3. Use only copper or copper-clad conductor for connec-

tions between field-supplied electrical disconnect switch

and unit. The use of aluminum wire is not recom-

mended. Maximum wire size is no. 2 AWG (American

Wire Gage) on units with heat (up to 34 kW). The maxi-

mum wire size is no. 2/0 AWG on units with heat (over

34 kW).

4. Units with accessory electric heat must also have the

correct single point box kit to meet UL (Underwriters’

Laboratories) requirements. Refer to installation instruc-

tions shipped with the accessory for more details.

5. Voltage to compressor terminals during operation must

be within voltage range indicated on unit nameplate (also

see Tables 2A and 2B). On 3-phase units, voltages be-

tween phases must be balanced within 2% and the cur-

rent within 10%. Use the formula shown in Tables 2A

and 2B, Note 2 to determine the percent voltage imbal-

ance. Operation on improper line voltage or excessive

phase imbalance constitutes abuse and may cause dam-

age to electrical components. Such operation would in-

validate any applicable warranty.

6. Insulate low-voltage wires for highest voltage con-

tained within conduit when low-voltage control wires are

run in same conduit as high-voltage wires. Install con-

duit through side panel openings. For units without ac-

cessory electric heat, install conduit between disconnect

and control box.

7. Do not damage internal components when drilling through

any panel to mount electrical hardware, conduit, etc.

8. Install power lines to terminal connections as shown in

Fig. 10.

9. For units with accessory electric heat, refer to accessory

installation instructions for wiring the accessory.

During operation, voltage to compressor terminals must be

within range indicated on unit nameplate (see Tables 2A and

2B). On 3-phase units, voltages between phases must be bal-

anced within 2%, and the current within 10%. Use the for-

mula shown in Tables 2A and 2B, Note 2 to determine the

percentage of voltage imbalance. Operation on improper line

voltage or excessive phase imbalance constitutes abuse and

may cause damage to electrical components. Such operation

would invalidate any applicable warranty.

