3

TABLE OF CONTENTS

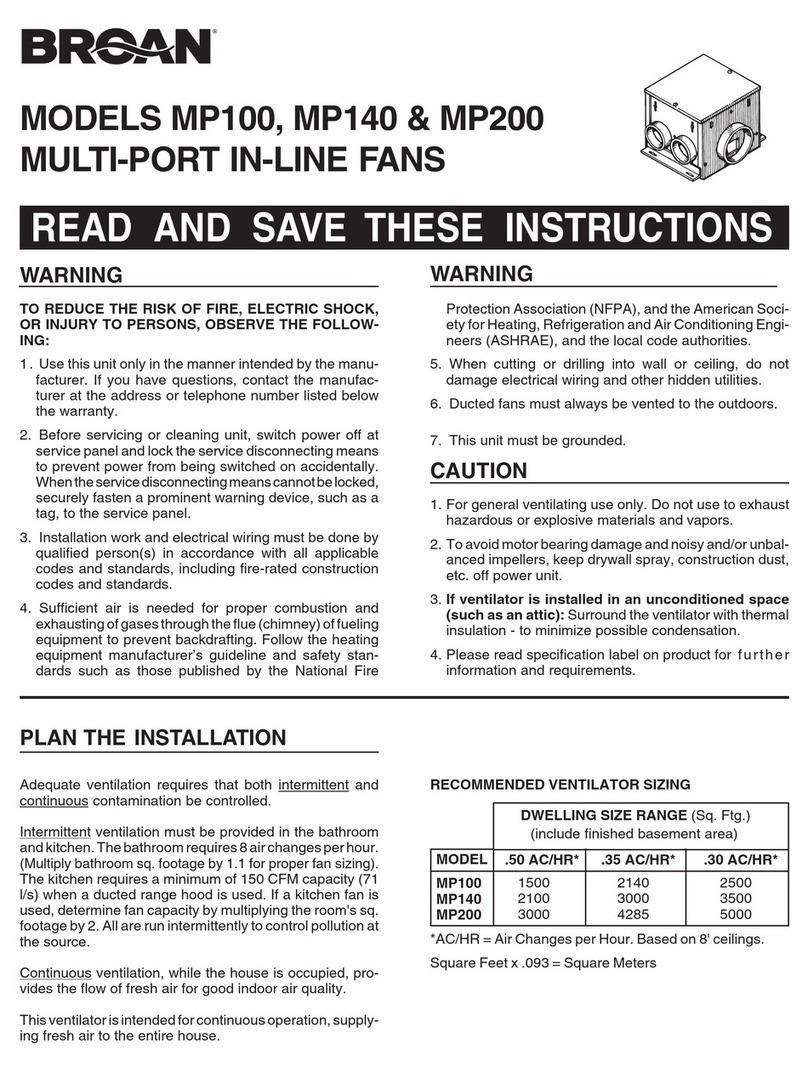

1. TECHNICAL DATA ...............................................................................................................4

1.1 AIR DISTRIBUTION (NORMAL OPERATION) .............................................................................................4

2. INSTALLATION....................................................................................................................4

2.1 LOCATING AND MOUNTING THE UNIT .....................................................................................................4

2.2 INSTALLING THE DUCTWORK AND THE REGISTERS.............................................................................6

2.2.1 FULLY DUCTED SYSTEM (T-1) (THIS CONFIGURATION ALLOWS RECIRCULATION MODE TO OPERATE.)............................6

2.2.2 EXHAUST DUCTED SYSTEM (T-2) (THIS CONFIGURATION ALLOWS RECIRCULATION MODE TO OPERATE.) .......................6

2.2.3 SIMPLIFIED INSTALLATION (T-4) (THIS CONFIGURATION DOES NOT ALLOW RECIRCULATION MODE TO OPERATE.) ..............7

2.3 CONNECTING THE DRAIN (HRV ONLY)....................................................................................................8

2.4 INSTALLING DUAL EXTERIOR HOOD USING TANDEM®TRANSITION KIT (OPTIONAL) .......................8

2.5 INSTALLING THE EXTERIOR HOODS .......................................................................................................9

2.6 CONNECTING THE DUCTS TO THE UNIT.................................................................................................9

2.6.1 DUCTS CONNECTION ................................................................................................................................. 10

