Touch Screen instructions

Your new FireFly curing system is equipped with a touch

screen display that runs Brown Manufacturing Group, Inc.

proprietary software that controls all the parameters of your

new oven and stores them for future use. The machine also

features additional display information devices.

About the Display.

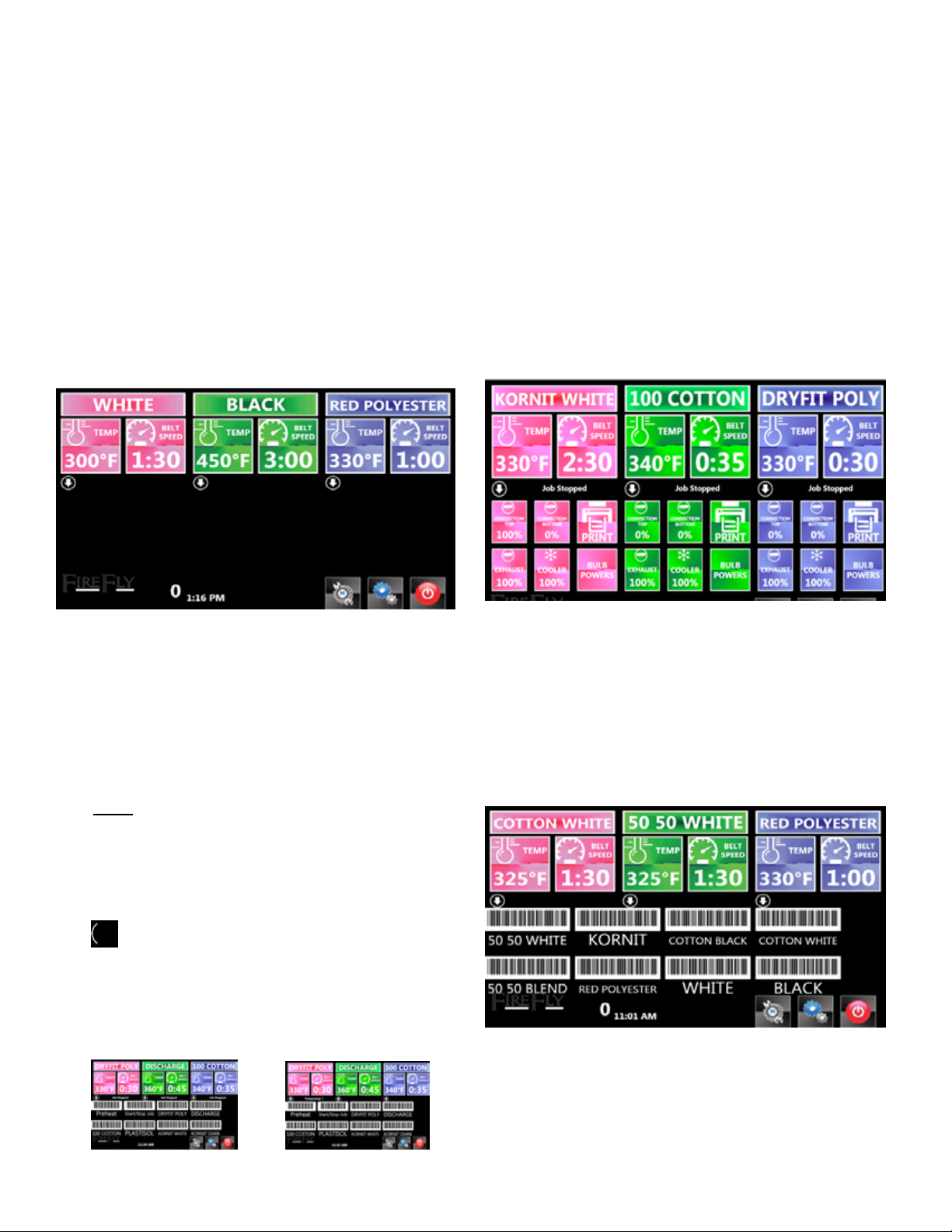

When the oven turns on, the model number of the oven and

the version number of the software is displayed.

The oven then moves to the HOME display screen.

Each top colored section shows the following informa-

tion for each lane:

»PROGRAM NAME: The stored program that the lane

is running.

»TEMP: The temperature that the lane is programmed

to run.

»BELT SPEED: The time in chamber for that lane.

Note: For correct belt speed operation, the belt

sensor wires must be connected correctly as shown

in the Machine Set-Up Guide.

The Center Section of the control panel displays the

following icons:

»: This arrow toggles the windows below for addi-

tional information.

»PREWARMING: If a lane has been set for a prewarm

mode, this will display with a countdown timer.

»JOB STOPPED: If a lane has been paused, this mes-

sage will illuminate.

The Lower Section of the control panel can display the

following information:

»CONVECTION TOP: This is the percentage speed of

convection air movement in the upper air chamber.

»CONVECTION BOTTOM: This is the percentage

speed of convection air in the bottom air chamber.

»EXHAUST: This is the percentage speed of the ex-

haust fan.

»COOLER: This is the percentage speed of the Shirt

Cooling fan.

»BULB POWERS: This lists the percentage of power

each quartz bulb is emitting for this program.

»PRINT: If the unit is equipped with the Linx System,

this print button will output the bar code label for this

program.

Figure 3: Home Screen with lane details

The Lower Section of the control panel can display the

following information:

»BAR CODES: The top 8 program bar codes can be

shown on the screen. These can be scanned with the

Linx Scanners if the machine is equipped with this

option.

Figure 4: Home Screen with Linx Bar Codes

Figure 1: Home Screen

Figure 2: Home Screens with Job Stopped or Prewarming