Repair Instructions – Cooking

2017-03-23 / DIS 184_58300000197442_ARA_EN_A Copyright by BSH Hausgeräte GmbH Page 1 of 101

1 Concerning this document 3

1.1 Purpose and target group.............................................................................. 3

1.2 Other applicable documents...........................................................................3

2 Safety 4

2.1 Qualification.................................................................................................... 4

2.2 Information in warning messages...................................................................4

2.3 Basic safety instructions................................................................................. 6

2.4 Grouped safety messages..............................................................................7

3 Design and function 8

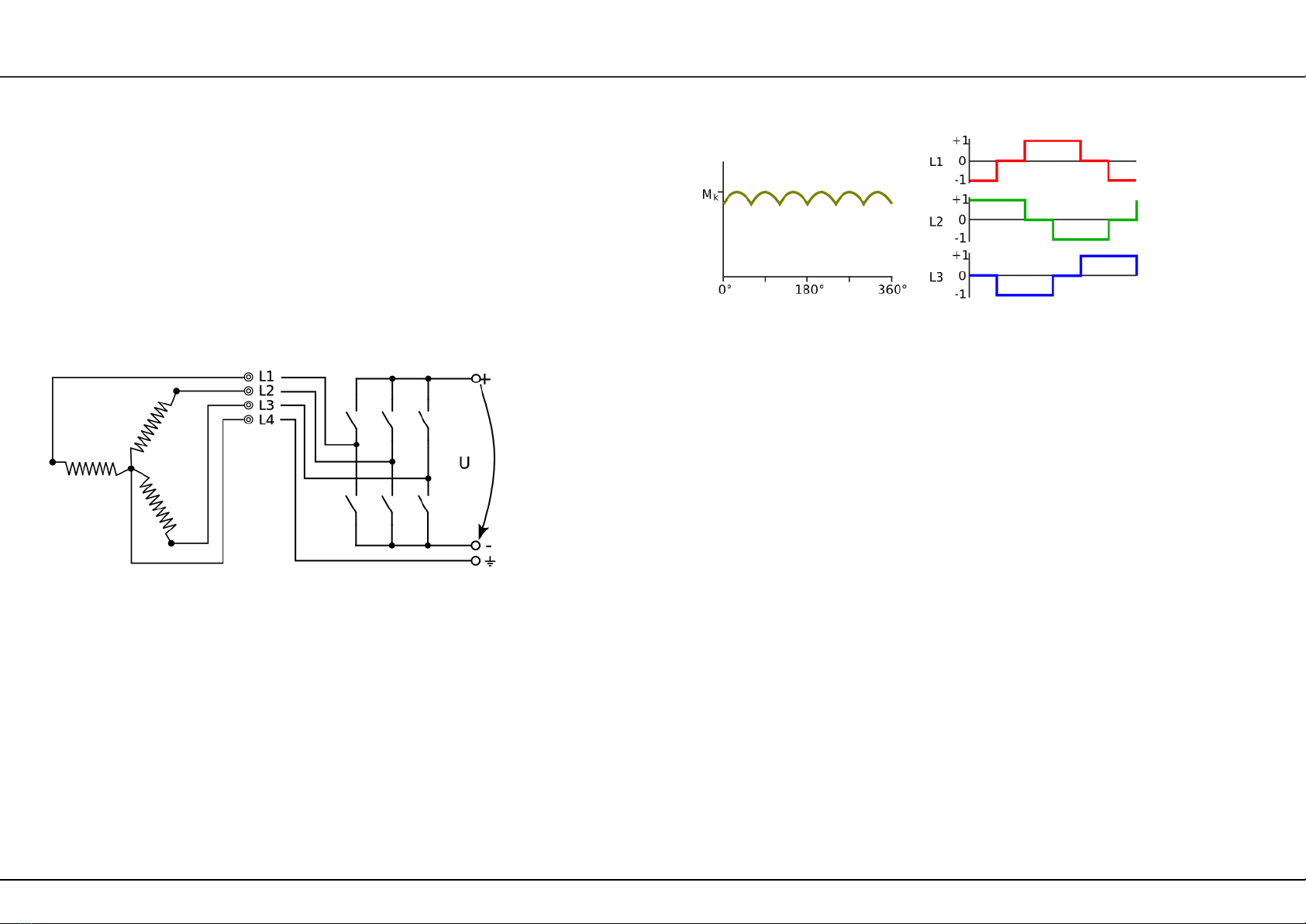

3.1 Brushless direct current motor....................................................................... 8

3.2 EcoClean Direct............................................................................................11

3.3 Cooking compartment temperature sensor (Pt500 / Pt1000)....................... 12

3.4 Fold-down door.............................................................................................13

3.5 Temperature regulation in the various operating modes (60 cm wide)......... 14

3.6 Temperature regulation in the various operating modes (45 cm wide)......... 19

3.7 Clock............................................................................................................. 24

3.8 Vapour extraction system............................................................................. 25

4 Fault diagnosis 28

4.1 Result faults................................................................................................ 28

Food is not cooked.......................................................................................28

Food is heated too slowly............................................................................ 28

Cleaning action is inadequate...................................................................... 28

Pieces of dough form a skin........................................................................ 28

Food dries out.............................................................................................. 29

4.2 Malfunctions................................................................................................ 30

A short acoustic signal can be heard every 11 minutes, when the appliance

is switched off...............................................................................................30

Display is mirrored........................................................................................30

Rails - Sloping down at the back/askew...................................................... 30

Rails - Jam/become caught..........................................................................30

Baking tray/universal pan warped, bent, bounces ...................................... 31

Operating ring can be rotated easily / no change on the display................. 31

Operating ring does not respond / no display.............................................. 31

Operating ring is hard to turn / remains stuck in a specific position............. 31

Operation is not interrupted when the door is opened................................. 32

Display background white/display hard to read............................................32

Fault code is displayed.................................................................................32

Floor of cooking compartment becomes deformed during or after the drying

phase............................................................................................................ 32

Appliance does not generate any steam......................................................33

Appliance continues to heat although the setpoint temperature has been

attained......................................................................................................... 33

Brightness of microwave differs from that of the oven................................. 33

Cooling fan overruns for too long.................................................................33

Reset during operation in main menu "MyProfile"........................................34

Door (fold-down door) does not open 90°....................................................34

Clock gains > 1 minute every day................................................................34

Time - is fast / slow...................................................................................... 34

Clock loses several minutes a day.............................................................. 35

Time jumps back when switching on the appliance..................................... 35

4.3 Noise............................................................................................................ 36

Rails squeaking............................................................................................ 36

High-frequency whistling sound....................................................................36

Cooling fan motor makes a high-frequency noise........................................36

Cooling fan motor whistles at a high frequency at certain speeds............... 36

Cooling fan overrun too loud........................................................................36

Door closes loudly........................................................................................ 37

4.4 Other faults (surface defects, cracks, breaks)........................................ 38

Rails discoloured after pyrolysis...................................................................38

Baking tray/universal pan do not fit on the rails........................................... 38

Control panel and/or door askew................................................................. 38

Difference in display colour/brightness.........................................................38

Difference in colour of microwave/oven turning handle................................38

Gap between panel and door varies............................................................ 39

Connecting sleeve of the cooking compartment seal is becoming frayed

...................................................................................................................... 39

4.5 Leaks............................................................................................................ 40

Steam escapes in the top right-hand corner................................................ 40

Water drips onto the floor or furniture when the door is opened.................. 41