Bridge BriPower ESA Series User manual

User manual of ESA Series Power Supply

Product features might be changed by software upgrade. Please acquire the

latest version of the manual from our website or contact technical support.

2

www.bripower.cn

About Bridge Technology

Bridge Technology is a company focusing on business of power supplies and

test systems for new energy applications. We are devoted to providing high

quality products and solutions for customers.

Bridge Technology has a top-class R&D team in China, works on

modularization and standardization power supplies and systems. We have

sales, technical support, R&D and manufacture in Shanghai and Nanjing.

Nanjing Bridge New Energy Technology was founded on Jan 12th, 2016,

focusing on R&D and manufacturing BriPower brand power systems, including

bi-directional AC sources for grid simulation, bi-directional DC sources for

battery simulation, and regenerative loads. The BriPower AC&DC power

systems are widely used in new energy and related fields.

Date and Revision

Sep 2019 Revision 1.0

Contact Information

Factory: Nanjing Bridge New Energy Technology Co., Ltd

Sales Company: Shanghai Bridge Electronic Technology Co., Ltd

General information: [email protected]

Technical Support: [email protected]

Repair &Calibration: [email protected]

Int'l Sales: [email protected]

Tel:+86 40010-18618

Web: www.bripower.cn

3

www.bripower.cn

Summary of Safety Requirement

Please review the following safety precautions carefully before putting

the equipment into operation to avoid any personal injury or damage to

the equipment and any product connected to it. To prevent potential

hazards, please follow the instructions specified in this manual to use

the instrument properly.

Use Proper Cables

Please choose the proper specification cable according to the equipment

specification within the local country could be used.

Ground the Equipment

The equipment is grounded through the Protective Earth Bus. To avoid electric

shock, connect the earth terminal to the Protective Earth terminal before

connecting any input or output terminals.

Use Proper Overvoltage Protection

Ensure that no overvoltage (such as that caused by a bolt of lightning) can

reach the product. Otherwise, the operator might be exposed to the danger of

an electric shock.

Avoid Circuit or Wire Exposure

Do not touch exposed junctions and components when the module is powered

on.

Keep Equipment Surfaces Clean and Dry

To avoid dust or moisture from affecting the performance of the equipment,

keep the surfaces of the equipment clean and dry.

4

www.bripower.cn

Safety Notices and Symbols

Safety Notices in this Manual:

WARNING

Indicates a potentially hazardous situation or practice which, if not

avoided, will result in serious injury or death.

CAUTION

Indicates a potentially hazardous situation or practice which, if not

avoided, could result in damage to the product or loss of important

data.

Safety Terms in this Manual:

Safety Symbols on the Product or in this Manual:

Hazardous Voltage Safety Warning Protective Earth Terminal

Test Ground Chassis Ground

It calls attention to an operation, if not correctly performed, could

result in injury or hazard immediately.

It calls attention to an operation, if not correctly performed, could

result in potential injury or hazard.

It calls attention to an operation, if not correctly performed, could

result in damage to the product or other devices connected to the

product.

DANGER

WARNING

CAUTION

5

www.bripower.cn

Important Safety Instructions

Please read this manual thoroughly before putting the equipment into

operation. Pay regard to the following safety instructions and keep this

manual nearby for future purpose.

INITIAL OPERATION

This operating manual is based on the state of technology at the time of

printing. However, it is possible that despite regular control and correction, the

present document contains printing errors or deficiencies. Nanjing Bridge New

Energy Technology Co.,Ltd assumes no liability for any technical, printing or

translational errors within this manual.

UNPACKING

Please make sure that the shipping carton and the packaging is free of

damage. If external damage is found, it is important to record the type of

damage. Please keep the original packaging to ensure the device is

adequately protected in case it needs to be transported in the future or claims

for compensation need to be asserted.

SETTING UP

To avoid electric shocks and product failure, the device should be installed in a

temperature and humidity controlled indoor environment. The ambient

temperature must not exceed 40℃. The device must never be exposed to

liquids or extreme humidity.

