i18 User Manual V11 120219 Page 3 of 19

1. Operational Environment

Important: To the Operator

1.1. Important Information

Every piece of Brüllen equipment has its own internal system, rules and technicalities that need to be observed.

The Brüllen User Manual is intended to help you become acquainted with your equipment quickly, so that you are able to

operate it correctly and efficiently.

If you follow our advice on operating and cleaning your Brüllen equipment, you will be rewarded with a long service life

and the perfect operation of your equipment.

We recommend that you use only the best quality raw materials such as sterilized liquid Product mixture.

1.2. Operational Environment

•Environmental Temperature:10℃~40℃。

•Relative Humidity:55%~85%。

2. Power

Please install the ground wire according to the national electrical safety standard. The section area of the ground wire

cannot be smaller than 1mm².

Ensure the use of the correct power supply including the power plug and electrical equipment is set to the appropriate safety

standard.

•Make sure the power supply to the equipment has short-circuit and electrical leakage-protector.

•Single phase electricity is 220V/50HZ. Voltage range is 198V-242V.

•Three phase electricity is 380V/50HZ.

oThree phase four wires electricity is 380V/50Hz and one wire is neutral.

oThe section area of the power cable should not be less than 1.5mm2

oFor 380V equipment: observe the turning direction of the Quartet Beater shaft. For the correct running

of your BRÜLLEN equipment the shaft should run in a clockwise direction. If the shaft runs in an

anticlockwise direction, alternate any two of the power phases.

•DO NOT touch the electrical plug or switch with wet hands,

•DO NOT operate the equipment, if it is not correctly grounded.

•DO NOT perform any maintenance to the equipment before ensuring that the electricity supply has been

isolated.

•If the equipment malfunctions or the power cable is damaged, it must be serviced or replaced by the

manufacturer, its service agent or a similarly qualified person in order to avoid a potential safety hazard.

3. Installation

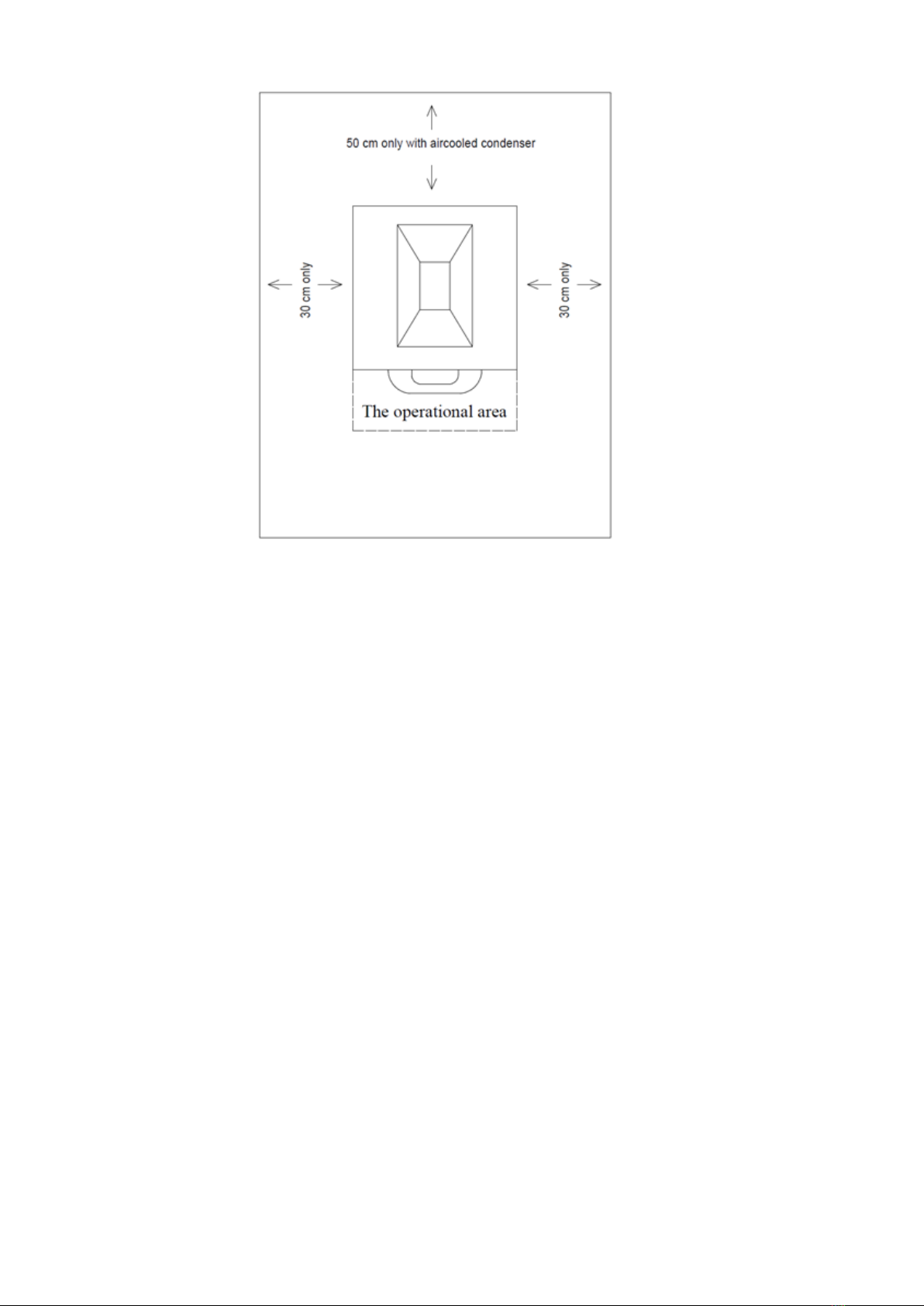

•The equipment should be used indoors. It should be placed on flat, dry solid ground. Clearance around the

equipment should be as indicated in diagram below.

•Keep the equipment out of direct sunlight or high temperature storage areas.

•There should not be any heat source over 40◦C or under 10◦C. impacting the air intake of the equipment. The air

inlet and outlet should be kept clear, avoid any loose or foreign objects around the equipment that could be

picked up by the air intake/or block the air outlet.

•For equipment with truckle brake, to avoid movement during operation, please depress the truckle brake once

the equipment is in its operational position (For floor standing models only) MACHINE WITH AIRCOOLED

CONDENSER

•Machines with air-cooled condenser must be installed no closer than 50 cm to any wall in order to allow free air

circulation around the condenser.