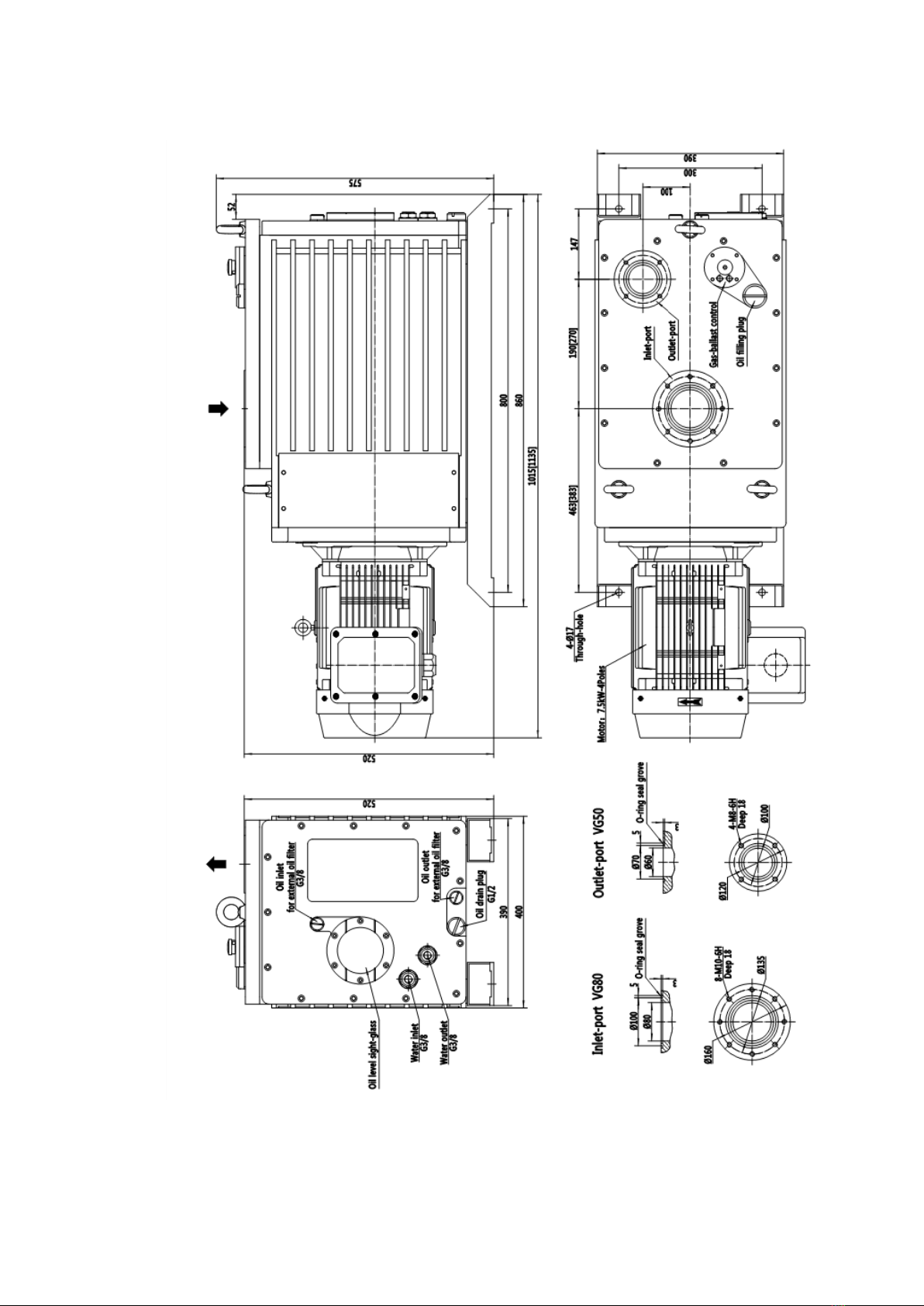

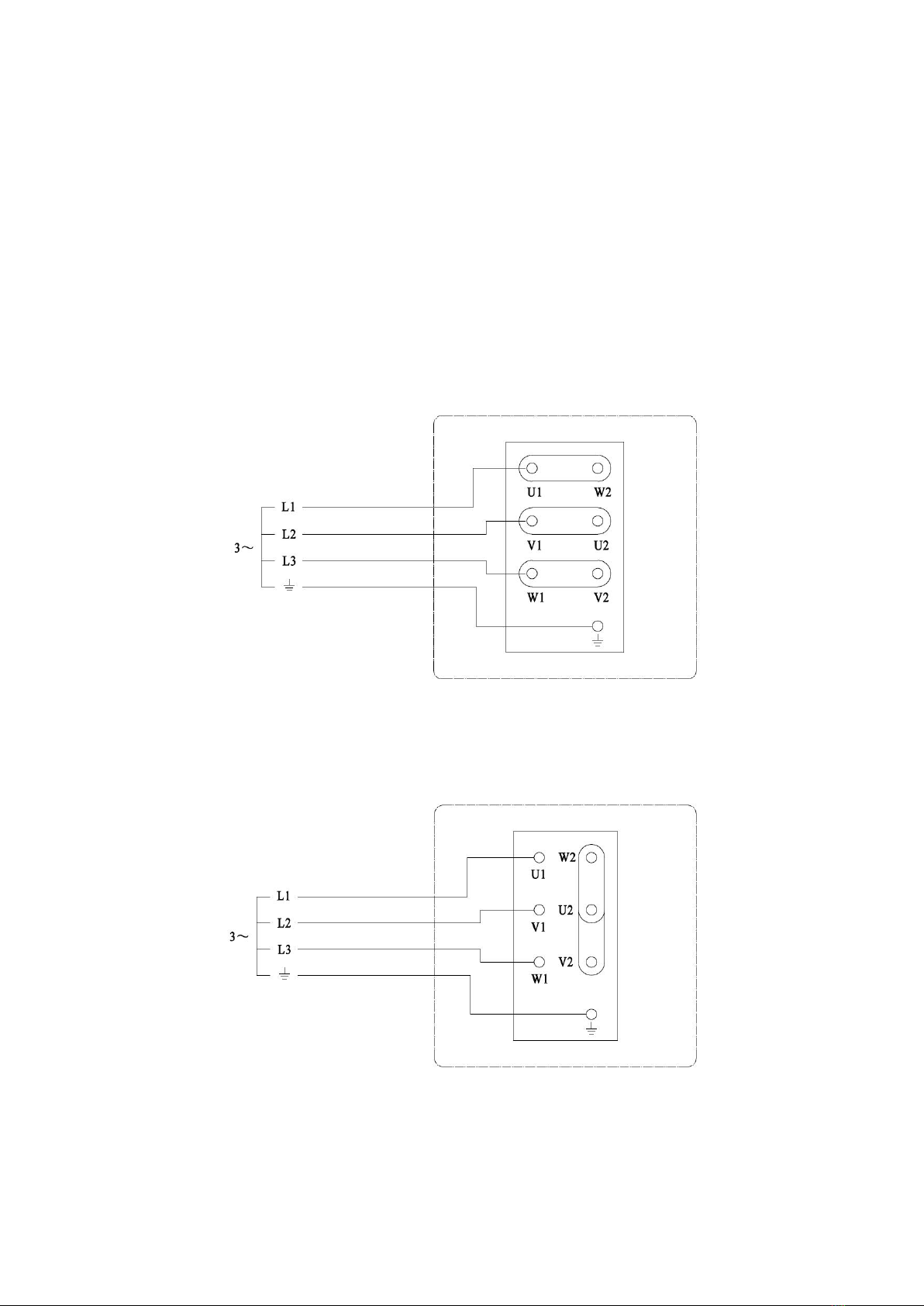

BSV175/BSV275 shown on drawing 2.

BSV175/BSV275 pump is a two stage direct coupling oil rotary vane vacuum pump, which can

work in the laboratorial and industrial environment for long time. It is directly driven by a

three-phase four pole motor with flexible coupling. The pump is mounted on a steel rail.

Pump is equipped with two high and low vacuum rotors and cylinder assembly, as well as

integral vane pump.

The rotor is arranged in an eccentric ground in the pump cylinder, and two rotary vanes

separate the chamber into several spaces of which the volume varies periodically with the

rotation of rotors.

Vanes driven by the rotors rotates against the wall of chamber with the help from centrifugal

force and air spring, which leads to the separation of air inlet and outlet. The air intake cavity

inhales as its volume expands periodically. The exhaust cavity compressed the gas

periodically as its volume decreases. By the pressure from compressed gas and oil, discharge

valve slice is pushed away to obtain vacuum.

Vane oil pump provides lubrication. Oil goes through the oil inlet pipe and is inhaled into the

spring distribution valve. The valve will distributes a little pressurized oil into the vacuum

chamber and will transport redundant oil to the storage cavity by bypass.