VISUAL INSPECTION

The unit must be examined immediately for defects or damages in transit.

Damage caused during transport may be loose or broken control knobs and

bent or broken connectors. Do not use the device if any physical damage is

apparent. Please inform the carriers and a representative of Bridge

Technology immediately.

6

www.bripower.cn

MAINS OPERATION

Make sure to verify the model number and voltage stated on the nameplate.

Damages due to wrong power feed are not covered by guarantee conditions.

CAUTION

The unit must only be operated when connected directly to the mains.

To avoid damage, do not connect the unit to isolating transformers,

autotransformers, magnetic current limiters or similar devices.

INTENDED USE

The device corresponds to protection class I and has a galvanic isolation

between the input and the output circuit. The device must be grounded on the

input side, since the grounding ensures protection against contact. In the case

of locally variable devices, the earth is connected to the device by means of a

cold-plug connector, and the ground is connected to the screw terminal

provided for locally-variable devices (screw contacts at the grid input). In the

case of devices with high leakage current (marking on the device), the existing

grounding bolt must additionally be connected to the domestic installation

earth. For compliance with the EMC and safety regulations (CE, approvals),

the device may only be operated with PE connected. The device may only be

operated by trained personnel and in accordance with the instructions for use.

Typical fields of application are laboratories, industry and service engineering.

Applications which can lead to injuries or death in the event of a fault in the

device are not permitted.

7

www.bripower.cn

ESA Series Overview

Main Features

➢Single system from 30kVA to 500kVA and parallel up to 4MVA and above

➢Independent three-phase output

➢Voltage and frequency sequencing programming via GUI, slew rate can be

programmed

➢ON and OFF output phase angle can be programmed

➢Current limit can be programmed, output can be shorted for short circuit

test

➢Triger out, TTL signal output for voltage or frequency change

➢LAN/RS485/analog interfaces (standard), RS232 interface (optional)

➢4 quadrant operation, regenerative up to 100% of rated output power back

to grid (-R option)

➢Up to 40th harmonic waveform generation

➢Voltage drop simulation (LVRT for inverter test)

➢RLC load simulation (-RLC option)

➢Regenerative AC load (-LD option)

➢TFT-Touch panel operation

➢Mod-bus/SCPI protocols

➢CE conformity

➢Customized voltage, current and power ranges

➢Emergency stop button

➢Switchable insulation monitoring

➢Output contactor

➢Remote sense

8

www.bripower.cn

Document Overview

Chapter 1 Quick Start

Introduce the appearance, front panel, rear panel user interface as well as

internal structure of power source. In addition, it provides the detailed

procedures of power connection, power-on/off inspection.

Chapter 2 GUI Control Software

Introduce the function and operation method of product’s control software in

detail.

Chapter 3 Remote Control

Introduce how to realize the remote control of the equipment.

Appendix A — Specification of ESA Series Power Supply

List the specifications of ESA series power supply.

9

www.bripower.cn

Contents

Chapter 1 Quick Start ...................................................................................................10

1.1 General Inspection ...............................................................................................11

1.1.1 Inspect the packing ....................................................................................11

1.1.2 Inspect the product.....................................................................................11

1.1.3 Check the accessories...............................................................................11

1.2 Appearance and outline........................................................................................11

1.3 Front Panel ...........................................................................................................12

1.3.1 LCD ............................................................................................................12

1.3.2 Indicator of Status ......................................................................................13

1.3.3 Emergency Stop Button .............................................................................13

The emergency stop button is only used when an unexpected emergency occurs.

