Adani Solar ASP-7-AAA User manual

ASP-7-AAA

ASP-6-AAA

ASP-6-B-AAA

ASP-6-AB-AAA

ASM-7-PERC-AAA

ASM-6-PERC-AAA

ASM-6-B-PERC-AAA

ASM-6-AB-PERC-AAA

ASP-14-AAA

ASM-14-PERC-AAA

Applies to the below PV Module

Adani House,

Near Mithakhali Circle,

Navrangpura, Ahmedabad – 380009,

Gujarat, India

Tel : +91 79 2656 5555 Fax: +91 79 2555 55.

MUNDRA SOLAR PV LIMITED

MANUAL IEC & UL VERSION

PV MODULE INSTALLATION

1. DISCLAIMER OF LIABILITY 3

2. SAFETY MEASURES 4

2.1 Fire Safety 5

3. PV MODULE UNPACKING AND STORAGE 5

3.1 Module Identification 5

4. ENVIRONMENTAL CONSIDERATIONS 6

4.1 Climate Conditions 6

5. SITE SELECTION 7

6. MOUNTING INSTRUCTION 7

6.1 Mounting Methods 7

A. Bolt Type Fixing 7

B. Clamp Type Fixing 9

6.2 Pv Module Grounding 12

6.3 Electrical Wiring 14

6.4 Connectors 17

6.5 Bypass Diodes 17

7. ELECTRICAL & MECHANICAL PARAMETERS 18

8. ELECTRICAL CONFIGURATION 19

8.1. Fuse Rating 20

8.2 Selection of Inverter and Compatibility 20

9. PV MODULE MAINTENANCE AND CARE 20

10. PRODUCT RECYCLING & END OF LIFE 21

11. WARNING 21

12. CONTACT DETAILS 21

CONTENT

2. SAFETY MEASURES

•On direct exposure to sun light PV module

produces electricity, which can result in electric

shock or while working with module exposed

under direct sunlight, it is advised to use

installation tools and for precaution, wear hand

gloves to protect from electrical hazards. Also it

is advised to keep away from any metallic

contact touching the human body.

•Standing on module is strictly prohibited as it

can impact the module's performance and is not

applicable to warranty claims if it is discovered

that people have stood on PV modules, no one

should stand on the module rare and front

surface. Uneven pressure develop during

standing on it can damage solar cell.

•Module front surface is made of tempered glass

and has an ARC coating, so it needs special care

in handling. If glass breaks due to any reason, it

is advised to keep human contact away. At

ambient wet condition any human contact with

the broken glass surface may lead to electrical

shocks. Once module glass breaks it has to be

scraped or disposed after removing it from

String after String is disconnected from the

load.

•Any loose connection in connectors of PV

module can cause electrical arcing and can lead

to fire hazard. It is recommended to not keep

any gap in connectors. Also ensure all the

connectors should be corrosion free and

protected against corrosion and soiling. It is

strictly prohibited to remove or cut any

connector of PV Module for installation

easiness by the installer / customer and the

module is deemed out of warranty.

•Do not install or handle any PV Modules in

unfavourable environmental condition like high

flow winds and wet snowy roof surfaces for

personal safety. Modules should always be dry

while installing.

•Please Ensure the polarity of the modules or

strings is not reversed in relation to the other.

• This Installation Manual is

applicable for Mundra Solar PV

Ltd.'s (MSPVL) PV Modules. MSPVL

is referred as Adani / Adani Solar in

the Installation Manual as MSPVL is

part of Adani Group.

• This manual is for authorized &

trained users only. ADANI is not

responsible for any type of

mishandling or failure to follow

instruction manual. Any type of

Loss, Damage, Hazard, Injury or

Expense because of improper

installation, Handling, Usage &

Maintenance is not in scope of

ADANI.

• Adani Solar assumes no

responsibility for the infringement

of intellectual property rights or

other rights of third parties that

may result from use of the module.

No license is granted in this regard,

either expressly or implicitly, or

under any patent rights.

• Information contains in this

instruction manual is based on

ADANI Information and expertise.

This manual and specification can

be changed by the company

without giving any prior

information. Adani has rights to

amend this document any time

including PV module specification

without prior notification.

• The Installation manual is

applicable for both 1500V & 1000V

series modules. It is recommended

to check & get a confirmation from

the manufacturer on the rated

system voltage of the product

before using the panels.

•Any artificial sunlight

focusing on PV module is not

recommended as it can

reduce its performance and

life cycle.

•Adani PV modules are

certified to operate in Class A

condition installed below a

specified voltage level (1500V

/ 1000V dc). Consider this

voltage range while designing

the power plant. This value

should be taken into

consideration when designing

the power plant, as per the

temperature ranges present

at the site. The mixing of

power classes in one string is

not allowed and can be

harmful. Damage to modules

due to such mixing can lead to

the invalidity of product

warranties.

•At different environmental

conditions, PV module can

produce high current and

voltage than the measured in

STC condition. Snow and

water causes reflection which

can increase the sunlight

intensity which can increase

the flow of current and Power

output. The Isc value should

be multiplied by 1.25 when

determining the conductor

current ratings, fuse sizes, and

the size of controls connected

to SPV output. Refer to

Section 690.8 of the National

Electric Code (for modules

under UL spec) to check when

an additional multiplying

factor of 1.25 may be

applicable.

