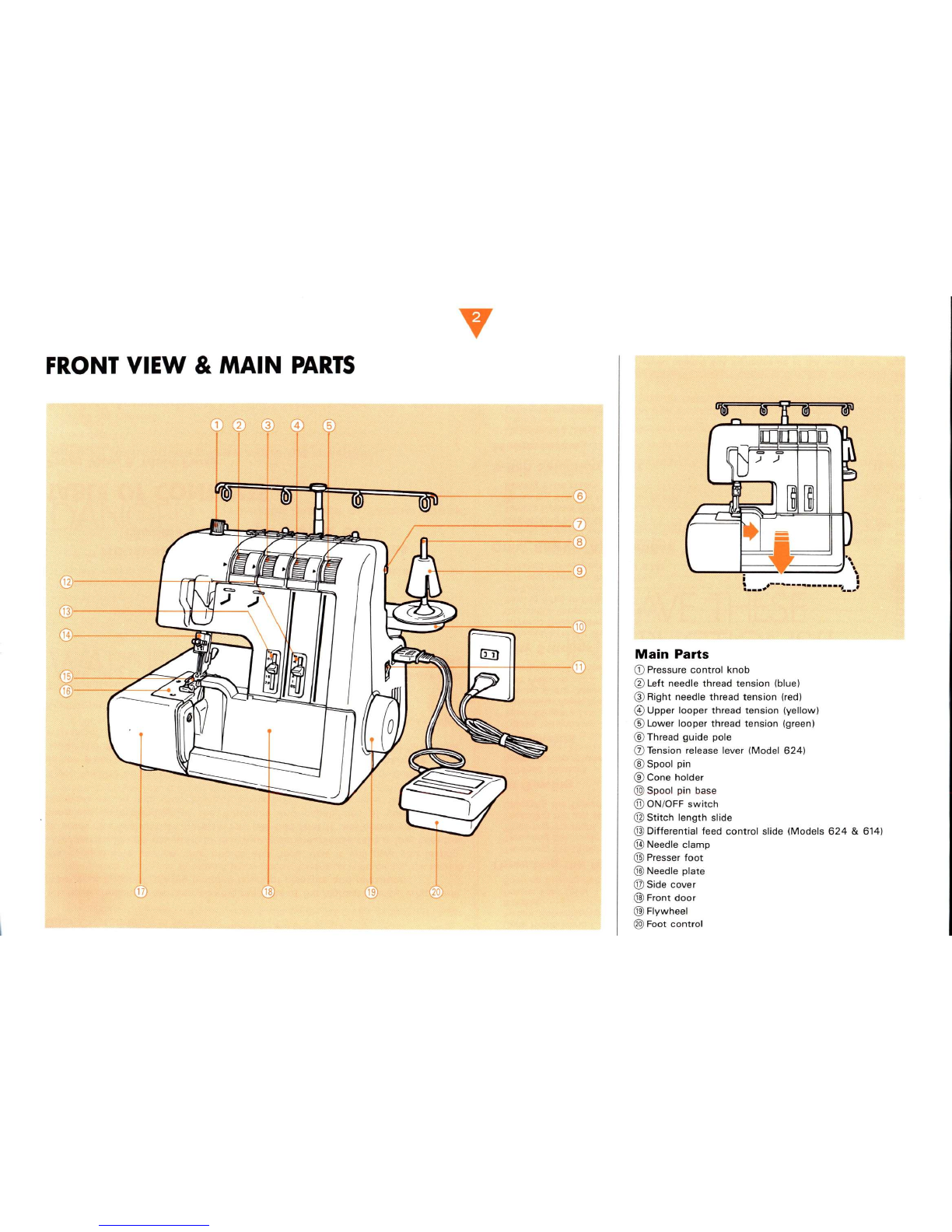

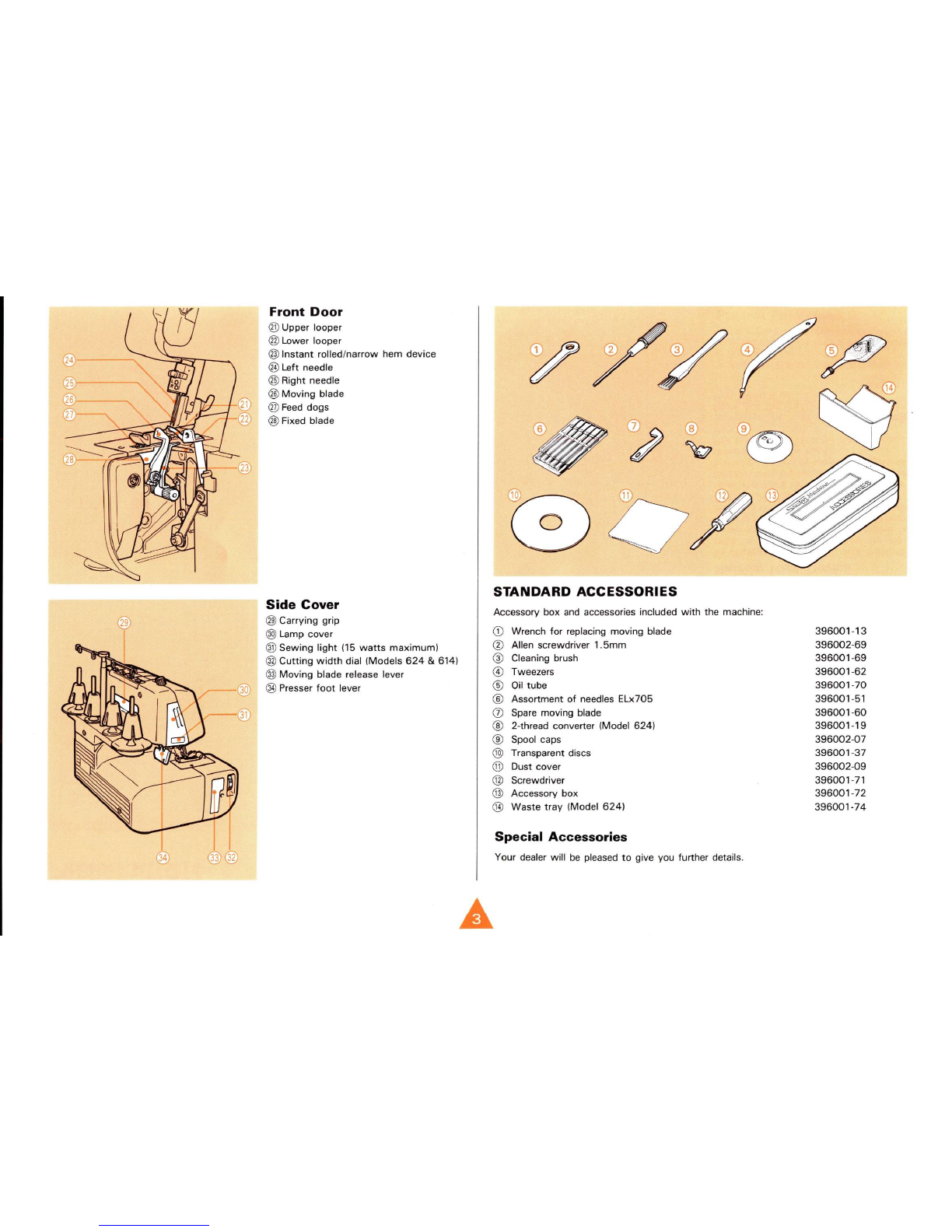

PREPARATION

Connectthefootcontrol,pushingthe

plugwellintothemachineplugbox.

TheON/OFFswitchturnsthelighton(I)

oroff(0),aswellasthesupplyofelectric

currenttothemotor.Switchontorunthe

machineandoffwhenyouarenotsew-

ing.

Theelectricfootcontrolregulates

motorandsewingspeeds.Thegreaterthe

pressureonthecontrol,thehigherthe

speed.