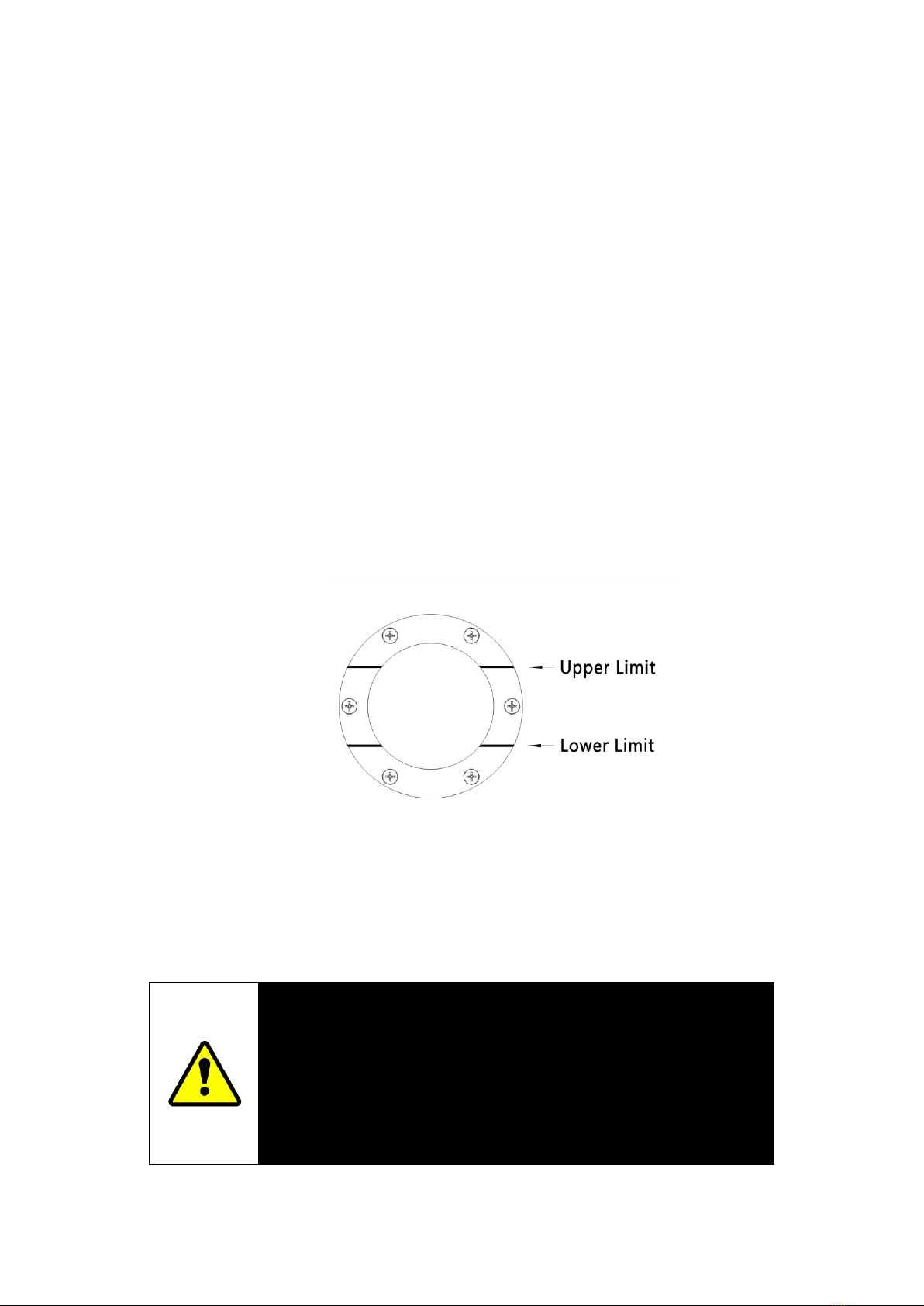

Check the oil level and quality through oil level sight glass(6). There is a oiling plug(2) screw

top of the oil cavity and draining plug screw(8) bottom of it.

The air inlet is VG80 flange. Gas outlet is VG50 flange. The oil-out port for external oil filter is

G3/8. The oil outlet (7) and the oil return port (5) is for external oil filter.

The water cooling system is adopted. Suggest adopting thermostatic control valve to adjust

the flow of water so that the vacuum pump can work at optimum working temperature as well

as keep water economy to prompt gas ballasting.

The function of gas ballasting

The gas ballast valve (3) should be turned on when discharge or inhale high load steam. The

air or inactive gas is fed into the low pressure cavity of the pump through the gas ballast inlet to

prevent condensation of vapor carried by the process gas, which can reduce oil pollution and

pump corrosion caused by condensation of steam from the process gas.

A filter / muffler is installed in the gas ballast system to prevent dust from entering the pump

and to reduce noise.