Version 1.0 Page 2

Table of contents

INTRODUCTION.........................................................................................................................3

1DESCRIPTION AND OPERATION OF THE PRODUCT...............................................4

1.1 Description............................................................................................................................4

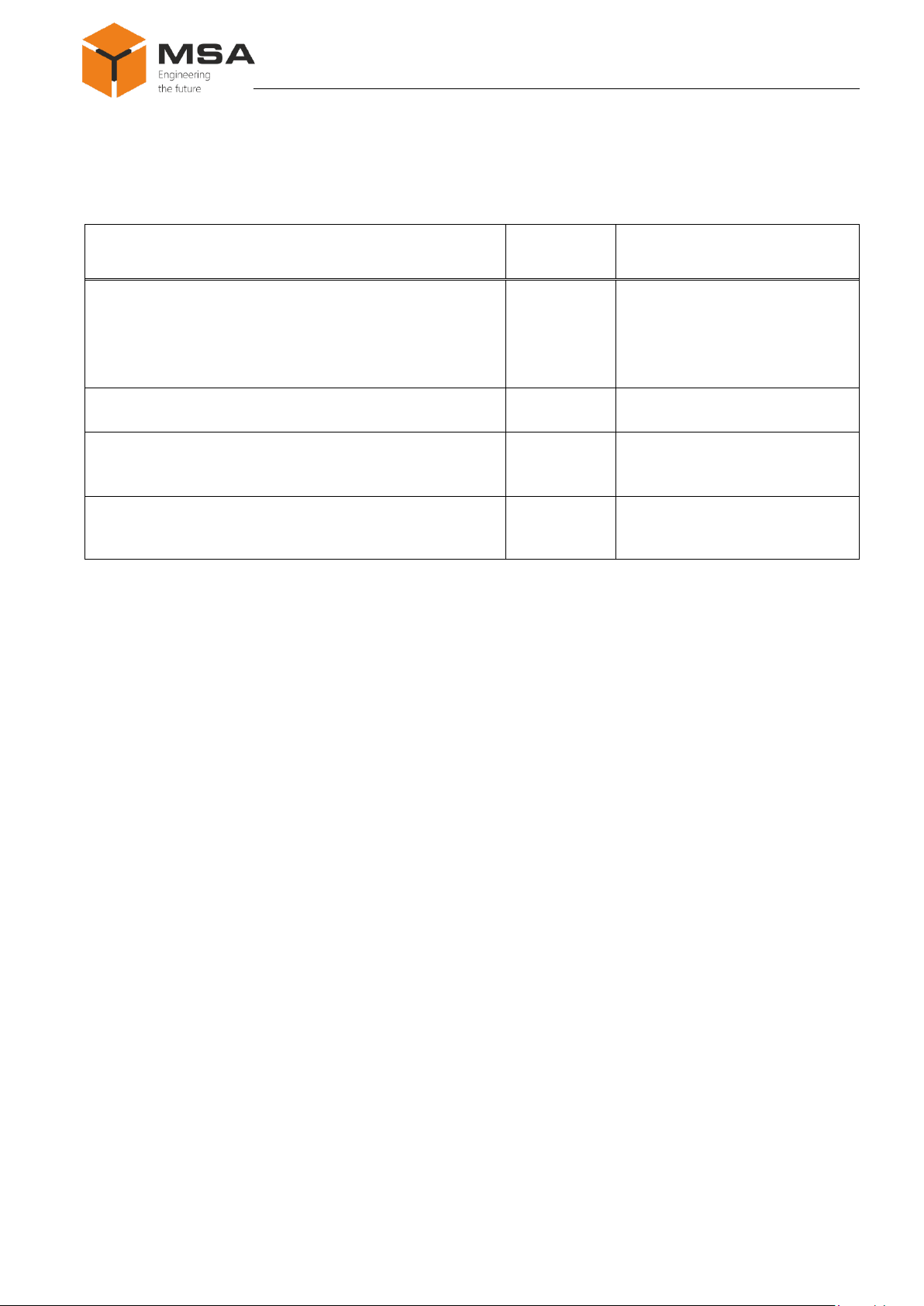

1.2 Technical specifications........................................................................................................4