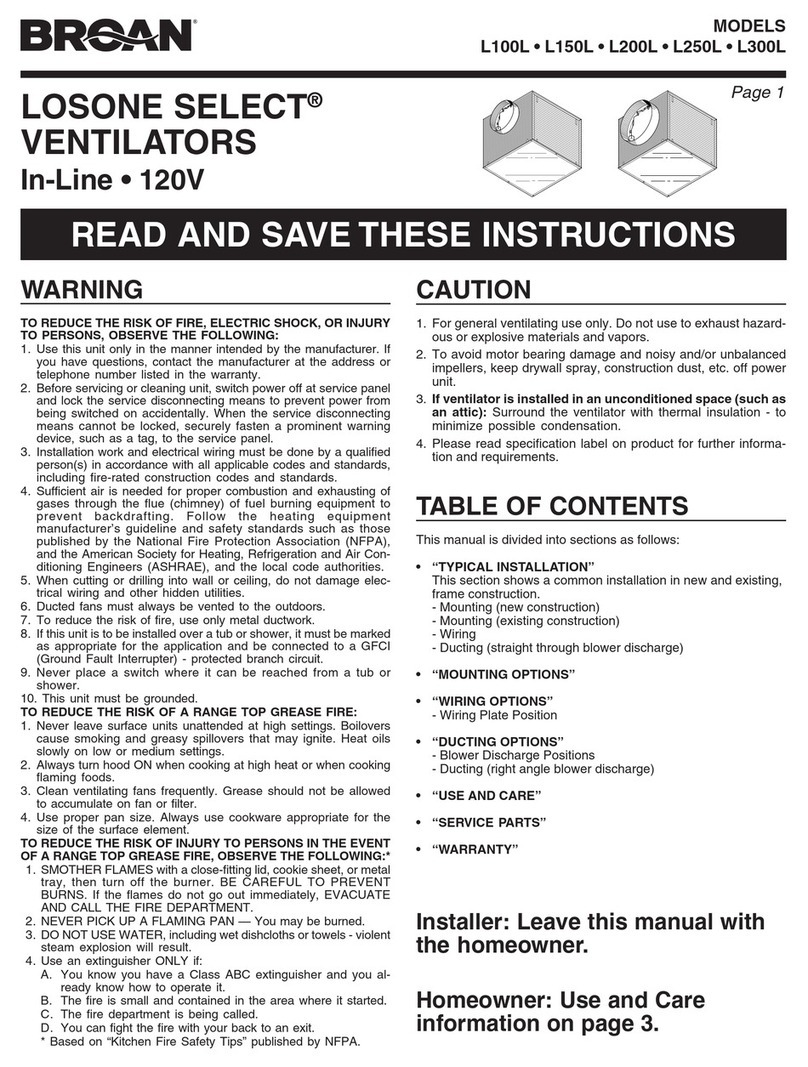

3. CONNECTIONS.................................................................................................................11

3.1 ELECTRICAL CONNECTION TO OPTIONAL MAIN WALL CONTROL .................................................... 11

3.1.1 ELECTRICAL CONNECTION TO SPEED, DEHUMIDISTAT OR AUTOMATIC OPTIONAL MAIN WALL CONTROL ..................... 11

3.1.2 ELECTRICAL CONNECTION TO ADVANCED OPTIONAL MAIN WALL CONTROL.......................................................... 11

3.2 ELECTRICAL CONNECTION TO OPTIONAL AUXILIARY WALL CONTROL ........................................... 12

3.2.1 ELECTRICAL CONNECTION TO 20-40-60 OPTIONAL AUXILIARY WALL CONTROL................................................... 12

3.2.2 ELECTRICAL CONNECTION TO DRY CONTACT OPTIONAL AUXILIARY WALL CONTROL (E.G. CRANK TIMER)................. 12

3.3 CONNECTION TO THE CENTRAL FORCED-AIR SYSTEM .....................................................................13

3.3.1 UNIT OPERATION USING ADRY CONTACT CONNECTION................................................................................... 13

3.3.2 UNIT INTERCONNECTION WITH CENTRAL FORCED-AIR SYSTEM (R/C/G/GF)....................................................... 13

3.3.3 SYNCHRONIZATION WITH CENTRAL FORCED-AIR SYSTEM FUNCTION................................................................... 13

4. WIRING DIAGRAM ............................................................................................................14

