5

1 – INTRODUCTION

The purpose of this manual is to provide all the

information required for the correct installation and

maintenance of model 6400 safety valves.

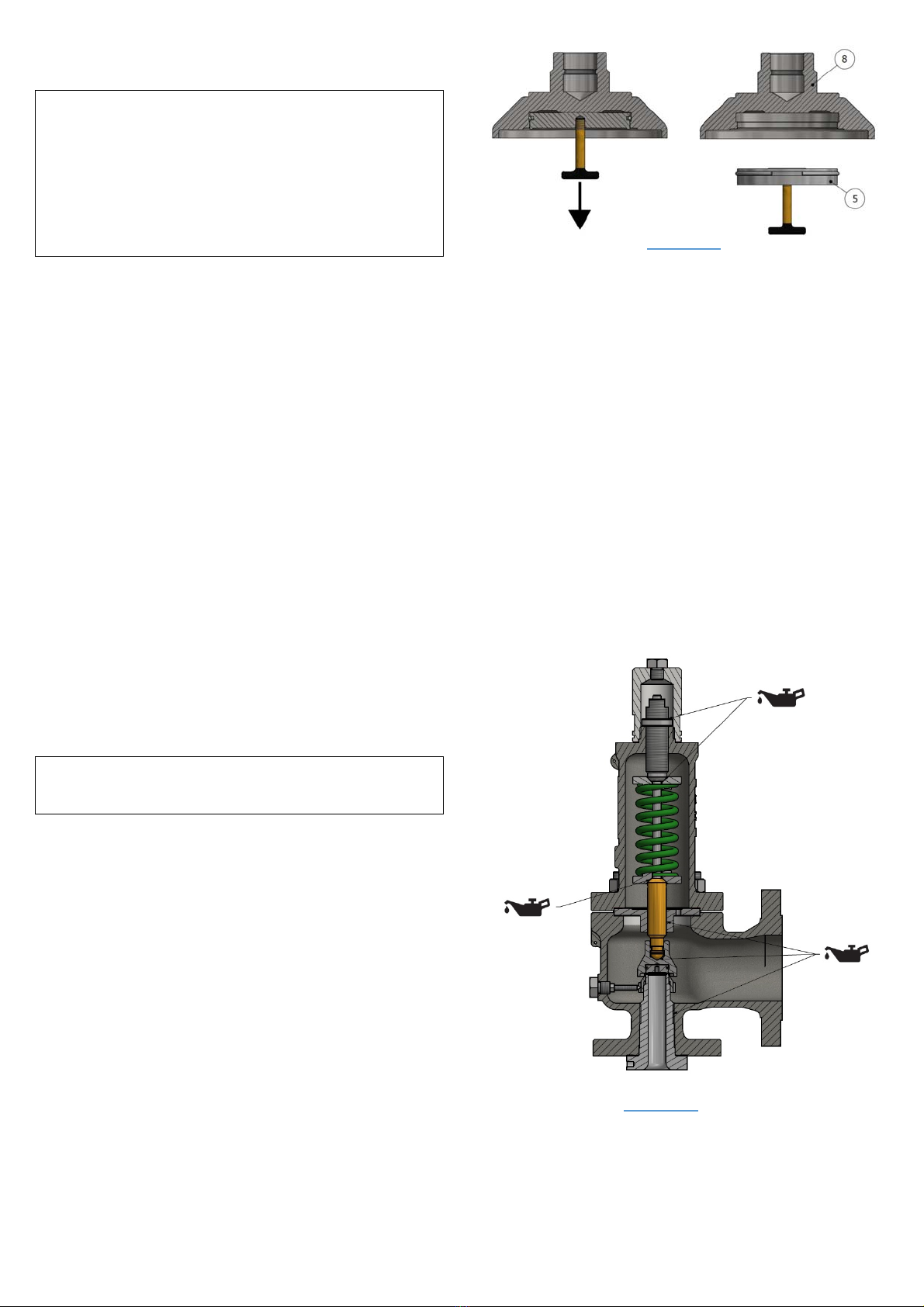

2 – DESCRIPTION

The model 6400 safety valves have been designed,

manufactured and tested in compliance with the

Pressure Equipment Directive 2014/68/UE Category IV

and Directive 2014/34/UE (ATEX) Group II Category II.