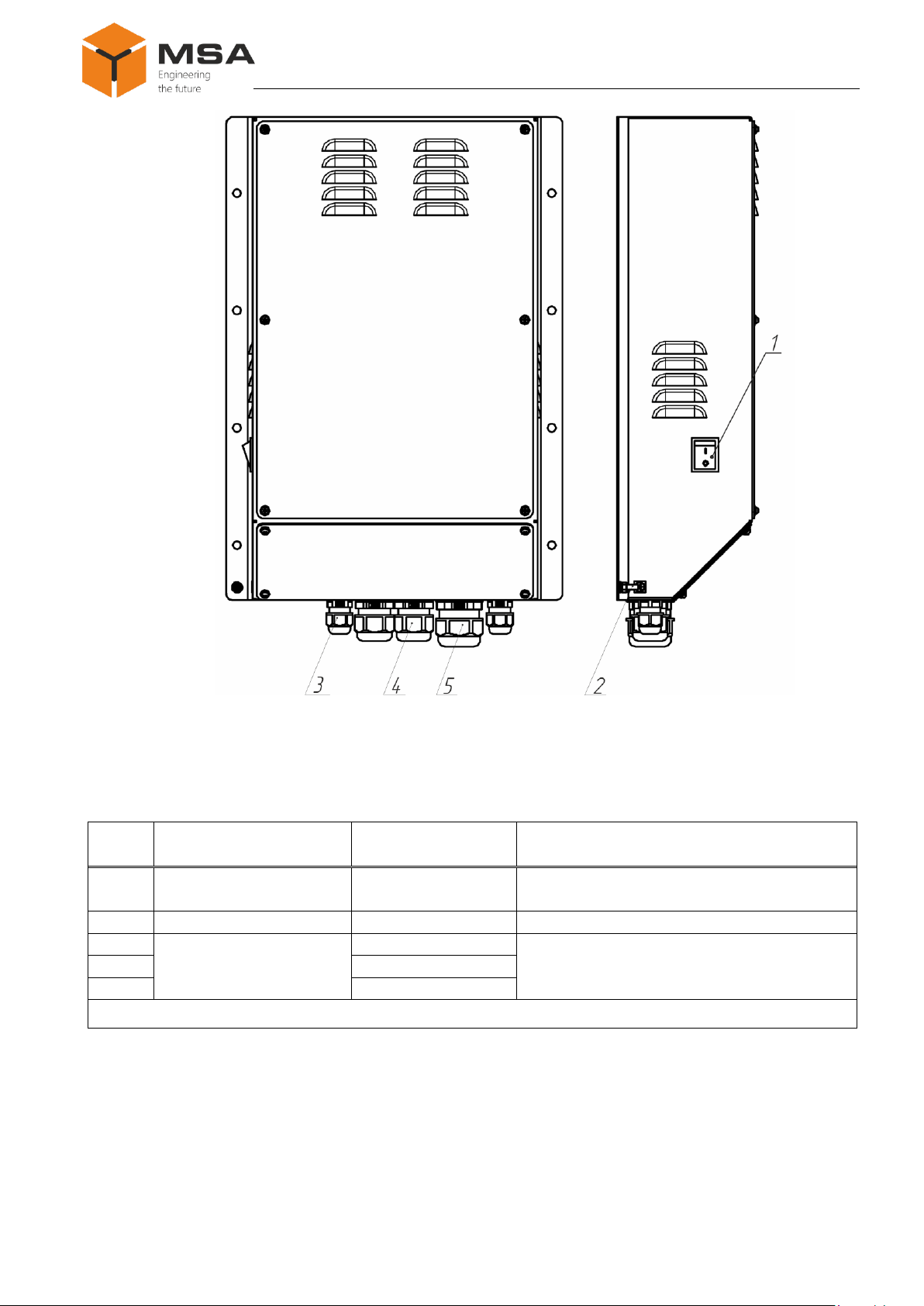

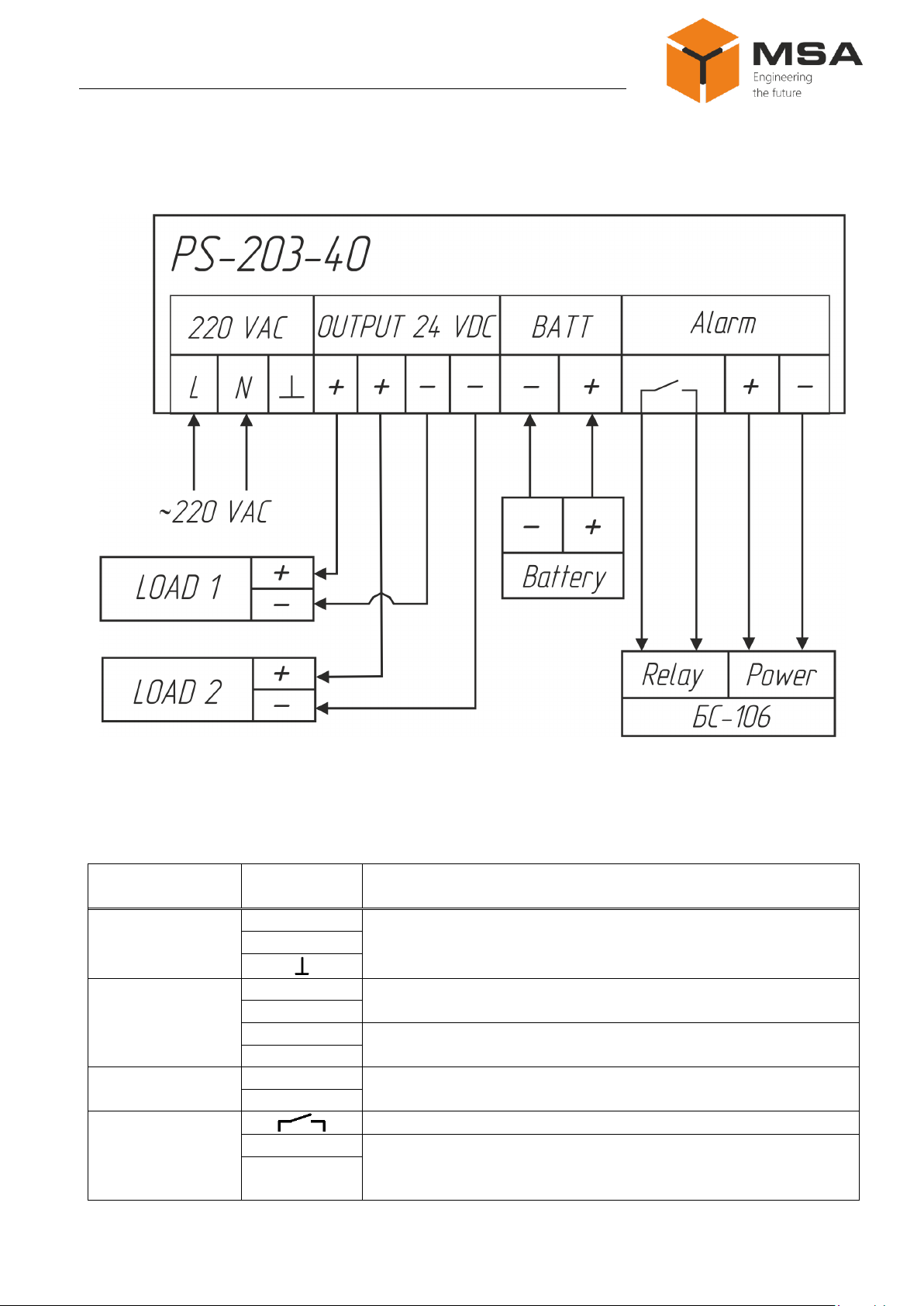

1.3 Structure and operation of the Product..................................................................................4

1.4 Measurement instruments, tools and appliances...................................................................7

1.5 Marking and sealing..............................................................................................................7

1.6 Packaging..............................................................................................................................7

2INTENDED USE OF THE PRODUCT................................................................................8

2.1 Operational limitations..........................................................................................................8

2.2 Usage preparations................................................................................................................8

3TECHNICAL SERVICE OF THE PRODUCT.................................................................10

3.1 General description .............................................................................................................10

3.2 Safety features.....................................................................................................................10

3.3 Maintenance routine............................................................................................................10

3.4 Preservation.........................................................................................................................11

4CURRENT REPAIR OF THE PRODUCT........................................................................12

4.1 General description .............................................................................................................12

4.2 Safety features.....................................................................................................................12

4.3 Current repair ......................................................................................................................12

5STORAGE.............................................................................................................................13

6TRANSPORTATION...........................................................................................................14

7DISPOSAL.............................................................................................................................15

8WARRANTY.........................................................................................................................16

APPENDIX A (MANDATORY) REGULATORY DOCUMENTS ......................................17