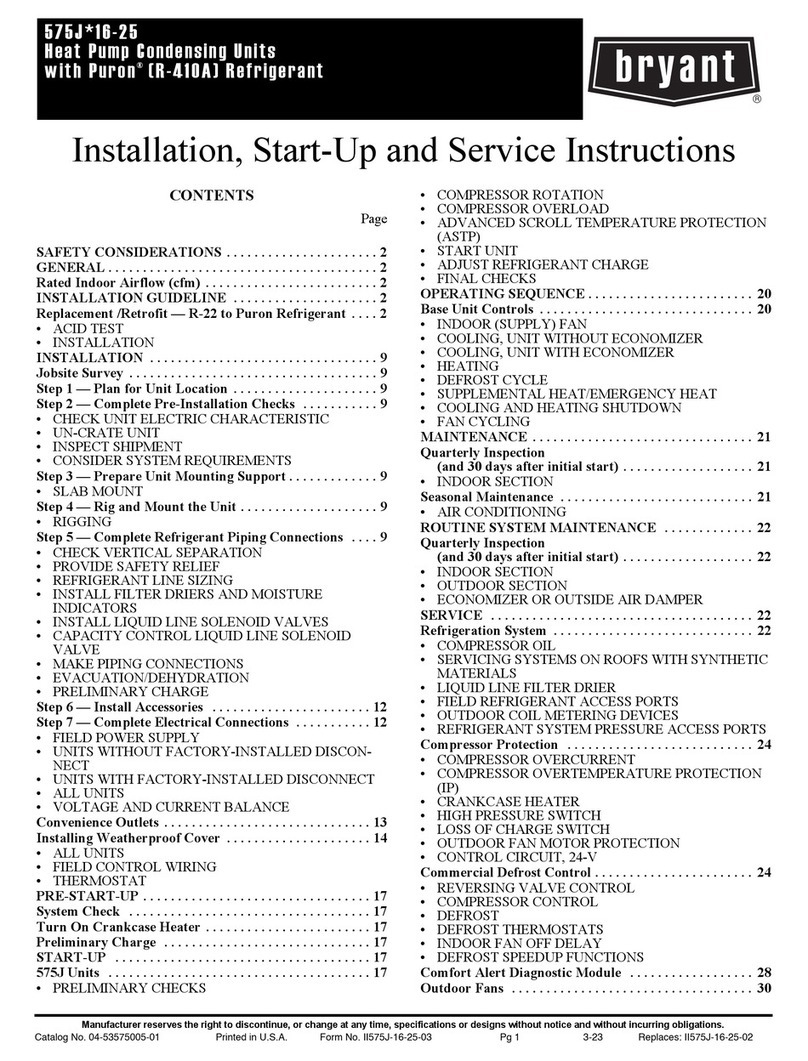

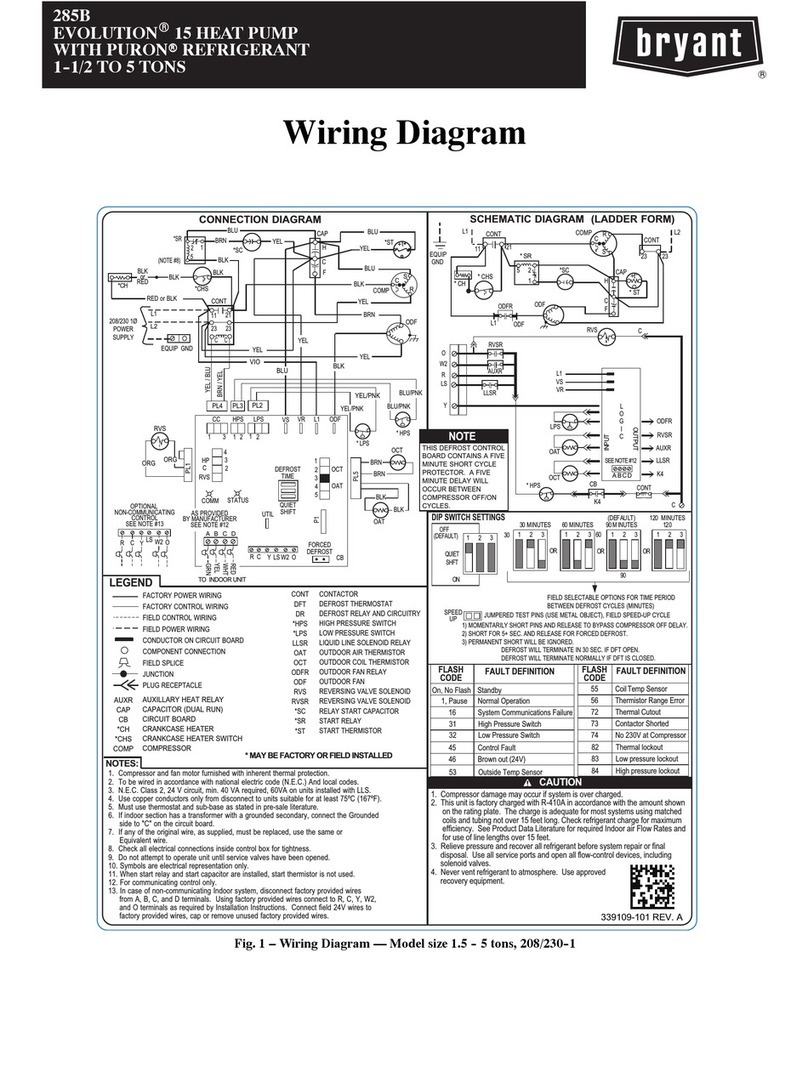

High-Voltage Connections (Fig. 10)

The unit must have a separate electrical service with a field-

supplied, waterproof fused disconnect switch mounted at, or

within sight from, the unit. Refer to the unit rating plate for

maximum fuse/circuit breaker size and minimum circuit amps

(ampacity) for wire sizing. Be sure disconnect switch does not

obstruct unit rating plate. A factory-installed disconnect is

available.

The field-supplied disconnect switch box may be mounted on

the unit over the high-voltage inlet hole in the control corner

panel.

Proceed as follows to complete the high-voltage connections

to the unit:

1. Connect ground lead to chassis ground connection when

using separate ground wire.

2. Pigtails are provided for field power connection. Use

factory-supplied splices or UL-approved copper/aluminum

connector. Install conduit connectors in side panel power

supply knockout openings indicated in Fig. 2. Route power

lines through connector to unit control box.

NOTE: If accessory thru-the-bottom power connections are

used, refer to the accessory installation instructions for in-

formation on power wiring. Refer to Fig. 2 for drilling holes

in basepan.

Special Procedures for 208-V Operation

DANGER: Make sure that the power supply to the

unit is switched off before making any wiring changes.

Electrical shock can cause personal injury or death.

For operation on 208 v, disconnect the black wire from the

230-v orange wire on the transformer and connect it to the

200-v red wire from the transformer. Insulate the end of the

orange wire.

Control Voltage Connections

Install a factory-approved room thermostat. See Table 3,

page 11. Locate the thermostat on an inside wall in the space

to be conditioned where it will not be subjected to either a

cooling or heating source or direct exposure to sunlight. Mount

the thermostat 4 to 5 ft above the floor.

NOTE: For wire runs up to 50 ft, use no. 18 AWG insulated

wire (35 C minimum). For 51 to 75 ft, use no. 16 AWG insu-

lated wire (35 C minimum). For 76 to 155 ft, use no. 14 AWG

insulated wire (35 C minimum). All wire larger than no. 18

AWG cannot be connected directly to the thermostat and will

require a junction box and splice at the thermostat.

LEGEND

C—Contactor

COMP — Compressor

IFC — Indoor Fan Contactor

NEC — National Electrical Code

Field Wiring

Factory Wiring

Splice Connection (Factory-Supplied)

Fig. 10 — Power Wiring Connections

—8—