Presspreferablywiththesoleof

thefoot,notwiththetoes.

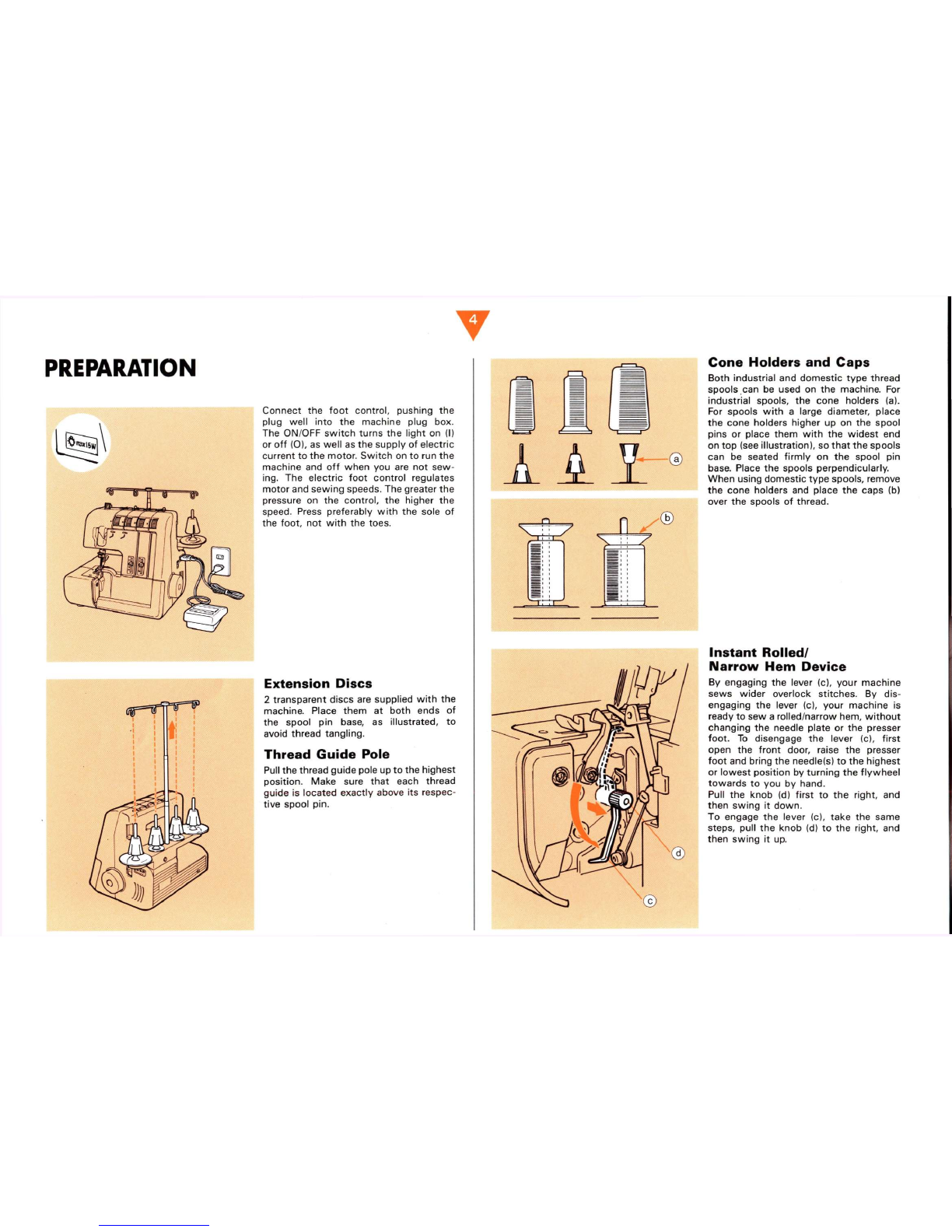

Extension

Discs

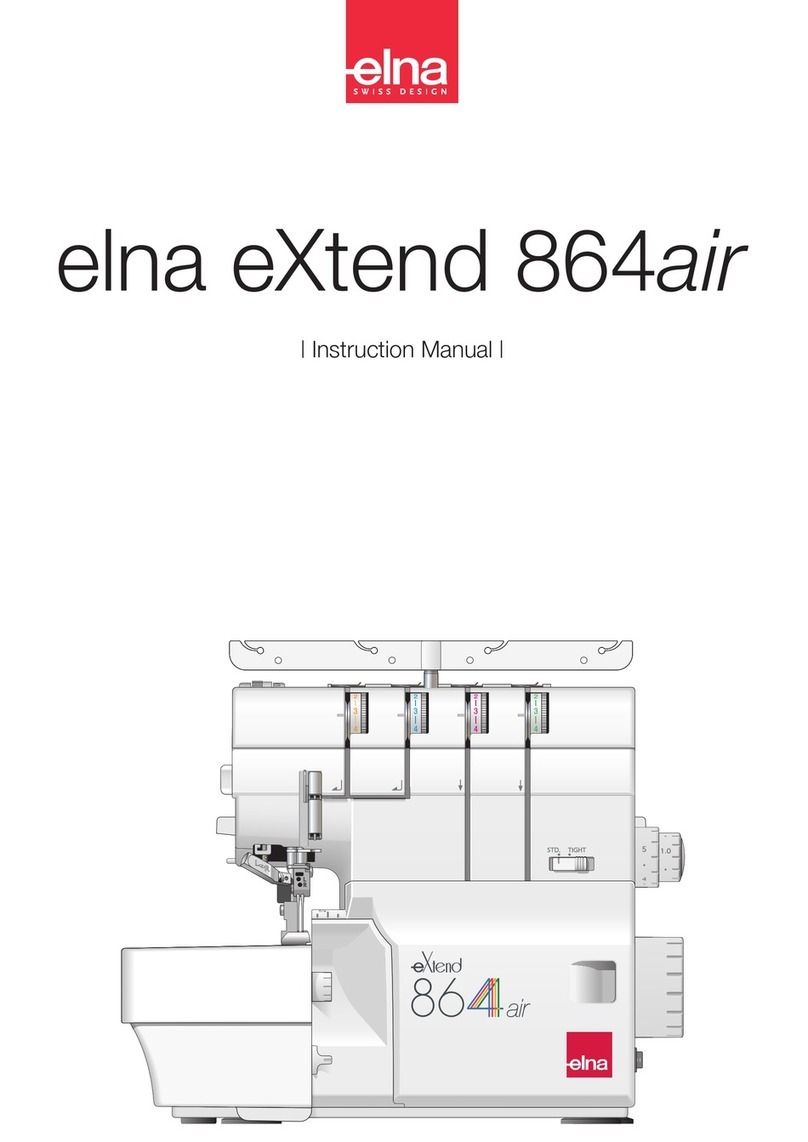

2transparentdiscsaresuppliedwiththe

machine.Placethematbothendsof

thespoolpinbase,asillustrated,to

avoidthreadtangling.