The model 6400 safety valves are safety devices whose

main function is to protect all kinds of pressurised

containers, with gases, vapours, liquids or mixtures,

from excess pressure.

For improved performance, the internal parts of the

valve have been designed depending on whether the

application is to work with gas of liquid. In both cases,

the valve opens instantly (pop).

Model 64G.- Designed to work with gases or vapours.

Model 64L.- Designed to work with liquids or gas-liquid

mixtures.

Depending on the requirements of the application, they

can be supplied as conventional valves (C), bellows

valves (F) or as piston valves (P).

They are constructed with an angle of 90º between the

inlet and outlet connections. The flanged body has a

large internal capacity to avoid backpressures when the

valve discharges. Other parts are: a fixed complete

nozzle easy to disassemble, a closed bonnet, an

helicoidal spring-loaded, a disc holder mechanism

designed accurately to obtain a good discharge

coefficient with both gases and liquids. Perfect alignment

of the guided components, avoiding rubbing and

premature wear and tear.

All safety valves are calculated and manufactured for a

specific application. If you wish to reuse an existing

valve for any other application, you must contact the

V.N. Technical Department for the corresponding

adaptation study.

3 – TRANSPORTATION AND STORAGE

The internal components of the safety valve are

precision-manufactured and fitted in such a way that

they will remain perfectly aligned.

Rough handling can damage the closing surfaces or

unalign the internal parts of the valve, causing leaks

or malfunctions. Therefore, handle the safety valve

with care.

Do not remove the adhesive protective disc that covers

the inlet and outlet flanges until the valve is in its final

position. This ensures the protection of the closing

surfaces and prevents foreign bodies from entering into

the internal chamber of the valve.

Carbon steel valves are protected externally with a

phosphated anticorrosive primer coat and enamelled

final coat which provides the valve a strong external

protection from oxidation. The studs and nuts are

protected with a dichromatized, a protection electrolytic

treatment.

If the valves have to be stored for a long period of time,

it is better not to remove them from their packing. It is

essential for the adhesive disc that protect the inlet and

outlet flanges not to be removed until their installation. It

is recommended the warehouse atmosphere to be

clean, dry and protected from open-air. If this is not

possible, the valve must be appropriately protected to

prevent from deterioration.

4 - INSTALLATION

Correct installation is essential for the safety valve to

operate correctly.

Remove the adhesive protective discs from the inlet

and outlet flange.

Once the valve has been fitted, it will probably need to

be serviced in the short term when the valve has not

been installed correctly, when the protected line is

contaminated with dirt or slag, when it is given a use for

which it was not designed or when the valve is not

handled correctly.

Before fitting the valve, make sure that the valve is

correct by checking the identification plate. Make sure

the seal has not been broken (otherwise, the set

pressure and tightness have to be checked again). Make

sure the valve is perfectly clean and that there is no dirt

inside the nozzle or in its body. If necessary, perform a

blow.

The pipe, the connection flanges and the valve holders

must be perfectly clean. You must be completely certain

that there are no foreign bodies such as particles on the

gaskets, slag, and/or dust which could be deposited on

the closing surface between the disc and the nozzle.

All the bolts that fasten the valve to the container must

be cross-fastened evenly to prevent deformations to the

body of the valve.

When the discharge is performed through a pipe to the

atmosphere, make sure that no water, dirt or

condensation accumulates inside the body of the valve.

The free discharge pipes must be fastened securely to

prevent the stress produced during discharge being

withstood by the neck of the valve.

The valve must always be fitted in vertical position. The

valve inlet pipe from the equipment or the installation

must be direct and as short as possible. The return

connection to the tank must be curved to avoid

turbulence and to enable the discharge of the fluid by

the valve.