•The top structure and

installation may affect the

building fire safety; improper

installation may lead to fire

hazards. As required by the local

authorities, use such devices as

ground fault cut-outs and fuses.

•Please do not operate the panel

in the environment vulnerable to

combustible gases or near any

equipment.

•MSPVL PV Modules (for modules

under UL spec) have a Type 1 fire

resistance rating in accordance

with UL 1703 certification. The

fire rating of this PV module is

valid only when mounted in the

manner specified in the

mechanical mounting

instructions. When PV modules

are mounted on rooftops, the

roof must have a fire resistant

covering suitable for this

application. PV modules are

electrical generating devices

that may affect the fire safety of

a building.

•In the event of a fire, PV modules

may continue to produce a

dangerous voltage, even if they

have been disconnected from

the inverter, have been partly or

entirely destroyed, or the system

wiring has been compromised or

destroyed. In the event of a fire,

inform the fire crew about the

particular hazards from the PV

system, and stay away from all

elements of the PV system

during and after a fire until the

necessary steps have been taken

to make the PV system safe.

2.1 Fire Safety

Consult your local

authorities for

guidance and

requirements for

installation or

building fire

safety.

1. DISCLAIMER OF LIABILITY

3. PV MODULE

UNPACKING AND

STORAGE

•After receiving the PV

Modules, Customers are

requested to match the

product specification as it had

been ordered. All the module

serial number and other details

are present on the box of the

PV modules.

•Do not stack packing boxes

(pallets) more than 2 boxes

high. If pallets are temporarily

stored outside, an external

protective cover should be

placed over them and the

stack height should not be

more than 1 pallet high.

•During unpacking there should

be two people to unpack from

vertical side as shown in figure

below. Also keep attention

during unpacking that one

module should not fall on other

module inside the box.

•Improper handling of

PV module may cause

scratches and damage to

module. It is not recommended

to apply adhesive or paints on

the surface and frame of the

module.

•Do not short the –Ve & + Ve

terminal of the Junction box of

the PV Module at any time.

•Always use cutting pliers to

cut the cable tie of the

PV module. Do not use any

knife as it can damage the PV

Module.

•It is not recommended to place

modules directly on another

module.

3.1 Module Identification

Every module has a unique serial number, which is laminated

behind the glass. Please do not tamper with the serial

number of the module and always record all serial numbers

in an installation for your future records.

4.1 Climate Conditions

All Adani Solar modules are tested for IEC 61215, IEC

61730-I & II, UL 1703, IEC 61701, IEC 62716, IEC 62804.

The modules are qualified for application Class A.

Modules qualified for safety through IEC 61730 within

this application class is considered to meet the

requirements of Safety Class II. ADANI PV modules meet

the requirement of European standards as they are also

tested for the Ammonia fumes that may be present in

Barns sheltering Cattle, Pigs, as well as sustainability for

Installation in Humid (Coastal) Areas of high Sand Storms.

Adani module Passed in testing of Salt mist IEC 61701 Salt

mist corrosion test (Severity VI) with a salt concentration

of 5% by weight, galvanic corrosion can occur between

the aluminium frame and mounting or ground materials if

such materials are made of dissimilar metals. Stainless

steel and aluminium metal's direct contact is not

recommended for seaside installations to avoid metal

corrosion.

Environmental Condition

Ambient temperature: -40°C to +50°C.

Operating temperature: -40°C to +85°C.

Storage temperature: -20°C to +50°C.

Humidity: ≤85 RH%

4. ENVIRONMENTAL CONSIDERATIONS

Design Load: 800Pa and 1800 Pa

Safety Factor: 3

Mechanical Load Pressure:

5400Pa (112.8lb/ft2) from front and 2400 from

the rear (50.12lb/ ft2).

Stability of structure

Structure matching the mounting hole pitch of

different types of modules is used to survive the

load required and fatigue of the outdoor

application. The structure should be coated to

survive in external environment till lifecycle of PV

module of 25 Years. Please consult the Mundra

Solar technical support department for more

information on the use of modules in special

climates, , such as an altitude greater than 2000 m.

Important instruction for Mounting

•Always avoid loop formation during

designing, to minimize the risk during

indirect light striking.

•Confirm mounting system must withstand

the Loads of wind & and snow should not

cross the maximum rated load bearing

capacity of PV module that is 2400 Pa for

wind and 5400 Pa for snow. Adani advices

the customer to choose the modules

carefully considering the environmental

conditions.

•Modules are evaluated by third party lab for

max. positive loading of 5400 Pa.

•Module installation in projects must face

north while being installed in the southern

hemisphere and the modules should be

south facing while being installed in the

northern hemisphere. Electricity generation

reduces when the module installed at site

facing west or east. Failure to follow this

instruction will lead to lesser power

generation.

•When the modules are connected in series,

the angle at which it is installed should be

the same for all the modules. If modules in

series connected system are installed at

different angles, the radiation of sun

becomes uneven which will result in different

fluctuating current across the string and will

lead to loss in Power Output.

•PV module facing directly to sun produces

more power. When solar modules are

installed on permanent structure it is

recommended to tilt the PV modules for

optimum performance during winter season.

Measurement of tilt angle done between the

solar module and the ground. Recommended

Tilt Angle for a fixed system is listed below.

