Hydrolysis - electrolysis low intensity OXILIFE / 9

4.9

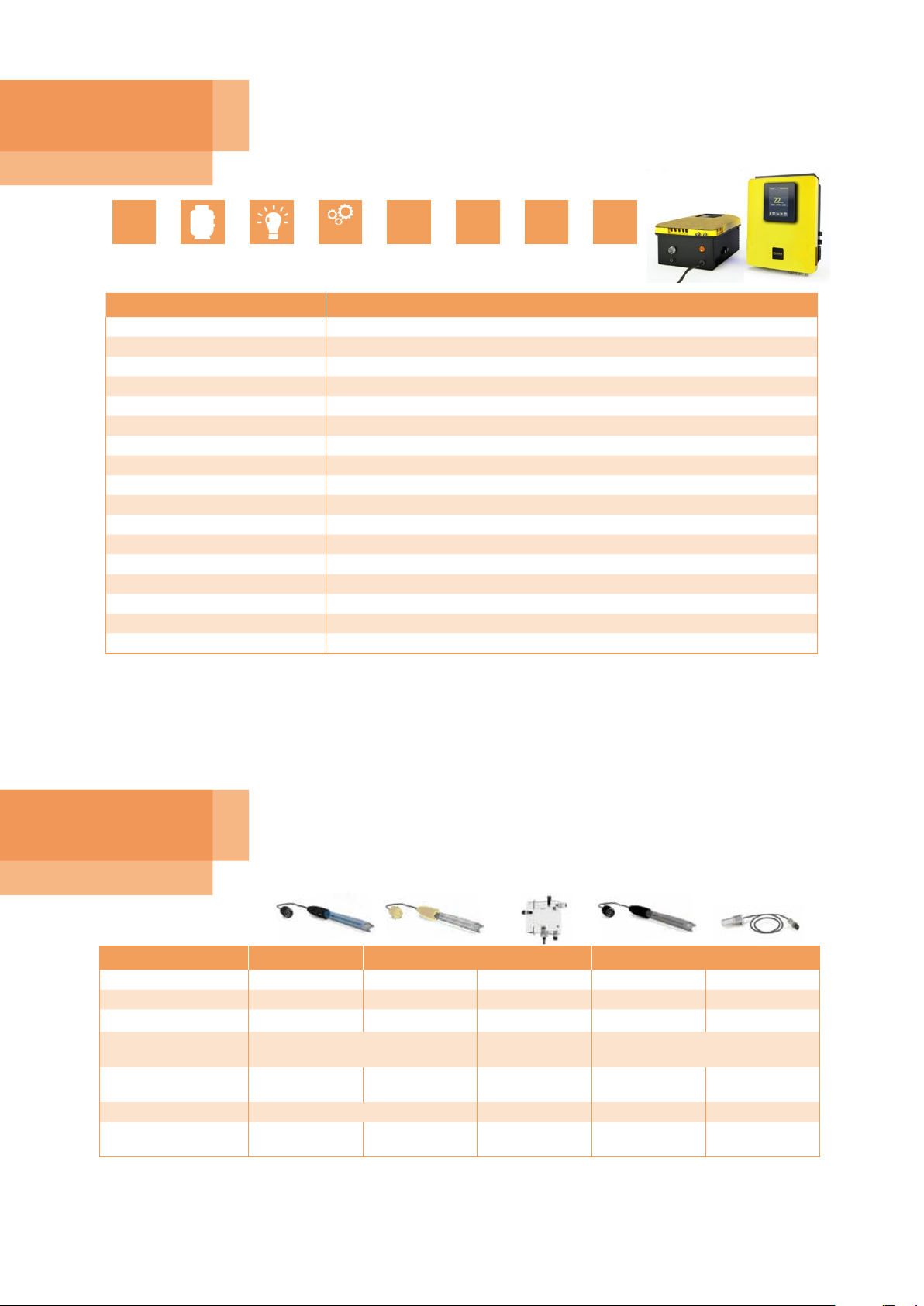

Calibration of the redoX probe: Recommended

every 2 months during usage season.

4.10

Calibration with buer (buer solution

465mV): Follow the instructions in 4 steps that

appear in the display (screen

4.11

corresponds

to step 1).

The option Reset Cal clears the calibrations made

previously.

4.12

Manual calibration: Allows to adjust

the probes at 1 point (without buers) – only

recommended to adjust small deviation in the

readings.

4.13

Without removing the probe from the

water, use the plus/minus keys to adjust the

reading so it matches with your reference value

(photometer or other measurement).