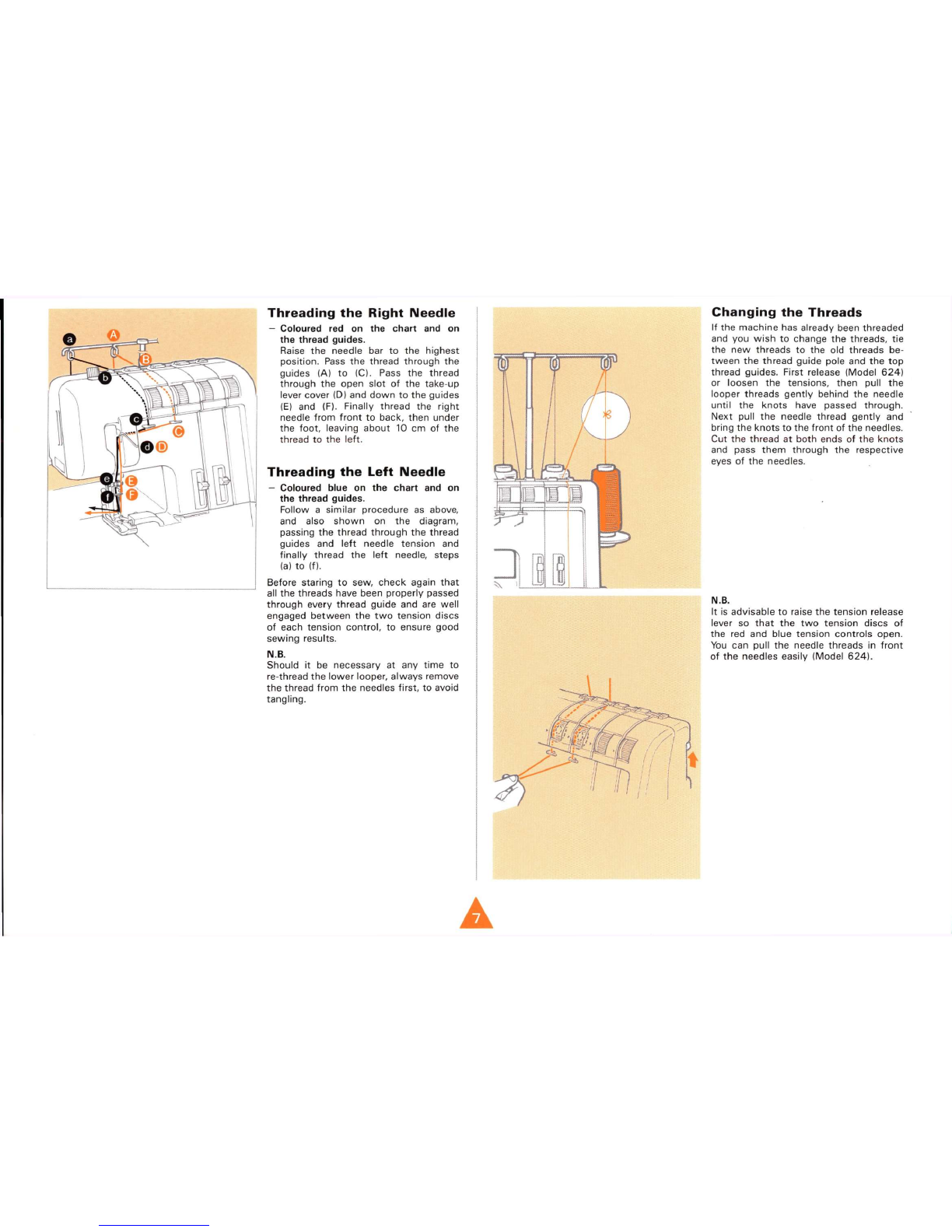

Thread

GuidePole

Pullthethreadguidepoleuptothehighest

position.

Makesurethateachthread

guideislocatedexactlyaboveitsrespec-

tivespoolpin.

Cone

Holdersand

Caps

Bothindustrialanddomestictypethread

spoolscanbeusedonthemachine.For

industrialspools,theconeholders(a).

Forspoolswitha largediameter,place

theconeholdershigheruponthespool

pinsorplacethemwiththewidestend

ontop(seeillustration),sothatthespools

canbeseatedfirmlyonthespoolpin

base.

Placethespoolsperpendicularly.

Whenusingdomestictypespools,remove

theconeholdersandplacethecaps(b)

overthespoolsofthread.