•PV modules should not be installed under

shade or shadow under any conditions as it

may lead to current mismatch across the

solar cells leading to damage of the solar

module. Shadow on the solar module is only

acceptable if the irradiation is lesser than

200 W/m2.

•Never disconnect module cables when it is

connected with load.

• The mechanical load bearing capacity depends upon the installer's

mounting methods and failure to follow the instructions in this

manual may result in different capabilities to withstand snow and

wind loads. The system installer should ensure that the installation

methods used meet these requirements as well as any local codes

and regulations.

• In installations not under the requirements of the NEC, the values

of ISC and VOC marked on this module should be multiplied by a

factor of 1.25 when determining component voltage ratings,

conductor capacities. . Installation shall be in accordance with CSA

C22.1, Safety Standard for Electrical Installations, Canadian

Electrical Code, Part 1”.overcurrent device ratings, and size of

controls connected to the PV output if the modules are being used

in canada.

• MSPVL sending modules always in packed condition. The qty.

details is always indicating outside box on sticker. If customer

received any lose module / open box condition at the time of receipt

of consignment, Receiver is advised to hold unloading and inform

MSPVL - Logistics team on mobile no-91 9099003579 and start

unloading as per his advice.

• Customer need to compare receipt no of Pallets qty. against

mentioned qty. on transporter’s LR / MSPVL packing list at the time

of receiving of consignment, For any difference in QTY of no of

pallets, recipient is advised to mentioned discrepancy clearly on LR

and obtain signature of vehicle driver and also obtain driving

License copy of driver.

• For any “ physically damage of pallets on vehicle “ Customers are

requested to intimate us along with support photographs of

damaged pallets-on vehicle for Insurance claim purpose on same

day of receipt of container and same need to inform MSPVL-

Logistics team on mobile no-91 9099003579 and start unloading as

per his advice.

• It is necessary to mentioned discrepancy remark clearly on

transporter LR duly signed and stamped, It is also necessary to

obtain signature of driver on LR / POD. The discrepancy remarks

should be agreed by Vehicle driver

• All LR (POD) shall be stamped and sealed duly signature by

customer mentioning number of pallets received.

• For the detail Procedure for transit damage insurance claim please

refer to document no. MSPVL/MDL/PQA/SOP/15

Fig 1: Method of

module unpacking

Fig 2: 72 Cell Module Drawing of

ASM-7-PERC-AAA & ASP-7-AAA

3.1 Module Identification

PV modules can be installed or fixed by Bolts

method or by clamp method. For bolts type

fixing corrosion resistive M8 bolts to be

used, Mounting methods should ensure

following things:-

•Minimum clearance required between

module frame and surface of the roof or

wall is 200 mm.

•Minimum distance between each Solar

PV Module should be 10.50 mm.

•Drainage holes should be kept open and

no blockage is allowed in the drainage

hole.

PV modules are not to be subjected to wind

or snow loads exceeding the maximum

permissible loads and should not be

subjected to excessive forces due to the

thermal expansion of support structures,

careful consideration has to be shown

during system design and installation such

that thermal expansion of support

structures do not cause any breakage of PV

modules which will not be part of Adani

Solar's Warranty Document. When modules

are ground mounted, select the height of

the mounting system in such a way as to

prevent the lowest edge of the module from

being covered by snow for a long time in

winter in areas that experience severe snow

fall. If snow settles on the PV modules, the

regular clearing of snow and other foreign

particles and dust and dirt is highly

recommended to ensure the long-term

reliability of the PV modules. Failure to

comply may result in damage to the module

and lead to deformation or drop in power

output which will not be covered under

warranty.

* “The module is considered to be in compliance with UL 1703 only when the module is mounted in the

manner specified by the mounting instructions below.”

*“Any module without a frame (laminate) shall not be considered to comply with the requirements of

UL 1703 unless the module is mounted with hardware that has been tested and evaluated with the

module under this standard or by a field Inspection certifying that the installed module complies with

the requirements of UL 1703”,

A. Bolt Type Fixing

Every module frame contains 8 mounting holes of 9 mm X 14mm. It is recommended from ADANI to use

corrosion resistance stainless steel fixing. The module fixed with the support of M8 bolt, washer and

nut. For reference please see the below image. The assembly of M8 bolt, nut, washer and the PV

module should be tightened to a minimum torque of 16-25 Nm.

Mechanical Drawings of PV Module “ASM-7-PERC-AAA & ASP-7-AAA”.

• PV modules should be installed in a

place where no shading occurs

throughout the year. Shading can be

minimized by ensuring that the

distance between an obstruction and

the solar array is more than three times

the height of the obstruction.

• PV module can be installed in portrait

or landscape orientation, impact of dirt

shading can be minimized by orienting

the PV modules in portrait. The module

facing should be south in northern

hemisphere and north in southern

hemisphere.

• Sufficient row to row gap has to be

chosen and PV modules should be

spaced between two rows

appropriately such that no shadows

appear on the PV module at any part of

the day during 365 days due to inter

row spacing.

• For optimum energy production, solar

modules should normally be mounted

facing the equator at an angle to the

horizontal plane equivalent to the

latitude of the installation. If the PV

module is placed at a different angle or

orientation, this could have a direct

impact on the power output.

• To maintain the fire class rating any

slope of 1: 2.4 is required.

• Do not use mounting methods where

drainage holes are blocked.

• At any condition PV module should not

be installed by immersing the module

under water.