Do not press this button in normal working condition.........................................13

1.4 Rear Panel............................................................................................................13

1.5 Internal Structure..................................................................................................14

1.6 Connect to Power.................................................................................................15

1.6.1 Check the input power ...............................................................................15

1.6.2 Check the fuse ...........................................................................................15

1.6.3 Cable selection...........................................................................................15

1.6.4 Connect the AC power ...............................................................................15

1.7 Power on Inspection.............................................................................................17

1.7.1 AC Input power on......................................................................................17

1.7.2 Control module power on...........................................................................17

1.8 User Interface.......................................................................................................19

Chapter 2 Control Software .........................................................................................20

2.1 Setting...................................................................................................................21

2.1.1 Communication parameters.......................................................................21

2.1.2 Protection parameters................................................................................22

2.1.3 Line impedance parameters ......................................................................23

2.1.4 Administrator account.................................................................................24

2.2 Comprehensive Test.............................................................................................24

2.3 Island Test.............................................................................................................26

2.4 Measurement Parameter Monitoring....................................................................27

2.5 Wave Monitoring...................................................................................................29

2.6 Fault Monitoring....................................................................................................30

Chapter 3 Remote Control ...........................................................................................32

3.1 Computer Setting..................................................................................................33

3.2 Software Setting ...................................................................................................34

3.3 Remote Control ....................................................................................................34

Appendix A — Specification of ESA Series ..................................................................35

10

www.bripower.cn

Chapter 1 Quick Start

The contents of this chapter are as follows:

1.1 General Inspection

1.2 Appearance and Outline

1.3 Front Panel

1.4 Rear Panel

1.5 Internal Structure

1.6 Connect to Power

1.7 Power-on/off Inspection

1.8 User Interface

11

www.bripower.cn

1.1 General Inspection

1.1.1 Inspect the packing

If the packaging has been damaged, do not dispose the damaged packaging

or cushioning materials until the shipment has been checked for completeness

and has passed both electrical and mechanical inspection.

The consigner or carrier shall be liable for the damage to the product resulting

from shipment. Factory would not be responsible for free maintenance/rework

or replacement of the product.

1.1.2 Inspect the product

In case of any mechanical damage, missing parts, or failure in passing the

electrical and mechanical tests, contact your local sales representative.

1.1.3 Check the accessories

Please check the accessories according to the packing lists. If the accessories

are damaged or incomplete, please contact your local sales representative.

