2

PREFACE

Thank you for choosing the BSK Heat Recovery Units. The purpose of this document is

to inform the users of the BSK Heat Recovery Unit about the parts and features of the

device, to give information about operation and maintenance.

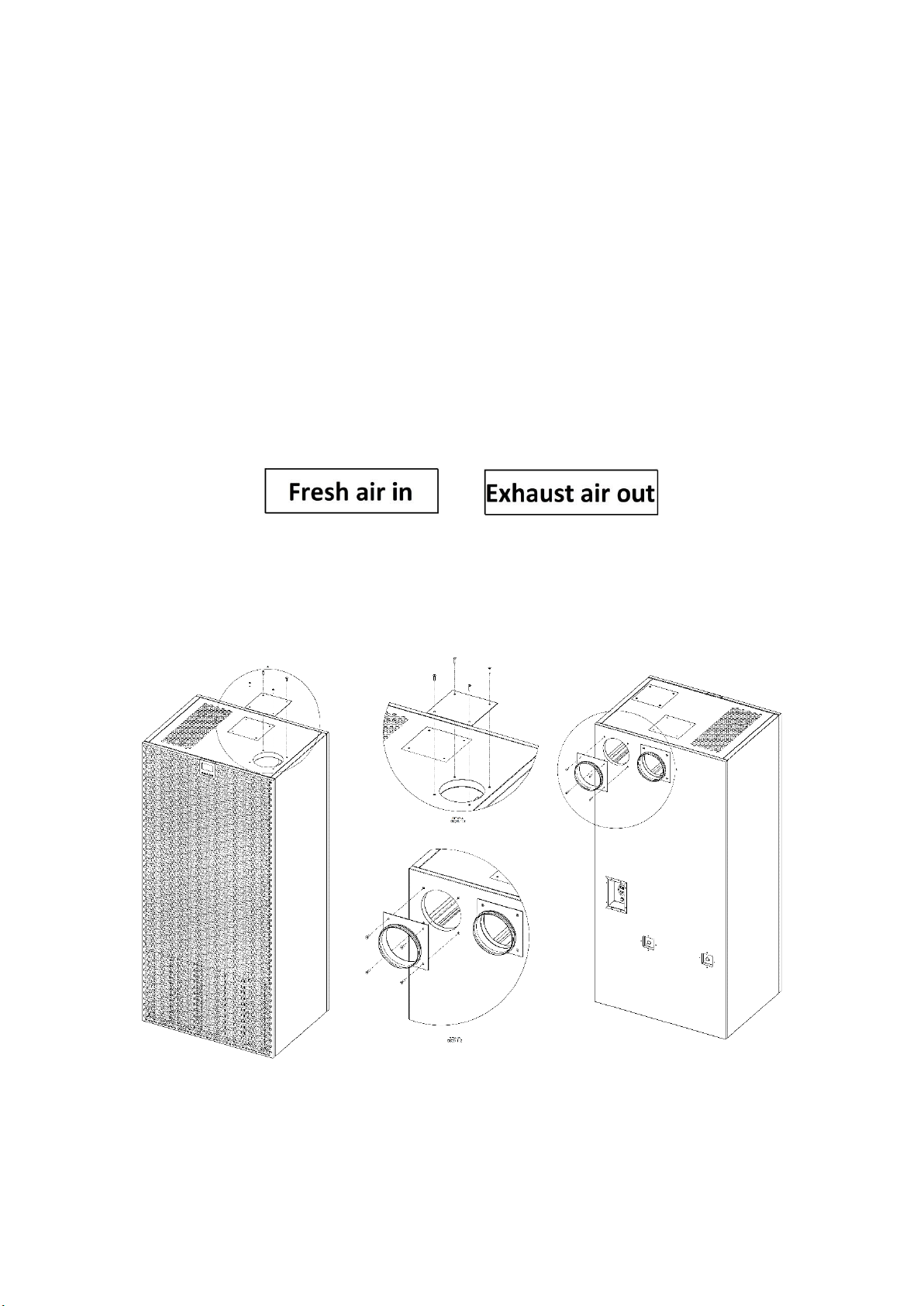

BSK heat recovery unit ensures high indoor air quality and energy savings at the same

time. Heat transfer between the fresh air and the exhaust air is achieved by means of a

plastic plate, counter-flow heat exchanger. It ensures high performance and high thermal

conductivity, and efficient heat transfer between warm and cold air. The devices are

designed to be easy to assemble, use and maintain. They work quietly thanks to the low

noise self-motorized fans and noise isolation inside the device. Extensive controls, and

accessory options give users the ability to custom fit their needs perfectly.

WARRANTY DETAILS

BSK guarantees that the heat recovery units it produced are of good quality. It

ensures repair and exchange during the warranty period for faults which could manifest

from structural weld flaws, material defects, or manufacturing problems as well as fans,

damper system or electronics. BSK does not accept any liability for damage caused by

improper and irresponsible use conditions.

Failings related to all mechanical and electrical components such as fans, motors, and

circuitry, caused by defective modules or incorrect assembly are covered by warranty for 2

years, starting from the date of invoice to the customer.

If repairs or modifications to parts have been made without the written permission of

BSK or the authorized service, the device will not be covered by the warranty. Repaired

device malfunctions, and changed defective parts handled by means of the technical staff

appointed by BSK or an authorized service will not void the warranty. Also the replacement

of the G4 / F7 cassette filters contained in the device, made by BSK, will be excluded from

this scope.

BSK warranty includes the replacement spare parts for fans, damper motor and

system, and electronic components. It does not include the wages of service personnel,

operation and / or maintenance costs. If the defect is within the coverage of the warranty,

all transportation and exchange costs of the device and the technical staff appointment shall

be borne by the authorized service, otherwise these costs must be met by the customer.