• PV module should not be installed on

moving objects like vehicle or vessel.

• ADANI solar module is fire rated with

Type 1 for Class C.

5. SITE SELECTION 6. MOUNTING INSTRUCTION

B. Clamp Type Fixing

ADANI Solar has done number of tests on clamps

and on the basis of that test results, it is

recommended to use clamps with EPDM or with

insulating type washer only.

• Total 4 numbers of clamps are required to fix the

PV module on structure or mounting rail.

•To avoid any kind of breakage of glass, clamps

should not touch the glass and the shadow of

clamp should not come on the module front

surface.

•No modification or changes in the structure of

module frame is permissible.

When modules fixed with clamp type fixing

method, 4 clamps are required to fix the module, 2

clamps on each long side frame and 2 clamps on

each short type frame side. ADANI solar modules

are certified for bearing 2400 Pa wind load and

5400 Pa snow load on the front side of the PV

module. To bear this load more number of clamps

can be used to fix the module.

Fig 3: PV Modules Installed with screw fitting method

PV LAMINATE

ALLUMINIUM FRAME

SCREW

LOCKING NUT

NUT WASHER

SUPPORT STRUCTURE

Fringe Module Installation

Fig 4: PV Modules Installed with Fringe Clamping Method

Middle Modules Installation

Fig 5: Middle Modules Installed with Clamping Method

PV LAMINATE

ALLUMINIUM FRAME

SCREW

LOCKING NUT

NUT WASHER

SUPPORT STRUCTURE

• Figures to represent mounting

methods and applies to all 144,

72, & 60 Cell PV Modules.

Different Mounting

Configurations can be tried as

per Installer's calculations, but

however failure to comply with

the above suggestions may result

in a lowering of load handling

capabilities and may lead to

failure of any overload situation

which may not be covered under

product warranty.

Mounting Methods

Bolt type Fixing

Long Side Clamping

Short Side Clamping

At 2400 Pa load condition At 5400 Pa load condition

Mounting Hole Mounting Hole

Use Four Mounting Hole Use Eight Mounting Hole

Temp coefficient of Current

Temp coefficient for voltage

Temp coefficient of Power

System Voltage

NOMT

Series Fuse Rating

Junction Box

Aluminium Frame

Solar Glass

Weight

Product Certifications

Output cable

Bypass diode

1

2

3

4

5

6

7

8

9

10

11

12

13

0.069 %/°C

-0.31 %/°C

-0.40 %/°C

1000V/1500V (IEC & UL)*

45±2 °C

15

IP67 with MC4 compatible

connectors.

Anodized aluminium frame

with twin wall profile

High Transmittance ARC Glass

23.5 Kgs

IEC 61215 , IEC 61730 , IEC 62804 ,

IEC 62716 , IEC 61701

1200 mm length cable, MC4 &

Amphenol compatible connectors

3 DIODES

For more specification please refer product datasheet.

2. Typical specification of ASP-7-AAA series modules

Dimensions depending on Module type in (mm)

ASP-7-AAA;

ASM-7-PERC-

AAA

1998

965

48.31

202

499.5

249.75

241.25

ASP-6-AAA ;

ASM-6-PERC-

AAA; ASM-6-B-

PERC- AAA ;

ASM-6-AB-

PERC-AAA

1660

947

47.45

198.4

415

207.5

236.75

ASP-14-AAA

ASM-14-PERC-

AAA

1996

947

47.45

198.4

499

249.5

236.75

Length

Breadth wise

mounting hole pitch

X

Y

A

B

C

Model Name

Voltage (V)

1000W/m2

800W/m2

600W/m2

400W/m2

200W/m2

Current-Volage curve for mono crystalline

1000W/m2

800W/m2

600W/m2

400W/m2

200W/m2

0 21 3 5 7 8 9 1064

0 10 20 30 40 50

Current (A)

Voltage (V)

Current-Volage curve for multi crystalline

•Appropriate grounding is done by

bonding the module frames and all the

metallic structure together with the

help of a grounding conductor made of

copper, copper alloy or other material as

per the electrical conductor perspective

of National Electrical Codes. The

grounding connector should be

connected to earth with the help of

earth ground electrode.

•ADANI solar modules can be installed by

using any third party listed grounding

devices to connecting grounding

terminals. As per instruction manual of

grounding device manufacturer, the

grounding device should be installed. It

is recommended to ground every

module at the provided grounding holes

(4 mm or 5/32 inch diameter marked

with ground symbol.

•For grounding hole location and its size

please refer to the product catalogue.

•Adani recommends following grounding

procedures for the proper groundings.

Please refer below figure

6.2 PV Module Grounding

•As per National Electrical code (NEC

Guidelines) all the PV Module (modules

under UL spec) frames and mounting

structures must be properly grounded for

safety of people on the site. The module

frame must be properly grounded (refer to

NEC clause 250).

•Appropriate grounding is done by

bonding the module frames and all the

metallic structure together with the help

of a grounding conductor made of copper,

copper alloy or other material as per the

electrical conductor prospective of

respective national standards. The

grounding connector should be

connected to earth with the help of earth

ground electrode.

•In case of metallic support, the surface of

the frame must be electroplated.

•First, carefully strip 16mm of the

insulating jacket from the end of

grounding wire to avoid nicking or cutting

conductors, insert the wire into the slot of

the lug (see picture), and screw down the

slotted screw.

