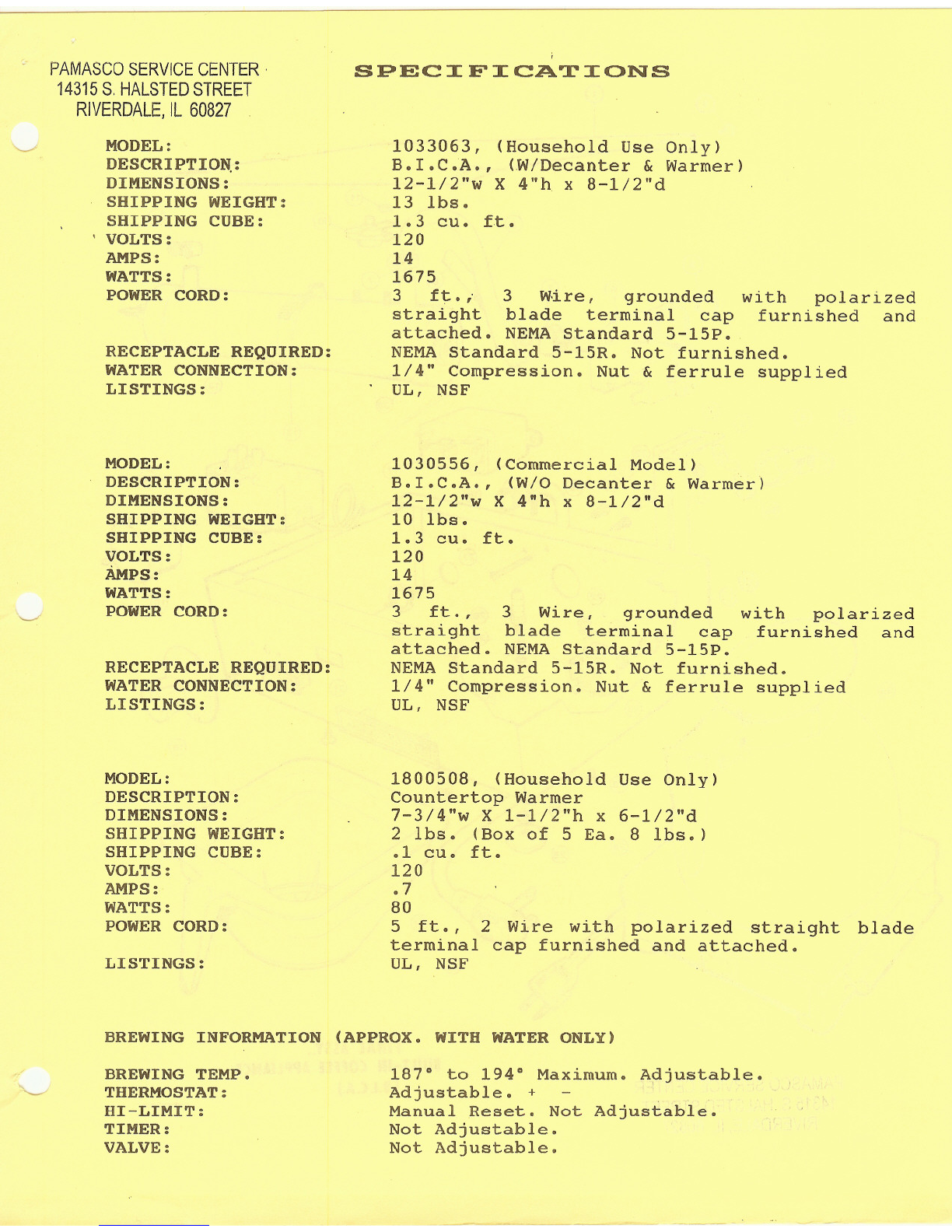

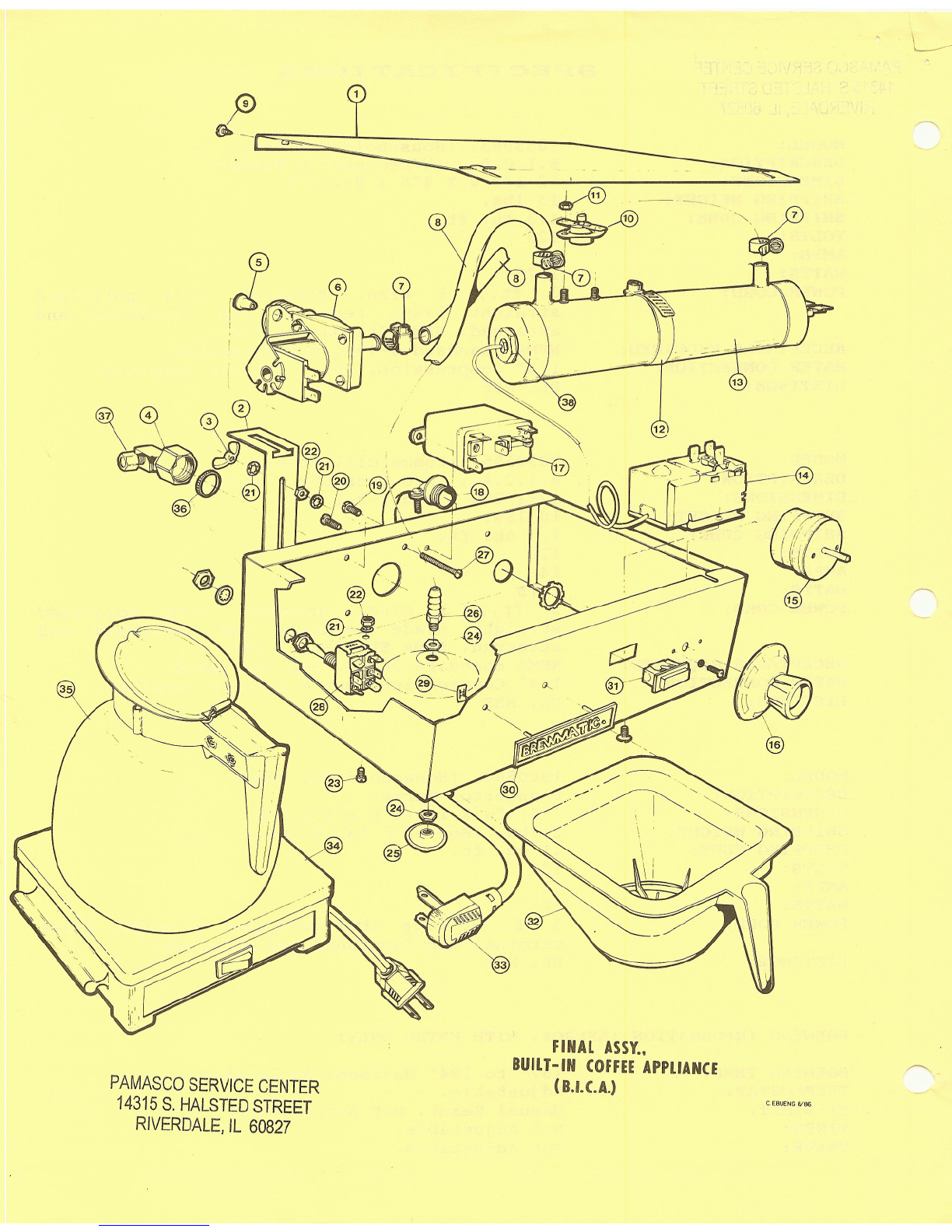

PAMASCO SERVICE CENTER

14315 S. HALSTED STREET

RIVERDALE, IL 60827

BREWMATIC COMPANY

IMPORTANT NOTICE

FOR SERVICE PERSONNEL

1. ONLY BREWMATIC AUTHORIZED REPLACEMENT PARTS SHOULD BE

USED. Part substitutions could create a fire hazard and

the danger of personal injury. Disconnect unit before

servlclng.

2. DO NOT BY-PASS ANY SAFETY MECHANISMS, such as the

automatic temperature limit control with reset button.