Optional redoX control

Metering and control of the

redoX as check value of the free

chlorine.

redoX

Free Chlorine calibration

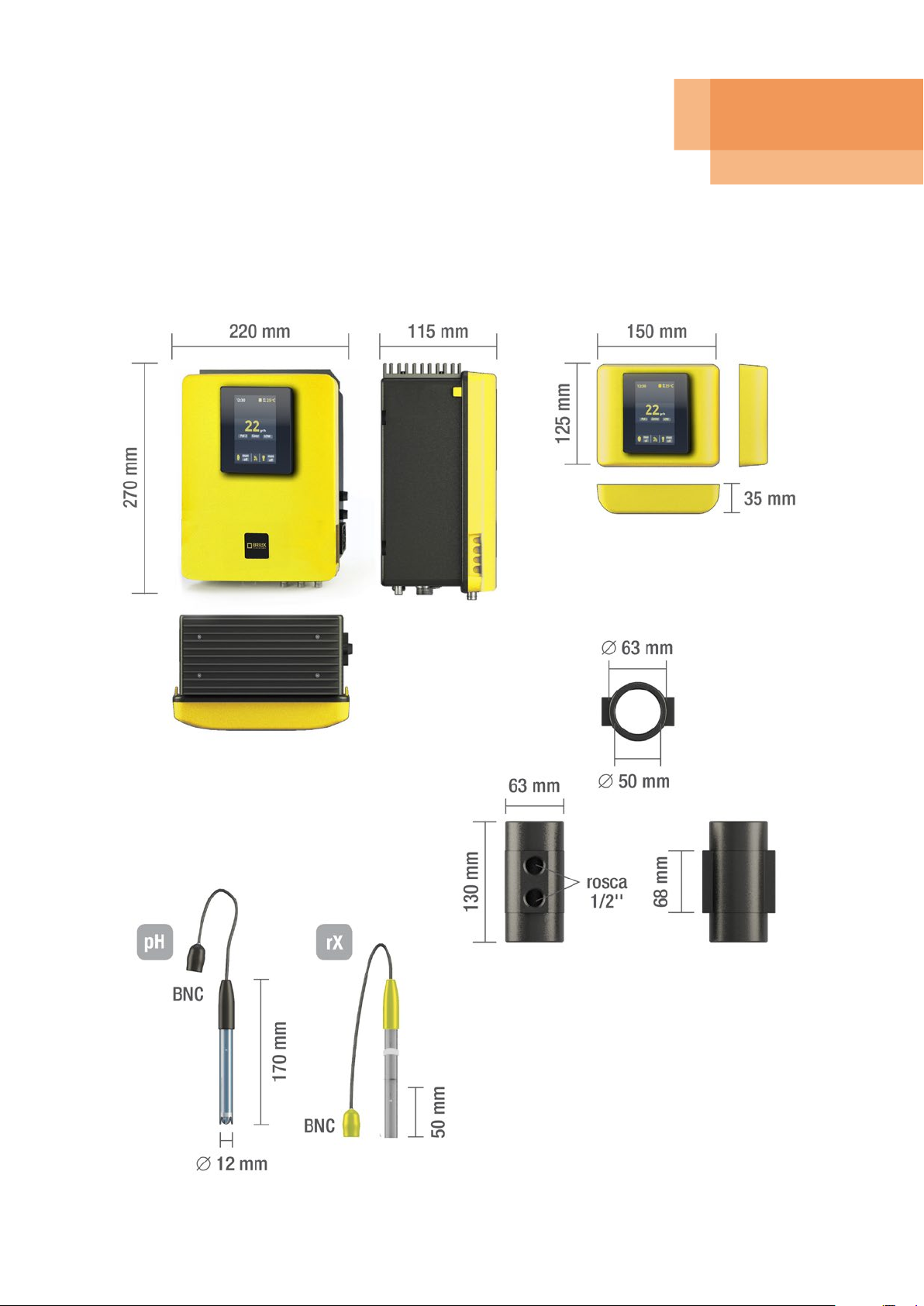

4.14

Calibration of the Free Chlorine probe:

Recommended every month during usage season.

4.15

Calibration with buer (photometer DPD1): Follow the

instructions in 6 steps that appear in the display.

4.16

Step 1 of 6 - Calibrate Cl at 0 ppm (oset): Close the

water flow through the probe and wait until the reading is

less than 0,10 ppm. Wait between 5 to 60 min. Press OK

when the reading is close to 0.

The option Reset Cal clears the calibrations made previously.

4.17

Step 3 of 6 - Calibrate Cl: Open the water flow until

achieving 80-100 liters/hour. Wait until obtaining a stable

reading of ppm. Wait between 5 to 20 min. Press OK when

the reading is stable.

4.18

Step 5 of 6 - Establish the real ppm values with the

plus/minus keys according to your analysis result of DPD1

(free chlorine).

4.19

Step 6 of 6 - If this screen is not shown repeat the

calibration process.

4.20

and

4.21

Manual calibration: Open de water fl w

and set the fl wmeter (rotameter) at the right level of fl w

(80-100l/h). Wait some minutes until the current level is

stable. With the plus/minus keys, insert manually the water

chlorine level (use a manual DPD1 test kit). Press OK when

the DPD1 value is correct on display (target measurement).

Optional Free Chlorine control

Metering and control in ppm of

the free chlorine of the water.

In case of using a Variable

Speed Pump, calibrate

the probe using the most

common filtration speed.