•To fulfil the grounding & bonding

requirements, please refer to the regional

and national safety and electrical

standards. Always use recommended

type of connectors or similar for

grounding.

•If grounding is required, the grounding

wire must be properly fastened to the

module frame to ensure

•Screw must be tightening with torque of

2.3 to 2.8 Nm [20 and 25 in. - lbs.]. The

head of the screw must be flushed with

the base and base must be flush with the

frame.

Fig: Grounding assembly of PV module

“A module with exposed conductive parts is considered to be in compliance with UL 1703 only

when it is electrically grounded in accordance with the instructions presented below and the

requirements of the National Electrical Code.

Procedure 1:- Grounding by bolts: 2058729-1

1) Wire bolt and slot 2) Mounting wash hex nut 3) Aluminium frame

4) 4 to 16mm2 cable 5) HEX nut

•Tyco made grounding hardware comes with

grounding bolt, mounting and grounding

hex nut inside the package.

•Electrical contact developed by penetration

of anodized coating of the aluminium frame

and tightening the mounting.

•Grounding wire dimension should be

considered of 6 to 12 AWG solid bar copper

and installed under the wire binding bolt.

•Tightening of wire binding bolt must be

done at proper torque level 45 in lb.

Procedure 2:- Grounding by bolts: # 2058729-1

•Tyco made grounding hardware comes with

grounding bolt, mounting and grounding

hex nut inside the package.

•Electrical contact developed by penetration

of anodized coating of the aluminium frame

and tightening the mounting hex nut by

applying proper torque of 25 in lb. Hex nut

comes with a star washer.

•Grounding wire dimension should be

considered of 6 to 12 AWG solid bar copper

and installed under the wire binding bolt.

•Tightening of wire binding bolt must be

done at proper torque level 45 in lb.

•Tyco grounding bolt is only recommended

to use with 6 to 12 AWG solid copper wire.

1) Wire slot (available for 4-6 mm2 cable) 2) Slider 3) Bolt 4) Base 5) Nut

Procedure 3: ERICO grounding bolt EL6CS14-6

1) Machine bolt A 2) Machine bolt B 3) Belleville washer 4) Flat washer 5) Clearance

hole for 10[M5] machine bolt 6) Aluminium frame 7) Machine bolt hex nut with lock

washer 8) Grounding bolt

It is recommended that lug should be installed on a surface that is larger than the bottom

surface of the lug.

•Lug should be fixed on the grounding hole present on the PV module.

•To secure grounding bolt to the module frame machine bolt A should be torqued to 35

in lb,

•Grounding bolt can be used with only 6-12 AWG bare copper wire.

•Machine bolt must be torqued up to 35 in lb for the proper wire binding.

•“Where common grounding hardware (nuts, bolts, star washers, spilt-ring lock washers,

flat washers and the like) is used to attach a listed grounding/bonding device, the

attachment must be made in conformance with the grounding device manufacturer’s

instructions.”

•“Common hardware items such as nuts, bolts, star washers, lock washers and the like

have not been evaluated for electrical conductivity or for use as grounding devices and

should be used only for maintaining mechanical connections and holding electrical

grounding devices in the proper position for electrical conductivity. Such devices,

where supplied with the module and evaluated through the requirements in UL 1703,

may be used for grounding connections in accordance with the instructions provided

with the module.”

• All wiring should be performed by

well-trained installers as per the local codes

and regulations.

• It is recommended to connect only such

number of modules in series such that the

system voltage should not exceed the rated

value at any time of the year. The EPC to

choose the appropriate design based on

the Inverter MPPT ratings and operating

voltage conditions and the environmental

conditions considering the lowest

temperature at the site.

• To increase the operating voltage , PV

module have to connect in series and for

connecting modules in series , positive

connector of one module is connected to

the negative terminal of another module.

During series connections, please ensure

the sound of click should come. Click sound

shows the proper connectivity between the

two terminals. Adani recommends a

maximum of 2 strings to be connected in

parallel with appropriate string fuse for

circuit protection.

• If any module/array/string is connected in

reverse polarity, in that case product can be

damaged permanently and repair is not

possible and Warranty will not rendered to

those modules. Before making parallel

connection always verify voltage level and

polarity of the string. If during

measurement any reverse polarity or a

voltage difference of 10 V found between

the strings then check the strings circuit or

string configuration before making

connection. All the wiring should be

performed by well trained and qualified

technicians only.

• It is highly recommended and advised for

the EPC to use Blocking diodes of

appropriate specifications in String

Combiner boxes to prevent any reverse

current arising out of parallel strings due to

voltage mismatch across Strings in Grid

Scale utility power plants or from Storage

devices if used with Storage solutions.

• ADANI Solar modules contains copper

cables with 4mm2 cross-sectional area

with voltage rating 1000V/1500V (IEC&UL)

for maximum system voltage, 90° C and are

also UV Resistant. Do not expose cable in

water logged place. When additional

connectors and cables are used then check

that connectors should be compatible with

MC4 and cables are 12AWG.

• Maximum system voltage should be less

than the rated system voltage or the

maximum input voltage of the inverter. Voc

α(1/T) so the open Circuit Voltage require

to calculated at the lowest Ambient

temperature for the location Power

generation unit.

For this below formula can be used:

System voltage =

X * Voc * [1 + ((Tα-Voc (%) x (25 - Tmin))] Where;

X - No: modules which are connected in series.