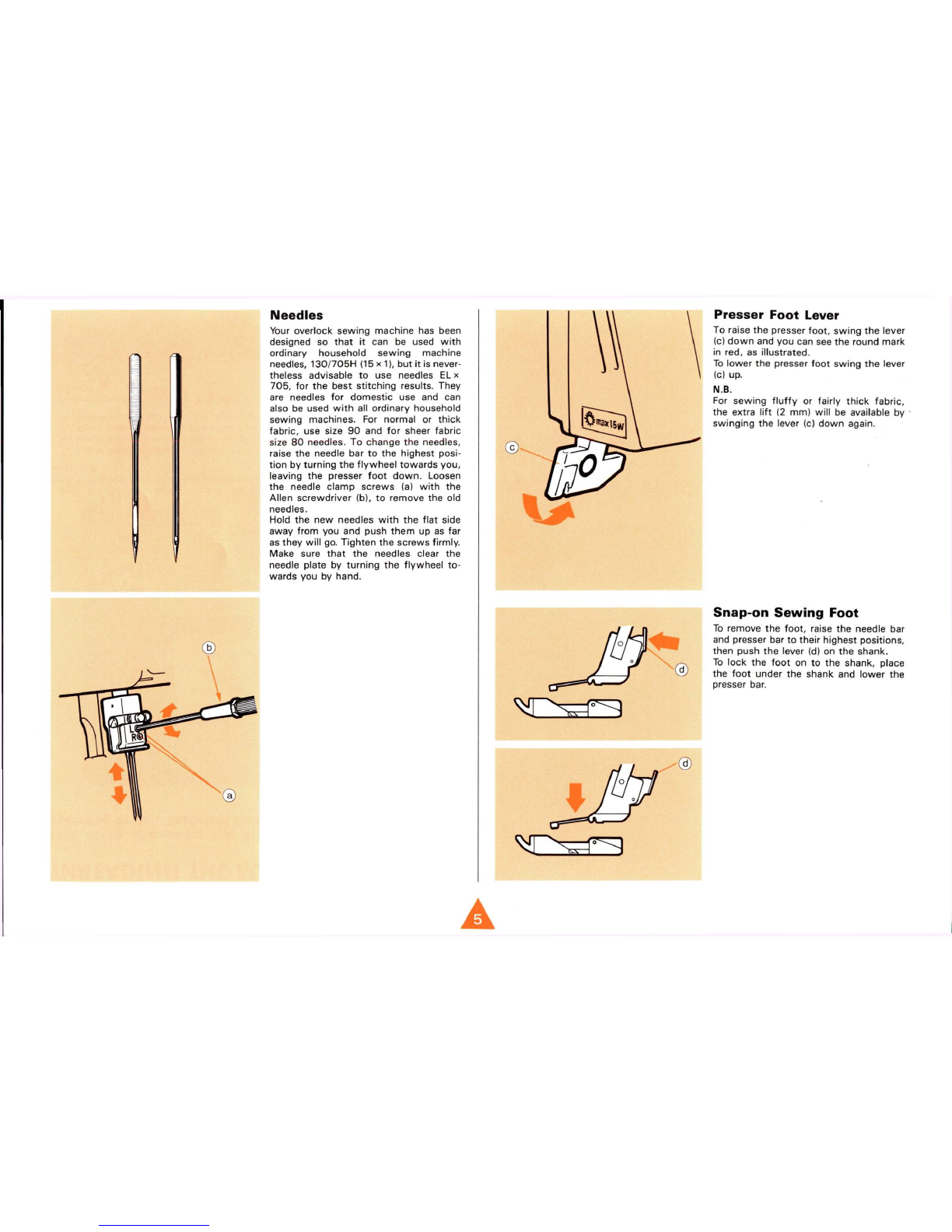

Instant

Rolled/

NarrowHemDevice

Byengagingthelever(c),yourmachine

sewswideroverlockstitches.Bydis-

engagingthelever(c),yourmachineis

readytosewa rolled/narrowhem,without

changingtheneedleplateorthepresser

foot.Todisengagethelever(c),first

openthefrontdoor,raisethepresser

footandbringtheneedle(s)tothehighest

orlowestpositionbyturningtheflywheel

towardstoyoubyhand.

Pulltheknob(d)firsttotheright,and

thenswingitdown.

Toengagethelever(c),takethesame

steps,

pulltheknob(d)totheright,and

thenswingitup.