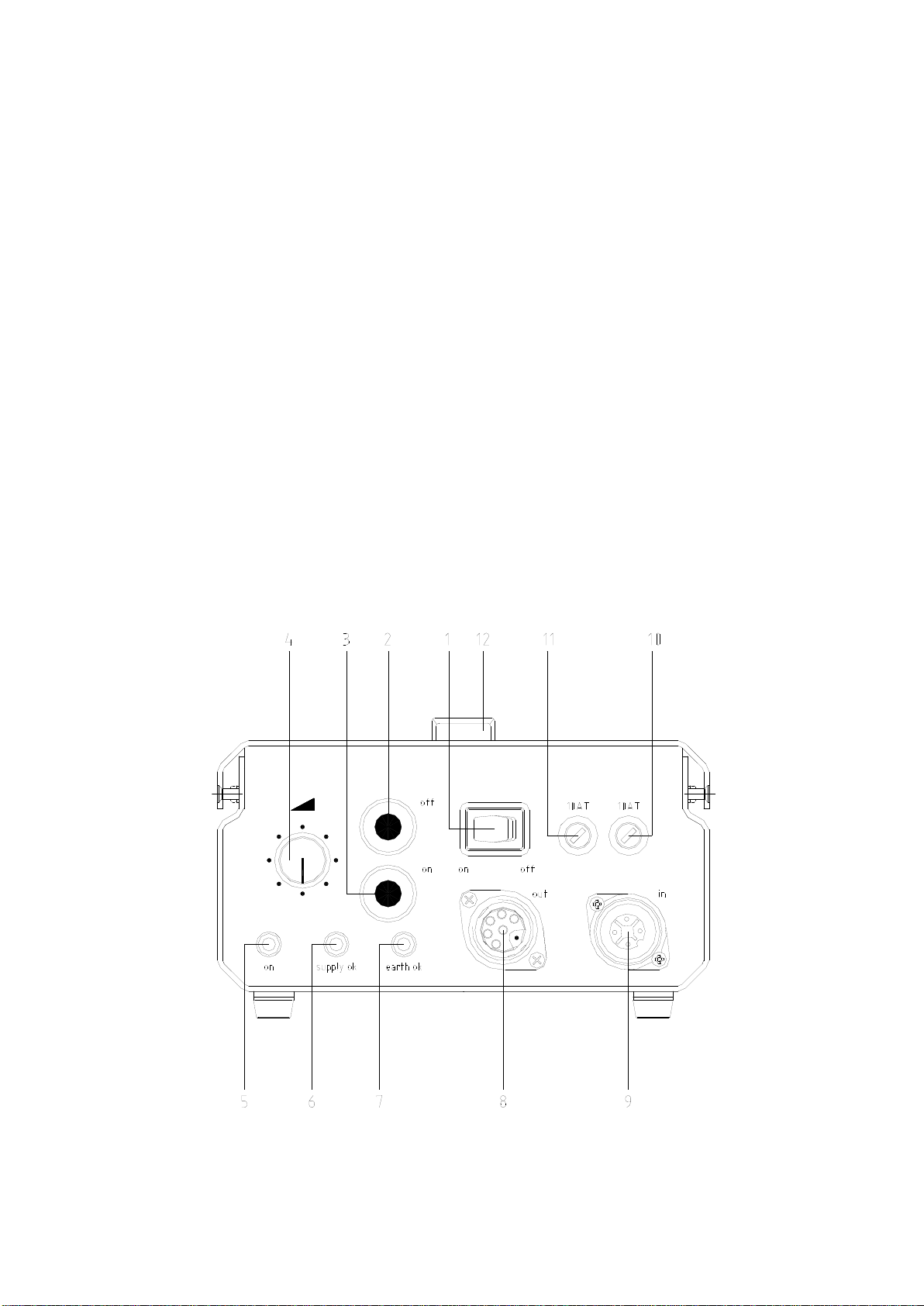

5.) Switch on the mains (AC-line) switch (1) on the ballast unit and check, whether the

yellow LED of the earth monitoring lamp „earth ok“ (7) as well as the red LED “supply

ok” of the mains control light up continuously. Under these conditions the ballast unit

is in operation. The green LED “on” (5) of the operation control lights up. If the mains

(AC-line) switch (1) of the lamp base is „on“, the lamp will light up.

6.) If the yellow LED „earth ok“ (7) does not light up, for safety reasons disconnect

immediately disconnect the ballast unit from the mains (AC-line) supply and control

the earth line. It is not possible to switch on if the red LED “supply ok” is blinking, it

means a technical fault has been detected (see chapter 4: LED displays).

7.) The optimal colour temperature of the lamp is reached after approx. 3 minutes of

operation. The ballast unit HMI 575.800 is equipped with an automatic heat-up

device, so that the operating temperature is reached after only 1 minute. In this

period the unit should only be switched off if absolutely necessary in order to prolong

the service life of the lamp. The heat-up process should always be carried out on full

power.

Attention: If the HMI/MSR lamp cannot be triggered, the ballast unit stops the

trigger process after about 1.5 s. A new attempt to trigger can be

initiated by first pressing the red “off” (2) and then the green “on” (3)

keys. After 10 attempts the unit will block the trigger circuit for about

30 seconds. After that further attempts are possible.

8.) Ensure that the ventilation slots of the ballast unit and the lamp base are

unobstructed during operation.

By pressing the red “off” (2) key on the ballast unit, the lamp will switch off. By pressing

the red “on” (3) key, the unit will operate again.

3. Power regulation

The required light output can be set with the power regulator (4). The adjustment range

extends from 60% - 100% and is equivalent to approximately 1 f-stop. It should be noted

that the colour temperature can change with the power output depending on the type of

lamp used. During heat-up the dimmer is blocked and the power is automatically set to

full until the operating temperature is achieved. The blocking time of the dimmer depends

on the lamp temperature when switching on and can vary between 5 s and 40 s.