Voc - Open circuit voltage of each module (Refer to the Data Sheet)

Tα-voc - Thermal coefficient of open circuit voltage for the module in Percentage

Tmin - Minimum ambient temperature of the location of the plant

• Outer cable diameter maximum is 7 mm and minimum is 5 mm.

• In field application it is recommended to use 4 mm2 cables insulated for minimum of 90°C

and designated as PV wire.

• Bending radius of junction box cable is minimum 42 mm.

Bending radius of

junction box should be

minimum 42 mm

Bend

Radius

Correct routing

Incorrect routing

1. SERIES WIRING

2. PARALLEL WIRING

3. SERIES PARALLEL WIRING

6.4 Connectors

• Protect unplugged connectors against moisture, dust and any

environmental pollution. Only clean and dry plugged connectors

fulfil their ingress protection (IP) class. Ensure that connector

caps are hand tight before connecting the modules. Do not

attempt making an electrical connection with wet, soiled, or

otherwise faulty connectors. Avoid sunlight exposure and water

immersion of the connectors. Avoid connectors resting on the

ground or roof surface.

• Faulty connections can result in arcs and electrical shock.

Check that all electrical connections are securely fastened.

Make sure that all locking connectors are fully engaged and

locked.

• The junction boxes used with MSPVL PV modules contain

bypass diodes wired in parallel with the PV cell strings. In the

case of partial shading, the diodes bypass the current generated

by the non-shaded cells, thereby limiting module heating and

performance losses. Bypass diodes are not overcurrent

protection devices.

*Modules equipped with PV wiring connectors that comply with

the Standard for Connectors for Use in Photovoltaic Systems, UL

6703, shall have the specific allowable mating connector

manufacturer(s) and model number(s) listed, as well as contact

information and/or website of the PV connector manufacturer.

If a specific module product is available with multiple PV wiring

connectors from various manufacturers, then the following shall

be included:

1) Means to identify each distinct PV connector manufacturer’s

product - such as a picture or illustration, unique physical

features, markings, company logos, etc,

2) Allowable mating connector manufacturer and model

number(s) listed for each distinct cable connector

manufacturer’s product(s), as well as contact information

and/or website of the PV connector manufacturer

6.5 Bypass Diodes

•Bypass diodes divert current from the cell strings in the

event of partial shading.

•Diode replacement of potting type Junction is not possible in

case of any type of failure. If any bypass diode stops working

then the only way to correct the problem is to replace the

complete Junction box with new one. To replace Junction

Box MSPVL recommends contacting the supplier.

6.6 Cables and Wiring

•Adani PV modules are provided with two (2) stranded,

sunlight resistant output cables that are terminated with PV

connectors (MC4 & Amphenol compatible) ready for most

installations. The positive (+) terminal has a female

connector while the negative (-) terminal has a male

connector. The module wiring is intended for series

connections (i.e. female (+) to male (-) interconnections), but

can also be used to connect suitable third-party electrical

devices that may have alternative wiring configurations so

long as the manufacturer’s instructions are followed.

•Use field wiring with suitable cross-sectional areas that are

approved for use at the maximum short-circuit current of the

PV module. Adani recommends installers to use only sunlight

resistant cables qualified for direct current (DC) wiring in PV

systems. The minimum wire size should be 12 AWG. The

temperature range of the cables is -40°C to +90°C.

•Cables should be fixed to the mounting structure in such a

way that mechanical damage to the cable and/or the module

is avoided. Maintain a minimum cable bending radius greater

or equal than five times the cable diameter. Route the cable

in a way that the tensile stress on the conductor or

connections is prevented. For fixing, use appropriate means,

such as sunlight resistant cable ties and/or wire

management clips specifically designed to attach to the PV

module frame. While the cables are sunlight resistant and

waterproof, where possible, avoid direct sunlight exposure

and water immersion of the cables.

7. ELECTRICAL & MECHANICAL PARAMETERS

315-350

8.10-9.60

43.3-46.7

Maximum system 1500

Voltage [VDC]

Rated maximum

power range

[W]

Module

technology

Number of cells

Rated short

circuit current

range [A]

Rated open

circuit voltage

range [V]

Over-current

protection

rating [A]

Dimensions

(l × w × h) [mm]

Maximum Series

Fuse, (A)

Fire Class Rating

Weight

Multicrystalline

72

15

1998x1010x35/40

15

Class C, Type 1

23.5 Kg (35 mm

frame variant)

28Kg(40 mm

340-385

265-270

8.10-9.50 8.7-10.37

43-48.69

1500

1500

frame variant)

Multicrystalline

60

36-38.4

15

1660x992x35/40

15

Class C, Type 1

17.5 Kg (35 mm

frame variant)

18.8 Kg(40 mm

frame variant)

Monocrystalline

72

15

1998x1010x35/40

15

Class C, Type 1

23.5 Kg (35 mm

frame variant)

28Kg(40 mm

frame variant)

Type name or

model number

ASP-7-AAA ASP-6-AAA

ASP-6-B-AAA

ASP-6-AB-AAA

ASM-7-PERC-

AAA

All electrical data

mentioned above shall be

shown as relative to

standard test conditions

(1000 W/m2, 25 °C, AM 1,5

according to IEC TS 61836).