Brewmatic Company requires that safety devices be in

place and functioning at all times to guard against a

fire rlsk.

3. when replacing electrical wiring, in part or in whole,

use only like rated terminals and wires of the same

gauge and insulation covering.

4. Any modification or alteration to the unit will result

in voiding the safety listings. Brewmatic Company will

not approve of any unauthorized changes to its basic

design.

5. BREWMATIC COMPANY DOES NOT RECOMMEND, AND WILL

FURNISH ANYONE WITH INFORMATION FOR CHANGING

ELECTRICAL RATING OF ANY EQUIPMENT MANUFACTURED

BREWMATIC COMPANY.

NOT

THE

BY

6. When calling with service questions have model number,

serial number, voltage, wattage, phase and date of

purchase available. Electrical information may be

obtained from the nameplate located on the side, back

or bottom of the unit.

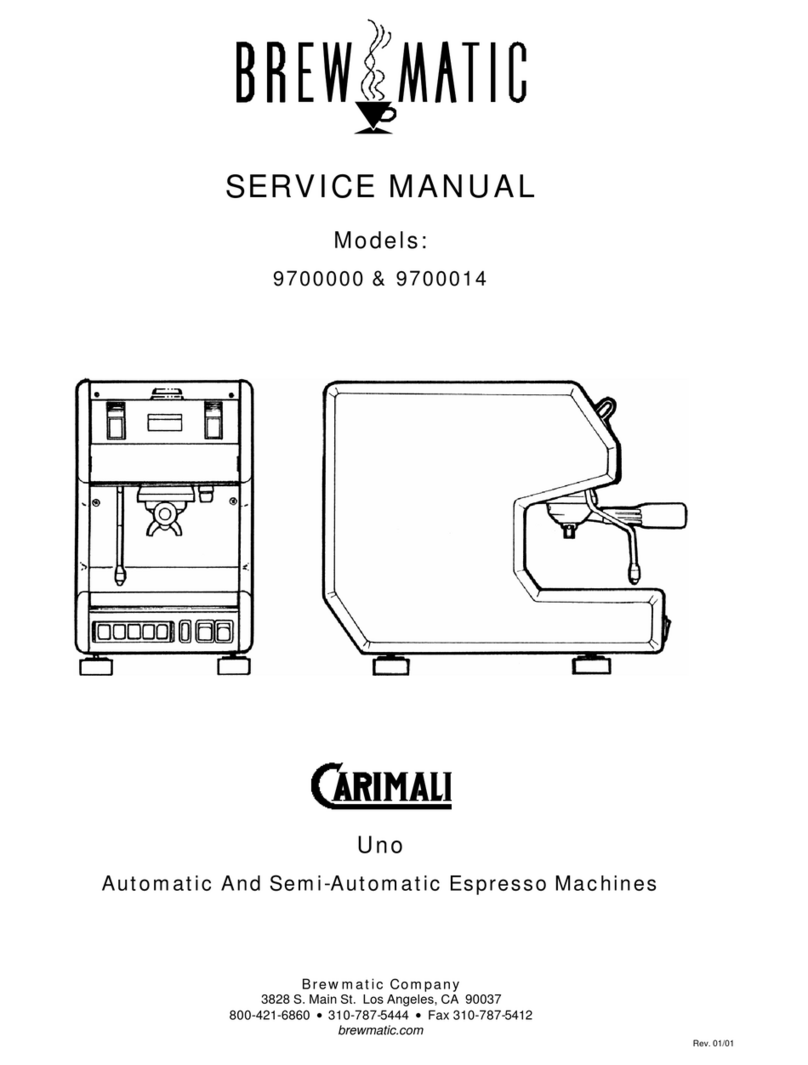

7. This manual is furnished only to qualified service

personnel for the repair of Brewmatic equipment.

Information, parts and specifications are subject to

change without notice.

Qualified service personnel should be acquainted with

all Brewmatic equipment. Service manuals and

information on any unit are available upon request.

Customer Service Department. 213-233-8204 or toll free

800-421-6860.