-7-

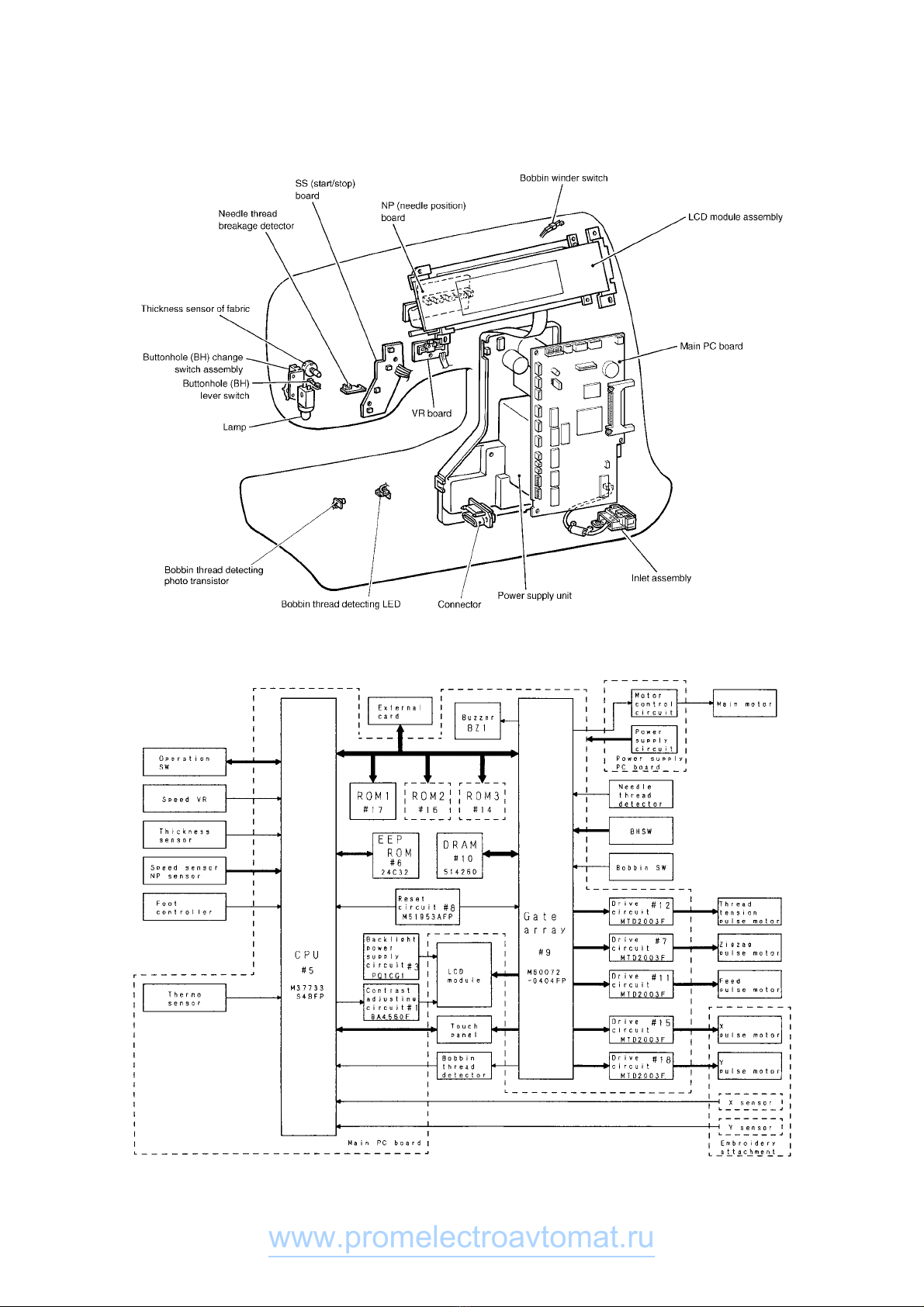

8. OTHER ELECTRONIC COMPONENT FUNCTIONS

Start/stop switch.................................. used to start and stop (SS) the machine. If you want to start sewing at low

speed, keep this switch depressed and start sewing.

Backstitch switch................................. used for backstitching and lockstitching. Backstitching is performed at low

speed in the reverse direction while the switch is pressed. For

lockstitching, three stitches are made at the current needle position and

then sewing stops.

Needle position (UP/DOWN) switch.... used to change the needle position either up or down.

Automatic thread cutter switch............ used to cut the thread automatically. When you press this switch, the

machine will automatically cut the thread, regardless of the needle

position, and stop with the needle at its upper position.

