B.

IF

You find

dirt

or

bits

of

metal

There

is

a flaw in

either diaphragm

or

the

check

valve sheet

The fuel inlet valve

(needle and

seat)

is

damaged

The

mountingflange

is

warped

MUFFLER INSPECTION

IF

It

appean

to

be

clogged

with

deposits

You

can hear loose

metal pieces

or

silencing material

when

you

shake

the

muffler

C.

CRANKCASE PRESSURE CHECK

The

pressure leaks

at

a rate greater

than

llb./min.

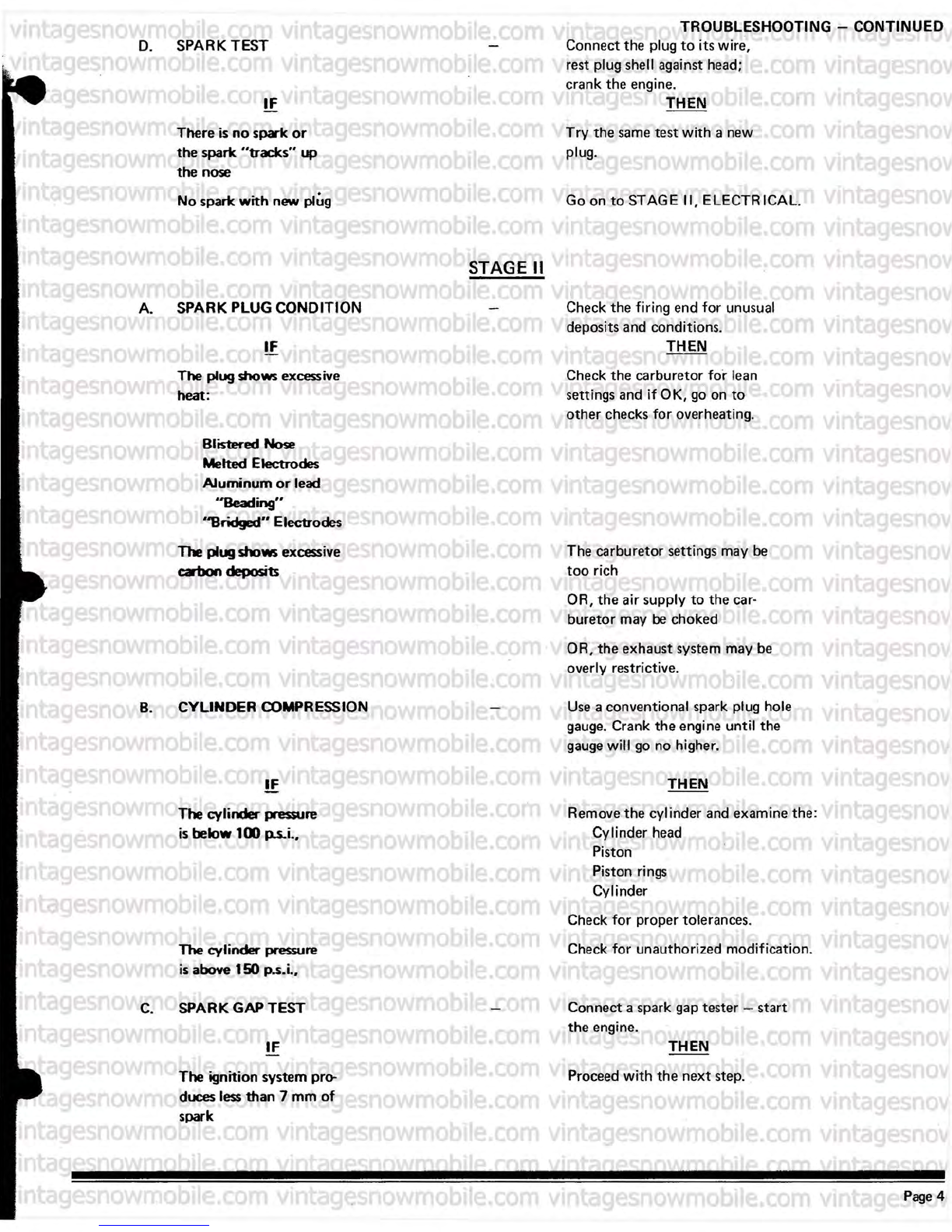

STAGE III

TROUBLESHOOTING -CONTINUE,D

Remove, disassemble and inspect

the

carburetor.

The carburetor will cause engine

flooding (wash clean).

The carburetor may

not

deliver

enough fuel and

the

engine will

run

hot

or

perhaps will

not

start

at

all

(replace damaged

parts).

The fuel will

not

be controlled

and

the

engine will be flooded.

Air will leak into

the

intake

port

and cause a lean mixture

(surface grind

the

flange).

Remove

the

muffler.

The engine will

not

produce

normal horsepower and may over·

heat (clean

out

the muffler).

The engine will

not

produce nor·

mal horsepower and may overheat

(replace

or

repair

the

muffler).

Seal

the

intake and exhaust ports

and connect a pressure checking

device. Pressurize

the

engine

to

10

p.s.i.

The air/fuel mixture will become

lean enough

to

be

noticed

as

a

"hot"

plug reading. The machine

will suffer from short plug life.

The air/fuel mixture may become

lean enough

to

cause preignition,

detonation, and perhaps melting

of

the

piston crown.

Page 6