1960x992x35/40 1674x1010x35/40 1960x992x35/40

The products can be

used in Grid Connected

Utility &standalone

system in houses,

rooftop, PV stations,

Communication stations,

Petrol, Ocean,

metrological, traffic and

solar building etc. The

maximum power of

ASP-7-AAA Multi

Crystalline Silicon 72

series modules is in

range of 300 Wp to 335

Wp with tolerance of

±3%. So the EPC /

Customer is advised to

not to mismatch any

modules & strings with

different currents and

different voltages which

can lead to adverse

effects of performance

generation of the entire

PV Power Plant.

• A solar array generates DC

electricity when sunlight

falls on the modules and the

inverter is in active mode.

Once the minimum voltage

and current requirements

are met, this is converted

into AC power accordingly.

• Adani’s ASP & ASM series

modules are made with 144,

66, 72 or 60 crystalline

silicon cells of high

efficiency. Cell circuit is

laminated with the help of

encapsulant sheet and front

surface is of tempered glass

with plastic polymer sheet

on its back side to provide

electrical insulation and

environmental protection.

Then the laminates are

inserted into anodized

aluminium frame. IP67 rating

terminal box made of plastic

material which is resistant to

high temperature contains

connection terminals and

bypass diodes. In aluminium

frames there is number of

holes to attach the modules

with structure in field.

8. ELECTRICAL

CONFIGURATION

Caution

Electrical hazard

While disconnecting the array from the circuit, use rated Isolator or DC switch. DC power

after disconnection may be active for some time and hence it is recommended only trained

person should operate or handle upon Panels, string Combiner Box etc. ADANI solar is not

responsible for any type of accident occurring in Power plant using ADANI panels.

•There is always a risk of Lightening to PV Power plants and PV modules and Adani Solar

requests the EPC Installer and the customer to analyse the risk of lightening as per IEC

62305-2 and install Lightening arrestors and SPD's such that no part of PV system and

PV Module is affected by Lightening or any other high voltage surges. To ensure effective

protection for entire power plant along with PV modules, a lightning protection system

with optimally coordinated elements with air-termination system, earth-termination

system, lightning equipotential bonding, surge protective devices for any DC

input/output devices as per IEC 61643-11. Consistent lightning and surge protection for

all systems allows to considerably increasing the performance ratio of Solar PV power

The modules are rated to operate at potentially dangerous voltage level of just under a

specified system voltage; coming in contact of this high voltage may cause electrical

hazards, Arcing and Fire hazards. It is recommend that all the solar Module, Module array

and the DC combiner box should be handled by only trained person. Adani is not responsible

for any hazards on the site and to the trained manpower in event of any safety hazard or

causality.

8.1. FUSE RATING

Connect Fuse in

non-grounded pole of solar

array. Maximum fuse rating

connected in series is 15 A.

Actual fuse rating is

mentioned in PV module

specification sheet and on

the PV Module's back label.

Fuse rating value also

indicates the maximum

current reverse current that

can flow from the module. It

is recommended to use 15 A

fuses per string.

8.2 Selection of Inverter and compatibility

Only connect the quantity of modules that corresponds to the

voltage specifications of the inverters used in the system.

When installed as per the IEC standards and regulations, Adani

Solar modules do not normally need to be electrically

connected to earth and can operate with either galvanically

isolated (with transformer) or transformerless inverters. If

galvanically isolated inverters with transformers are used, the

negative pole of the array must be connected to earth. If a

transformer less inverter is used, the installer should ensure

that the right active negative earthing / grounding or PID

Controller kit is installed by consulting with the inverter

supplier and taking approval from the inverter supplier. Both

methods are required in order to prevent the modules from

potential induced degradation in the field.

The module is considered to be i

n compliance with this standard

only when the module is mounte

d in the manner specified by the

mounting instructions. A module

with exposed conductive parts is

considered to be in compliance

with this standard only when it is

electrically grounded in accorda

nce with the manufacturer's inst

ructions and the requirements of

the National Electrical Code, AN

SI/NFPA 70 (2014-2017)

9. PV MODULE MAINTENANCE AND CARE 9. PV MODULE MAINTENANCE AND CARE

For better performance and reliability of the system, a minimum of maintenance is required in

well-designed PV plants.

•It is recommended to do yearly plant maintenance by trained professionals. Complete

everyday tracking of PV Module's performance through SCADA or through string

performance should be noted and tracked and analysed and if any discrepancy from normal

behaviour, it should be immediately notified to Adani Solar.

•Check the mounting structure status and

ensure any all the modules should be tightly fitted on the structure and should be as per the

mounting instruction provided above.

•Check for any shading on PV module, area of module on which light is falling should not be

shaded by any trees, objects and leaves. All these obstructing objects should be removed

immediately. Early morning / Late Evening shadowing where irradiance is lesser than 200

W/m2 is acceptable.

•Ensure all cable assemblies are tightly fitted and no part of the cable is immersed or

exposed to water logging.

•Check all the strings fuses of each non-earthed pole are working properly and in operation.