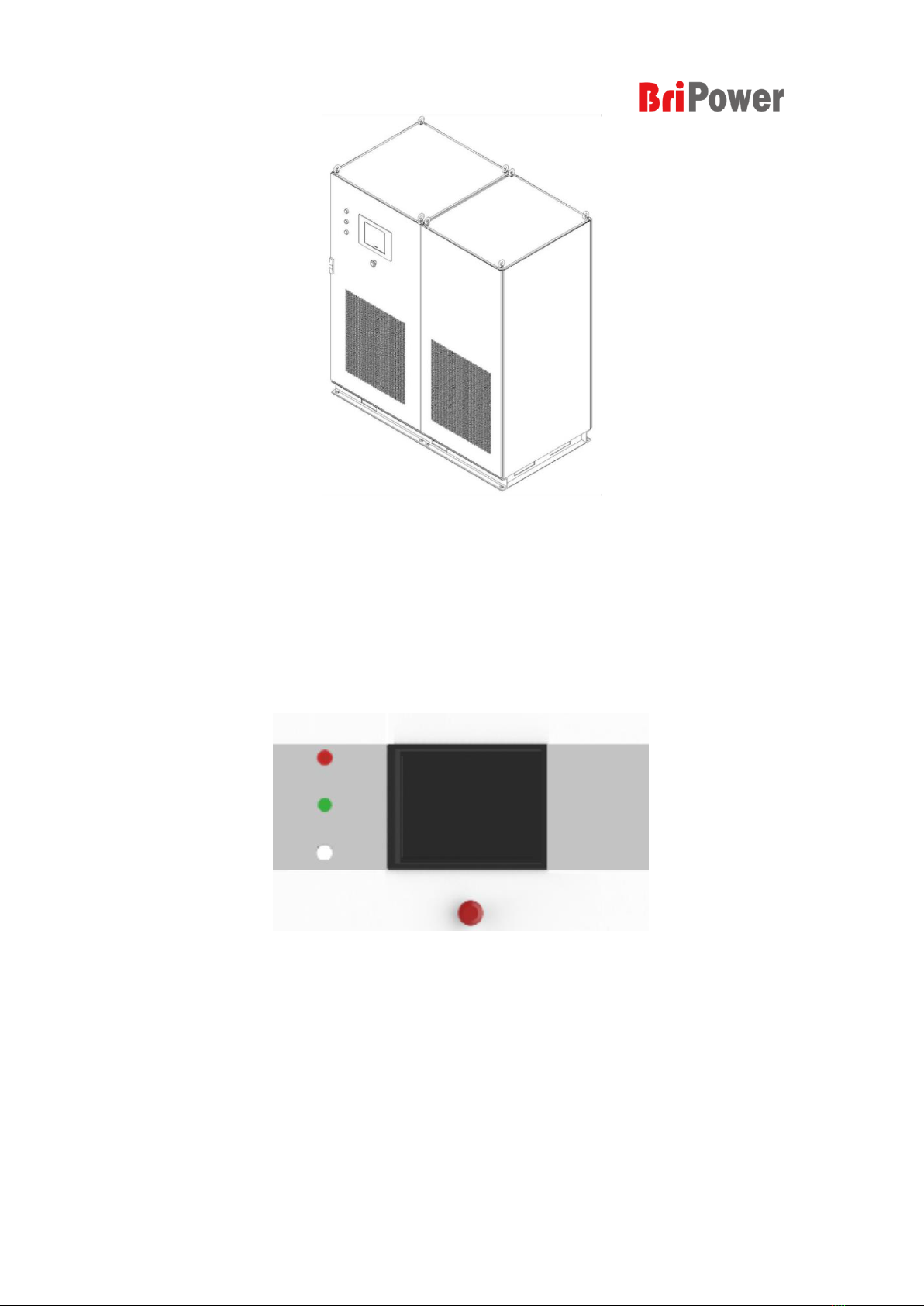

1.2 Appearance and outline

The equipment adopts integrated module design, the appearance is simple

and generous.

The overall appearance of the equipment is shown in Figure 1-1. The cabinet

is equipped with casters, which makes it easier to move. There are a 10-inch

touch screen, status indicators and an emergency stop button on the front

panel. The rear panel is composed of a communication port and a line voltage

drop compensation terminal.

12

www.bripower.cn

Figure1-1 Appearance of the equipment

1.3 Front Panel

This section introduces the front panel of ESA series power source. The

differences of models are introduced separately.

Firgure1-2 Front panel of ESA series

1.3.1 LCD

10 inches TFT display. It is used to display the system parameter setting,

system output state, menu items, prompt messages, etc. The touch displayer

panel is a capacitive touch TFT screen, and is based on Windows operating

system. GUI Control software is designed on the platform of LabView.

13

www.bripower.cn

1.3.2 Indicator of Status

Lights indicate the working state of the power source in a concise manner. It

includes indicator of standby mode, indicator of running and fault indicator.

Red

There is a system error.

Green

System is running normally.

White

System is standby.

1.3.3 Emergency Stop Button

The emergency stop button is only used when an unexpected emergency

occurs. Do not press this button in normal working condition.

