Contents

1. Introduction ..................................................................................................................................1

1.1.Application range and definition.......................................................................................1

1.2. Description........................................................................................................................1

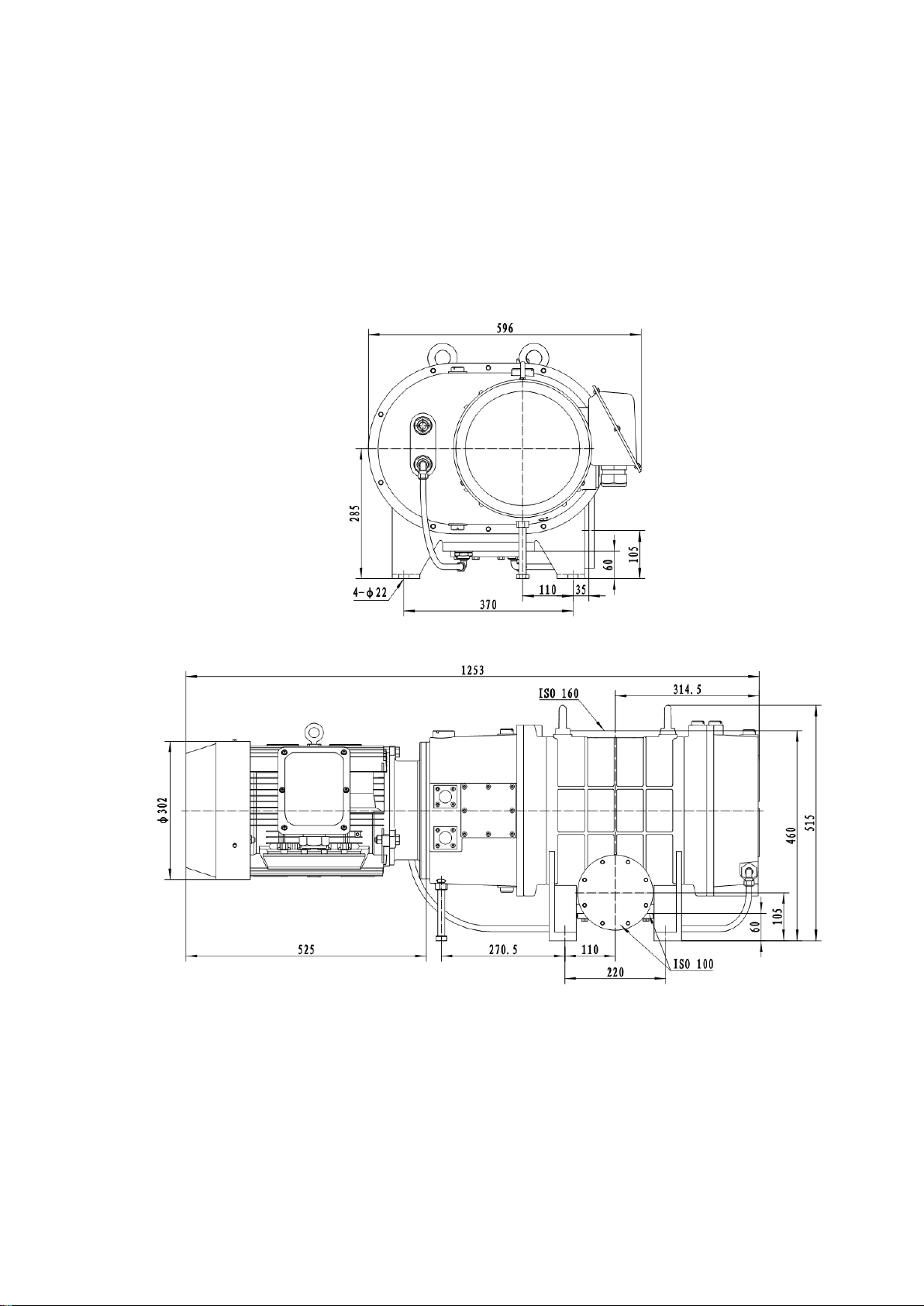

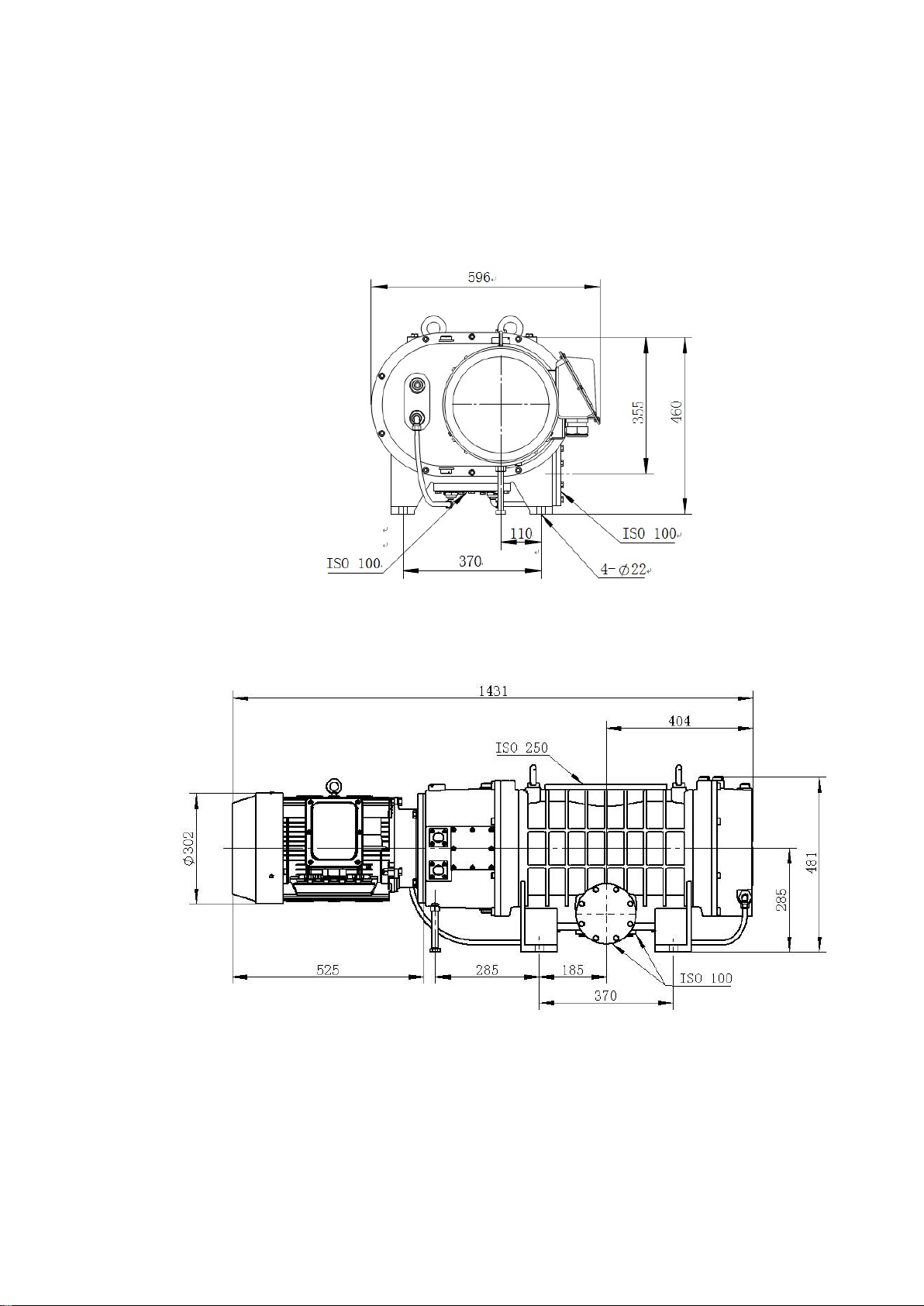

1.2.1. Outline...................................................................................................................1

