I- 2

2. SPECIFICATIONS

The tables below list the detailed specifications of typical models. The specifications of other

models differ from them on the points of with/without handset, LCD type and others according to

destinations as shown on page I-7. (1/2)

Model Name FAX560 FAX580MC MFC660MC

Engine Thermal transfer Thermal transfer Thermal transfer

Color Upper: New Personal white

(1485)

Lower: 1473 gray

Upper: New Personal white

(1485)

Lower: 1473 gray

Upper: MFC white

(1495 gray)

Lower: 1473 gray

Transmission Speed (sec) 15 9 9

Modem Speed (bps) 9600 14,400 14,400

Group Compatibility G3 G3 G3

Input/Output Width 8.5"/8.5" 8.5"/8.5" 8.5"/8.5"

ADF (pages) 10 10 10

Paper Feeder (sheets) Letter: 50*, Legal: 30 Letter: 50*, Legal: 30 Letter: 50*, Legal: 30

Ribbon Yield (letter-size) 150 pages (47 m) 150 pages (47 m) 150 pages (47 m)

Starter Ribbon Yield (letter-size) 30 pages (10 m) 30 pages (10 m) 30 pages (10 m)

Replacement Roll PC401: 47 m (150 pages) PC401: 47 m (150 pages) PC401: 47m (150 pages)

LCD Size 16 x 1 16 x 1 16 x 1

On-Screen Programming Yes Yes Yes

Super Fine Yes Yes Yes

Smoothing Yes Yes Yes

Gray Scale (levels) 64 by Dithered 64 by Dithered 64 by Dithered

One Touch 4 4 4

Speed Dial 50 50 50

Telephone Index Yes as "Search" Yes as "Search" Yes as "Search"

Speaker Phone Monitor Full duplex (digital) Full duplex (digital)

Handset Yes Yes Yes

FAX/TEL Switch Yes Yes Yes

Distinctive Ring Detection Yes Yes Yes

Caller ID Yes Yes Yes

Call Waiting Caller ID Yes Yes Yes

TAD Interface Yes Yes Yes

Enhanced Remote Activation Yes Yes Yes

Automatic Redial Yes Yes Yes

Next-FAX Reservation Yes Yes Yes

Multi-Resolution Transmission Yes Yes Yes

Polling Type Sim/Seq Sim/Seq Sim/Seq

Delayed Transmission 3-timer 3-timer 3-timer

Call Reservation Yes Yes Yes

Electronic Coverpage Yes-Super Yes-Super Yes-Super

Call Back Message Yes Yes Yes

Activity Report Yes Yes Yes

TX Verification Report Yes Yes Yes

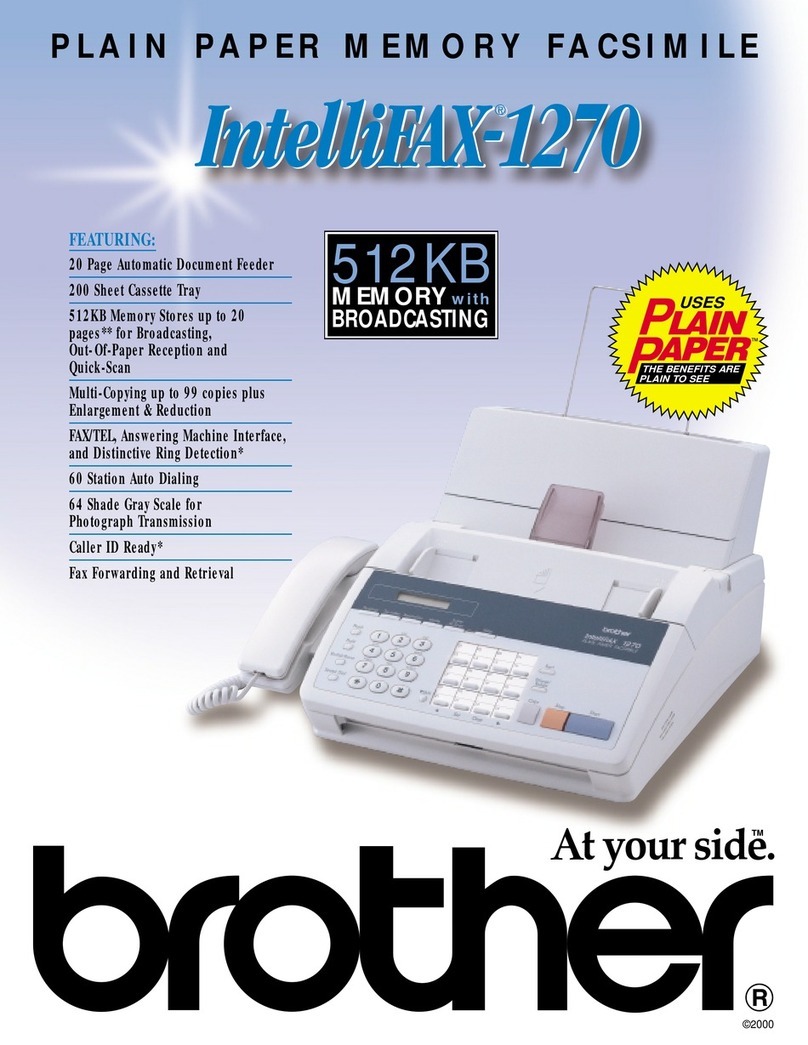

Memory Capacity (pages) 512 KB

(up to 25 pages for OPR**) 512 KB