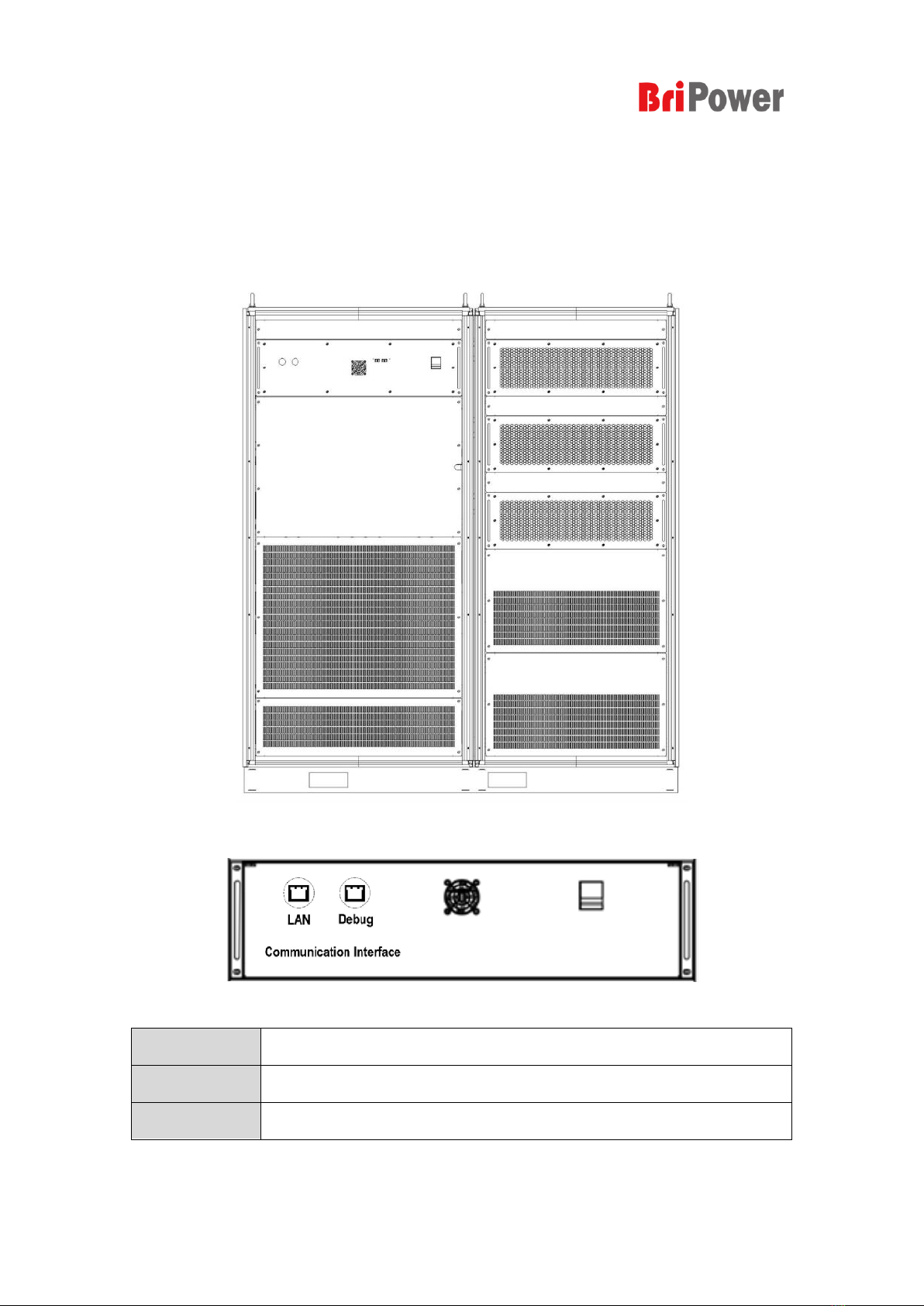

1.4 Rear Panel

This section introduces the rear panel of ESA series power source. The

introduction of each part is shown in the following table.

Figure1-3 Rear Panel of ESA Series

LAN

This interface is a communication interface used for remote control.

Debug

The Debug port is reserved for firmware update or debug.

External Sense

Terminal of voltage compensation for long distance.

The output voltages at the load can be directly monitored via the external

sense on the back of the power source, which is usually for long distance

power transfer.