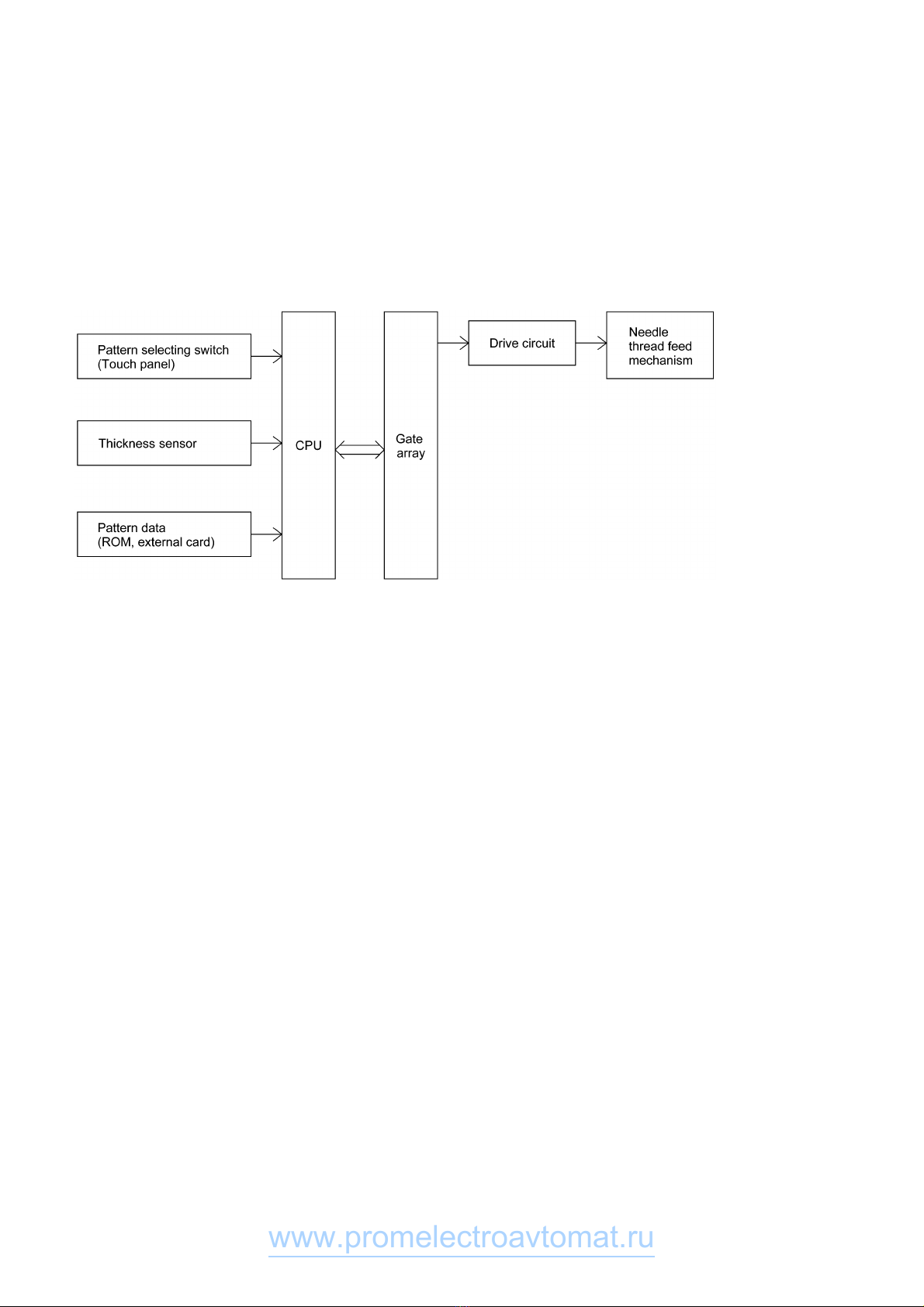

Touch panel......................................... used to select pattern and input number required for sewing by simply

touching the display on the panel. This simplifies the operation for

selecting the desired pattern and number.

Buttonhole stitch switch....................... used to detect the edges of the buttonhole stitch by means of the

buttonhole stitch presser foot and lever.

Buttonhole stitch lever switch.............. used to detect whether the buttonhole stitch lever is raised or lowered.

Rotation sensor ................................... detects the drive timing of the embroidery frame drive, zigzag, feed and

thread feed pules motor and detects the vertical position of the needle.

Also detects the turning angle of the upper shaft by means of a

photointerruptor and shutter installed on the upper shaft.

Speed sensor ...................................... used to detect the rotation speed of the main motor.

detects the operating speed of the main motor by means of a

photointerruptor and shutter installed on the upper shaft.

Bobbin winder switch........................... used to detect whether the bobbin winder has been set when winding the

lower thread.

Junction for foot controller................... when using the foot controller, connect it to this terminal.

Transformer......................................... used for driving the pulse motors, to illuminate the lamps and to supply

power to the electronic circuitry.

Lamp.................................................... is 12V 5W.

www.promelectroavtomat.ru