© 2007-2008 Broseley Fires Ltd 7

10 LIGHTING AND MAINTAINING A LOG FIRE

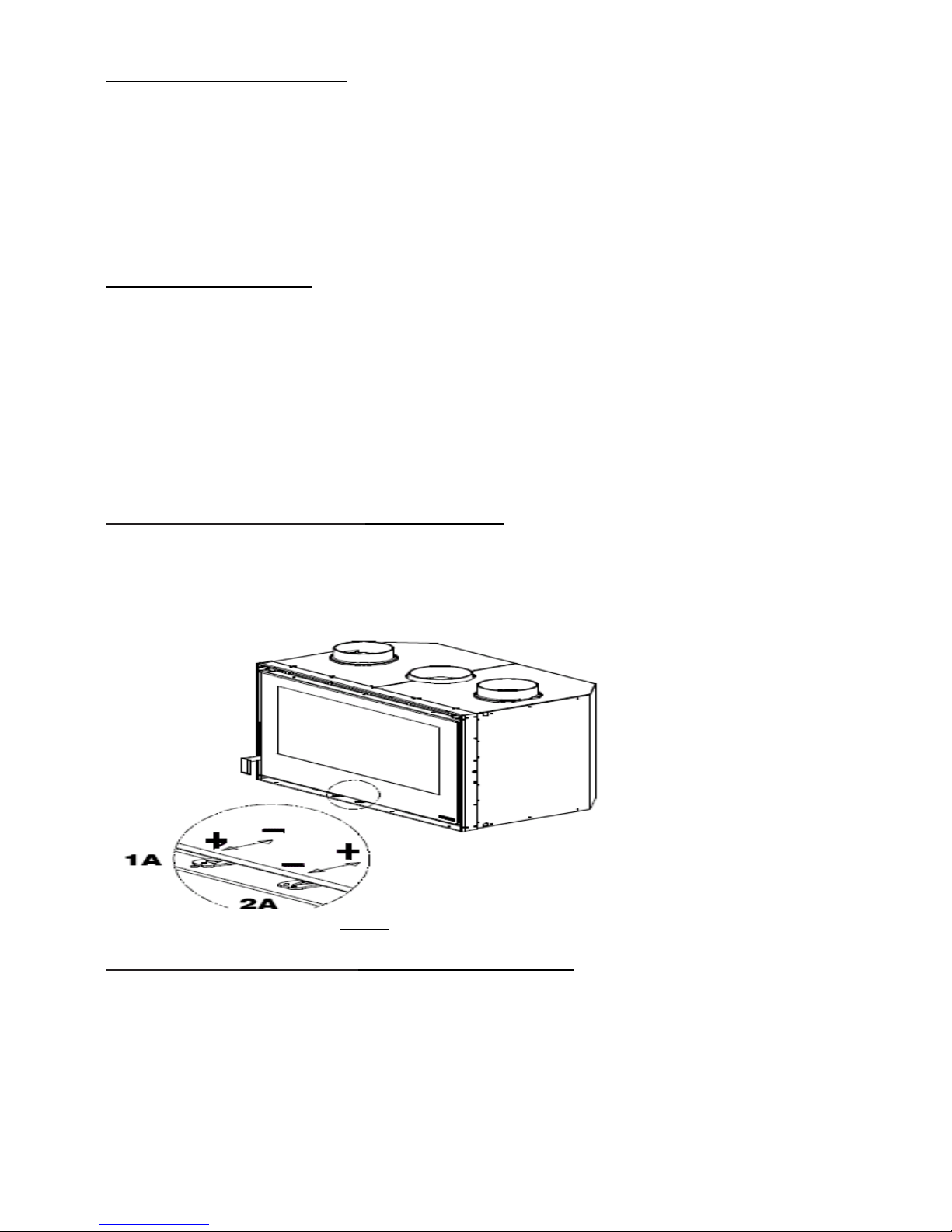

•Use scrunched up paper and dry kindling to start the fire. An alternative is to use fire lighters.

•Open the primary and secondary air controls to the fully open position. It will take a short time for the fire

to establish itself.

•When the fire is burning hot, add small pieces of very dry wood, preferably hardwood as these generate

better embers.

•Keep all the draft controls fully open till a bed of hot, glowing embers is established.

•Once you have some red hot burning embers, open the door and rake the embers evenly over the grate

before adding larger pieces of wood.

•We suggest that you do not fully load the appliance until you have become completely familiar with the

operation of ALL the controls.

•For best results, open the secondary air control and close the primary air control. The output of the

appliance can now be controlled using the secondary air control. This is when burning LOGS.

•Do not open the loading door too quickly when reloading the appliance, as this can cause fumes to flash

out the door.

•A typical load will be 2 KG; this will maintain the output of this appliance

•Do not burn painted or varnished woods, MDF, oak bark or any wood with more than 20% humidity.

•It is not necessary to riddle the ash using the ‘riddling grate’ as wood burns best on a flat surface.

•

11 ASH REMOVAL – CLEANING OUT THE ASH

The removal of the ashes should be done when the appliance is cold.

When you burn logs, you will be left with ashes. They must be removed periodically for the correct and efficient

operation of your appliance.

Don’t wait till the ash pan's completely full. The frequency of this ash removal will depend on the type of fuel being

burned, i.e. Softwood & hardwood; all create differing amounts of ash.

Keep in mind that cleaning your appliance boosts its efficiency, as ash, soot or tar deposits will block the heat

from coming out of the appliance.

Excess ash in the pan will cause a coal fire to go out and may cause severe damage to the grate. It may also

prevent the ash door from being shut correctly.

Take care when removing the ash, as small bits of hot embers can stay dormant for long periods when buried in

ashes. These will then flare up again when exposed to oxygen. Use a metal container to carry any ash.

For your own protection, a pair of heat proof gloves and a dust mask may be necessary.

12 WOOD ASH DISPOSAL

The best thing to do with your ashes is to put them in your garden. Wood ashes are high in potassium, calcium,

sodium, magnesium, and phosphorus.

Wood ash will make your soil more alkaline, so apply it appropriately for your soil.

If you have no garden, you can dispose of completely cold ash with your household trash.

Place it in a tightly closed bag to keep it contained. Use the same precautions as disposing of coal ash.

14 OPERATING IN TRANSITION PERIODS (Summer)

When the outside temperature gets to be more than the temperature within the property, there is a strong

possibility of the flue working in reverse. If the appliance is not lit, this will cause the draught of the flue to travel in

a downward direction and the smell of smoke will be obvious in the room.

If you experience problems lighting the appliance because of the greater outside temperature, then it will be

necessary to warm the flue before loading the appliance with kindling. There are various methods for this

procedure. Ask your local supplier or registered chimney sweep for advice.

If the fire is lit, the heat output of the appliance is often reduced and the exhaust gases may not come out the

chimney completely. This can cause them to come back into the room. In this case:

•shake the embers more frequently,

•increase the air for combustion and

•only load a reduced quantity of fuel.

This will help to keep the chimney hot and working efficiently.

Check that all the seals of the appliance are in good order and that the connections to the chimney are also

sound.