5. NAVIGATION ON LCD SCREEN.......................................................................................15

5.1 LCD SCREEN ............................................................................................................................................ 16

5.2 UNIT FIRST BOOT.....................................................................................................................................16

5.3 SETTINGS MODIFICATION....................................................................................................................... 16

5.3.1 PROCEDURE TO MODIFY MIN CFM SETTING.................................................................................................... 16

5.3.2 PROCEDURE TO MODIFY MAX CFM SETTING................................................................................................... 16

5.3.3 PROCEDURE TO MODIFY OPTIONS SETTING................................................................................................... 16

5.3.4 PROCEDURE TO MODIFY INDEPENDENT AIRFLOWS SETTING.............................................................................. 16

5.4 FACTORY SETTINGS RESET ...................................................................................................................17

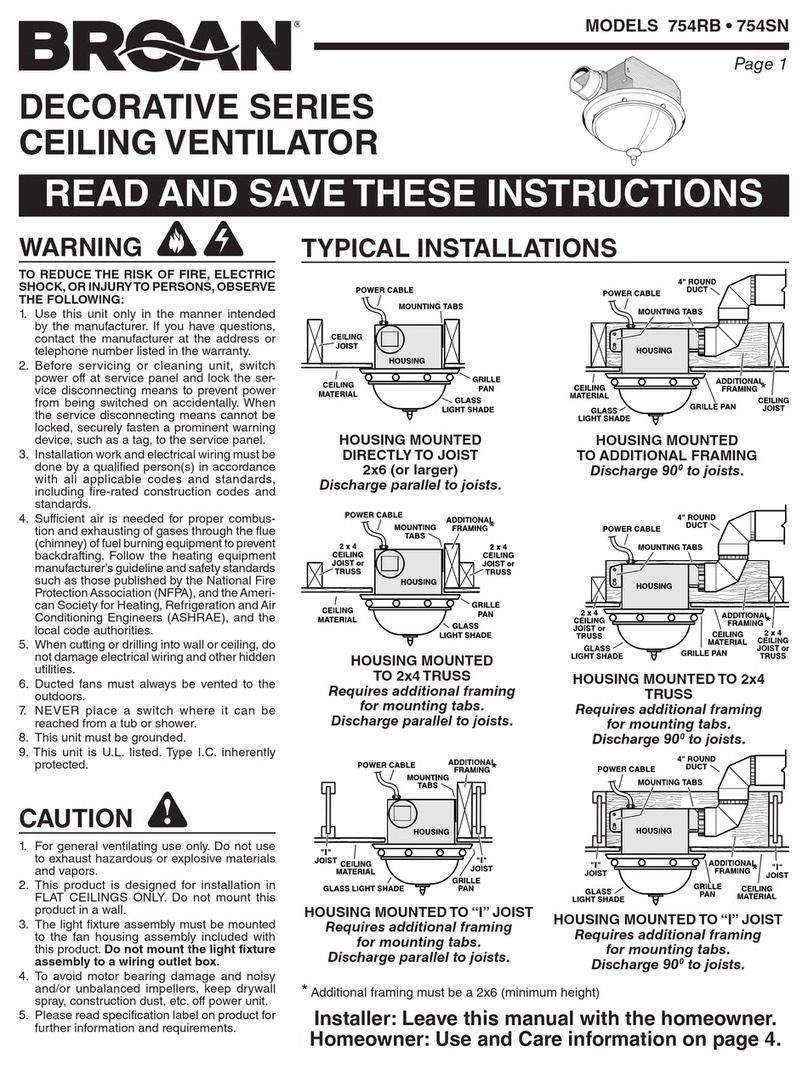

6. USING THIS UNIT..............................................................................................................17

6.1 YOUR VENTILATION SYSTEM .................................................................................................................. 17

6.2 INTEGRATED CONTROL ..........................................................................................................................17

6.3 AHU MODE DISPLAY ................................................................................................................................ 17

7. SERVICE PARTS................................................................................................................18

8. INSTALLER’S TROUBLESHOOTING ...............................................................................20

9. MAINTENANCE.................................................................................................................23

9.1 QUARTERLY ..............................................................................................................................................23

9.2 ANNUAL (AT FALL) ....................................................................................................................................24

10. USER’S TROUBLESHOOTING .......................................................................................24

11. WARRANTY......................................................................................................................25