ASL-700 OPERATOR 02-03-2022 Bruno Independent Living Aids

6

OPERATION

Lowering the platform

1. Open the keyswitch cover.

2. Insert the key and turn it to ON position.

3. Press and hold the DOWN switch to

lower the platform.

4. Release the switch when the platform

reaches the ground.

5. Position the mobility device on the

platform.

• Have an authorized Bruno dealer

remove the mobility device seat,

mount the docking plate (see above)

between the seat and the swivel

plate of the mobility device and place

the seat assembly back on the mobility

device.

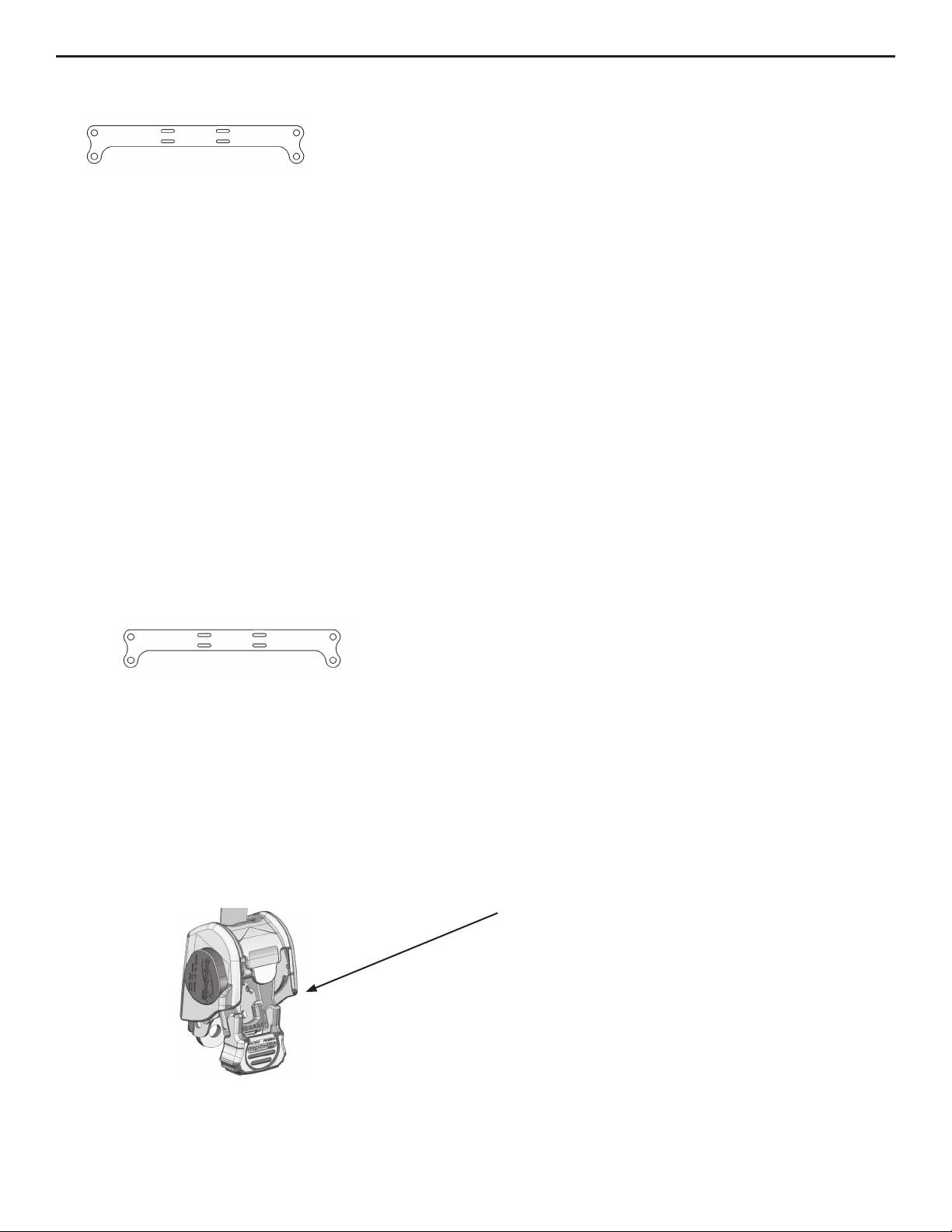

Retractable belt hooks

attach to this docking

plate.

Raising the platform (Loading)

• Open the keyswitch cover.

• Insert the key and turn it to the ON

position.

• Make sure an authorized Bruno dealer

has installed the docking plate shown

earlier in this manual.

• Press and hold the UP switch to raise the

platform/mobility device.

• Release the switch when the platform

reaches the uppermost position.

• Secure the mobility device to the platform

using the (3) ratcheting belts. See the

next page for belt operation.

• Turn the key to the OFF position.

• Remove the key from the key switch.

• Close the key switch cover.

• Have an authorized Bruno dealer

remove the mobility device seat,

mount the docking plate (see

above) between the seat and the

swivel plate of the mobility device

and place the seat assembly back

on the mobility device.

Retractable belt hooks

attach to this docking

plate.