14

www.bripower.cn

1.5 Internal Structure

As shown in Figure 1-4, the left cabinet consists of control module, input circuit

breaker, capacitor output filter, pre-charging resistor and transformer; the right

cabinet consists of power module and output reactor components, etc.

Firgure1-4 Internal Structure

Firgure1-5 Control Module

LAN

This interface is a communication interface used for remote control

Debug

The Debug port is reserved for firmware update or debug

Power Switch

This switch is used to power on the control module.

15

www.bripower.cn

1.6 Connect to Power

ESA series power source supports the world grid standards, but a particular

product supports the GRID SYSTEM only for one country or region. Before the

power supply is used, it is necessary to verify that the product specifications

are consistent with the Local GRID. And please connect the power following

the steps below.

1.6.1 Check the input power

Make sure that specifications of the power source are consistent with the local

GRID, such as voltage and frequency.

1.6.2 Check the fuse

When the product leaves factory, the specified fuse is installed. Please check

whether the fuse matches the actual input voltage according to the "Input

Power Requirements" at the rear panel of the product.

1.6.3 Cable selection

The user should select the appropriate cable and cold-pressed terminal

according to the equipment's input/output voltage level and current, and crimp

the grid side AC input cable and the AC output cable.

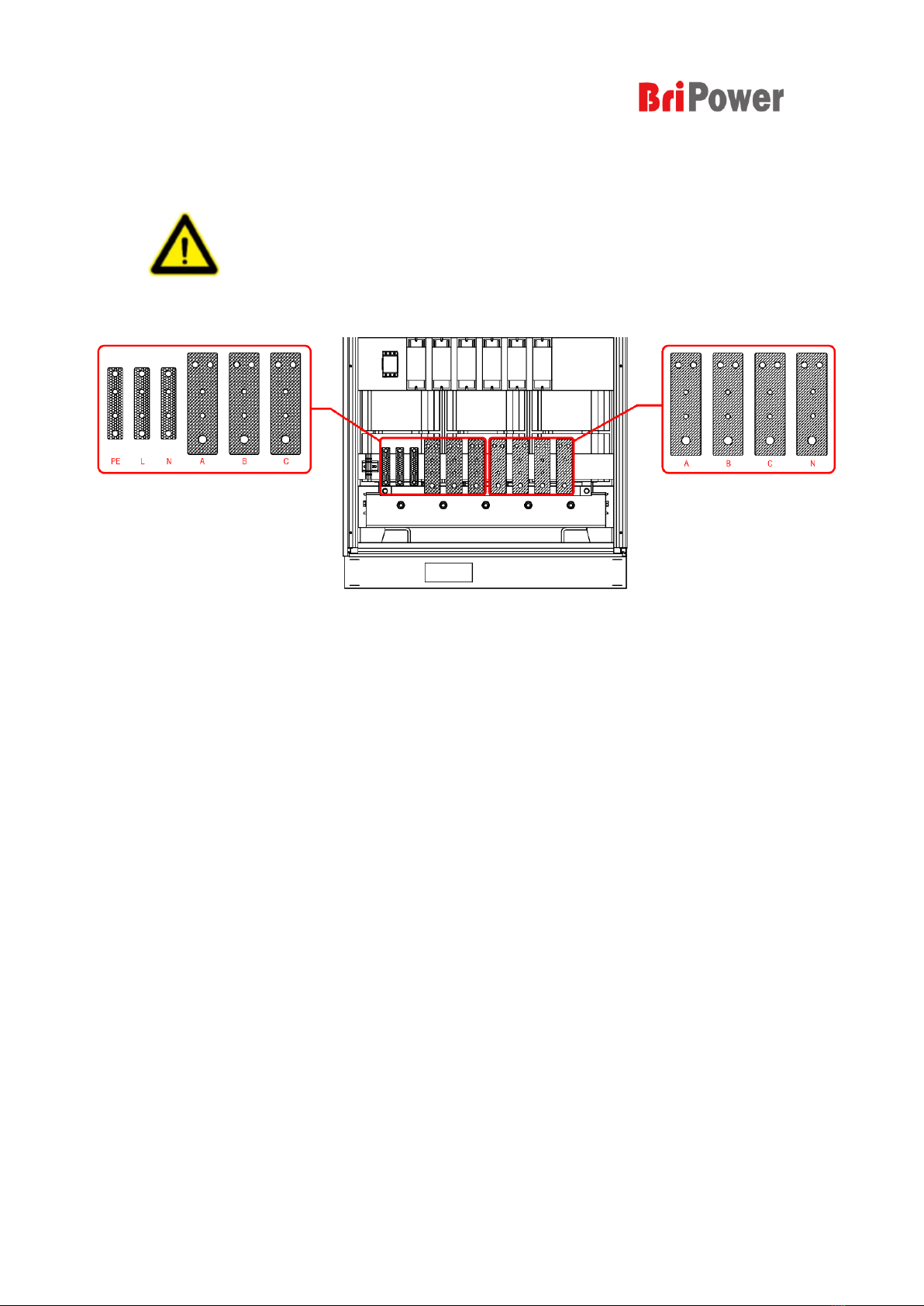

1.6.4 Connect the AC power

Connect the power source to AC power supply with proper specification cable

according to the product specification within the local country could be used.

Wiring methods refer to the following steps.

A. Remove the bottom baffle after opening the front cabinet door. The user

can access the grid side incoming line, earthing protection wire PE, the

16

www.bripower.cn

positive and negative poles on the DC side into the cabinet through the

threading holes at the bottom of the cabinet (marked in red in Figure 1-6),

and reliably connect with the terminal/wire copper bar.

Figure1-6 Holes for cables Figure1-7 The wiring copper bar

B. Lay the PE cable from the cable hole at the bottom of the cabinet and

reliably connect with the connection copper bar shown in Figure 1-7, and

ensure both side of PE cable are well grounded. The grounding terminals

are connected with the main components, and the users should connect