Chlorine probe detector

Fl 2 (rotameter)

3black

5brown

6blue

Free Chlorine probe

3red 4black

Conductivity calibration

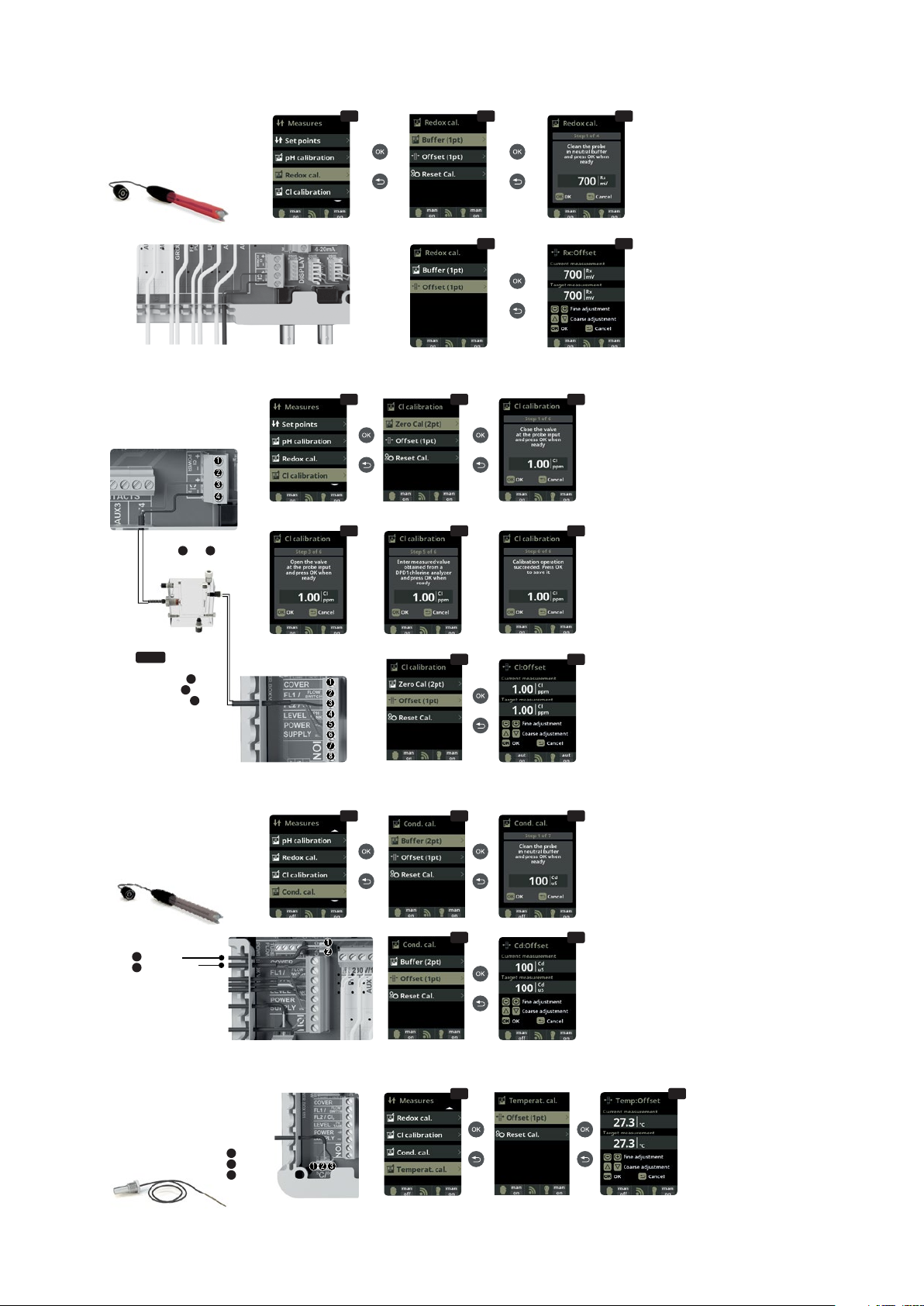

4.22

Calibration of the Conductivity probe: Recommended

every month during usage season.

4.23

Calibration with buer (buer solution 1413 µS/ 12880

µS/ neutral): Follow the instructions in 7 steps that appear in

the display (screen 4.24 corresponds to step 1).

The option Reset Cal clears the calibrations made previously.

4.25

Manual calibration: Allows to adjust the probes

at 1 point (without buers) – only recommended to adjust

small deviation in the readings.

4.26

Without removing the probe from the water, use the

plus/minus keys to adjust the reading so it matches with your

reference value (photometer or other measurement).

Optional Conductivity probe

Metering and control of the

conductivity of the water in

Msiemens.

Conductivity probe

1yellow

2transparent

Temperature calibration

4.27

and

4.28

Temperature calibration:

To set dierence between the measured

value of the probe and the actual

temperature, use the plus/minus and up/

down keys. Set to the actual temperature

of the probe and press OK.

The option Reset Cal clears the

calibrations made previously.

Optional Temperature

Temperature probe

necessary to activate

the filtration modes:

heating, intelligent,

smart.

Temperature

probe

1red

2yellow

3black