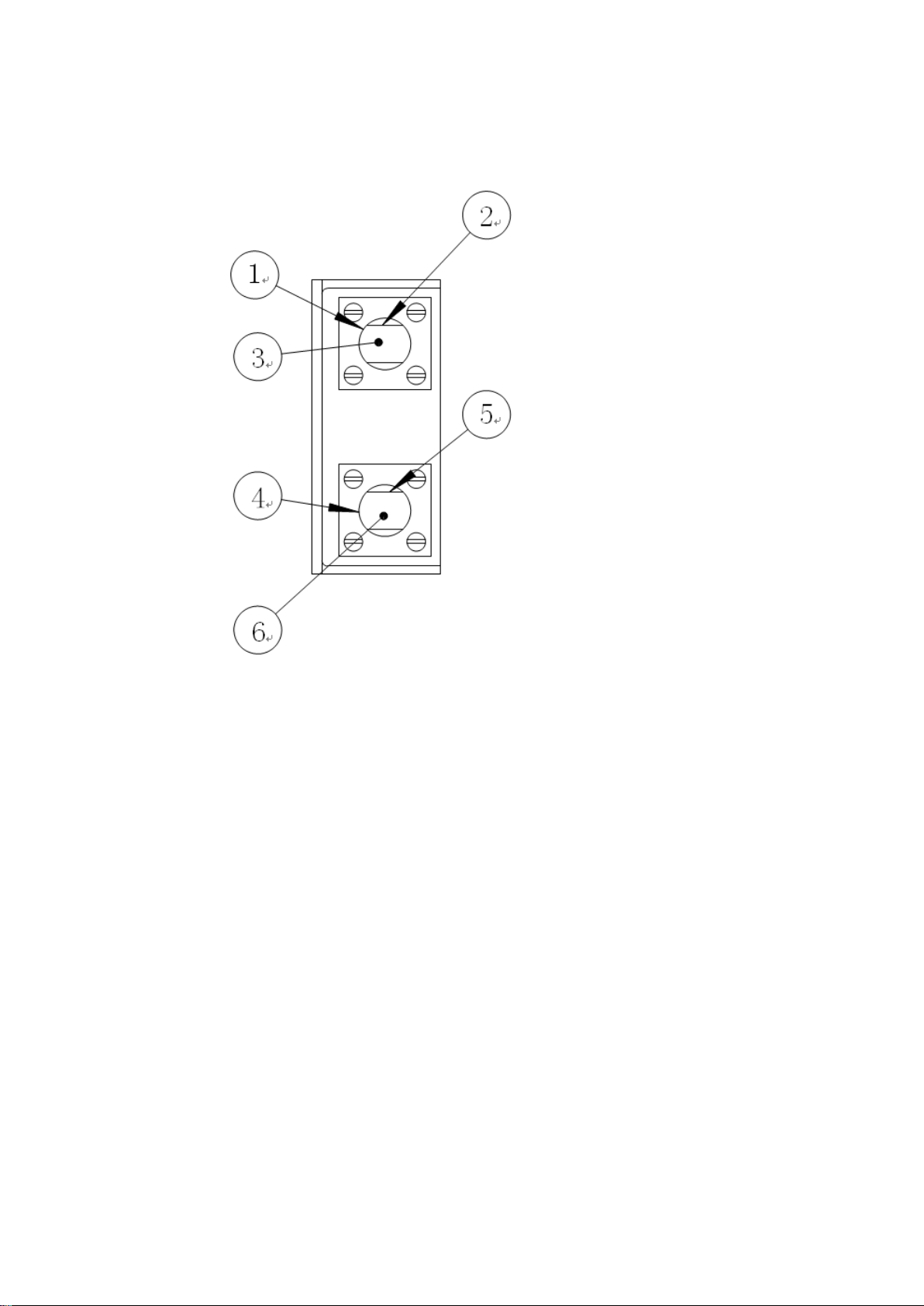

1.2.2. Structure ...............................................................................................................2

1.2.3. Working Principle ..................................................................................................2

1.2.4. Hydraulic transmission..........................................................................................2

2. Technical Data ...............................................................................................................................2

2.1. Operation and storage......................................................................................................2

2.2. Performance .....................................................................................................................3

2.3. Mechanical data................................................................................................................3

2.4. Electric data ......................................................................................................................4

2.5. Lubrication data ................................................................................................................4

2.6. Cooling water data............................................................................................................4

2.7. Vibration and Noise data ..................................................................................................5

2.8. Connection........................................................................................................................5

3. Installation ....................................................................................................................................5

3.1. Safety ................................................................................................................................5

3.2. System requirement .........................................................................................................6

3.3. Unpacking inspection........................................................................................................7

3.4. Oil filling ............................................................................................................................8

3.4.1. Hydraulic drive ......................................................................................................8

3.4.2. Shaft seal oil reservoir...........................................................................................8

3.4.3. Gear cover.............................................................................................................9

3.5. Electric connection............................................................................................................9

3.5.1. Power supply.........................................................................................................9

3.5.2. Motor connection .................................................................................................9