them with the earth through suitable cables before putting them into use.

C. The AC incoming line (L1/L2/L3/N) and the positive and negative

terminals/copper bar on the DC side are shown in figure 1-8. After the

cables are threaded through the holes at the bottom, it is connected to the

terminal block/wiring copper bar. After the connection is completed, the

phase sequence and connection reliability should be carefully checked to

Warning

For safety reasons, the grounding protection PE must be

connected reliably.

17

www.bripower.cn

ensure that the phase sequence is correct, the connection is reliable, and

the identification is clear to facilitate maintenance and repair in the future.

Figure 1-8

Connection terminals

1.7 Power on Inspection

1.7.1 AC Input power on

After the cable connection is completed, the circuit breaker on the grid side

could be turned on (as shown in Figure 1-9). It should be noted that the input

connection is 3P+N, and the correct phase sequence must be confirmed.

1.7.2 Control module power on

After power-on for grid side, open the cabinet door, close the power switch of

the control module shown in Figure 1-10 (②), then the control unit starts to

work. After completing these operations, close the cabinet door, and the power

supply will enter standby state.

Warning

Before connecting the cable, make sure that the upper switch is in

the off state. Live work is strictly prohibited. At the same time,

ensure that a reliable protective grounding has been made.

18

www.bripower.cn

Figure1-9 Connection of Mains and DUT

配电网

断路器

2

1

Figure 1-10 Power on the Control module

19

www.bripower.cn

1.8 User Interface

The GUI software is installed in the touch panel, which is in fact a computer

with Microsoft Windows. The software can also be installed in control PC

connected to power supply. The GUI software provides functions including

output settings, island test settings, protection parameter settings, waveform

display, measurement display and faults display.

Also, the power source can be controlled in local and remote style. Both of

which have same interface and operation. The modes will be described in

Chapter 2.

While the Power knob is turn on, it takes several seconds to initialize the

controller and other units. Make sure that the power’s output connection

terminals are correctly connected. Then, All the functions and parameters can

be set and run via touch panel displayer or GUI software.