•To clean the module always use soft module cleaning kit or do cleaning with soft cloth and

slight detergent as an alternate solution. Cleaning can be performed by Wet Cleaning, Soft

Cleaning, Compressed Air cleaning, rotating brush, Dry Brush cleaning. Cleaning should be

performed in a way that no stress on PV modules is caused and no cracks on solar cells to

be caused out of cleaning. Water used for cleaning should be of same temperature as of

module, and water should be regularly checked for TDS, it is immediately recommended to

install RO at the site if the TDS of the water is deviating from appropriate standards and

acceptable limit of less than 500mg/l. Water used for cleaning should be of the same

temperature as of the module and if not used, temperature difference can create thermal

shocks by which PV module can be damaged and will not be a part of the Warranty. During

cleaning, always ensure at all condition module should not be damaged from micro crack

and other type of defects. Climbing of personal on the PV modules is strictly prohibited as it

can cause irreversible damage to the solar cells of the PV modules. The PV Modules are

advised to be cleaned regularly ensuring dust/dirt free and devoid of any bird droppings.

Failing to clean the same can cause damage to the solar cells of the PV modules.

•For maximum power output and generation and best reliability, it is recommended to keep

modules clean and tidy.

•The rare surface of the module does not require cleaning unless any objects or dirt stuck on

the backsheet. Avoid cleaning by sharp edges objects which can damage the material of

backsheet and can cause a cut and impact the performance of the PV module and the plant

due to cascading effect.

Product should be recycled in useful renewable method after end of its life cycle.

Please contact Adani Solar after the end of product life cycle for recycling procedure.

11. WARNING

While performing any type of electrical maintenance, all the system should be isolated /

shutdown and maintenance should be performed by well trained professionals only. Any failure t

o follow instruction may results in lethal electric shocks, burns, other injuries and some time m

ay death also. ADANI solar is not responsible for any type of accident occurring in Power pl

ant using ADANI panels.

The documentation includes a statement advising that external or otherwise artificially concen

trated sunlight shall not be directed onto the front or back face of the PV module (if not qualifi

ed for).

12. Contact Details

PV modules do not contain any serviceable parts. If customer has any

doubts that installation is not working properly, please contact your

installer / EPC / O&M. Immediately and immediately please leave a note

to the Adani's Customer Service Team.

1. Contact ADANI Solar sales and service team at [email protected]

2. Email customer feedback at [email protected]

This manual suits for next models

4

Table of contents

Popular Control Unit manuals by other brands

Beale Street Audio

Beale Street Audio DBT-TAYLOR quick start guide

Nice

Nice WA20/A Instructions and warnings for installation and use

AMCI

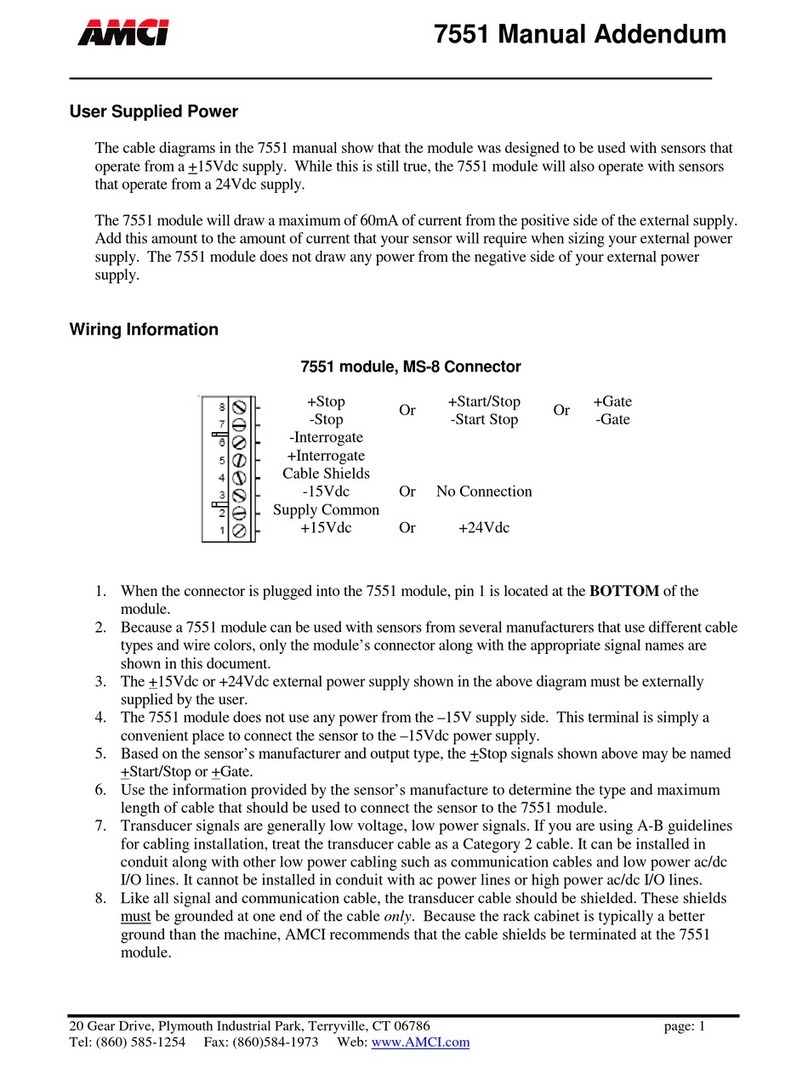

AMCI 7551 Manual addendum

Carrier

Carrier INDUCTION AIR TERMINALS 36S installation instructions

ACM

ACM LS 1297 Instructions and warnings for fitters

Evco

Evco C-PRO 3 CLIMA sistema+ Installer manual