20

www.bripower.cn

Chapter 2 Control Software

The contents of this chapter are as follows:

2.1 Setting

2.2 Comprehensive Test

2.3 Island Test

2.4 Measurement Parameter Monitoring

2.5 Wave Monitoring

2.6 Fault Monitoring

Other manuals for BriPower ESA Series

1

Table of contents

Other Bridge Power Supply manuals

Popular Power Supply manuals by other brands

MSA

MSA UNICONT PS-203-40 operating manual

Chauvin Arnoux

Chauvin Arnoux PA30W user manual

Extron electronics

Extron electronics P/S 150 user guide

TDK-Lambda

TDK-Lambda HWS ME Series instruction manual

Raycap

Raycap PowerPlus System 100-3-1U Series Installation instructions operations manual

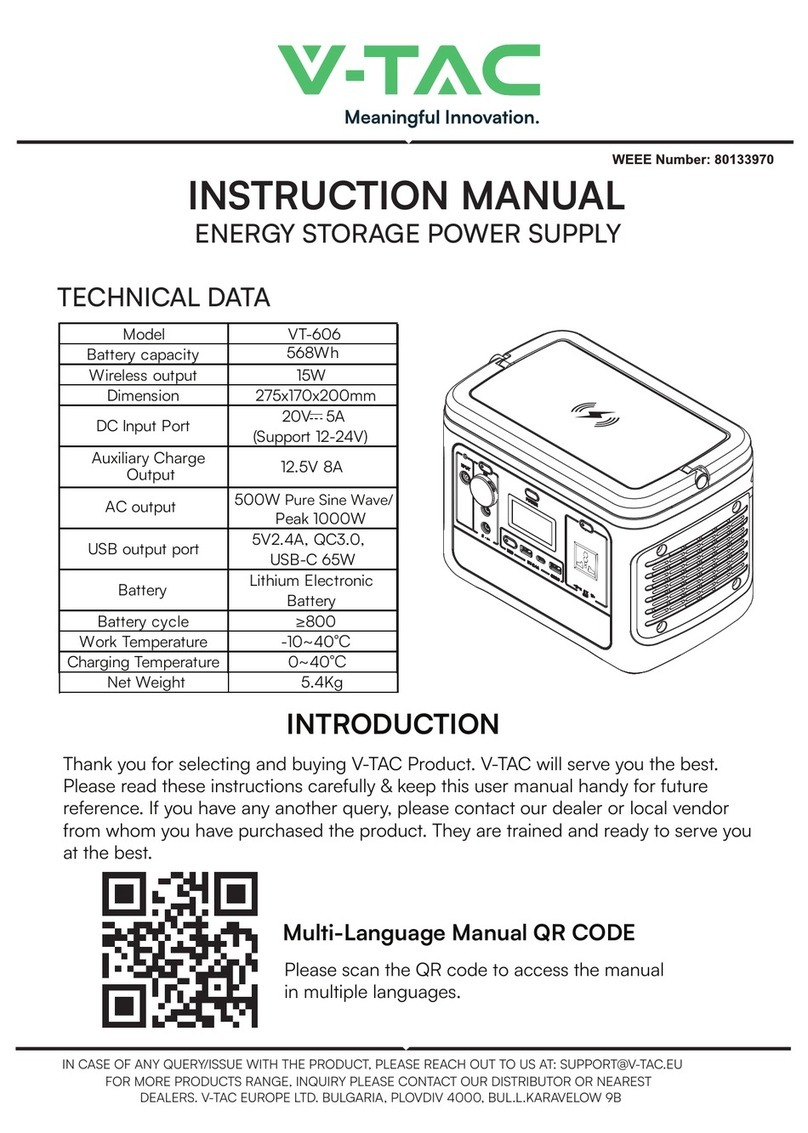

V-TAC

V-TAC VT-606 instruction manual